Abstract

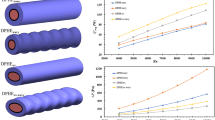

The need to reduce energy usage is one of the main issues with creating heat exchangers. This may be accomplished by increasing the heat transfer augmentation which results in the higher thermal performance factor (TPF). The aim of the present study is to experimentally determine the thermal hydraulic performance factor of DPHE with a novel wire coil insert. The experiments were performed in the range of Reynolds number (Re): 5500–15000, and the data were recorded for fifteen different combinations of wire coil (WC) inserts, including five different pitch ratios (P/Dc = 0.625, 1.25, 1.875, 2.5 and 3.125) and three wire diameters (d = 1, 1.5 and 2 mm). The application of WC inserts results in notable enhancement in heat transfer rate as compared to different TT. For the given range of Re, the heat transfer performance was improved to a maximum of 126.7% for pitch ratio (PR) P/Dc = 0.625 at wire diameter (d = 2 mm), while friction was recorded in the range of 2.67–4.71 times higher compared to PT. The TPF (η) with WC inserts for all combination was recorded greater than unity. The maximum value of TPF (η) obtained for wire coil inserts is 1.35 with PR (P/Dc = 0.625) and (d = 2 mm). Since TPF(η) in all cases is greater than 1.0 which shows that it is an effective approach.

Similar content being viewed by others

Abbreviations

- A i :

-

Inner surface area of inner pipe (m2)

- A o :

-

Outer surface area of inner pipe (m2)

- ASHRAE:

-

American Society of Heating, Refrigeration and Air-conditioning Engineer

- CPVC:

-

Chlorinated polyvinyl chloride

- C p :

-

Specific heat capacity at constant pressure (J kg−1 K−1)

- d i :

-

Inner copper pipe inner diameter (m)

- d o :

-

Inner copper pipe outer diameter (m)

- d :

-

Wire coil diameter

- D c :

-

Coil diameter (m)

- D i :

-

Outer CPVC pipe inner diameter (m)

- D o :

-

Outer CPVC pipe outer diameter (m)

- D h :

-

Hydraulic diameter (m)

- f :

-

Friction factor (dimensionless)

- \({f}_\text{t}\) :

-

Friction factor of the inner pipe with wire coil inserts (dimensionless)

- f o :

-

Friction factor of the plain pipe (dimensionless)

- \({h}_{{\text{i}}}\) :

-

Inner pipe average convective heat transfer coefficient (W m−2 K−1)

- \({h}_{{\text{o}}}\) :

-

Outer pipe average convective heat transfer coefficient (W m−2 K−1)

- \({h}_\text{p}\) :

-

Plain pipe average convective heat transfer coefficient (W m−2 K−1)

- \({h}_\text{t}\) :

-

Average convective heat transfer coefficient of inner pipe with wire coil inserts (W/m−2 K−1)

- \({k}_{{\text{i}}}\) :

-

Hot water thermal conductivity (W m−1 K−1)

- \({k}_{{\text{p}}}\) :

-

Inner pipe material thermal conductivity (W m−1 K−1)

- L :

-

Length of inner copper pipe (m)

- \({{\text{Nu}}}_\text{o}\) :

-

Average Nusselt number of the plain tube (dimensionless)

- \({{\text{Nu}}}_\text{t}\) :

-

Average Nusselt number of the inner tube with wire coil inserts (dimensionless)

- P :

-

Pitch of the wire coil inserts

- Pr:

-

Prandtl number

- \({Q}_{{\text{h}}}\) :

-

Rate of heat transfer for the hot water in the inner tube (W)

- \({Q}_{{\text{c}}}\) :

-

Rate of heat transfer for the cold water in the annulus tube (W)

- \({Q}_{{\text{loss}}}\) :

-

Heat loss (W)

- Re:

-

Reynolds number (dimensionless)

- T b :

-

Mean bulk water temperature (K)

- T c :

-

Cold water temperature (K)

- T h :

-

Hot water temperature (K)

- T w :

-

Mean wall temperature of inner pipe (K)

- u :

-

Hot water velocity in the inner pipe (m s−1)

- U i :

-

Overall heat transfer coefficient of inner pipe based on internal surface area (W m−2 K−1)

- µ :

-

Dynamic viscosity of hot water (kg m−1 s−1)

- ρ :

-

Mass density of hot water (kg m−3)

- η :

-

Thermal performance factor (dimensionless)

- ave:

-

Average

- i:

-

Inlet

- o:

-

Outlet

- h:

-

Hot

- c:

