Abstract

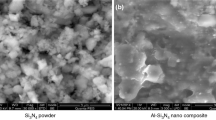

The thermal stability of a shape stable composite phase change material (SSCPCM) has been investigated using a thermogravimetric analyser. X-ray diffraction, Scanning Electron Microscope, Fourier transform infrared, Brunauer–Emmett–Teller, and Differential Scanning Calorimeter analysis are used to characterize the PCM and SSCPCM. The activation energy of PCM and SSCPCM is estimated using multiple value model-free methods, namely, Friedman, Kissinger–Akahira–Sunose, Starink, Ozawa–Flynn–Wall, and Vyazovkin. The SSCPCM exhibits 4.96, 6.95, 6.76, 8.02, and 4% higher activation energy than the pure PCM as determined by the Friedman, KAS, OFW, Vyazovkin, and Starink methods, respectively. The degradation temperature of SSCPCM improved by 12.86, 7.85, and 10.41%, compared to PCM, at a heating rate of 5,10, and 15 °C min−1, respectively. ANFIS modeling is used in this study to predict the degradation of PCM and SSCPCM. The mass loss (%) of PCM and SSCPCM samples is predicted by considering the input parameters as PCM type, temperature, and heating rate of the sample. It is found that the combination of a generalized bell-shaped input and a linear output membership function is best suitable for predicting the mass loss. The developed hybrid ANFIS model very well predicts the experimental mass loss of the SSCPCM with a coefficient of determination (R2) of 0.99.

Similar content being viewed by others

References

IEA, IMF. IEA. Sustainable recovery: world energy outlook special Report. World Energy Outlook (p. 185). World Energy Outlook. 2020;185. Available from: https://www.iea.org/reports/sustainable-recovery%0Ahttps://webstore.iea.org/download/direct/4022?fileName=Energy_Technology_Perspectives_2020_-_Special_Report_on_Clean_Energy_Innovation.pdf%0Ahttps://www.oecd-ilibrary.org/energy/sustainable-recovery_3f36f

Renewable energy market update. Renewable energy market update. 2020

Gupta N, Kumar A, Dhasmana H, Kumar A, Verma A, Shukla P, et al. Effect of shape and size of carbon materials on the thermophysical properties of magnesium nitrate hexahydrate for solar thermal energy storage applications. J Energy Storage. 2021;41:102899. https://doi.org/10.1016/j.est.2021.102899

Kalapala L, Devanuri JK. Influence of operational and design parameters on the performance of a PCM based heat exchanger for thermal energy storage—a review. J Energy Storage. 2018;20:497–519. https://doi.org/10.1016/j.est.2018.10.024

Weiss J, Ortega-Fernández I, Müller R, Bielsa D, Fluri T. Improved thermocline initialization through optimized inlet design for single-tank thermal energy storage systems. J Energy Storage. 2021;42:2352–152. https://doi.org/10.1016/j.est.2021.103088

Jaberi Khosroshahi A, Hossainpour S. Investigation of storage rotation effect on phase change material charging process in latent heat thermal energy storage system. J Energy Storage. 2021;36:102442. https://doi.org/10.1016/j.est.2021.102442

Chen KQ, Pu WH, Zhang Q, Xing XL, Xiong C, Guo M Di. Thermodynamic and economic assessment on the supercritical compressed carbon dioxide energy storage system coupled with solar thermal storage. J Energy Storage. 2021;41:102959. https://doi.org/10.1016/j.est.2021.102959

Koçak B, Fernandez AI, Paksoy H. Review on sensible thermal energy storage for industrial solar applications and sustainability aspects. Solar Energy. 2020;209:135–69. https://doi.org/10.1016/j.solener.2020.08.081

Chopra K, Tyagi V V., Pandey AK, Sharma RK, Sari A. PCM integrated glass in glass tube solar collector for low and medium temperature applications: thermodynamic and techno-economic approach. Energy. 2020;198:117238. https://doi.org/10.1016/j.energy.2020.117238

