Abstract

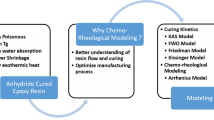

Curing kinetic model is a crucial basis for the processing analysis and simulation of resin matrix composites. The existing dynamic and isothermal models have systematic errors for an actual curing cycle with heating and holding stages. In this study, a piecewise model was proposed to be consistent with curing cycles. First, the dynamic and isothermal models of an epoxy/amine system were developed by analyzing differential scanning calorimetry (DSC) data. Then they were applied to heating and holding stages, respectively, to establish the piecewise model, which was verified by carrying out cyclic DSC tests and comparing the accuracies of models. The prediction error of the proposed model could be lowered by over threefold relative to the existing models. Moreover, the proposed model had a favorable universality compared to the cyclic DSC test. These advantages could be conducive to the numerical simulation and parameter optimization of curing process.

Similar content being viewed by others

References

Hui XY, Xu YJ, Zhang WC, Zhang WH. Multiscale collaborative optimization for the thermochemical and thermomechanical cure process during composite manufacture. Compos Sci Technol. 2022;224:109455.

Mesogitis TS, Skordos AA, Long AC. Stochastic simulation of the influence of cure kinetics uncertainty on composites cure. Compos Sci Technol. 2015;110:145–51.

Lorenz N, Muller-Pabel M, Gerritzen J, Muller J, Groger B, Schneider D, et al. Characterization and modeling cure- and pressure-dependent thermo-mechanical and shrinkage behavior of fast curing epoxy resins. Polym Test. 2022;108:107498.

Sorrentino L, Esposito L, Bellini C. A new methodology to evaluate the influence of curing overheating on the mechanical properties of thick FRP laminates. Compos Part B-Eng. 2017;109:187–96.

Yuksel O, Sandberg M, Baran I, Ersoy N, Hattel JH, Akkerman R. Material characterization of a pultrusion specific and highly reactive polyurethane resin system: elastic modulus, rheology, and reaction kinetics. Compos Part B-Eng. 2021;207:108543.

Mohseni M, Zobeiry N, Fernlund G. Process-induced matrix defects: post-gelation. Compos Part a-Appl S. 2020;137:106007.

Zbed RS, Le Corre S, Sobotka V. Process-induced strains measurements through a multi-axial characterization during the entire curing cycle of an interlayer toughened Carbon/Epoxy prepreg. Compos Part a-Appl S. 2022;153:106689.

Mesogitis TS, Skordos AA, Long AC. Uncertainty in the manufacturing of fibrous thermosetting composites: a review. Compos Part a-Appl S. 2014;57:67–75.

Thomas R, Wehler S, Fischer F. Predicting the process-dependent material properties to evaluate the warpage of a co-cured epoxy-based composite on metal structures. Compos Part a-Appl S. 2020;133:105857.

Ding AX, Li SX, Wang JH, Ni AQ, Zu L. A new path-dependent constitutive model predicting cure-induced distortions in composite structures. Compos Part a-Appl S. 2017;95:183–96.

Yoon JS, Kim K, Seo HS. Computational modeling for cure process of carbon epoxy composite block. Compos Part B-Eng. 2019;164:693–702.

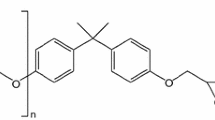

McCoy JD, Ancipink WB, Clarkson CM, Kropka JM, Celina MC, Giron NH, et al. Cure mechanisms of diglycidyl ether of bisphenol A (DGEBA) epoxy with diethanolamine. Polymer. 2016;105:243–54.

Song YJ, Liu M, Zhang LY, Mu CZ, Hu X. Mechanistic interpretation of the curing kinetics of tetra-functional cyclosiloxanes. Chem Eng J. 2017;328:274–9.

