Abstract

Orange pomace with mass of 39.65 ± 0.76 g with moisture content of 82.56 ± 0.17 g/100 g was dried in a microwave oven using two different power levels, 40% and 100%, until the moisture ratio stabilized. Sample mass and temperature measurements were taken to analyze the effect of power level on drying parameters and drying kinetics. The kinetic drying model that best fitted the experimental data was the Midilli. Drying at 40% takes longer (9.67 min) than at 100% (8.93 min). An initial rapid increase in temperature was observed for both power levels. The evaporated mass of available water was higher to 100% with drying mass efficiency of 96.4%. Both energy and exergy efficiencies were higher for 40% power level, respectively, 27.8% and 2.3%. High temperatures are a main factor for the exergy efficiency to be relatively low, specially at 100%, with more energy being converted to sensible heat rather than being used in water evaporation. The constant drying rate period is decisive for microwave drying. The analysis of the process with a power level of 40% showed average values of exergy efficiency in the constant and decreasing rate periods equal to 3.6% and 0.6%, respectively, resulting in a global average of 2.3% in the entire process. A high-energy consumption at the end of the process suggests that a combination of the microwave with other drying operations should be assessed.

Graphical abstract

Similar content being viewed by others

References

IBGE. Systematic Survey of Agricultural Production. https://www.ibge.gov.br/estatisticas/economicas/agricultura-e-pecuaria/9201-levantamento-sistematico-da-producao-agricola.html. Accessed 29 Apr 2022. (in Portuguese).

FAO. World Food and Agriculture – Statistical Yearbook 2021. Rome; 2021. https://doi.org/10.4060/cb4477en

Santos RM, Nääs IA, Mollo Neto M, Vendrametto O. An overview on the Brazilian orange juice production chain. Rev Bras Frutic. 2013;35:218–25. https://doi.org/10.1590/S0100-29452013000100025.

Marín FR, Soler-Rivas C, Benavente-García O, Castillo J, Pérez-Alvarez JA. By-products from different citrus processes as a source of customized functional fibres. Food Chem. 2007;100:736–41. https://doi.org/10.1016/j.foodchem.2005.04.040.

Petrotos K, Giavasis I, Gerasopoulos K, Mitsagga C, Papaioannou C, Gkoutsidis P. Optimization of vacuum-microwave-assisted extraction of natural polyphenols and flavonoids from raw solid waste of the orange juice producing industry at industrial scale. Molecules. 2021;26:246. https://doi.org/10.3390/molecules26010246.

de Evan T, Cabezas AL, Fuente J, Carro MD. Feeding agroindustrial byproducts to light lambs: influence on growth performance, diet digestibility, nitrogen balance, ruminal fermentation, and plasma metabolites. Animals (Basel). 2020;10:600. https://doi.org/10.3390/ani10040600.

Luzardo S, Banchero G, Ferrari V, Ibáñez F, Roig G, Aznárez V, Clariget J, La Manna A. Effect of fresh citrus pulp supplementation on animal performance and meat quality of feedlot steers. Animals. 2021;11:3338. https://doi.org/10.3390/ani11123338.

Shahram H, Dinani ST. Influences of electrohydrodynamic time and voltage on extraction of phenolic compounds from orange pomace. LWT Food Sci Technol. 2019;111:23–30. https://doi.org/10.1016/j.lwt.2019.05.002.

Shofinita D, Langrish TAG. Spray drying of orange peel extracts: yield, total phenolic content, and economic evaluation. J Food Eng. 2014;139:31–42. https://doi.org/10.1016/j.jfoodeng.2014.03.028.

Gavahian M, Chu Y, Khaneghah AM. Recent advances in orange oil extraction: an opportunity for the valorisation of orange peel waste a review. Int J Food Sci Technol. 2019;54:925–32. https://doi.org/10.1111/ijfs.13987.

Soysal Y, Arslan M, Keskin M. Intermittent microwave-convective air drying of oregano. Food Sci Technol Int. 2009;15:397–406. https://doi.org/10.1177/1082013209346588.

