Abstract

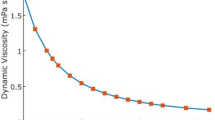

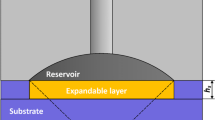

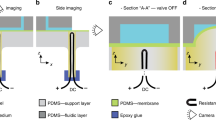

To assure correct patient care and lower pharmaceutical mistakes that might cause serious harm or death, this research introduces a microfluidic heating flowmeter for tracking injectable pumping based on a mechanically pulsating heat exchanger. It is impossible to use the usual gravimetric approach for flow-rate measurement in clinics because it necessitates extensive preparations and laboratory equipment. Consequently, there is a huge need for a standard technique substitute that can be used for distant, frequent, small-scale infusion-pump surveillance. Here, to give precise measurements, the research presents a downsized heated flowmeter made of a silicon platform, a platinum heating layer atop a silicon dioxide thin membrane, and polymer microchannels. A microfluidics temperature compensation and tracking method is suggested in this research. Based on this architecture, the research put forth a heat transmission concept in which the researchers looked at the regional correlations among the macro-scale temperature detector and the microscale liquids. The accuracy of temperature management for microscale reagents was demonstrated using a series of temperature-sensitive nucleic acid multiplication experiments. The efficacy of the heat transport model is further confirmed by comparisons of mathematical and empirical data. The isothermal multiplication polymerase chain reaction temperature-related minor fluctuations in fluorescence intensity could be identified with the aid of the compensatory method that was given. If the amplifying temperature differs by 1 °C, the likelihood density plots of fluorescence intensity are significantly different from one another. This technique is useful for micro–macro-interaction monitoring generally and extends beyond microfluidic purposes.

Similar content being viewed by others

References

Alizadeh A, Movahedi P, Mirzahosseini S, Ekhtiari S. Investigating different types of fluids in pulsating heat pipes for improving heat transfer in an air-cooled heat exchanger. Proc Inst Mech Eng Part A J Power Energy. 2022. https://doi.org/10.1177/095765092210766.

Grimstein M, Yang Y, Zhang X, Grillo J, Huang SM, Zineh I, Wang Y. Physiologically based pharmacokinetic modelling in regulatory science: an update from the US Food and Drug Administration’s Office of Clinical Pharmacology. J Pharm Sci. 2019;108(1):21–5.

Abu-Hamdeh NH, Bantan RA, Aalizadeh F, Alimoradi A. Controlled drug delivery using the magnetic nanoparticles in non-Newtonian blood vessels. Alex Eng J. 2020;59(6):4049–62.

Parot J, Caputo F, Mehn D, Hackley VA, Calzolai L. Physical characterization of liposomal drug formulations using multi-detector asymmetrical-flow field flow fractionation. J Control Release. 2020;320:495–510.

Doh I, Sim D, Kim SS. Microfluidic thermal flowmeters for drug injection monitoring. Sensors. 2022;22(9):3151.

Bhavana HT, Sunil MA, Sanjana T, Harshitha B. Recent Advances in Drug Delivery Systems: MEMS Perspective. In: Disruptive developments in biomedical applications, 1st edition, Chapter 20, pp 299–309 (2023).

Meng J, Yu C, Li S, Wei C, Dai S, Li H, Li J. Microfluidics temperature compensating and monitoring based on liquid metal heat transfer. Micromachines. 2022;13(5):792.

Zhao PJ, Gan R, Huang L. A microfluidic flow meter with micromachined thermal sensing elements. Rev Sci Instrum. 2020;91(10):105006.

Jderu A, Soto MA, Enachescu M, Ziegler D. Liquid flow meter by fibre-optic sensing of heat propagation. Sensors. 2021;21(2):355.

Van Erp R, Soleimanzadeh R, Nela L, Kampitsis G, Matioli E. Co-designing electronics with microfluidics for more sustainable cooling. Nature. 2020;585(7824):211–6.

Chen G, Zheng J, Liu L, Xu L. Application of microfluidics in wearable devices. Small Methods. 2019;3(12):1900688.