-

Cold

- w:

-

Wall

- b:

-

Bulk

- \(\Delta P\) :

-

Difference in pressure between inlet and outlet of hot water (Pa)

- \(\Delta {T}_{{\text{LMTD}}}\) :

-

Logarithmic mean temperature difference (K)

- TT:

-

Twisted tape

- TPF:

-

Thermal performance factor

- NTU:

-

Number of transfer unit

- WC:

-

Wire coil

- PR:

-

Pitch ratio

- VC:

-

Volume concentration

- DPHE:

-

Double-pipe heat exchanger

- HT:

-

Heat transfer

- D-HST:

-

Double-helical screw tape

References

Wijayanta AT, Yaningsih I, Aziz M, Miyazaki T, Koyama S. Double-sided delta-wing tape inserts to enhance convective heat transfer and fluid flow characteristics of a double-pipe heat exchanger. Appl Therm Eng. 2018;145(September):27–37. https://doi.org/10.1016/j.applthermaleng.2018.09.009.

Che Sidik NA, Mahmud Jamil M, Aziz Japar WMA, Muhammad Adamu I. A review on preparation methods, stability and applications of hybrid nanofluids. Renew Sustain Energy Rev. 2017;80(May):1112–22. https://doi.org/10.1016/j.rser.2017.05.221.

Khaled ARA, Siddique M, Abdulhafiz NI, Boukhary AY. Recent advances in heat transfer enhancements: a review report. Int J Chem Eng. 2010;1:2010. https://doi.org/10.1155/2010/106461.

Song KW, Xi ZP, Su M, Wang LC, Wu X, Wang LB. Effect of geometric size of curved delta winglet vortex generators and tube pitch on heat transfer characteristics of fin-tube heat exchanger. Exp Therm Fluid Sci. 2017;82:8–18. https://doi.org/10.1016/j.expthermflusci.2016.11.002.

Xu Y, Islam MD, Kharoua N. Numerical study of winglets vortex generator effects on thermal performance in a circular pipe. Int J Therm Sci. 2017;112:304–17. https://doi.org/10.1016/j.ijthermalsci.2016.10.015.

Patel BV, Sarviya RM, Rajput SPS. Numerical investigations for the performance improvement of a tubular heat exchanger with anti-clockwise clockwise twisted tape inserts. Energy Sour Part A Recover Util Environ Eff. 2022;44(2):4381–97. https://doi.org/10.1080/15567036.2022.2075993.

Patel BV, Sarviya RM, Rajput SPS. Experimental study of thermal characteristics of alternatively twisted swirl generator tape in a heat exchanger tube. Energy Sour Part A Recover Util Environ Eff. 2022;44(4):9603–19. https://doi.org/10.1080/15567036.2022.2134520.

Roy S, Saha SK. Thermal and friction characteristics of laminar flow through a circular duct having helical screw-tape with oblique teeth inserts and wire coil inserts. Exp Therm Fluid Sci. 2015;68:733–43. https://doi.org/10.1016/j.expthermflusci.2015.07.007.

Chaurasia SR, Sarviya RM. Comparative thermal performance analysis on helical screw insert in tube with number of strips with nanofluid at laminar flow regime. J Therm Sci Eng Appl. 2021. https://doi.org/10.1115/14047214.

Chaurasia SR, Sarviya RM. Comparative thermal performance analysis with entropy generation on helical screw insert in tube with number of strips with nanofluid at laminar flow regime. Int Commun Heat Mass Transf. 2021;122(January):105138. https://doi.org/10.1016/j.icheatmasstransfer.2021.105138.

Abdul Hamid K, Azmi WH, Mamat R, Sharma KV. Heat transfer performance of TiO2–SiO2 nanofluids in a tube with wire coil inserts. Appl Therm Eng. 2019;152:275–86. https://doi.org/10.1016/j.applthermaleng.2019.02.083.

Azmi WH, Abdul Hamid K, Ramadhan AI, Shaiful AIM. Thermal hydraulic performance for hybrid composition ratio of TiO2–SiO2 nanofluids in a tube with wire coil inserts. Case Stud Therm Eng. 2021;25(November 2020):100899. https://doi.org/10.1016/j.csite.2021.100899.

Saravanan A, Senthilkumaar JS, Jaisankar S. Performance assessment in V-trough solar water heater fitted with square and V-cut twisted tape inserts. Appl Therm Eng. 2016;102:476–86. https://doi.org/10.1016/j.applthermaleng.2016.03.088.

