Abstract

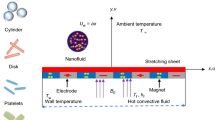

This article is motivated by the effect of nanoparticle shapes on fluid motion and heat transmission across melting heat-stretchable impermeable surfaces. Thus, the impact of three different nanoparticle shapes (sphere, cylinder and lamina) at different volume fractions for two nanoparticles, i.e., \({\text{Fe}}_{3} {\text{O}}_{4}\) and \({\text{MgO}}\), in the presence of three base fluids (\({\text{H}}_{2} {\text{O}}\), \({\text{methanol}}\), \({\text{engine}}\;{\text{oil}}\)) is investigated. The system of nonlinear partial differential equations (PDEs) is reduced to a set of ordinary differential equations (ODEs) using suitable local similarity variables. To validate the theoretical findings of this investigation, the Runge–Kutta–Fehlberg method is used and MATLAB’s inbuilt program bvp4c is employed through which graphical outputs are deliberated to show the impact of nanoparticles on momentum and energy domain. This study shows that the lamina shape of \({\text{MgO}} - {\text{Fe}}_{3} {\text{O}}_{4} /{\text{engine}}\;{\text{oil}}\) has a major impact on \(\Theta \left( \xi \right)\) with increasing \(\varphi_{1} ,\varphi_{2}\). Due to the stronger thermal conductivity of \({\text{MgO}}\) lamina-shaped nanoparticles compared to other nanoparticle shapes within the flow region, the velocity profile increases with the augmentation of \(\varphi_{1}\, \text{and}\, \varphi_{2}\) . \({\text{MgO}} - {\text{Fe}}_{3} {\text{O}}_{4} /{\text{H}}_{2} {\text{O}}\) exhibits a more significant impact than the others.

Similar content being viewed by others

Abbreviations

- \(A\) :

-

Velocity ratio parameter/–

- \(B,B_{0}\) :

-

Applied magnetic field/\({\text{N}}\,{\text{m}}^{ - 1} \,{\text{A}}^{ - 1}\)

- \({\mathbb{C}}_{{{\text{fx}}}}\) :

-

Coefficient of skin friction/–

- \(C_{{\text{p}}}\) :

-

Specific heat/\({\text{J}}\,{\text{kg}}^{ - 1} \,{\text{K}}^{ - 1}\)

- \(C_{{\text{S}}}\) :

-

Heat capacity of solid surface\(/{\text{J}}\,{\text{kg}}^{ - 1} \,{\text{K}}^{ - 1}\)

- \({\text{Ec}}\) :

-

Eckert number/–

- \(f,f^{\prime } ,F\) :

-

Non-dimensional velocity/–

- \(M\) :

-

Magnetic number/–

- \(m\) :

-

Flow behavior index parameter/–

- \({\text{Me}}\) :

-

Melting parameter/–

- \({\mathbb{N}}_{ux}\) :

-

Nusselt number/–

- \(\Pr\) :

-

Prandtl number/–

- \(Q_{0}\) :

-

Volumetric heat coefficient\(/{\text{J}}\,{\text{K}}^{ - 1} \,{\text{m}}^{ - 3}\)

- \(Q\) :

-

Heat source/sink/–

- \({\text{Rd}}\) :

-

Radiation parameter/–

- \(q_{{\text{r}}}\) :

-

Heat flux/\({\text{W}}\,{\text{m}}^{ - 2}\)

- \(t_{{\text{w}}}\) :

-

Wall shear stress/\({\text{N}}\,{\text{m}}^{ - 2}\)

- \(E_{{\text{w}}}\) :

-

Heat flux/\({\text{W}}\,{\text{m}}^{ - 2}\)

- \({\text{Re}}\) :

-

Local Reynolds number/–

- \(a\) :

-

Wall thickness parameter

- \({\text{hnf}}\) :

-

Hybrid nanofluid

- \({\text{nf}}\) :

-

Nanofluid

- \(f\) :

-

Fluid

- \(T\) :