Kim KW, Kim DK, Kim BS, An KH, Park SJ, Rhee KY, et al. Cure behaviors and mechanical properties of carbon fiber-reinforced nylon6/epoxy blended matrix composites. Compos Part B-Eng. 2017;112:15–21.

Hardis R, Jessop JLP, Peters FE, Kessler MR. Cure kinetics characterization and monitoring of an epoxy resin using DSC, Raman spectroscopy, and DEA. Compos Part a-Appl S. 2013;49:100–8.

Xu MZ, Luo YS, Lei YX, Liu XB. Phthalonitrile-based resin for advanced composite materials: curing behavior studies. Polym Test. 2016;55:38–43.

Zu Y, Zong LS, Wang JY, Jian XG. Kinetic analysis of the curing of branched phthalonitrile resin based on dynamic differential scanning calorimetry. Polym Test. 2021;96:107062.

Bai Y, Yang P, Zhang S, Li YQ, Gu Y. Curing kinetics of phenolphthalein-aniline-based benzoxazine investigated by non-isothermal differential scanning calorimetry. J Therm Anal Calorim. 2015;120(3):1755–64.

Chen MF, Peng SQ, Zhao MY, Liu YH, Liu CP. The curing and degradation kinetics of modified epoxy-SiO2 composite. J Therm Anal Calorim. 2017;130(3):2123–31.

Hesabi M, Salimi A, Beheshty MH. Effect of tertiary amine accelerators with different substituents on curing kinetics and reactivity of epoxy/dicyandiamide system. Polym Test. 2017;59:344–54.

Xu XQ, Zhou Q, Song N, Ni QR, Ni LZ. Kinetic analysis of isothermal curing of unsaturated polyester resin catalyzed with tert-butyl peroxybenzoate and cobalt octoate by differential scanning calorimetry. J Therm Anal Calorim. 2017;129(2):843–50.

Tezel GB, Sarmah A, Desai S, Vashisth A, Green MJ. Kinetics of carbon nanotube-loaded epoxy curing: rheometry, differential scanning calorimetry, and radio frequency heating. Carbon. 2021;175:1–10.

Liu FY, Yu WW, Wang YJ, Shang RJ, Zheng Q. Curing kinetics and thixotropic properties of epoxy resin composites with different kinds of fillers. J Mater Res Technol. 2022;18:2125–39.

Song XX, Xu SA. Curing kinetics of pre-crosslinked carboxyl-terminated butadiene acrylonitrile (CTBN) modified epoxy blends. J Therm Anal Calorim. 2016;123(1):319–27.

Monteserin C, Blanco M, Laza JM, Aranzabe E, Vilas J. Thickness effect on the generation of temperature and curing degree gradients in epoxy-amine thermoset systems. J Therm Anal Calorim. 2018;132(3):1867–81.

Bornosuz NV, Gorbunova IY, Petrakova VV, Shutov VV, Kireev VV, Onuchin DV, et al. Isothermal kinetics of epoxyphosphazene cure. Polymers-Basel. 2021;13(2):297.

Kim J, Moon TJ, Howell JR. Cure kinetic model, heat of reaction, and glass transition temperature of AS4/3501-6 graphite-epoxy prepregs. J Compos Mater. 2002;36(21):2479–98.

Hayaty M, Beheshty MH, Esfandeh M. Cure kinetics of a glass/epoxy prepreg by dynamic differential scanning calorimetry. J Appl Polym Sci. 2011;120(1):62–9.

Hayaty M, Beheshty MH, Esfandeh M. Isothermal differential scanning calorimetry study of a glass/epoxy prepreg. Polym Advan Technol. 2011;22(6):1001–6.

D’Elia R, Dusserre G, Del Confetto S, Eberling-Fux N, Descarnps C, Cutard T. Cure kinetics of a polysilazane system: experimental characterization and numerical modelling. Eur Polym J. 2016;76:40–52.

Newcomb BA. Time-temperature-transformation (TTT) diagram of a carbon fiber epoxy prepreg. Polym Test. 2019;77:105859.

