Abstract

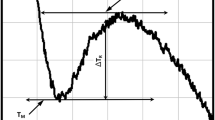

The computer-aided cooling curve analysis (CA-CCA) was employed to investigate the solidification behavior of Al-Ce-Mg-xCe (x = 0, 0.5, 1.0, 1.5, and 3.0 mass %) alloys. Field emission scanning electron microscopy (FE-SEM), energy-dispersive X-ray spectroscopy (EDS), and X-ray diffraction (XRD) techniques were used, along with the liquidus projection of ternary Al-Cu-Mg and Al-Cu-Ce phase diagrams, to evaluate the microstructure and predict the sequence of main reactions involved in the solidification of alloys. According to the results, Al2CuMg, Al2Cu, Al15(CuFeMn)3Si2, and Mg2Si were found to be the main compounds present in the microstructure of Al 2024 alloy. The addition of Ce up to 1.5 mass % resulted in the formation of AlCeCuSi, Al8CeCu4, and Al24Cu8Ce3Mn compounds in the microstructure. Further addition of Ce up to 3.0 mass % promoted the formation of a new Ce-rich phase (Al4Ce) in the microstructure. The formation temperature (range) and reactions during which the Ce-rich compounds are formed were also suggested. The formation of Al4Ce compound in the microstructure of 3 mass % Ce-containing samples suppressed the nucleation and growth temperatures of the Al2Cu eutectic, prolonged the solidification time, significantly reduced the solidification end temperature, and increased the alloy solidification range.

Similar content being viewed by others

References

Zamani M, Toschi S, Morri A, Ceschini L, Seifeddine S. Optimisation of heat treatment of Al–Cu–(Mg–Ag) cast alloys. J Therm Anal Calorim. 2020;139:3427–40.

Ghosh KS. Calorimetric studies of 2024 Al–Cu–Mg and 2014 Al–Cu–Mg–Si alloys of various tempers. J Therm Anal Calorim. 2019;136:447–59.

Shabestari SG, Ghoncheh MH, Momeni H. Evaluation of formation of intermetallic compounds in Al2024 alloy using thermal analysis technique. Thermochim Acta. 2014;10(589):174–82.

Czerwinski F. Cerium in aluminum alloys. J Mater Sci. 2020;55(1):24–72.

Fang MM, Yan H, Song XC, Sun YH. Effect of (Pr+ Ce) additions on microstructure and mechanical properties of AlSi5Cu1Mg alloy. App Sci. 2019;9(9):1856.

Hu B, Zhu WJ, Li ZX, Lee SB, Li DJ, Zeng XQ, Choi YS. Effects of Ce content on the modification of Mg2Si phase in Mg-5Al-2Si alloy. J Mag Alloys. 2021;7:2299.

Alkahtani SA, Elgallad EM, Tash MM, Samuel AM, Samuel FH. Effect of rare earth metals on the microstructure of Al-Si based alloys. Mater. 2016;9(1):45.

Wang WT, Zhang XM, Gao ZG, Jia YZ, Ye LY, Zheng DW, Liu L. Influences of Ce addition on the microstructures and mechanical properties of 2519A aluminum alloy plate. J Alloys Comp. 2010;491(1–2):366–715.

Xiao D, Wang J, Ding D, Yang H. Effect of rare earth Ce addition on the microstructure and mechanical properties of an Al–Cu–Mg–Ag alloy. J Alloys Compd. 2003;352:84–8.

Xiao D, Wang J, Ding D. Effect of minor cerium additions on microstructure and mechanical properties of cast Al–Cu–Mg–Ag alloy. Mater Sci Technol. 2004;20(10):1237–40.

Yu X, Dai H, Li Z, Sun J, Zhao J, Li C, Liu W. Improved recrystallization resistance of Al–Cu–Li–Zr alloy through Ce addition. Metals. 2018;8(12):1035.

Wang W, Zhang X, Gao Z, Jia Y, Ye L, Zheng D, Liu L. Influences of Ce addition on the microstructures and mechanical properties of 2519A aluminum alloy plate. J Alloys Compd. 2010;491(1–2):366–71.

Vončina M, Medved J, Steinacher M, Ozimič K. The influence of La and Ce additions on the solidification of alloys from the Al–Fe system. J Therm Anal Calorim. 2024;26:1.

Belov NA, Aksenov AA, Eskin DG. Iron in aluminium alloys: impurity and alloying element. London: CRC Press; 2002.

Goto S, Kim B, Park H, Belov NA, Zolotorevkij VS, Aso S, Komatsu Y. Application of eutectics to development of high strength cast aluminum alloys. J Soci Mater Eng Res Japan. 2002;15(2):66–73.

Niu G, Mao J, Wang J. Effect of Ce addition on fluidity of casting aluminum alloy A356. Metall Mater Trans A. 2019;50:5935–44.

Zeng Z, Pan H, Pan Z, Wang S, Huang Y, Tang W, Yang C, Ren Y, Qin G. Effect of Sm and Ce content on microstructure and mechanical property of newly developed Mg-Sm-Ce-Mn based alloy. Mater Character. 2023;1(206): 113420.

Wang C, Zeng L, Zhang W, Tang F, Ding W, Xiao S, Liang T. Enhanced mechanical properties and corrosion resistance of rolled Mg-1.5 Sn-0.5 Ca alloy by Ce microalloying. Mater Character. 2021;179:111325.

Del Olmo R, Mohedano M, Visser P, Rodriguez A, Matykina E, Arrabal R. Effect of cerium (IV) on thin sulfuric acid anodizing of 2024–T3 alloy. J Mater Res Technol. 2021;15:3240–54.

