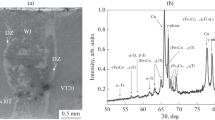

We have studied the effect of laser alloying of 20Kh13 and 12Kh18N10T steels with niobium on their physicochemical properties. Microalloyed surface layers of thickness more than 350 μm, enriched with niobium, carbon, and oxygen in the solid solution and separate oxycarbide inclusions, were formed by means of laser treatment. The microhardness of the external layers of steels becomes 2–3 times higher (up to 7.1–7.7 GPa). Laser alloying reduces the wear of 20Kh13 steel by a factor of 5–6 under a contact pressure of 0.29 MPa and cuts it in half under 0.42 MPa. The wear of 12Kh18N10T steel is reduced by a factor of 2–3. We have also proposed a scheme of the wear of steels, according to which their wear resistance increases owing to the formation of hardened surface layers, where the oxycarbide inclusions exert a reinforcing action on the more plastic solid solution of niobium, carbon, and oxygen in iron.

Similar content being viewed by others

References

J. M. Poate, G. Foti, and D. C. Jacobson (editors), Surface Modification and Alloying by Laser, Ion, and Electron Beams, Plenum, New York (1983).

H. V. Pokhmurs’ka, Formation of Structural Heterogeneity in Metals at Their Laser Treatment and Its Influence on the Main Service Properties [in Ukrainian], Abstract of Doctoral Thesis (Engineering), Zaporizhzhya (2006).

G. I. Brover and S. V. Kreinin, “Structural features of the laser alloying of steels and alloys from coatings of different composition,” Sovrem. Probl. Nauki Obraz., No. 6 (Prilozh. “Tekh. Nauki”) (2008), p. 9.

O. I. Dudka, Formation of Boron- and Boron-Chromium-Containing Coatings of Tribotechnical Purpose by Laser Treatment [in Ukrainian], Abstract of Candidate’s Thesis (Engineering), Kyiv (1999).

T. M. Nagornova, Heat and Mass Transfer in the Near-Surface Layer of a Metal at the Laser Treatment of Elements of the Heat-Mechanic Equipment of Thermal Power Plants [in Russian], Abstract of Candidate’s Thesis (Engineering), Tomsk (2006).

A. H. Maryns’kyi, Hard Gradient Coatings and Electron-Beam Technology of Their Production [in Ukrainian], Abstract of Candidate’s Thesis (Engineering), Kyiv (2003).

A. M. Semirga, Laws of the Formation of the Structural-Phase State of Coatings and Near-Surface Layers of Iron- and Titanium-Based Alloys at Combined Pulse Treatment [in Russian], Abstract of Candidate’s Thesis (Engineering), Kiev (2004).

V. N. Tokarev, Stability of the Surface of Materials at Intense Laser Action [in Russian], Abstract of Doctoral Thesis (Engineering), Moscow (2006).

J. C. Ion, Laser Processing of Engineering Materials, Elsevier (2005).

M. I. Gol’dshtein and V. M. Farber, Dispersion Strengthening of Steel [in Russian], Metallurgiya, Moscow (1979).

Z. A. Duryahina and H. V. Laz’ko, “Effect of complex laser alloying with Nb and N on the character of structure formation in the near-surface layers of stainless steels,” Mashynoznavstvo, 94, No. 4, 52–55 (2005).

M. I. Pashechko, V. V. Shyrokov, Z. A. Duryahina, and Kh. B. Vasyliv, “Structure and corrosion-mechanical properties of the surface layers of steels after laser alloying,” Fiz.-Khim. Mekh. Mater., 39, No. 1, 95–102 (2003); English translation: Mater. Sci., 39, No. 1, 108–117 (2003).

Z. A. Duryahina, “Optimization of the structural-phase state of the surface of stainless steels by laser alloying,” in: Bulletin of “L’vivs’ka Politekhnika” State University, Optimization of Production Processes and Technical Control in Machine Building and Instrument Making [in Ukrainian], No. 394 (2000), pp. 116–120.

V. V. Shyrokov, O. V. Shyrokov, E. M. Rudkovs’kyi, and Kh. B. Vasyliv, A Device for Determining the Triboelectrochemical Characteristics of Metals under Conditions of the Corrosion Influence of Electrolytes [in Ukrainian], Patent of Ukraine No. 32128, application No. u2007 12589, 13.11.2007.

V. V. Shyrokov, L. A. Arendar, Yu. I. Koval’chyk, Kh. B. Vasyliv, and O. M. Vasyliv, “Computer processing of profilograms of friction surfaces,” Fiz.-Khim. Mekh. Mater., 41, No. 1, 93–96 (2005); English translation: Mater. Sci., 41, No. 1, 107–112 (2005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 45, No. 4, pp. 12–18, July–August, 2009.

Rights and permissions

About this article

Cite this article

Shyrokov, V.V., Vasyliv, K.B., Duryahina, Z.A. et al. Effect of laser microalloying with niobium on the wear resistance of stainless steels. Mater Sci 45, 473–480 (2009). https://doi.org/10.1007/s11003-010-9204-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-010-9204-5