-

Temperature/\({\text{K}}\)

- \(T_{\infty }\) :

-

Ambient fluid temperature/\({\text{K}}\)

- \(T_{{\text{m}}}\) :

-

Melting surface temperature/\({\text{K}}\)

- \(T_{0}\) :

-

Reference temperature/\({\text{K}}\)

- \(U_{{\text{w}}}\) :

-

Surface velocity/\({\text{m}}\,{\text{s}}^{ - 1}\)

- \(U_{\infty } ,U_{{\text{e}}}\) :

-

Free stream velocity/\({\text{m}}\,{\text{s}}^{ - 1}\)

- \(u,\,v\) :

-

Velocity components/\({\text{m}}\,{\text{s}}^{ - 1}\)

- \(\kappa^{ * }\) :

-

Rosseland mean absorption\(/{\text{m}}^{ - 1}\)

- \(\alpha\) :

-

Thermal diffusivity\(/{\text{m}}^{2} \;{\text{s}}^{ - 1}\)

- \(\lambda\) :

-

Latent heat \(/{\text{J}}\;{\text{Kg}}^{ - 1}\)

- \(\mu\) :

-

Dynamic viscosity/\({\text{kg}}\,{\text{m}}^{ - 1} \;{\text{s}}^{ - 1}\)

- \(\rho\) :

-

Fluid density/\({\text{kg}}\,{\text{m}}^{ - 3}\)

- \(\nu\) :

-

Kinematic viscosity/\({\text{m}}^{2} \;{\text{s}}^{ - 1}\)

- \(\theta ,\Theta\) :

-

Dimensionless temperature/–

- \(\Theta_{{\text{r}}}\) :

-

Temperature ratio parameter

- \(\beta\) :

-

Slip parameter/–

- \(\beta^{ * }\) :

-

Slip coefficient\(/{\text{m}}\)

- \(\varphi_{1} ,\varphi_{2}\) :

-

Volume fraction of 1st and 2nd nanoparticles/–

- \(\sigma^{ * }\) :

-

Stefan–Boltzmann constant\(/{\text{Wm}}^{ - 2} \;{\text{K}}^{ - 4}\)

- \(\eta ,\xi\) :

-

Similarity variable/–

- \(\sigma\) :

-

Electrical conductivity/\({\text{simens}}\,.\,{\text{m}}^{ - 1}\)

- \(\kappa\) :

-

Thermal conductivity\(/{\text{Wm}}^{ - 1} \;{\text{K}}^{ - 1}\)

- \(\psi\) :

-

Stream function/–

References

Nadeem S, Haq RU, Khan ZH. Numerical study of MHD boundary layer flow of a Maxwell fluid past a stretching sheet in the presence of nanoparticles. J Taiwan Inst Chem Eng. 2014;45(1):121–6.

Anusha T, Huang HN, Mahabaleshwar US. Two-dimensional unsteady stagnation point flow of Casson hybrid nanofluid over a permeable flat surface and heat transfer analysis with radiation. J Taiwan Inst Chem Eng. 2021;000:1–13.

Biswas R, Hossain MS, Islam R, Ahmmed SF, Mishra SR, Afikuzzaman M. Computational treatment of MHD Maxwell nanofluid flow across a stretching sheet considering higher-order chemical reaction and thermal radiation. J Comput Math Data Sci. 2022;4:100048.

Usman M, Gul T, Khan A, Alsubie A, Ullah MZ. Electromagnetic couple stress film flow of hybrid nanofluid over an unsteady rotating disc. Int Commun Heat Mass Transf. 2021;127:105562.

Dawar A, Islam S, Shah Z, Mahmuod SR, Lone SA. Dynamics of inter-particle spacing, nanoparticle radius, inclined magnetic field and nonlinear thermal radiation on the water-based copper nanofluid flow past a convectively heated stretching surface with mass flux condition: a strong suction case. Int Commun Heat Mass Transf. 2022;137:106286.