Nakhchi ME, Esfahani JA. Performance intensification of turbulent flow through heat exchanger tube using double V-cut twisted tape inserts. Chem Eng Process - Process Intensif. 2019;141(April):107533. https://doi.org/10.1016/j.cep.2019.107533.

Yakut K, Sahin B, Celik C, Alemdaroglu N, Kurnuc A. Effects of tapes with double-sided delta-winglets on heat and vortex characteristics. Appl Energy. 2005;80(1):77–95. https://doi.org/10.1016/j.apenergy.2004.03.003.

Thianpong C, et al. Multi objective optimization of TiO2/water nanofluid flow within a heat exchanger enhanced with loose-fit delta-wing twisted tape inserts. Int J Therm Sci. 2022;172(PA):107318. https://doi.org/10.1016/j.ijthermalsci.2021.107318.

Dandoutiya BK, Kumar A. W-cut twisted tape’s effect on the thermal performance of a double pipe heat exchanger: a numerical study. Case Stud Therm Eng. 2022;34(March):102031. https://doi.org/10.1016/j.csite.2022.102031.

Mohammed HA, Hasan HA, Wahid MA. Heat transfer enhancement of nanofluids in a double pipe heat exchanger with louvered strip inserts. Int Commun Heat Mass Transf. 2013;40(1):36–46. https://doi.org/10.1016/j.icheatmasstransfer.2012.10.023.

Yaningsih I, Wijayanta AT, Miyazaki T, Koyama S. Thermal hydraulic characteristics of turbulent single-phase flow in an enhanced tube using louvered strip insert with various slant angles. Int J Therm Sci. 2018;134(April):355–62. https://doi.org/10.1016/j.ijthermalsci.2018.08.025.

Nakhchi ME, Esfahani JA, Kim KC. Numerical study of turbulent flow inside heat exchangers using perforated louvered strip inserts. Int J Heat Mass Transf. 2020;148: 119143. https://doi.org/10.1016/j.ijheatmasstransfer.2019.119143.

Abdul Hamid K, Azmi WH, Mamat R, Sharma KV. Heat transfer performance of TiO2–SiO2 nanofluids in a tube with wire coil inserts. Appl Therm Eng. 2019;152(September 2018):275–86. https://doi.org/10.1016/j.applthermaleng.2019.02.083.

Syam Sundar L, Bhramara P, Ravi Kumar NT, Singh MK, Sousa ACM. Experimental heat transfer, friction factor and effectiveness analysis of Fe3O4 nanofluid flow in a horizontal plain tube with return bend and wire coil inserts. Int J Heat Mass Transf. 2017;109:440–53. https://doi.org/10.1016/j.ijheatmasstransfer.2017.02.022.

Keklikcioglu O, Ozceyhan V. Experimental investigation on heat transfer enhancement of a tube with coiled-wire inserts installed with a separation from the tube wall. Int Commun Heat Mass Transf. 2016;78:88–94. https://doi.org/10.1016/j.icheatmasstransfer.2016.08.024.

Singh SK, Sarkar J. Thermohydraulic behavior of concentric tube heat exchanger inserted with conical wire coil using mono/hybrid nanofluids. Int Commun Heat Mass Transf. 2021;122(January):105134. https://doi.org/10.1016/j.icheatmasstransfer.2021.105134.

Hamid KA, Azmi WH, Nabil MF, Mamat R, Sharma KV. Experimental investigation of thermal conductivity and dynamic viscosity on nanoparticle mixture ratios of TiO2–SiO2 nanofluids. Int J Heat Mass Transf. 2018;116:1143–52. https://doi.org/10.1016/j.ijheatmasstransfer.2017.09.087.

Moldoveanu GM, Huminic G, Minea AA, Huminic A. Experimental study on thermal conductivity of stabilized Al2O3 and SiO2 nanofluids and their hybrid. Int J Heat Mass Transf. 2018;127:450–7. https://doi.org/10.1016/j.ijheatmasstransfer.2018.07.024.

Wanatasanappan VV, Abdullah MZ, Gunnasegaran P. Thermophysical properties of Al2O3–CuO hybrid nanofluid at different nanoparticle mixture ratio: an experimental approach. J Mol Liq. 2020;313: 113458. https://doi.org/10.1016/j.molliq.2020.113458.

Urmi WT, Rahman MM, Hamzah WAW. An experimental investigation on the thermophysical properties of 40% ethylene glycol based TiO2–Al2O3 hybrid nanofluids. Int Commun Heat Mass Transf. 2020;116(June):104663. https://doi.org/10.1016/j.icheatmasstransfer.2020.104663.

