Abstract

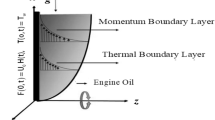

In this research article, we intend to perform a numerical investigation of the thermal features of MHD Williamson hybrid nanofluid flow over a linearly stretching surface with viscous dissipation and nonlinear thermal radiation effects. An external magnetic field exists in the vicinity of stagnation point along with the creation of induced magnetic field due conducting fluid. A thin film of viscous and incompressible base fluid, engine oil \((EO)\), encumbered with titanium alloy \((Ti_{6} Al_{4} V)\) and zinc oxide \((ZnO)\) nanoparticles is examined taking pure nanofluid and hybrid nanofluid cases simultaneously in a single frame in Cartesian coordinates. The governing equations are first transformed to ordinary differential equations employing similarity transformations and then simulated by successive over-relaxation method. Approximate solutions are assessed through graphs for velocity, temperature and induced magnetism corresponding to the prominent parameters. A significant improvement in wear resistance, lubrication and thermal features of the engine oil has been observed due to titanium alloy and zinc oxide hybrid nanocomposite.

Similar content being viewed by others

Abbreviations

- \(A_{1}\) :

-

First Rivlin–Erickson vector

- \(\mu_{\text{hnf}}\) :

-

Hybrid nanofluid viscosity \(({{kg}}\, {{ms}}^{-1})\)

- \(k_{\text{hnf}}\) :

-

Thermal conductivity of hybrid nanofluid \((W \, m^{ - 1} {\text{ k}}^{ - 1} )\)

- \(\rho_{\text{hnf}}\) :

-

Hybrid nanofluid density \(\text{kg}\, \text{ms}^{-3}\)

- \(c_{\text{p}}\) :

-

Specific heat at constant pressure \((J \, mol^{ - 1} {\text{ k}}^{ - 1} )\)

- \(\sigma_{\text{hnf}}\) :

-

Electrical conductivity of hybrid nanofluid (\({\text{S}}\, {\text{m}}^{-1}\))

- \(b\) :

-

Stretching rate

- \(\theta\) :

-

Dimensionless temperature

- \(B_{0}\) :

-

Magnetic field strength \((kg \, s^{ - 2} \, A^{ - 1} )\)

- \(\theta_{\text{w}}\) :

-

Temperature ratio parameter

- \(k\) :

-

Thermal conductivity \((W \, m^{ - 1} {\text{ k}}^{ - 1} )\)

- \(\omega\) :

-

Relaxation parameter

- \(Nr\) :

-

Thermal radiation parameter

- \(\eta_{0}\) :

-

Magnetic diffusivity

- \(T\) :

-

Fluid temperature (\(k\))

- \(\beta\) :

-

Induced magnetic field

- \(T_{\text{w}}\) :

-

Temperature at the surface (\(k\))

- \(\lambda_{0}\) :

-

Reciprocal magnetic Prandtl number

- \(T_{\infty }\) :

-

Temperature far off the surface (\(k\))

- \(\phi_{1}\) :

-

Concentration of zinc oxide nanoparticles

- \(Pr\) :

-

Prandtl number

- \(\phi_{2}\) :

-

Concentration of titanium alloy nanoparticles

- \(Re_{\text{x}}\) :

-

Local Reynolds number

- \(\mu_{\text{e}}\) :

-

Magnetic permeability

- \(Ec\) :

-

Eckert number

- \(\mu_{0}\) :

-

Limiting viscosity at zero shear rate

- \(We\) :

-

Weissenberg number

- \(\mu_{\infty }\) :

-

Limiting viscosity at infinite shear rate

- \(H_{1}\) :

-

\(x -\) Component of induced magnetic field

- \(\Gamma\) :

-

Time constant

- \(H_{2}\) :

-

\(y -\) Component of induced magnetic field

- \(\varepsilon\) :

-

Stretching ratio

- \(H_{0}\) :

-

Strength of uniform induced magnetic field

- \(\tau_{\text{w}}\) :

-

Wall share stress

- \(Ti_{6} Al_{4} V\) :

-

Titanium alloy

- \(ZnO\) :

-

Zinc oxide

- \(EO\) :

-

Engine oil

References

Choi SU, Eastman JA. Enhancing Thermal conductivity of fluids with nanoparticles. Tech rep, Argonne national lab., IL (United States), 1995

Shah Z, et al. Numerical modeling on hybrid nanofluid (Fe3O4 + MWCNT/H2O) migration considering MHD effect over a porous cylinder. PLoS ONE. 2021;16: e0251744.

