Abstract

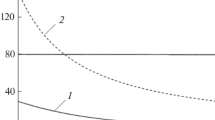

We have determined the kinetic parameters of interaction of VT1-0, VT5, OT4-1, and VT16 alloys with a rarefied gaseous medium. We have established the interrelation between the parameters of chemical heat treatment (T, τ, and p, the interstitial hardening of surface layers of the metal, and its phase and structural state. The conditions of saturation (T, τ, and p) being equal, hardened layers differing in the microhardness and thickness of the layer H and l are formed on titanium alloys of different structural classes. Single-phase VT1-0 and VT5 α-titanium alloys as well as OT4-1 pseudo-α-alloy are the most sensitive to the conditions of gas saturation: the hardness and its gradient in the hardened layer grow significantly. As the β-phase content increases (VT16), changes in the parameters of chemical heat treatment affect less the hardness of the surface layer, but the depth of the hardened zone grows with temperature T and time τ.

Similar content being viewed by others

REFERENCES

H. Fujii, K. Takahashi, and Y. Yamashita, “Application of titanium and its alloys for automobile parts,” Nippon Steel Tech. Rep., No. 88, 70–75 (2003).

R. M. Strericher, H. Weber, R. Schon, and M. Semlistch, “New surface modification Ti-6Al-7Nb alloy: oxygen diffusion hardening (ODH),” Biomaterials, 12, 125–129 (1991).

C. Boettcher, “Deep case hardening of titanium alloys with oxygen,” Surf. Eng., 16, No.2, 148–152 (2000).

M. A. Hongyan, M. Wang, and W. Wu, “Oxygen permeation behaviors and hardening effect of titanium alloys at high temperature,” J. Mater. Sci. Technol., No. 6, 719–723 (2004).

V. M. Fedirko, A. T. Pichugin, O. H. Luk'yanenko, and Z. O. Siryk, “Evaluation of the serviceability of articles manufactured of titanium alloys of different structural classes with gas-saturated layers,” Fiz.-Khim. Mekh. Mater., 32, No.6, 49–54 (1996).

G. G. Maksimovich, V. N. Fedirko, Ya. I. Spektor, and A. T. Pichugin, Heat Treatment of Titanium and Aluminum Alloys in Vacuum and Inert Media [in Russian], Naukova Dumka, Kiev (1987).

C. E. Wicks and F. E. Block, Thermodynamic Properties of 65 Elements, Their Oxides, Halides, Carbides, and Nitrides [Russian translation], Metallurgiya, Moscow (1965).

E. Fromm and E. Gebhardt, Gase und Kohlenstoff in Metallen, Springer, Berlin (1976).

U. Zwicker, Titan und Titanlegierungen, Springer, Berlin (1974).

G. G. Maksimovich, V. N. Fedirko, and M. N. Zima, “Effect of the pressure of residual gases of a vacuum atmosphere on the oxidation and gas saturation of titanium alloys,” Fiz.-Khim. Mekh. Mater., 24, No.1, 101–104 (1988).

Author information

Authors and Affiliations

Additional information

__________

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 41, No. 2, pp. 63–70, March–April, 2005.

Rights and permissions

About this article

Cite this article

Fedirko, V.M., Pichuhin, A.T., Luk'yanenko, O.H. et al. Interstitial Hardening of the Surface of Titanium Alloys by Vacuum Heat Treatment. Mater Sci 41, 208–216 (2005). https://doi.org/10.1007/s11003-005-0152-4

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11003-005-0152-4