Abstract

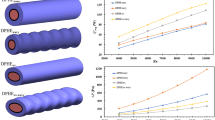

The primary objective of this study is to conduct a practical investigation of heat transfer (HT) and friction factor (f) characteristics within a double pipe heat exchanger (DPHE) configured in a counter-flow arrangement. To achieve this, a novel approach involving twisted tape (TT) with dimple inserts accompanied by adjacent holes working fluid is water implemented. This dimples, characterized by their concave geometry, are strategically employed to augment the heat exchange process while concurrently mitigating any adverse impact on fluid pressure. A pivotal facet of this study centered on examining the influence of dimple diameter, as well as a consistent dimple-to-depth ratio (D/H), on both heat transfer efficiency and friction factor. The performance of TT inserts featuring diverse diameter (D) = 2, 4 and 6 mm is meticulously scrutinized in terms of their impact on heat transfer and friction factor characteristics. The outcomes of the study furnished intriguing insights. It is observed that the diameter of the dimples wielded a discernible encouragement on friction factor, revealing a direct correlation. The maximum rate of friction factor is recorded at a 2 mm dimple diameter configuration. When evaluating Nusselt number (Nu) and performance evaluation criteria (PEC), it is revealed that the most favorable results is achieved with the 4 mm dimple diameter configuration. Drawing upon these empirical findings, a significant conclusion can be drawn. Utilization of twisted tape inserts adorned at dimples is a practical, efficient and economically viable approach to heighten HT efficiency within heat exchangers. By optimizing dimple diameter and adhering to a consistent diameter-to-depth ratio, substantial improvements in HT capabilities can be harnessed without disproportionately compromising fluid pressure. This innovative methodology holds the potential to revolutionize heat exchanger design, offering an avenue to enhance HT efficiency with practical and cost-effective solutions.

Similar content being viewed by others

Abbreviations

- L :

-

Length of twisted tape (m)

- l :

-

Tube length of the experimental section (m)

- d :

-

Diameter of inner tube (m)

- T hi :

-

Inlet temperature of hot water (K)

- T ho :

-

Outlet temperature of hot water (K)

- T h :

-

Bulk temperature of hot water (K)

- T ci :

-

Inlet temperature of cold water (K)

- T co :

-

Outlet temperature of cold water (K)

- T c :

-

Bulk temperature of cold water (K)

- T w :

-

Average inner tube wall temperature (K)

- U h :

-

Mean velocity of hot water (m s−1)

- Δp :

-

Pressure drop (Pa)

- V h :

-

Volume flow rate of hot water (m3 s−1)

- V c :

-

Volume flow rate of cold water (m3 s−1)

- ρ in :

-

Density of hot water at inlet temperature (kg m−3)

- ρ h :

-

Density of hot water at bulk temperature (kg m−3)

- C ph :

-

Specific heat capacity of hot water (J kg−1 K−1)

- C pc :

-

Specific heat capacity of cold water (J kg−1 K−1)

- υ :

-

Kinematic viscosity of hot water (m2 s−1)

- K h :

-

Thermal conductivity of hot water (W m−1 K−1)

- A :

-

Surface area of inner tube (m2)

- h i :

-

Heat transfer coefficient (W m−2 K−1)

- Q h :

-

Heat transfer rate released by hot water (W)

- Q c :

-

Heat transfer rate absorbed by cold water (W)

- Q :

-

Mean heat transfer rate (W)

- Re:

-

Reynolds number

- D :

-

Dimple diameter (m)

- f :

-

Friction factor

- H :

-

Depth of dimple (m)

- Nu:

-

Nusselt number

- PEC:

-

Performance evaluation criteria

References

Mudhsh M, El-Said EMS, Aseeri AO, Almodfer R, Elaziz MA, Elshamy SM, Elsheikh AH. Modelling of thermo-hydraulic behavior of a helical heat exchanger using machine learning model and fire hawk optimizer. Case Stud Therm Eng. 2023;49:103294.