Tekir M, et al. Effect of constant magnetic field on Fe3O4-Cu/water hybrid nanofluid flow in a circular pipe. Heat Mass Transf. 2022;58:707–17.

Ahmad S, et al. Novel thermal aspects of hybrid nanofluid flow comprising of manganese zinc ferrite MnZnFe2O4, nickel zinc ferrite NiZnFe2O4 and motile microorganisms. Ain Shams Eng J. 2022;13: 101668.

Turkyilmazoglu M. Exact analytical solutions for heat and mass transfer of MHD slip flow in nanofluids. Chem Eng Sci. 2012;84:182–7.

Baranovskii ES. Flows of a polymer fluid in domain with impermeable boundaries. Comput Math Math Phys. 2014;54:1589–96.

Sakiadis BC. Boundary-layer behaviour on continuous solid surface. I. boundary-layer equations for two-dimensional and axisymmetric flow. AICHE J. 1961;7:26–8.

Sakiadis BC. Boundary-layer behaviour on continuous solid surfaces. II. The boundary layer on a continuous flat surface. AICHE J. 1961;7:221–5.

Crane LJ. Flow past a stretching plate. Z fur Angew Math Phys. 1970;21:645–7.

Andersson HI, Bech KH, Dandapat BS. Magnetohydrodynamic flow of a power-law fluid over a stretching sheet. Int J Non Linear Mech. 1992;27:929–36.

Andersson HI. MHD flow of a viscoelastic fluid past a stretching surface. Acta Mech. 1992;95:227–30.

Vishalakshi AB, et al. MHD hybrid nanofluid flow over a stretching/shrinking sheet with skin friction: effects of radiation and mass transpiration. Magnetochemistry. 2023;9:118. https://doi.org/10.3390/magnetochemistry9050118.

Ahmad S, et al. Thermal characteristics of kerosene oil based hybrid nanofluids (Ag- MnZnFe2O4): a comprehensive study. Front Energy Res. 2022;10: 978819. https://doi.org/10.3389/fenrg.2022.978819.

Jamshed W, et al. The improved thermal efficiency of prandtl-eyring hybrid nanofluid via classical keller box technique. Sci Rep. 2021;11:23535. https://doi.org/10.1038/s41598-021-02756-4.

Ahmad S, et al. Novel thermal aspects of hybrid nanoparticles Cu-TiO2 in the flow of ethylene glycol. ICHMT. 2021;129: 105708.

Ali K, et al. Simulation analysis of MHD hybrid CuAl2O3/H2O nanofluid flow with heat generation through a porous media. Int J Energy Res. 2021;45:19165–79.

Aminuddin NA, et al. Impact of thermal radiation on MHD GO-Fe2O4/EG flow and heat transfer over a moving surface. Symmetry. 2023;15:584. https://doi.org/10.3390/sym15030584.

Chinas-Castillo F, Spikes HA. Mechanism of action of colloidal solid dispersions. J Tribol. 2003;125:552–7.

Xue Q, Liu W, Zhang Z. Friction and wear properties of a surface modified TiO2 nanoparticle as an additive in liquid paraffin. Wear. 1997;213:29–32.

Riaz M, Khan N, Shehzad SA. Rheological behavior of magnetized ZnO–SAE 50 nanolubricant over riga plate: a theoretical study. Adv Mech Eng. 2023;15(3):1–15. https://doi.org/10.1177/16878132231162305.

Wu YY, Tsui WC, Liu TC. Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear. 2007;262:819–25. https://doi.org/10.1016/j.wear.2006.08.021.

Rasheed AK, et al. Heat transfer and tribological performance of graphene nanolubricant in an internal combustion engine. Tribol Int. 2016;103:504–15.

