Abstract

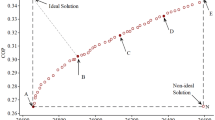

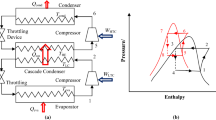

Conserving energy is an important factor in industry which could lead to reduce the operating costs of the system. Improving energy efficiency is a serious concern to many researchers and numerous studies have been conducted on this goal. A valuable method to locate the inefficient system components is the conventional exergy analysis. Furthermore, to estimate the cost efficiency of a thermodynamic system, exergo-economic analysis is indispensable. This study evaluates the ejector trans-critical \({{\text{CO}}}_{2}\) refrigeration cycle from exergo-economic viewpoint. The thermodynamic system was modeled using Engineering Equation Solver (EES) software. In order to utilize the waste heat of the gas cooler, a thermo-electric generator is introduced. Energy, exergy, and exergo-economic (3E) analysis has been performed. A parametric study was conducted of gas cooler pressure, low-pressure compressor outlet pressure, and evaporator pressure. Multi-criteria optimization has been conducted to optimize COP and refrigeration cost rate using NSGA-II (non-dominated sorting genetic algorithm). The results showed the system could provide a COP of 1.593 for the base case of the cycle operation. The high-priority components to improve were expansion valve, thermo-electric generator, and low-pressure compressor which had the highest exergy destruction ratio as 0.211, 0.180, and 0.158 respectively. The refrigeration cost rate was 2.898 $ h−1 for the base case of the system. Optimization results showed that the exergy efficiency and the exergy destruction ratio of the optimum design point are 0.284 and 0.574.

Similar content being viewed by others

Abbreviations

- e:

-

Specific exergy (kJ kg−1)

- \(\dot{E}\) :

-

Exergy rate \((kW)\)

- \(h\) :

-

Specific enthalpy \((kJ \, kg^{-1})\)

- \(\dot{m}\) :

-

Mass flow rate \((kg \, s^{-1})\)

- \(P\) :

-

Pressure \((kPa)\)

- \(P\) :

-

Power \((kW)\)

- \(\dot{W}\) :

-

Work \((kW)\)

- \(\dot{Q}\) :

-

Heat transfer \((kW)\)

- \(s\) :

-

Specific entropy \((kJ\, kg^{-1} \,K^{-1})\)

- \(T\) :

-

Temperature \((K)-(^\circ C)\)

- \(v\) :

-

Velocity \((m\,s^{-1})\)

- \(x\) :

-

Quality

- \(\dot{C}\) :

-

Cost rate ($ h−1)

- \(c\) :

-

Specific exergy cost ($ GJ−1)

- \(Z\) :

-

Investment cost of component \((\mathrm{\$})\)

- \(\dot{Z}\) :

-

Investment cost rate of component ($ h−1)

- \(\alpha\) :

-

Seebeck coefficient \((V \,K^{-1})\)

- \(\sigma\) :

-

Electrical conductivity \((S\,m^{-1})\)

- \(\lambda\) :

-

Thermal conductivity \((W\,m^{-1}\,K^{-1})\)

- \(\omega\) :

-

Entrainment ratio of ejector

- \(\eta\) :

-

Efficiency

- \(\delta\) :

-

Exergy destruction ratio

- \(T\) :

-

Thermal

- \(M\) :

-

Mechanical

- \(\text{do}\) :

-

Diffuser outlet

- \(\text{D}\) :

-

Destruction

- \(\text{hpc}\) :

-

High-pressure compressor

- \(\text{lpc}\) :

-

Low-pressure compressor

- \(\text{ex}\) :

-

Exergy

- \(\text{F}\) :

-

Fuel

- \(\text{P}\) :

-

Product

- \(\text{L}\) :

-

Loss

- \(\text{is}\) :

-

Isentropic

- \(\text{n}\) :

-

Nozzle

- \(\text{d}\) :

-

Diffuser

- \(\text{m}\) :

-

Mixing chamber

- \(\text{high}\) :

-

High-pressure stage

- \(\text{low}\) :

-

Low-pressure stage

- \(\text{in}\) :

-

Inlet

- \(\text{out}\) :

-

Outlet

- \(\text{teg}\) :

-

Thermo-electric generator

- \(0\) :

-

Reference parameter

References

Mosaffa AH, Farshi LG, Infante Ferreira CA, Rosen MA. Exergoeconomic and environmental analyses of CO2/NH3 cascade refrigeration systems equipped with different types of flash tank intercoolers. Energy Convers Manag. 2016;117:442–53. https://doi.org/10.1016/j.enconman.2016.03.053.