Archarjee A, Afrin SM, Sit N. Physicochemical, textural and rheological properties of yoghurt enriched with orange pomace powder. J Food Process Preserv. 2020;45: e15193. https://doi.org/10.1111/jfpp.15193.

Kaur M, Dhaliwal M, Kaur H, Singh M, Punia Bangar S, Kumar M, Pandiselvam R. Preparation of antioxidant-rich tricolor pasta using microwave processed orange pomace and cucumber peel powder: a study on nutraceutical, textural, color, and sensory attributes. J Text Stud. 2021. https://doi.org/10.1111/jtxs.12654.

O’shea N, Ktenioudaki A, Smyth TP, Mcloughlin P, Doran L, Auty MAE, Arendt E, Gallagher E. Physicochemical assessment of two fruit by-products as functional ingredients: apple and orange pomace. J Food Eng. 2015;153:89–95. https://doi.org/10.1016/j.jfoodeng.2014.12.014.

Charbel AT, Trinchero BD, Morais DD, Mesquita H, Santos VS. Evaluation of the potential of fruit peel biomass after conventional and microwave drying for use as solid fuel. Appl Mech Mater. 2015;798:480–5. https://doi.org/10.4028/www.scientific.net/AMM.798.480.

Bani Hani EH, Alhuyi Nazari M, Assad MEH, Fard HF, Malekl A. Solar dryers as a promising drying technology: a comprehensive review. J Therm Anal Calorim. 2022;147:12285–300. https://doi.org/10.1007/s10973-022-11501-6.

Mutlu ÖÇ, Büchner D, Theurich S, Zeng T. Combined use of solar and biomass energy for sustainable and cost-effective low-temperature drying of food processing residues on industrial-scale. Energies. 2021;14:561. https://doi.org/10.3390/en14030561.

Wilkins R, Brusey J, Gaura E. Modelling uncontrolled solar drying of mango waste. J Food Eng. 2018;237:44–51. https://doi.org/10.1016/j.jfoodeng.2018.05.012.

Moussaoui H, Bahammou Y, Tagnamas Z, Kouhila M, Lamharrar A, Idlimam A. Application of solar drying on the apple peels using an indirect hybrid solar-electrical forced convection dryer. Renew Energy. 2021;168:131e140. https://doi.org/10.1016/j.renene.2020.12.046.

Zhang M, Tang J, Mujumdar AS, Wang S. Trends in microwave-related drying of fruits and vegetables. Trends Food Sci Technol. 2006;17:524–34. https://doi.org/10.1016/j.tifs.2006.04.011.

Kentish S, Davidson M, Hassan H, Bloore C. Milk skin formation during drying. Chem Eng Sci. 2005;60:635–46. https://doi.org/10.1016/j.ces.2004.08.033.

Ozkan IA, Akbudak B, Akbudak N. Microwave drying characteristics of spinach. J Food Eng. 2007;78:577–83. https://doi.org/10.1016/j.jfoodeng.2005.10.026.

Sharma GP, Prasad S. Specific energy consumption in microwave drying of garlic cloves. Energy. 2006;31:1921–6. https://doi.org/10.1016/j.energy.2005.08.006.

Zheng H, Li Q, Ling Y, Omran M, Gao L, Chen G. Optimisation on the microwave drying of ammonium polyvanadate (APV) - based on a kinetic study. J Market Res. 2021;13:1056–67. https://doi.org/10.1016/j.jmrt.2021.05.056.

Holtz E, Ahrné L, Rittenauer M, Rasmuson A. Influence of dielectric and sorption properties on drying behaviour and energy efficiency during microwave convective drying of selected food and non-food inorganic materials. J Food Eng. 2010;97:144–53. https://doi.org/10.1016/j.ifset.2009.10.003.

Nair GR, Li Z, Gariepy Y, Raghavan V. Microwave drying of corn (Zea mays L. ssp.) for the seed industry. Drying Technol. 2011;29:1291–6. https://doi.org/10.1080/07373937.2011.591715.

