Abstract

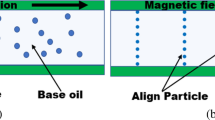

A new metal foam magneto-rheological (MR) fluid damper is optimized, and the mechanical performance is investigated experimentally. With a magnetic field, MR fluid is extracted from the metal foam and fills up the shear gap to produce the MR effect. The magnetic field density in the shear gap and the structural parameters are taken as the optimization object, and the optimal parameters of the metal foam MR fluid damper are updated. A testing system, including a DC motor with a speed controller, a force sensor with an amplifier and a power supply, is built to investigate the shear force of the metal foam MR fluid damper. The test signals are gathered and processed by a DAQ and a PC with LabVIEW software. A timer is designed to synchronize the start of the magnetic field. The experimental results show that the shear force decreases as the shear rate increases, and for the same shear rate, when the current ranges from 0.5 to 1.0 A, the difference of the shear force in the metal foam MR fluid damper is the most obvious. Additionally, the shear force after optimization clearly increases. When the current increases gradually, the shear force also increases. When the excited current increases from 0.5 to 1.5 A, as the current increases, the shear force increases obviously; however, once the current is above 1.5 A, the increase of the shear force is no longer obvious. In addition, for a shear rate of 2 s−1 and a current of 1.0 A, the shear force of the metal foam MR fluid damper is improved by a factor of 1.46 compared to the value before optimization.

Similar content being viewed by others

References

Carlson, J.D.: Low-Cost MR Fluid Sponge Devices. J. Intell. Mater. Syst. Struct. 10, 589–594 (1999)

Carlson, J.D., Sproston J.L.: Controllable fluids in 2000-status of ER and MR fluid technology. In: The 7th International Conference on New Actuofor, pp. 126–130. Bermen, Germany (2000)

Choi, S.B., Lee, H.H., Song, H.J., Park, J.S.: Vibration control of a passenger car using MR engine mounts. Proc. SPIE’s 9th Ann. Symp Smart Struct. Mater. 4701, 1–8 (2002)

Gordaninejad, F., Wang, X., Hitchcock, G., Bangrakulur, K., Ruan, S., Siino, M.: Modular high-force seismic magneto-rheological fluid damper. J. Struct. Eng. 136, 135–143 (2010)

Lee, H.S., Choi, S.B.: Control and response characteristics of a magneto-rheological fluid damper for passenger vehicles. J. Intell. Mater. Syst. Struct. 11, 80–87 (2000)

Liu, X.H., Wong, P.L., Wang, W., Bullough, W.A.: Feasibility study on storage of magneto-rheological fluid using metal foams. J. Intell. Mater. Syst. Struct. 21, 1193–1200 (2010)

Liu, X.H., Gao, X.L., Li, F., et al.: Shear performance of a metal foam MR fluid damper. IEEE Trans. Magn. 51(1), 46001 (2015)

Nguyen, Q.H., Choi, S.B.: Optimal design of MR shock absorber and application to vehicle suspension. Smart Mater. Struct. 18(3), 035012 (2009)

Rabinow, J.: The magnetic fluid clutch. Electr. Eng. 67(12), 1167 (1951)

Yao, X.Y., Liu, X.H., Yu, M., et al.: Dynamic response time of a metal foam magneto-rheological damper. Smart Mater. Struct. 22, 025026 (2013)

Acknowledgements

The work described in this paper was supported the National Natural Science Foundation of China (No. 51675345), the Zhejiang Basic Public Welfare Research Project No. LGG19F020013, and the Shanghai Natural Science Foundation of China (16ZR1435800).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhi Shen, W., Hong Bo, W., Tiantian, G. et al. Parameter optimization of a metal foam magneto-rheological damper. Int J Mech Mater Des 16, 323–330 (2020). https://doi.org/10.1007/s10999-019-09463-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10999-019-09463-z