Wang K, Wei M, Liao Z, Jin S, Wan B, Lei Z, Tang P, Tian J, Zhang L, Li W. A comparative study of iron, cobalt or cerium micro-alloying on microstructure and apparent viscosity of Al-5Ni alloy. J Alloys Comp. 2023;952: 170052.

Luo S, Wang L, Cao Y. Effect of Zr grain refinement on solidification behavior of Mg–3Nd alloy by cooling curve thermal analysis. J Therm Anal Calorim. 2023;148(10):4049–58.

Mostafapoor S, Malekan M, Emamy M. Effects of Zr addition on solidification characteristics of Al–Zn–Mg–Cu alloy using thermal analysis. J Therm Anal Calorim. 2018;134:1457–69.

Li J, Chen R, Ma Y, Ke W. Computer-aided cooling curve thermal analysis and microstructural characterization of Mg–Gd–Y–Zr system alloys. Thermochim Acta. 2014;20(590):232–41.

Farahany S, Ghandvar H. On the effect of praseodymium on solidification characteristics, microstructure, and mechanical properties of commercial ADC12 alloy. J Therm Anal Calorim. 2023;148(12):5247–55.

Elesbão DS, Kakitani R, Cheung N, Garcia A, de Barcellos VK, da Costa EM, dos Santos CA. Influence of Cu and Cr contents on the solidification path and microstructure formation of hypoeutectic as-cast Al–Cu–Cr alloys. J Therm Anal Calorim. 2023;148(18):9403–21.

Mahmoud MG, Mosleh AO, Pozdniakov AV, Khalifa W, Mohamed MS. Characterization of the solidification behavior, microstructure and mechanical properties of aluminum alloy 6063 with samarium addition. J Alloys Comp. 2022;25(929): 167234.

Ghoncheh MH, Shabestari SG, Abbasi MH. Effect of cooling rate on the microstructure and solidification characteristics of Al2024 alloy using computer-aided thermal analysis technique. J Therm Anal Calorim. 2014;117:1253–61.

Ghoncheh MH, Shabestari SG. Effect of cooling rate on the dendrite coherency point during solidification of Al2024 alloy. Metal Mater Trans A. 2015;46:1287–99.

Amin KM, Mufti NA. Investigating cooling curve profile and microstructure of a squeeze cast Al–4% Cu alloy. J Mater Proc Technol. 2012;212(8):1631–9.

Meetsma A, De Boer JL, Van Smaalen S. Refinement of the crystal structure of tetragonal Al2Cu. J Solid State Chem. 1989;83(2):370–2.

Hu Y, Wu S, Shen Z, Cao H, Zhong X, Withers PJ. Fine equiaxed zone induced softening and failure behavior of 7050 aluminum alloy hybrid laser welds. Mater Sci Eng A. 2021;21(821): 141597.

Morris RG, Redin RD, Danielson GC. Semiconducting properties of Mg 2 Si single crystals. Phys Rev. 1958;109(6):1909.

Mrówka-Nowotnik G, Sieniawski J. Analysis of intermetallic phases in 2024 aluminium alloy. Solid State Phenom. 2013;11(197):238–43.

Henderson HB, Hammons JA, Baker AA, McCall SK, Li TT, Perron A, Sims ZC, Ott RT, Meng F, Thompson MJ, Weiss D. Enhanced thermal coarsening resistance in a nanostructured aluminum-cerium alloy produced by additive manufacturing. Mater Des. 2021;1(209): 109988.

Perrin A, Bahl S, Leonard DN, Michi R, Sisco K, Plotkowski A, Shyam A, Dehoff R, Shin D, Yang Y. Phase stability in cast and additively manufactured Al-rich Al-Cu-Ce alloys. J Alloys Comp. 2022;10(926): 166984.

Belov NA, Khvan AV. The ternary Al–Ce–Cu phase diagram in the aluminum-rich corner. Acta Mater. 2007;55(16):5473–82.

Zolotorevsky VS, Belov NA, Glazoff MV. Casting aluminum alloys. Amsterdam: Elsevier; 2007.

Sims ZC, Weiss D, McCall SK, McGuire MA, Ott RT, Geer T, Rios O, Turchi PA. Cerium-based, intermetallic-strengthened aluminum casting alloy: high-volume co-product development. JOM. 2016;68:1940–7.

Belov NA, Eskin DG, Aksenov AA. Multicomponent phase diagrams: applications for commercial aluminum alloys. 1st ed. Boston: Elsevier; 2005. p. 167.

Liang Y, Shi Z, Li G, Zhang R, Li M. Effects of rare earth modification on microstructure refinement and mechanical properties of Al-2 wt% Fe alloys. Mater Res Exp. 2019;6(10): 106504.

Nafisi S, Ghomashchi R. Semi-solid processing of aluminum alloys. Swizerland: Springer International Publishing; 2016. p. 104.

Schiller T, Sondermann E, Meyer A. New analyzing approaches for in situ interdiffusion experiments to determine concentration-dependent diffusion coefficients in liquid Al–Au. Metals. 2021;11(11):1772.

Stelian C, Duffar T. Numerical analysis of solute distribution and interface stabilization during experimental Bridgman growth of concentrated GaInSb alloys. J Cryst Growth. 2005;275(1–2):e585–94.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mohammadi, H., Taghiabadi, R. & Malekan, M. Assessment of Ce-rich intermetallics formation in Al-Cu-Mg-xCe alloys using thermal analysis cooling curves. J Therm Anal Calorim (2024). https://doi.org/10.1007/s10973-024-13267-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10973-024-13267-5