Haq MdZ, Ayon MdSR, Nouman MdWB, Bihani R. Thermodynamic analysis and optimisation of a novel transcritical CO2 cycle. Energy Convers Manag. 2022;273: 116407. https://doi.org/10.1016/j.enconman.2022.116407.

Yu B, Yang J, Wang D, Shi J, Chen J. An updated review of recent advances on modified technologies in transcritical CO2 refrigeration cycle. Energy. 2019;189: 116147. https://doi.org/10.1016/j.energy.2019.116147.

Dai B, Liu S, Zhu K, Sun Z, Ma Y. Thermodynamic performance evaluation of transcritical carbon dioxide refrigeration cycle integrated with thermoelectric subcooler and expander. Energy. 2017;122:787–800. https://doi.org/10.1016/j.energy.2017.01.029.

Qyyum MA, Naquash A, Sial NR, Lee M. CO2 precooled dual phase expander refrigeration cycles for offshore and small-scale LNG production: energy, exergy, and economic evaluation. Energy. 2023;262: 125378. https://doi.org/10.1016/j.energy.2022.125378.

Mansour A, Oberti R, Nesreddine H, Poncet S. Thermodynamic analysis of a transcritical CO2 heat pump integrating a vortex tube. Appl Therm Eng. 2023;224: 120076. https://doi.org/10.1016/j.applthermaleng.2023.120076.

Huang C, Li Z, Ye Z, Wang R. Thermodynamic study of carbon dioxide transcritical refrigeration cycle with dedicated subcooling and cascade recooling. Int J Refrig. 2022;137:80–90. https://doi.org/10.1016/j.ijrefrig.2022.02.004.

Dai B, Liu S, Sun Z, Ma Y. Thermodynamic performance analysis of CO2 transcritical refrigeration cycle assisted with mechanical subcooling. Energy Procedia. 2017;105:2033–8. https://doi.org/10.1016/j.egypro.2017.03.579.

Chen X, Yang Q, Chi W, Zhao Y, Liu G, Li L. Energy and exergy analysis of NH3/CO2 cascade refrigeration system with subcooling in the low-temperature cycle based on an auxiliary loop of NH3 refrigerants. Energy Rep. 2022;8:1757–67. https://doi.org/10.1016/j.egyr.2022.01.004.

Aghazadeh Dokandari D, Setayesh Hagh A, Mahmoudi SMS. Thermodynamic investigation and optimization of novel ejector-expansion CO2/NH3 cascade refrigeration cycles (novel CO2/NH3 cycle). Int J Refrig. 2014;46:26–36. https://doi.org/10.1016/j.ijrefrig.2014.07.012.

Braimakis K. Solar ejector cooling systems: a review. Renew Energy. 2021;164:566–602. https://doi.org/10.1016/j.renene.2020.09.079.

Liu J, Liu Y, Yu J. Performance analysis of a modified dual-ejector and dual-evaporator transcritical CO2 refrigeration cycle for supermarket application. Int J Refrig. 2021;131:109–18. https://doi.org/10.1016/j.ijrefrig.2021.06.010.

Eskandari Manjili F, Cheraghi M. Performance of a new two-stage transcritical CO2 refrigeration cycle with two ejectors. Appl Therm Eng. 2019;156:402–9. https://doi.org/10.1016/j.applthermaleng.2019.03.083.

Lee JS, Kim MS, Kim MS. Experimental study on the improvement of CO2 air conditioning system performance using an ejector. Int J Refrig. 2011;34(7):1614–25. https://doi.org/10.1016/j.ijrefrig.2010.07.025.

Liu J, Zhou L, Lyu N, Lin Z, Zhang S, Zhang X. Analysis of a modified transcritical CO2 two-stage ejector-compression cycle for domestic hot water production. Energy Convers Manag. 2022;269: 116094. https://doi.org/10.1016/j.enconman.2022.116094.