Moradi A, Zareh M, Afrand M, Khayat M. Effects of temperature and volume concentration on thermal conductivity of TiO2-MWCNTs (70–30)/EG-water hybrid nano-fluid. Powder Technol. 2020;362:578–85. https://doi.org/10.1016/j.powtec.2019.10.008.

Hemmat Esfe M, Abbasian Arani AA, Rezaie M, Yan WM, Karimipour A. Experimental determination of thermal conductivity and dynamic viscosity of Ag-MgO/water hybrid nanofluid. Int Commun Heat Mass Transf. 2015;66:189–95. https://doi.org/10.1016/j.icheatmasstransfer.2015.06.003.

Nuim Labib M, Nine MJ, Afrianto H, Chung H, Jeong H. Numerical investigation on effect of base fluids and hybrid nanofluid in forced convective heat transfer. Int J Therm Sci. 2013;71:163–71. https://doi.org/10.1016/j.ijthermalsci.2013.04.003.

Chaurasia SR, Sarviya RM. Thermal performance analysis of CuO/water nanofluid flow in a pipe with single and double strip helical screw tape. Appl Therm Eng. 2020;166(October 2019):114631. https://doi.org/10.1016/j.applthermaleng.2019.114631.

Saeedinia M, Akhavan-Behabadi MA, Nasr M. Experimental study on heat transfer and pressure drop of nanofluid flow in a horizontal coiled wire inserted tube under constant heat flux. Exp Therm Fluid Sci. 2012;36:158–68. https://doi.org/10.1016/j.expthermflusci.2011.09.009.

Akhavan-Behabadi MA, Shahidi M, Aligoodarz MR. An experimental study on heat transfer and pressure drop of MWCNT-water nano-fluid inside horizontal coiled wire inserted tube. Int Commun Heat Mass Transf. 2015;63:62–72. https://doi.org/10.1016/j.icheatmasstransfer.2015.02.013.

García A, Vicente PG, Viedma A. Experimental study of heat transfer enhancement with wire coil inserts in laminar-transition-turbulent regimes at different Prandtl numbers. Int J Heat Mass Transf. 2005;48(21–22):4640–51. https://doi.org/10.1016/j.ijheatmasstransfer.2005.04.024.

Kline SJ, Shapiro AH. Experimental investigation of the effects of cooling on friction and on boundarylayer transition for low-speed gas flow at the entry of a tube (No. NACA-TN-3048). 1953.

Sarviya RM, Fuskele V. Heat transfer and pressure drop in a circular tube fitted with twisted tape insert having continuous cut edges. J Energy Storage. 2018;19(July):10–4. https://doi.org/10.1016/j.est.2018.07.001.

Kathait PS, Patil AK. Thermo-hydraulic performance of a heat exchanger tube with discrete corrugations. Appl Therm Eng. 2014;66(1–2):162–70. https://doi.org/10.1016/j.applthermaleng.2014.01.069.

Goudarzi K, Jamali H. Heat transfer enhancement of Al2O3-EG nanofluid in a car radiator with wire coil inserts. Appl Therm Eng. 2017;118:510–7. https://doi.org/10.1016/j.applthermaleng.2017.03.016.

Srinivas T, Venu Vinod A. Heat transfer intensification in a shell and helical coil heat exchanger using water-based nanofluids. Chem Eng Process Process Intensif. 2016;102:1–8. https://doi.org/10.1016/j.cep.2016.01.005.

Diwaker MK, Kumar A. Thermohydraulic performance of DPHE affected by triangular and semi-circular cut size on insert: IoT-based experimentation. Case Stud Therm Eng. 2023;43(November):102796. https://doi.org/10.1016/j.csite.2023.102796.

Kumar R, Nandan G, Dwivedi G, Kumar Shukla A, Shrivastava R. Modeling of triangular perforated twisted tape with V-Cuts in double pipe heat exchanger. Mater Today Proc. 2020;46:5389–95. https://doi.org/10.1016/j.matpr.2020.09.038.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Uncertainty analysis

Appendix: Uncertainty analysis

The error has been calculated based on the sensitivity and the least count of the instruments used in this experiment.

Heat transfer coefficient

Heat flux

Nusselt number

Reynolds number

Friction factor

Thermal performance factor

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ahirwar, B.K., Kumar, A. Effect of wire coil inserts on heat transfer enhancement and fluid flow characteristics of a double-pipe heat exchanger. J Therm Anal Calorim 149, 3027–3042 (2024). https://doi.org/10.1007/s10973-024-12889-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-024-12889-z