Elsheikh AH, Guo J, Lee K-M. Thermal deflection and thermal stresses in a thin circular plate under an axisymmetric heat source. J Therm Stresses. 2019;42(3):361–73.

Mohamed HA, MajedAlhazmy F, Mansour, Negeed E-SR. Heat transfer enhancement using CuO nanofluid in a double pipe U-bend heat exchanger. J Nanofluids. 2023;12(5):1260–74.

Singh SK, Kumar A. Experimental study of heat transfer and friction factor in a double pipe heat exchanger using twisted tape with dimple inserts. Energy Sour Part A Recov Util Environ Effects. 2021. https://doi.org/10.1080/15567036.2021.1927248.

Abushanab WS, Zayed ME, Sathyamurthy R, Moustafa EB, Elsheikh AH. Performance evaluation of a solar air heater with staggered/longitudinal finned absorber plate integrated with aluminium sponge porous medium. J Build Eng. 2023;73:106841. https://doi.org/10.1016/j.jobe.2023.106841.

El-Said EMS, Abdelaziz GB, Sharshir SW, Elsheikh AH, Elsaid AM. Experimental investigation of the twist angle effects on thermo-hydraulic performance of a square and hexagonal pin fin array in forced convection. Int Commun Heat Mass Transf. 2021;126:105374. https://doi.org/10.1016/j.icheatmasstransfer.2021.105374.

Samruaisin P, Changcharoen W, Thianpong C, Chuwattanakul V, Pimsarn M, Eiamsa-Ard S. Influence of regularly spaced quadruple twisted tape elements on thermal enhancement characteristics. Chem Eng Process Process Intens. 2018;128:114–23.

Zheng Lu, Xie Y, Zhang Di. Numerical investigation on heat transfer performance and flow characteristics in circular tubes with dimpled twisted tapes using Al2O3-water nanofluid. Int J Heat Mass Transf. 2017;111:962–81.

Suri AR, Singh AK, Maithani R. Heat transfer enhancement of heat exchanger tube with multiple square perforated twisted tape inserts: experimental investigation and correlation development. Chem Eng Process. 2017;116:76–96.

Dagdevir T, Ozceyhan V. An experimental study on heat transfer enhancement and flow characteristics of a tube with plain, perforated and dimpled twisted tape inserts. Int J Therm Sci. 2021;159:106564.

Zhang X, Liu Z, Liu W. Numerical studies on heat transfer and flow characteristics for laminar flow in a tube with multiple regularly spaced twisted tapes. Int J Therm Sci. 2012;58:157–67.

Yuxiang H, Xianhe D, Zhang L. 3D numerical study on compound heat transfer enhancement of converging-diverging tubes equipped with twin twisted tapes. Chin J Chem Eng. 2012;20(3):589–601.

Mokkapati V, Lin C-S. Numerical study of an exhaust heat recovery system using corrugated tube heat exchanger with twisted tape inserts. Int Commun Heat Mass Transfer. 2014;57:53–64.

Zhenfei Z, Ruijuan S. Rotational and resistance characteristics in a circular tube fitted with triangular groove twisted-tape insert. Chem Equip Technol. 2012;2(19):20.

Zhang C, Wang D, Ren K, Han Y, Youjian Zhu Xu, Peng JD, Zhang X. A comparative review of self-rotating and stationary twisted tape inserts in heat exchanger. Renew Sustain Energy Rev. 2016;53:433–49.

Nanan K, Yongsiri K, Wongcharee K, Thianpong C, Eiamsa-Ard S. Heat transfer enhancement by helically twisted tapes inducing co-and counter-swirl flows. Int Commun Heat Mass Transfer. 2013;46:67–73.

Promvonge P, Suwannapan S, Pimsarn M, Thianpong C. Experimental study on heat transfer in square duct with combined twisted-tape and winglet vortex generators. Int Commun Heat Mass Transfer. 2014;59:158–65.

Patil S, Vijay Babu P. Experimental heat transfer and friction factor studies through a square duct fitted with helical screw tapes. Can J Chem Eng. 2014;92(4):663–70.