Xu HJ, Tian GF, Meng Y, Li XY, Wu DZ. Cure kinetics of a nadic methyl anhydride cured tertiary epoxy mixture. Thermochim Acta. 2021;701:178942.

Tziamtzi CK, Chrissafis K. Optimization of a commercial epoxy curing cycle via DSC data kinetics modelling and TTT plot construction. Polymer. 2021;230:124091.

Shin DD, Hahn HT. A consistent cure kinetic model for AS4/3502 graphite/epoxy. Compos Part a-Appl S. 2000;31(9):991–9.

Faria H, Pereira CMC, Pires FMA, Marques AT. Kinetic models for the SR1500 and LY556 epoxies under manufacturer’s recommended cure cycles. Eur Polym J. 2013;49(10):3328–36.

Mphahlele K, Ray SS, Kolesnikov A. Cure kinetics, morphology development, and rheology of a high-performance carbon-fiber-reinforced epoxy composite. Compos Part B-Eng. 2019;176:107300.

Vidil T, Tournilhac F, Musso S, Robisson A, Leibler L. Control of reactions and network structures of epoxy thermosets. Prog Polym Sci. 2016;62:126–79.

Barros JJP, Silva IDD, Jaques NG, Wellen RMR. Approaches on the non-isothermal curing kinetics of epoxy/PCL blends. J Mater Res Technol. 2020;9(6):13539–54.

Bernath A, Karger L, Henning F. Accurate cure modeling for isothermal processing of fast curing epoxy resins. Polymers-Basel. 2016;8(11):390.

Jensen M, Jakobsen J. Enthalpy relaxation and post shrinkage of sub and sup-Tg cured epoxy. J Non-Cryst Solids. 2018;498:60–3.

Jahani Y, Baena M, Barris C, Perera R, Torres L. Influence of curing, post-curing and testing temperatures on mechanical properties of a structural adhesive. Constr Build Mater. 2022;324:126698.

Zhao L, Hu XA. Autocatalytic curing kinetics of thermosetting polymers: a new model based on temperature dependent reaction orders. Polymer. 2010;51(16):3814–20.

Xu YJ, Chen L, Rao WH, Qi M, Guo DM, Liao W, et al. Latent curing epoxy system with excellent thermal stability, flame retardance and dielectric property. Chem Eng J. 2018;347:223–32.

Kudisonga C, Villacorta B, Chisholm H, Vandi LJ, Heitzmann M. Curing kinetics of a siloxane pre-ceramic prepreg resin. Ceram Int. 2021;47(14):20678–85.

Zheng T, Xi H, Wang ZX, Zhang XH, Wang Y, Qiao YJ, et al. The curing kinetics and mechanical properties of epoxy resin composites reinforced by PEEK microparticles. Polym Test. 2020;91:106781.

Acknowledgements

This study was supported by National Natural Science Foundation of China under Grant No. 52275441 and Natural Science Foundation of Shenzhen City under Grant No. WDZC20200817152115001. The authors would like to thank Testing Technology Center of Materials and Devices, Tsinghua Shenzhen International Graduate School (https://mdtc.sz.tsinghua.edu.cn) for the assistances of DSC measurements and analysis.

Author information

Authors and Affiliations

Contributions

LZ Investigation, Software, Writing—Original Draft. PF Conceptualization, Writing—Review and Editing, Supervision. JX Methodology, Writing—Review and Editing. YL Investigation, Writing—Review and Editing. WG Methodology, Writing—Review and Editing. GL Writing—Review and Editing, Supervision. FF Conceptualization, Writing—Review & Editing, Project administration.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, L., Feng, P., Xu, J. et al. A piecewise kinetic model consistent with curing cycle of epoxy/amine composite. J Therm Anal Calorim 148, 12781–12793 (2023). https://doi.org/10.1007/s10973-023-12550-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12550-1