Fennell LP, Boldor D. Continuous microwave drying of sweet sorghum bagasse biomass. Biomass Bioenerg. 2014;70:542–52. https://doi.org/10.1016/j.biombioe.2014.08.012.

Li Z, Raghavan GSV, Orsat V. Optimal power control strategies in microwave drying. J Food Eng. 2010;99:263–8. https://doi.org/10.1016/j.jfoodeng.2010.02.024.

Soysal Y, Öztekin S, Eren Ö. Microwave drying of parsley: modelling, kinetics, and energy aspects. Biosys Eng. 2006;93:403–13. https://doi.org/10.1016/j.biosystemseng.2006.01.017.

Zarein M, Samadi SH, Ghobadian B. Investigation of microwave dryer effect on energy efficiency during drying of apple slices. J Saudi Soc Agric Sci. 2015;14:41–7. https://doi.org/10.1016/j.jssas.2013.06.002.

Talens C, Castro-Giraldez M, Fito PJ. Study of the effect of microwave power coupled with hot air drying on orange peel by dielectric spectroscopy. LWT Food Sci Technol. 2016;66:622e628. https://doi.org/10.1016/j.lwt.2015.11.015.

Talens C, Arboleya JC, Castro-Giraldez M, Fito PJ. Effect of microwave power coupled with hot air drying on process efficiency and physico-chemical properties of a new dietary fibre ingredient obtained from orange peel. LWT Food Sci Technol. 2017;77:110e118. https://doi.org/10.1016/j.lwt.2016.11.036.

Rokhbin A, Azadbakht M. The shrinkage of orange slices during microwave drying and ohmic pretreatment. J Food Process Preserv. 2021;45: e15400. https://doi.org/10.1111/jfpp.15400.

Albano E. Microwave and blanching pretreatments for hot air drying of orange-fleshed sweet potato slices (Ipomoea batatas). Int J Food Sci. 2020;2020:12. https://doi.org/10.1155/2020/8872429.

Azadbakht M, Torshizi MV, Noshad F, Rokhbin A. Application of artificial neural network method for prediction of osmotic pretreatment based on the energy and exergy analyses in microwave drying of orange slices. Energy. 2018;165:836e845. https://doi.org/10.1016/j.energy.2018.10.017.

Terzi, R. Application of Exergy Analysis to Energy Systems. In: Application of Exergy [Internet]. London: IntechOpen; 2018. https://doi.org/10.5772/intechopen.74433

Rashidi MM, Mahariq I, Alhuyi Nazari M, Accouche O, Bhatti MM. Comprehensive review on exergy analysis of shell and tube heat exchangers. J Therm Anal Calorim. 2022;147:12301–11. https://doi.org/10.1007/s10973-022-11478-2.

Darvishi H. Quality, performance analysis, mass transfer parameters and modeling of drying kinetics of soybean. Braz J Chem Eng. 2017;34:143–58. https://doi.org/10.1590/0104-6632.20170341s20150509.

Surendhar A, Sivasubramanian V, Vidhyeswari D, Deepanraj B. Energy and exergy analysis, drying kinetics, modeling and quality parameters of microwave-dried turmeric slices. J Therm Anal Calorim. 2019;136:185–97. https://doi.org/10.1007/s10973-018-7791-9.

Song C, Wang Y, Wang S, Cui Z, Xu Y. Non-uniformity investigation in a combined thermal and microwave drying of silica gel. Appl Therm Eng. 2016;98:872–9. https://doi.org/10.1016/j.applthermaleng.2015.12.089.

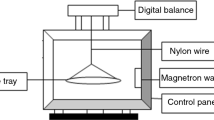

Mai I. Using a microwave oven and a computer hard drive as a physics laboratory. Dissertation thesis, Universidade Federal do Rio Grande do Sul; 2008. (in Portuguese).

AOAC INTERNATIONAL, method 934.06-1934. Loss on drying (moisture) in dried fruit; 1996.

Alibas I, Yilmaz A. Microwave and convective drying kinetics and thermal properties of orange slices and effect of drying on some phytochemical parameters. J Therm Anal Calorim. 2022;147:8301–21. https://doi.org/10.1007/s10973-021-11108-3.