Eiamsa-Ard P, Piriyarungroj N, Thianpong C, Eiamsa-Ard S. A case study on thermal performance assessment of a heat exchanger tube equipped with regularly-spaced twisted tapes as swirl generators. Case Stud Therm Eng. 2014;3:86–102.

Murugesan P, Mayilsamy K, Suresh S. Turbulent heat transfer and pressure drop in tube fitted with square-cut twisted tape. Chin J Chem Eng. 2010;18(4):609–17.

Sun B, Zhang Z, Yang Di. Improved heat transfer and flow resistance achieved with drag reducing Cu nanofluids in the horizontal tube and built-in twisted belt tubes. Int J Heat Mass Transf. 2016;95:69–82.

Seemawute P, Eiamsa-Ard S. Thermohydraulics of turbulent flow through a round tube by a peripherally-cut twisted tape with an alternate axis. Int Commun Heat Mass Transfer. 2010;37(6):652–9.

Eiamsa-Ard S, Wongcharee K, Eiamsa-Ard P, Thianpong C. Thermohydraulic investigation of turbulent flow through a round tube equipped with twisted tapes consisting of centre wings and alternate-axes. Exp Thermal Fluid Sci. 2010;34(8):1151–61.

Eiamsa-ard S, Kongkaitpaiboon V, Nanan K. Thermohydraulics of turbulent flow through heat exchanger tubes fitted with circular-rings and twisted tapes. Chin J Chem Eng. 2013;21(6):585–93.

Eiamsa-Ard S, Promvonge P. Thermal characteristics in round tube fitted with serrated twisted tape. Appl Therm Eng. 2010;30(13):1673–82.

Chang SW, Guo MH. Thermal performances of enhanced smooth and spiky twisted tapes for laminar and turbulent tubular flows. Int J Heat Mass Transf. 2012;55(2526):7651–67.

Eiamsa-Ard S, Somkleang P, Nuntadusit C, Thianpong C. Heat transfer enhancement in tube by inserting uniform/non-uniform twisted-tapes with alternate axes: effect of rotated-axis length. Appl Therm Eng. 2013;54(1):289–309.

Bhuiya MMK, Chowdhury MSU, Shahabuddin M, Saha M, Memon LA. Thermal characteristics in a heat exchanger tube fitted with triple twisted tape inserts. Int Commun Heat Mass Transfer. 2013;48:124–32.

Murugesan P, Mayilsamy K, Suresh S, Srinivasan PSS. Heat transfer and pressure drop characteristics in a circular tube fitted with and without V-cut twisted tape insert. Int Commun Heat Mass Transfer. 2011;38(3):329–34.

Terekhov VI, Kalinina SV, Mshvidobadze YM. Heat transfer coefficient and aerodynamic resistance on a surface with a single dimple. J Enhan Heat Transf. 1997;4(2):131–45. https://doi.org/10.1615/JEnhHeatTransf.v4.i2.60.

Yadav AS. Effect of half length twisted-tape turbulators on heat transfer and pressure drop characteristics inside a double pipe u-bend heat exchanger. JJMIE. 2009;3(1):17–22.

Naphon P. Heat transfer and pressure drop in the horizontal double pipes with and without twisted tape insert. Int Commun Heat Mass Transfer. 2006;33(2):166–75.

Mogaji TS, Idowu ET, Jen T-C. Numerical simulation for comparative thermo-hydraulic performance of turbulent flow in tubes with twisted tape inserts. J Eng Sci. 2020;16(2):71–100. https://doi.org/10.21315/jes2020.16.2.4.

Salam B, Biswas S, Saha S, Bhuiya MMK. Heat transfer enhancement in a tube using rectangular-cut twisted tape insert. Proc Eng. 2013;56:96–103.

Elsheikh AH, Shanmugan S, Muthuramalingam T, Kumar R, Essa FA, Ibrahim AMM. Modeling of the transient temperature field during laser heating. Lasers Manuf Mater Process. 2021;8:97–112.

Yang L, Kai Du. A comprehensive review on heat transfer characteristics of TiO2 nanofluids. Int J Heat Mass Transf. 2017;108:11–31.