Abbasi A, Gulzar S, Mabood F, Farooq W. Nonlinear thermal radiation and activation energy features in axisymmetric rotational stagnation point flow of hybrid nanofluid. Int Commun Heat Mass Transf. 2021;126:105335.

Reddy SRR, Reddy PBA, Bhattacharyya K. Effect of nonlinear thermal radiation on 3D magneto slip flow of Eyring-Powell nanofluid flow over a slendering sheet inspired through binary 6 chemical reaction and Arrhenius activation energy. Adv Powder Technol. 2019;30:3203–13.

Waqas H, Khan SA, Khan SU, Khan MI, Kadry S, Chu YM. Falkner-Skan time-dependent bioconvection flow of cross nanofluid with nonlinear thermal radiation, activation energy and melting process. Int Commun Heat Mass Transf. 2021;120:105028.

Khan SA, Hayat T, Alsaedi A. Melting heat in entropy optimized flow of third grade nanomaterials with radiation by a Riga plate. J Energy Storage. 2022;45:103713.

Hayat T, Khan MI, Waqas M, Alsaedi A, Farooq M. Numerical simulation for melting heat transfer and radiation effects in stagnation point flow of carbon-water nanofluid. Comput Methods Appl Mech Eng. 2017;315:1011–24.

Muhammad T, Waqas H, Farooq U, Alqarni MS. Numerical simulation for melting heat transport in nanofluids due to quadratic stretching plate with nonlinear thermal radiation. Case Stud Therm Eng. 2021;27:101300.

Soomro FA, Usman M, Haq RU, Wang W. Melting heat transfer analysis of Sisko fluid over a moving surface with nonlinear thermal radiation via Collocation method. Int J Heat Mass Transf. 2018;126:1034–42.

Khan SA, Khan MI, Alzahrani F. Melting heat transportation in chemical reactive flow of third grade nanofluid with irreversibility analysis. Int Commun Heat Mass Transf. 2021;129:105696.

Abdulyaqin T, Makinde OD. Analysis of Blasius Flow of Hybrid Nanofluids over a Convectively Heated Surface. Defect Diffus Forum. 2017;377:29–41.

Sindhu S, Gireesha BJ, Sowmya G, Makinde OD. Hybrid nano liquid flow through a microchannel with particle shape factor, slip and convective regime. Int J Numer Methods Heat Fluid Flow. 2022;32(10):3388–410.

Shaw S, Samantaray SS, Misra A, Nayak MN, Makinde OD. Hydromagnetic flow and thermal interpretations of Cross hybrid nanofluid influenced by linear, nonlinear and quadratic thermal radiations for any Prandtl number. Int Commun Heat Mass Transf. 2022;130:105816.

Sen SSS, Das M, Nayak MK, Makinde OD. Natural convection and heat transfer of micropolar hybrid nanofluid over horizontal, inclined and vertical thin needle with power-law varying boundary heating conditions. Phys Scr. 2022;98(1):015206.

Mallesh MP, Makinde OD, Rajesh V, Kavitha M. Time-Dependent Thermal Convective Circulation of Hybrid Nanoliquid Past an Oscillating Porous Plate with Heat Generation and Thermal Radiation. J Appl Nonlinear Dyn. 2023;12(1):171–89.

Upreti H, Pandey AK, Joshi N, Makinde OD. Thermodynamics and heat transfer analysis of magnetized Casson Hybrid Nanofluid flow via a riga plate with thermal radiation. J Comput Biophys Chem. 2023;22:1–14.

Reddy JVR, Sugunamma V, Sandeep N. Impact of nonlinear radiation on 3D magnetohydrodynamic flow of methanol and kerosene based ferrofluids with temperature dependent viscosity. J Mol Liq. 2017;236:93–100.

Nandi S, Kumbhakar B, Sarkar S. MHD stagnation point flow of Fe3O4/Cu/Ag-CH3OH nanofluid along a convectively heated stretching sheet with partial slip and activation energy: numerical and statistical approach. Int Commun Heat Mass Transf. 2022;130:105791.