Leungtongkum T, Flick D, Hoang HM, Steven D, Delahaye A, Laguerre O. Insulated box and refrigerated equipment with PCM for food preservation: state of the art. J Food Eng. 2022;317:110874. https://doi.org/10.1016/j.jfoodeng.2021.110874

Xu H, Wang N, Zhang C, Qu Z, Karimi F. Energy conversion performance of a PV/T-PCM system under different thermal regulation strategies. Energy Convers Manage. 2021;229:113660. https://doi.org/10.1016/j.enconman.2020.113660

El-Khouly MM, El Bouz MA, Sultan GI. Experimental and computational study of using nanofluid for thermal management of electronic chips. J Energy Storage. 2021;39:102630. https://doi.org/10.1016/j.est.2021.102630

Lamrani B, Johannes K, Kuznik F. Phase change materials integrated into building walls: an updated review. Renew Sustain Energy Rev. 2021;140:110751. https://doi.org/10.1016/j.rser.2021.110751

Chaiyat N, Kiatsiriroat T. Energy reduction of building air-conditioner with phase change material in Thailand. Case Stud Thermal Eng. 2014;4:175–86. https://doi.org/10.1016/j.csite.2014.09.006

Muthya Goud V, Vaisakh V, Joseph M, Sajith V. An experimental investigation on the evaporation of polystyrene encapsulated phase change composite material based nanofluids. Appl Thermal Eng. 2020;168.

Ali MA, Fayaz, Viegas RF, Shyam Kumar MB, Kannapiran RK, Feroskhan M. Enhancement of heat transfer in paraffin wax PCM using nano graphene composite for industrial helmets. J Energy Storage. 2019;26:100982. https://doi.org/10.1016/j.est.2019.100982

Joseph M, Sajith V. Graphene enhanced paraffin nanocomposite based hybrid cooling system for thermal management of electronics. Appl Thermal Eng. 2019;163:114342. https://doi.org/10.1016/j.applthermaleng.2019.114342

Wang R, Xiao Y, Lei J. A solid-solid phase change material based on dynamic ion cross-linking with reprocessability at room temperature. Chem Eng J. 2020;390:124586. https://doi.org/10.1016/j.cej.2020.124586

Chiew J, Chin CS, Toh WD, Gao Z, Jia J. Thermal state-of-expansion or melting of phase change material based heat sink for underwater battery power system. J Energy Storage. 2019;26.

Sun Z, Kong W, Zheng S, Frost RL. Study on preparation and thermal energy storage properties of binary paraffin blends/opal shape-stabilized phase change materials. Solar Energy Mater Solar Cells. 2013;117:400–7. https://doi.org/10.1016/j.solmat.2013.07.003

Zhang Q, Zhao Y, Feng J. Systematic investigation on shape stability of high-efficiency SEBS/paraffin form-stable phase change materials. Solar Energy Mater Solar Cells. 2013;118:54–60. https://doi.org/10.1016/j.solmat.2013.07.035

Ghasemi K, Tasnim S, Mahmud S. PCM, nano/microencapsulation and slurries: A review of fundamentals, categories, fabrication, numerical models and applications. Sustain Energy Technol Assess. 2022;52:102084. https://doi.org/10.1016/j.seta.2022.102084

Muthya Goud V, Raval F, Ruben Sudhakar D. A sustainable biochar-based shape stable composite phase change material for thermal management of a lithium-ion battery system and hybrid neural network modeling for heat flow prediction. J Energy Storage. 2022 [cited 2022 Nov 27];56:106163. https://linkinghub.elsevier.com/retrieve/pii/S2352152X22021521

Gandhi M, Kumar A, Elangovan R, Meena CS, Kulkarni KS, Kumar A, et al. A review on shape-stabilized phase change materials for latent energy storage in buildings. Sustainability (Switzerland). 2020;12:1–17.

Manikandan G, Rajarajan G, Jayabharathi J, Thanikachalam V. Structural effects and thermal decomposition kinetics of chalcones under non-isothermal conditions. Arab J Chem. 2016;9:S570–5. https://doi.org/10.1016/j.arabjc.2011.06.029

Müller-Hagedorn M, Bockhorn H, Krebs L, Müller U. A comparative kinetic study on the pyrolysis of three different wood species. J Anal Appl Pyrol. 2003;68–69:231–49.