Tamna S, Kaewkohkiat Y, Skullong S, Promvonge P. Heat transfer enhancement in tubular heat exchanger with double V-ribbed twisted-tapes. Case Stud Therm Eng. 2016;7:14–24.

Sundar LS, Otero-Irurueta G, Singh MK, Sousa AC. Heat transfer and friction factor of multi-walled carbon nanotubes–Fe3O4 nanocomposite nanofluids flow in a tube with/without longitudinal strip inserts. Int J Heat Mass Transf. 2016;100:691–703.

Vashistha C, Patil AK, Kumar M. Experimental investigation of heat transfer and pressure drop in a circular tube with multiple inserts. Appl Therm Eng. 2016;96:117–29.

Man C, Yao J, Wang C. The experimental study on the heat transfer and friction factor characteristics in tube with a new kind of twisted tape insert. Int Commun Heat Mass Transfer. 2016;75:124–9.

Chougule SS, Sahu SK. Heat transfer and friction characteristics of Al2O3/water and CNT/water nanofluids in transition flow using helical screw tape inserts–a comparative study. Chem Eng Process Process Intens. 2015;88:78–88.

Kline SJ, McClintock FA. Analysis of uncertainty in single-sample experiments. Mech Eng. 1953;75(3)

Salmi M, Boursas A, Derradji M, Lorenzini G, Ahmad H, Menni Y, Ameur H, Maoudj R. Improved heat transfer in w-baffled air-heat exchangers with upper-inlet and lower-exit. Math Modell Eng Probl. 2021;8(1)

El-Said EM, AbdElaziz M, Elsheikh AH. Machine learning algorithms for improving the prediction of air injection effect on the thermohydraulic performance of shell and tube heat exchanger. Appl Therm Eng. 2021;185:116471.

Shelare SD, Aglawe KR, Belkhode PN. A review on twisted tape inserts for enhancing the heat transfer. Mater Today Proc. 2022;54:560–5.

Maddah H, Aghayari R, Mirzaee M, Ahmadi MH, Sadeghzadeh M, Chamkha AJ. Factorial experimental design for the thermal performance of a double pipe heat exchanger using Al2O3-TiO2 hybrid nanofluid. Int Commun Heat Mass Transf. 2018;97:92–102.

Aghayari R, Maddah H, Pourkiaei SM, Ahmadi MH, Chen L, Ghazvini M. Theoretical and experimental studies of heat transfer in a double-pipe heat exchanger equipped with twisted tape and nanofluid. Eur Phys J Plus. 2020;135:1–26.

Abdelhamid T, Elsheikh AH, Omisore OM, Saeed NA, Muthuramalingam T, Chen R, Alam MM. Reconstruction of the heat transfer coefficients and heat fluxes in heat conduction problems. Math Comput Simul. 2021;187:134–54.

Jawarneh AM, Al-Widyan M, Al-Mashhadani Z. Experimental study on heat transfer augmentation in a double pipe heat exchanger utilizing jet vortex flow. Heat Transf. 2023;52(1):317–32.

Mohamed HA, Alhazmy M, Mansour F, Negeed ESR. Enhancing heat transfer inside a double pipe heat exchanger using Al2O3 nanofluid, experimental investigation under turbulent flow conditions. J Nanofluids. 2023;12(2):356–71.

Acknowledgements

The authors are thankful to Dr. Jeet Prakash Sharma from School of Mechanical Engineering, Lovely Professional University, Phagwara-144411 Punjab, India and Dr. Bulbul Ongar, G.P. Kalimbetov from Satbayev University, Department of Power Engineering, 22a Satpaev str., Almaty, Kazakhstan for their valuable contribution in this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Heeraman, J., Sandeep, C. & Chaurasiya, P.K. Heat transfer enhancement in double pipe heat exchanger: exploring twisted tape inserts with dimple configuration. J Therm Anal Calorim (2024). https://doi.org/10.1007/s10973-024-13200-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10973-024-13200-w