Ettefaghi EOL, et al. Preparation and thermal properties of oil-based nanofluid from multi-walled carbon nanotubes and engine oil as nanolubricant. Int Commun Heat Mass Trans. 2013;46:142–7.

Khan U, et al. Activation energy on MHD flow of titanium alloy (Ti6Al4V) nanoparticle along with a cross flow and streamwise direction with binary chemical reaction and non-linear radiation: dual solutions. J Mater Res Technol. 2019;9:188–99. https://doi.org/10.1016/j.jmrt.2019.10.044.

Asifa, et al. Double slip effects and heat transfer characteristics for channel transport of engine oil with titanium and aluminum alloy nanoparticles: a fractional study. IEEE Access. 2021;9:52036–52. https://doi.org/10.1109/access.2021.3067937.

Hiemenz K. Die Grenzschicht an einem inden gleichförmigen Flüssigkeitsstrom eingetauchten geraden Kreiszylinder. Dingler’s Polytech J. 1911;326:321–4.

Reddy C, Shankar B. Magneto hydrodynamics stagnation point flow of a nano fluid over an exponentially stretching sheet with an effect of chemical reaction. Heat Sour Suction Inj WJM. 2015;5:211–21.

Kai Y, et al. A case study of different magnetic strength fields and thermal energy effects in vortex generation of Ag-TiO2 hybrid nanofluid flow. Case Stud Therm Eng. 2023;47: 103115.

Kai Y, et al. Thermal case study and generated vortices by dipole magnetic field in hybridized nanofluid flowing: alternating direction implicit solution. Res Phys. 2023;49: 106464.

Ahmad S, et al. A novel vortex dynamics for micropolar fluid flow in a lid-driven cavity with magnetic field localization a computational approach. Ain Shams Eng J. 2023. https://doi.org/10.1016/j.asej.2023.102448.

Ahmad S, et al. Localized magnetic fields and their effects on heat transfer enhancement and vortices generation in tri-hybrid nanofluids: a novel investigation. Case Stud Therm Eng. 2023;50: 103408.

Ahmad S, Cai J, Ali K. Prediction of new vortices in single-phase nanofluid due to dipole interaction. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-10237-5.

Ahmad S, et al. Unveiling the magic of localized magnetic field on vortex dynamics and heat transfer of tetra-hybrid nanofluid in lid-driven cavity: an insightful investigation. J Therm Anal Calorim. 2024. https://doi.org/10.1007/s10973-023-12733-w.

Cramer KR, Pai S. Magnetofluid dynamics for engineers and applied physicists. New York: McGraw-Hill; 1973. p. 204–37.

Hasibi A, et al. Importance of induced magnetic field and exponential heat source on convective flow of Casson fluid in a micro-channel via AGM. Theor Appl Mech Lett. 2022;12: 100342.

Iqbal Z, Azhar E, Maraj EN. Transport phenomena of carbon nanotubes and bioconvection nanoparticles on stagnation point flow in presence of induced magnetic field. Phys E: Low-Dimens Syst Nanostruct. 2017;91:128–35.

Ali K, Ashraf M. Thermal reversal in MHD stagnation point flow towards a stretching sheet with induced magnetic field and viscous dissipation effects. World Appl Sci J. 2012;16:1615–25.

Faridi AA, Khan N, Ali K. A novel numerical note on the enhanced thermal features of water-ethylene glycol mixture due to hybrid nanoparticles (MnZnFe2O4–Ag) over a magnetized stretching surface. Numer Heat Trans B-Fund. 2023. https://doi.org/10.1080/10407790.2023.2296082.

Williamson RV. The flow of pseudoplastic materials. Ind amp Eng Chem. 1929;21:1108–11.

Mahanthesh B, et al. Exponential heat source effects on the stagnation-point heat transport of williamson nanoliquid with nonlinear boussinesq approximation. Heat Transfer. 2021;50:6645–64.

Dawar A, et al. A convective flow of williamson nanofluid through cone and wedge with non-isothermal and non-isosolutal conditions: a revised buongiorno model. Case Stud Therm Eng. 2021;24: 100869. https://doi.org/10.1016/j.csite.2021.100869.