Yao F, Wu Q, Lei Y, Guo W, Xu Y. Thermal decomposition kinetics of natural fibers: ACTIVATION energy with dynamic thermogravimetric analysis. Polym Degrad Stab. 2008;93:90–8.

Sbirrazzuoli N, Vincent L, Mija A, Guigo N. Integral, differential and advanced isoconversional methods. Complex mechanisms and isothermal predicted conversion-time curves. Chemometrics Intell Lab Syst. 2009;96:219–26. https://doi.org/10.1016/j.chemolab.2009.02.002

Sathiya Prabhakaran SP, Swaminathan G, Joshi V V. Energy conservation – A novel approach of co-combustion of paint sludge and Australian lignite by principal component analysis, response surface methodology and artificial neural network modeling. Environ Technol Innov. 2020;20:101061. https://doi.org/10.1016/j.eti.2020.101061

Vyazovkin S, Burnham AK, Favergeon L, Koga N, Moukhina E, Pérez-Maqueda LA, et al. ICTAC Kinetics Committee recommendations for analysis of multi-step kinetics. Thermochim Acta. 2020;689:178597. https://doi.org/10.1016/j.tca.2020.178597

Fabiani C, Pisello AL, Barbanera M, Cabeza LF. Palm oil-based bio-PCM for energy efficient building applications: Multipurpose thermal investigation and life cycle assessment. J Energy Storage. 2020;28:101129. https://doi.org/10.1016/j.est.2019.101129

Venkitaraj KP, Suresh S. Experimental thermal degradation analysis of pentaerythritol with alumina nano additives for thermal energy storage application. J Energy Storage. 2019;22:8–16. https://doi.org/10.1016/j.est.2019.01.017

Xiang L, Luo D, Yang J, Sun X, Qi Y, Qin S. Preparation and comparison of properties of three phase change energy storage materials with hollow fiber membrane as the supporting carrier. Polymers. 2019;11.

Sun L, Qu Y, Li S. Co-microencapsulate of ammonium polyphosphate and pentaerythritol and kinetics of its thermal degradation. Polym Degradat Stabil. 2012;97:404–9. https://doi.org/10.1016/j.polymdegradstab.2011.12.003

Goud M, Ruben V, Dhanarathinam S. Design and selection of suitable sustainable phase change materials for latent heat thermal energy storage system using data ‑ driven machine learning models. J Therm Anal Calorimetry. 2023; https://doi.org/10.1007/s10973-023-12426-4

Mostafaei M. ANFIS models for prediction of biodiesel fuels cetane number using desirability function. Fuel. 2018;216:665–72. https://doi.org/10.1016/j.fuel.2017.12.025

Aghbashlo M, Tabatabaei M, Nadian MH, Davoodnia V, Soltanian S. Prognostication of lignocellulosic biomass pyrolysis behavior using ANFIS model tuned by PSO algorithm. Fuel. 2019;253:189–98. https://doi.org/10.1016/j.fuel.2019.04.169

Saleh B, Maher I, Abdelrhman Y, Heshmat M, Abdelaal O. Adaptive neuro-fuzzy inference system for modelling the effect of slurry impacts on PLA material processed by FDM. Polymers. 2021;13:1–17.

V. Muthya Goud, G. Satyanarayana, J. Ramesh, G. A. Pathanjali DRS. An experimental investigation and hybrid neural network modelling of thermal management of lithium-ion batteries using a non-paraffinic organic phase change material , Myristyl alcohol. J Energy Storage. 2023;72:108395. https://doi.org/10.1016/j.est.2023.108395

Janković B. Kinetic analysis of the nonisothermal decomposition of potassium metabisulfite using the model-fitting and isoconversional (model-free) methods. Chem Eng J. 2008;139:128–35.

Ozawa T. A New Method of Analyzing Thermogravimetric Data. Bull Chem Soc Jpn. 1965;38:1881–6.