Manjarres-Pinzon K, Cortes-Rodriguez M, Rodríguez-Sandoval E. Effect of drying conditions on the physical properties of impregnated orange peel. Braz J Chem Eng. 2013;30:667–76. https://doi.org/10.1590/S0104-66322013000300023.

Fiorentin LD, Menon BT, Alves JA, Barros STD, Pereira NC, Módenes AN. Determination of drying kinetics and isotherms of orange bagasse. Acta Scientiarum Technology. 2010;32:147–52. https://doi.org/10.4025/actascitechnol.v32i2.8242. (in Portuguese).

Nguyen TH, Sabbah I, Ball WP. Sorption nonlinearity for organic contaminants with diesel soot: method development and isotherm interpretation. Environ Sci Technol. 2004;38:3595–603. https://doi.org/10.1021/es0499748.

Wernecke R, Wernecke J. Industrial moisture and humidity measurement: a practical guide. Weinheim: Wiley-VCH; 2014. https://doi.org/10.1002/9783527652419.

O’callaghan JR, Menzies DJ, Bailey PH. Digital simulation of agricultural dryer performance. J Agric Eng Res. 1971;16:223–44. https://doi.org/10.1016/S0021-8634(71)80016-1.

Page, G.E. Factors influencing the maximum rates of air drying shelled corn in thin layers. MSc Thesis, Purdue University, Indiana, USA; 1949.

Hendorson SM. Grain drying theory (I) temperature effect on drying coefficient. J Agric Eng Res. 1961;6:169–74.

Yagcioglu, A.; Degirmencioglu, A.; Cagatay, F. Drying characteristics of laurel leaves under different drying conditions. In: Proceedings of the 7th international congress on agricultural mechanization and energy in agriculture, p. 565–569, Adana, Turkey, May, 1999.

Midilli A, Kucuk H, Yapar Z. A new model for single layer drying. Drying Technol. 2002;20:1503–13. https://doi.org/10.1081/DRT-120005864.

Wang, C.Y.; Singh, R.P. A single layer drying equation for rough rice. ASAE Paper No: 78–3001, ASAE, St. Joseph, MI, 1978.

Multari S, Carlin S, Sicari V, Martens S. Differences in the composition of phenolic compounds, carotenoids, and volatiles between juice and pomace of four citrus fruits from Southern Italy. Eur Food Res Technol. 2020;246:1991–2005. https://doi.org/10.1007/s00217-020-03550-8.

Dincer I, Sahin AZ. A new model for thermodynamic analysis of a drying process. Int J Heat Mass Transf. 2004;47:645–52. https://doi.org/10.1016/j.ijheatmasstransfer.2003.08.013.

Acevedo L, Usón S, Uche J. Exergy transfer analysis of microwave heating systems. Energy. 2014;68:349–63. https://doi.org/10.1016/j.energy.2014.02.041.

Acknowledgements

The authors are grateful to CNPq (National Council for Scientific and Technological Development) and Universidade Federal de São João del-Rei (UFSJ) for the financial support.

Author information

Authors and Affiliations

Contributions

DHSC was involved in conceptualization, methodology, software, validation, formal analysis, investigation, data curation, writing—original draft, writing—review and editing, visualization. VMA helped in methodology, software, investigation, data curation, writing—review and editing, visualization. LAFD contributed to conceptualization, methodology, investigation, writing—review and editing. MMO was involved in conceptualization, methodology, investigation, writing—review and editing. VSB helped in writing—review and editing, visualization, supervision, project administration, funding acquisition. ALTC was involved in conceptualization, methodology, validation, formal analysis, investigation, resources, writing—review and editing, visualization, supervision, project administration, funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors of this paper declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chaves, D.H.d.S., Avila, V.M., Domingues, L.A.F. et al. Energy and exergy efficiencies analysis of microwave drying of orange pomace biomass. J Therm Anal Calorim 148, 13413–13425 (2023). https://doi.org/10.1007/s10973-023-12644-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12644-w