Wang Y, Yin Y, Cao F. Comprehensive evaluation of the transcritical CO2 ejector-expansion heat pump water heater. Int J Refrig. 2023;145:276–89. https://doi.org/10.1016/j.ijrefrig.2022.09.008.

Casi Á, Aranguren P, Araiz M, Sanchez D, Cabello R, Astrain D. Performance assessment of an experimental CO2 transcritical refrigeration plant working with a thermoelectric subcooler in combination with an internal heat exchanger. Energy Convers Manag. 2022;268: 115963. https://doi.org/10.1016/j.enconman.2022.115963.

Santini F, Bianchi G, Battista DD, Villante C, Orlandi M. Experimental investigations on a transcritical CO2 refrigeration plant and theoretical comparison with an ejector-based one. Energy Procedia. 2019;161:309–16. https://doi.org/10.1016/j.egypro.2019.02.097.

Aranguren P, Sánchez D, Casi A, Cabello R, Astrain D. Experimental assessment of a thermoelectric subcooler included in a transcritical CO2 refrigeration plant. Appl Therm Eng. 2021;190: 116826. https://doi.org/10.1016/j.applthermaleng.2021.116826.

Yang D, Jie Z, Zhang Q, Li Y, Xie J. Evaluation of the ejector two-stage compression refrigeration cycle with work performance from energy, conventional exergy and advanced exergy perspectives. Energy Rep. 2022;8:12944–57. https://doi.org/10.1016/j.egyr.2022.09.108.

Liu X, Fu R, Wang Z, Lin L, Sun Z, Li X. Thermodynamic analysis of transcritical CO2 refrigeration cycle integrated with thermoelectric subcooler and ejector. Energy Convers Manag. 2019;188:354–65. https://doi.org/10.1016/j.enconman.2019.02.088.

Chen G, Volovyk O, Zhu D, Ierin V, Shestopalov K. Theoretical analysis and optimization of a hybrid CO2 transcritical mechanical compression–ejector cooling cycle. Int J Refrig. 2017;74:86–94. https://doi.org/10.1016/j.ijrefrig.2016.10.002.

Wang X, Yu J, Zhou M, Lv X. Comparative studies of ejector-expansion vapor compression refrigeration cycles for applications in domestic refrigerator-freezers. Energy. 2014;70:635–42. https://doi.org/10.1016/j.energy.2014.04.076.

Liu Q, He Z, Liu Y, He Y. Thermodynamic and parametric analyses of a thermoelectric generator in a liquid air energy storage system. Energy Convers Manag. 2021;237: 114117. https://doi.org/10.1016/j.enconman.2021.114117.

Tian Z, Chen X, Zhang Y, Gao W, Chen W, Peng H. Energy, conventional exergy and advanced exergy analysis of cryogenic recuperative organic rankine cycle. Energy. 2023;268: 126648. https://doi.org/10.1016/j.energy.2023.126648.

Zheng L, Hu Y, Mi C, Deng J. Advanced exergy analysis of a CO2 two-phase ejector. Appl Therm Eng. 2022;209: 118247. https://doi.org/10.1016/j.applthermaleng.2022.118247.

Abdolalipouradl M, Mohammadkhani F, Khalilarya S, Yari M. Thermodynamic and exergoeconomic analysis of two novel tri-generation cycles for power, hydrogen and freshwater production from geothermal energy. Energy Convers Manag. 2020;226: 113544. https://doi.org/10.1016/j.enconman.2020.113544.

Liu J, Liu Y, Yan G, Yu J. Theoretical study on a modified single-stage autocascade refrigeration cycle with auxiliary phase separator. Int J Refrig. 2021;122:181–91. https://doi.org/10.1016/j.ijrefrig.2020.11.009.

Al-Rashed AAAA, Afrand M. Multi-criteria exergoeconomic optimization for a combined gas turbine-supercritical CO2 plant with compressor intake cooling fueled by biogas from anaerobic digestion. Energy. 2021;223: 119997. https://doi.org/10.1016/j.energy.2021.119997.

Baniasad Askari I, Shahsavar A. The exergo-economic analysis of two novel combined ejector heat pump/humidification-dehumidification desalination systems. Sustain Energy Technol Assess. 2022;53:102561. https://doi.org/10.1016/j.seta.2022.102561.