Mabood F, Khan SU, Tlili I. Numerical simulations for swimming of gyrotactic microorganisms with Williamson nanofluid featuring Wu’s slip, activation energy and variable thermal conductivity. Appl Nanosci. 2023;13(1):131–44.

Khan SU, et al. Thermally radiative flow of williamson nanofluid containing microorganisms with applications of heat source and activation energy. Int J Mod Phys C. 2022;33(9):2250125.

Guedri K, et al. Numerical simulation for two-phase dusty thermally developed marangoni forced convective flow of williamson material: a finite difference scheme. ZAMM. 2022;103(3): e202100206.

Imran U, et al. Electro-magnetic radiative flowing of williamson-dusty nanofluid along elongating sheet: nanotechnology application. Arab J Chem. 2023;16(5): 104698.

Yahya AU, et al. Thermal characteristics for the flow of williamson hybrid nanofluid (MoS2 + ZnO) based with engine oil over a stretched sheet. Case Stud Therm Eng. 2021;26: 101196. https://doi.org/10.1016/j.csite.2021.101196.

Wasim J, et al. Computational frame work of cattaneo-christov heat flux effects on engine oil based williamson hybrid nanofluids: a thermal case study. Case Stud Therm Eng. 2021;26: 101179. https://doi.org/10.1016/j.csite.2021.101179.

Alhowaity A, et al. Numerical study of williamson hybrid nanofluid flow with thermal characteristics past over an extending surface. Heat Transfer. 2022;51:6641–55. https://doi.org/10.1002/htj.22616.

Ali K, et al. Quasi-linearization analysis for heat and mass transfer of magnetically driven 3rd-grade (Cu-TiO2/engine oil) nanofluid via a convectively heated surface. ICHMT. 2022;135: 106060. https://doi.org/10.1016/j.icheatmasstransfer.2022.106060.

Ahmad S, et al. Features of Cu and TiO2 in the flow of engine oil subject to thermal jump conditions. Sci Rep. 2021;11:19592. https://doi.org/10.1038/s41598-021-99045-x.

Zhang X, et al. Successive over relaxation (SOR) methodology for convective triply diffusive magnetic flowing via a porous horizontal plate with diverse irreversibilities. Ain Shams Eng J. 2023;14: 102137. https://doi.org/10.1016/j.asej.2023.102137.

Faridi AA, et al. Relaxation analysis and entropy simulation of triple diffusive slip effect on magnetically driven casson fluid flow. Int J Model Simul. 2024. https://doi.org/10.1080/02286203.2023.2301129.

Nadeem S, Hussain ST, Lee C. Flow of a williamson fluid over a stretching sheet. Braz J Chem Eng. 2013;30(3):619–25.

Khan SU, et al. Effects of nonlinear thermal radiation and activation energy on modified second-grade nanofluid with cattaneo-christov expressions. J Therm Anal Calorim. 2021;143:1175–86.

Hayat T, et al. Stagnation point flow with cattaneo-christov heat flux and homogeneous-heterogeneous reactions. J Mol Liq. 2017;113:310–7.

Animasaun IL, et al. Dynamics of ternary-hybrid nanofluid subject to magnetic flux density and heat source or sink on a convectively heated surface. Surf Interfaces. 2022;28: 101654.

Latha KBS, et al. Computation of stagnation coating flow of electro-conductive ternary williamson hybrid GO − AU − Co3O4/EO nanofluid with a cattaneo-christov heat flux model and magnetic induction. Sci Rep. 2023;13:10972.

Ali FM, et al. MHD stagnation-point flow and heat transfer towards stretching sheet with induced magnetic field. Appl Math Mech (Engl Ed). 2011;32:409–18.

Ali K, et al. Viscous dissipation and radiation effects in MHD Stagnation point flow towards a stretching sheet with induced magnetic field. World Appl Sci J. 2012;16:1638–48.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

All authors declare that there is no conflict of interests regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Faridi, A.A., Khan, N. & Ali, K. A computational note on thermal attributes of engine oil with titanium alloy and zinc oxide hybrid nanoparticles flowing over a stretching surface about a stagnation point. J Therm Anal Calorim 149, 3833–3849 (2024). https://doi.org/10.1007/s10973-024-12981-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-024-12981-4