Salahuddin T, Imtiaz I, Khan M. Analysis of entropy generation in AA7072-methanol and AA7072+AA7075-methanol flow near a parabolic surface. Appl Math Comput. 2022;413:126616.

Haq RU, Shahzad F, Al-Mdallal QM. MHD pulsatile flow of engine oil based carbon nanotubes between two concentric cylinders. Res Phys. 2017;7:57–68.

Mohammad R, Kandasamy R. Nanoparticle shapes on electric and magnetic force in water, ethylene glycol and engine oil-based Cu, Al2O3 and SWCNTs. J Mol Liq. 2017;237:54–64.

Ghadikolaei SS, Gholinia M. Terrific effect of H2 on 3D free convection MHD flow of C2H6O2eH2O hybrid base fluid to dissolve Cu nanoparticles in a porous space considering the thermal radiation and nanoparticle shapes effects. Int J Hydrog Energy. 2019;44:17072–83.

Xiong Q, Abohamzeh E, Ali JA, Hamad SM, Tlili I, Shafee A, Habibeh H, Nguyen TKh. Influences of nanoparticles with various shapes on MHD flow inside wavy porous space in appearance of radiation. J Mol Liq. 2019;292:111386.

Shamshuddin MD, Mishra SR, Bég OA, Kadir A. Numerical study of heat transfer and viscous flow in a dual rotating extendable disk system with a non-Fourier heat flux model. Heat Trans Asian Res. 2019;48(1):435–59.

Shamshuddin MD, Mishra SR, Bég OA, Kadir A. Adomian decomposition method simulation of von Kármán swrling bioconvection nanofluid flow. J Cent South Univ. 2019;26:2797–813.

Dogonchi AS, Mishra SR, Chamkha AJ, Ghodrat M, Elmasry Y, Alhumade H. Thermal and entropy analyses on buoyancy-driven flow of nanofluid inside a porous enclosure with two square cylinders: Finite element method. Case Stud Therm Eng. 2021;27:101298.

Pattnaik PK, Bhatti MM, Mishra SR, Abbas MA, Bég OA. Mixed convective-radiative dissipative magnetized micropolar nanofluid flow over a stretching surface in porous media with double stratification and chemical reaction effects: ADM-Padé computation. J Math. 2022;14(2022):1–9.

Thumma T, Mishra SR, Abbas MA, Bhatti MM, Abdelsalam SI. Three-dimensional nanofluid stirring with non-uniform heat source/sink through an elongated sheet. Appl Math Comput. 2022;421:126927.

Muhammad K, Hayat T, Alsaedi A. Numerical study for melting heat in dissipative flow of hybrid nanofluid over a variable thicked surface. Int Commun Heat Mass Transf. 2021;121:104805.

Hayat T, Farooq M, Alsaedi A. Homogeneous-heterogeneous reactions in the stagnation point flow of carbon nanotubes with Newtonian heating. AIP Adv. 2015;5:027130.

Hayat T, Muhammad K, Farooq M, Alsaedi A. Melting heat transfer in stagnation point flow of carbon nanotubes towards variable thickness surface. AIP Adv. 2016;6:015214.

Hussain SM, Jamshed W, Kumar V, Nisar KS, Eid MR, Safdar R, Uma Devi SS, Abdel-Aty AH, Yahia IS. Computational analysis of thermal energy distribution of electromagnetic Casson nanofluid across stretched sheet: Shape factor effectiveness of solid-particles. Energy Rep. 2021;7:7460–77.

Yasmin S, Khan SA, Fatima N, Imran M, Tahir M, Waqas H, Farooq U, Xu YJ. Computational analysis of MHD MgO—water nanofluid flow inside hexagonal enclosure fitted with fins. Case Stud Therm Eng. 2023;43:102788.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mahanta, C., Sharma, R.P. A comparative study of a hybrid nanofluid on a melting stretching surface using different nanoparticle shapes. J Therm Anal Calorim 148, 13655–13677 (2023). https://doi.org/10.1007/s10973-023-12621-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12621-3