Khanmohammadi S, Musharavati F, Kizilkan O, Duc Nguyen D. Proposal of a new parabolic solar collector assisted power-refrigeration system integrated with thermoelectric generator using 3E analyses: energy, exergy, and exergo-economic. Energy Convers Manag. 2020;220:113055. https://doi.org/10.1016/j.enconman.2020.113055.

“Gasoline and diesel prices by country,” GlobalPetrolPrices.com. Accessed: Aug. 06, 2023. [Online]. Available: https://www.globalpetrolprices.com/

Jahromi FS, Beheshti M, Rajabi RF. Comparison between differential evolution algorithms and response surface methodology in ethylene plant optimization based on an extended combined energy - exergy analysis. Energy. 2018;164:1114–34. https://doi.org/10.1016/j.energy.2018.09.059.

Qudah A, Almerbati A, Mokheimer EMA. Novel approach for optimizing wind-PV hybrid system for RO desalination using differential evolution algorithm. Energy Convers Manag. 2024;300: 117949. https://doi.org/10.1016/j.enconman.2023.117949.

Karmakar R, Chatterjee S, Datta D, Chakraborty D. Application of harmony search algorithm in optimizing autoregressive integrated moving average: a study on a data set of Coronavirus Disease 2019. Syst Soft Comput. 2024;6: 200067. https://doi.org/10.1016/j.sasc.2023.200067.

Lee GH, Sadollah A, Park SH, Geem ZW. HS-Solver: Spreadsheet based harmony search algorithm solver for various optimization problems. SoftwareX. 2022;20: 101262. https://doi.org/10.1016/j.softx.2022.101262.

Cheng H, et al. Economic, environmental, exergy (3E) analysis and multi-objective genetic algorithm optimization of efficient and energy-saving separation of diethoxymethane/toluene/ethanol by extractive distillation with mixed extractants. Energy. 2023;284: 129262. https://doi.org/10.1016/j.energy.2023.129262.

Kaseb Z, Rahbar M. Towards CFD-based optimization of urban wind conditions: comparison of genetic algorithm, particle swarm optimization, and a hybrid algorithm. Sustain Cities Soc. 2022;77: 103565. https://doi.org/10.1016/j.scs.2021.103565.

Vuolio T, Visuri V-V, Sorsa A, Ollila S, Fabritius T. Application of a genetic algorithm based model selection algorithm for identification of carbide-based hot metal desulfurization. Appl Soft Comput. 2020;92: 106330. https://doi.org/10.1016/j.asoc.2020.106330.

Zhang L, et al. Integrated optimization for utilizing iron and steel industry’s waste heat with urban heating based on exergy analysis. Energy Convers Manag. 2023;295: 117593. https://doi.org/10.1016/j.enconman.2023.117593.

Erodotou P, Voutsas E, Sarimveis H. A genetic algorithm approach for parameter estimation in vapour-liquid thermodynamic modelling problems. Comput Chem Eng. 2020;134: 106684. https://doi.org/10.1016/j.compchemeng.2019.106684.

Deb K, Goel T. Controlled Elitist Non-dominated Sorting Genetic Algorithms for Better Convergence. In: Zitzler E, Thiele L, Deb K, Coello Coello CA, Corne D, editors. In: Evolutionary Multi-Criterion Optimization. Berlin, Heidelberg: Springer, Berlin Heidelberg; 2001.

Pan M, et al. Thermodynamic, exergoeconomic and multi-objective optimization analysis of new ORC and heat pump system for waste heat recovery in waste-to-energy combined heat and power plant. Energy Convers Manag. 2020;222: 113200. https://doi.org/10.1016/j.enconman.2020.113200.

Acknowledgements

Authors would like to acknowledge the financial support of Kermanshah University of Technology for this research under grant number S/T/P/1430.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khanmohammadi, S., Sharifinasab, M.R. 3E analysis and multi-objective optimization of a trans-critical ejector-assisted Co2 refrigeration cycle combined with thermo-electric generator. J Therm Anal Calorim 149, 3951–3964 (2024). https://doi.org/10.1007/s10973-024-12968-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-024-12968-1