Drozin D, Sozykin S, Ivanova N, Olenchikova T, Krupnova T, Krupina N, et al. Kinetic calculation: Software tool for determining the kinetic parameters of the thermal decomposition process using the Vyazovkin Method. SoftwareX. 2020;11:100359. https://doi.org/10.1016/j.softx.2019.100359

Starink MJ. A new method for the derivation of activation energies from experiments performed at constant heating rate. Thermochim Acta. 1996;288:97–104.

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci Part C Polym Symp. 2007;6:183–95.

Prabhakaran SS, Swaminathan G, Joshi V V. Combustion and pyrolysis kinetics of Australian lignite coal and validation by artificial neural networks. Energy. 2021;242:122949. https://doi.org/10.1016/j.energy.2021.122949

Venkatesh M, Ravi P, Tewari SP. Isoconversional kinetic analysis of decomposition of nitroimidazoles: Friedman method vs Flynn-Wall-Ozawa method. J Phys Chem A. 2013;117:10162–9.

Arenas CN, Navarro MV, Martínez JD. Pyrolysis kinetics of biomass wastes using isoconversional methods and the distributed activation energy model. Bioresource Technol. 2019;288:121485. https://doi.org/10.1016/j.biortech.2019.121485

Cai J, Xu D, Dong Z, Yu X, Yang Y, Banks SW, et al. Processing thermogravimetric analysis data for isoconversional kinetic analysis of lignocellulosic biomass pyrolysis: case study of corn stalk. Renew Sustain Energy Rev. 2018;82:2705–15.

Li B, Liu G, Gao W, Cong H-Y, Bi M-S, Ma L, et al. Study of combustion behaviour and kinetics modelling of Chinese Gongwusu coal gangue: Model-fitting and model-free approaches. Fuel. 2020;268: 117284.

Senum GI, Yang RT. Rational approximations of the integral of the Arrhenius function. J Therm Anal. 1977;11:445–7.

Zheng C, Li D, Ek M. Mechanism and kinetics of thermal degradation of insulating materials developed from cellulose fiber and fire retardants. J Thermal Anal Calorimetry. 2019;135:3015–27. https://doi.org/10.1007/s10973-018-7564-5

Jagtap A. In uence of model free methods on pyrolysis kinetics and thermodynamic parameters of soybean straw. 2021;23.

Dewan MW, Huggett DJ, Warren Liao T, Wahab MA, Okeil AM. Prediction of tensile strength of friction stir weld joints with adaptive neuro-fuzzy inference system (ANFIS) and neural network. Mater Des. 2016;92:288–99. https://doi.org/10.1016/j.matdes.2015.12.005

Kottala RK, Ramaraj BK, Jinshah BS, Vempally MG, Lakshmanan M. Environmental Effects Experimental investigation and neural network modeling of binary eutectic / expanded graphite composites for medium temperature thermal energy storage. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects. 2022, 1–24. https://doi.org/10.1080/15567036.2022.2043490

V MG, D RS. A comprehensive investigation and artificial neural network modeling of shape stabilized composite phase change material for solar thermal energy storage. J Energy Storage. 2022;48:103992. https://doi.org/10.1016/j.est.2022.103992

Li W, Liu J, Zhao D. Mesoporous materials for energy conversion and storage devices. Nat Rev Mater. 2016;1.

Rao ZH, Zhang GQ. Thermal properties of paraffin wax-based composites containing graphite. Energy Sources Part A Recovery, Utilization Environ Effects. 2011;33:587–93.

Author information

Authors and Affiliations

Contributions

VMG: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Validation, Visualization, Software, Writing—original draft. DRS: Conceptualization, Formal analysis, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing—original draft, Writing—review and editing.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vempally, M.G., Dhanarathinam, R.S. An experimental investigation on kinetic analysis of thermal degradation of shape stable composite phase change materials and adaptive neuro fuzzy inference system modeling for predicting mass loss. J Therm Anal Calorim 148, 13441–13455 (2023). https://doi.org/10.1007/s10973-023-12631-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12631-1