Zhao X, Gao W, Yin J, Fan W, Wang Z, Hu K, Mai Y, Luan A, Xu B, Jin Q. A high-precision thermometry microfluidic chip for real-time monitoring of the physiological process of live tumour cells. Talanta. 2021;226:122101.

Saad MG, Selahi A, Zoromba MS, Mekki L, El-Bana M, Dosoky NS, Nobles D, Shafik HM. A droplet-based gradient is microfluidic to monitor and evaluate the growth of Chlorella Vulgaris under different levels of nitrogen and temperatures. Algal Res. 2019;44:101657.

Kong M, Li Z, Wu J, Hu J, Sheng Y, Wu D, Lin Y, Li M, Wang X, Wang S. A wearable microfluidic device for rapid detection of HIV-1 DNA using recombinase polymerase amplification. Talanta. 2019;205:120155.

Coluccio ML, Perozziello G, Malara N, Parrotta E, Zhang P, Gentile F, Limongi T, Raj PM, Cuda G, Candeloro P, Di Fabrizio E. Microfluidic platforms for cell cultures and investigations. Microelectron Eng. 2019;208:14–28.

Zhu JY, Suarez SA, Thurgood P, Nguyen N, Mohammed M, Abdelwahab H, Needham S, Pirogova E, Ghorbani K, Baratchi S, Khoshmanesh K. Reconfigurable, self-sufficient convective heat exchanger for temperature control of microfluidic systems. Anal Chem. 2019;91(24):15784–90.

Bunge F, van den Driesche S, Waespy M, Radtke A, Belge G, Kelm S, Waite AM, Mirastschijski U, Vellekoop MJ. The microfluidic oxygen sensor system is a tool to monitor the metabolism of mammalian cells. Sens Actuators B Chem. 2019;289:24–31.

Peng J, Fang C, Ren S, Pan J, Jia Y, Shu Z, Gao D. Development of a microfluidic device with precise on-chip temperature control by integrated cooling and heating components for single cell-based analysis. Int J Heat Mass Transf. 2019;130:660–7.

Luo X, Su P, Zhang W, Raston CL. Microfluidic devices in fabricating nano or micromaterials for biomedical applications. Adv Mater Technol. 2019;4(12):1900488.

Abdel-Latif K, Epps RW, Kerr CB, Papa CM, Castellano FN, Abolhasani M. Facile room-temperature anion exchange reactions of inorganic perovskite quantum dots enabled by a modular microfluidic platform. Adv Func Mater. 2019;29(23):1900712.

Arqub OA, Abo-Hammour Z. Numerical solution of systems of second-order boundary value problems using continuous genetic algorithm. Inf Sci. 2014;279:396–415.

Abo-Hammour Z, Abu Arqub O, Momani S, Shawagfeh N. Optimization solution of Troesch’s and Bratu’s problems of ordinary type using novel continuous genetic algorithm. Discrete Dyn Nat Soc. 2014:401696

Zahran EH, Arqub OA, Bekir A, Abukhaled M. New diverse types of soliton solutions to the Radhakrishnan–Kundu–Lakshmanan equation. AIMS Math. 2023;8:8985–9008.

Cavaniol C, Cesar W, Descroix S, Viovy JL. Flowmetering for microfluidics. Lab Chip. 2022;22(19):3603–17.

Cooksey GA, Patrone PN, Hands JR, Meek SE, Kearsley AJ. Dynamic measurement of nanoflows: realization of an optofluidic flow meter to the nanoliter-per-minute scale. Anal Chem. 2019;91(16):10713–22.

Wu T, Shen J, Li Z, Xing F, Xin W, Wang Z, Liu G, Han X, Man Z, Fu S. Microfluidic-integrated graphene optical sensors for real-time and ultra-low flow velocity detection. Appl Surf Sci. 2021;539:148232.

Cao Y, Wang T, Sepúlveda N. Microfluidic thermal flow sensor based on phase-change material with ultra-high thermal sensitivity. J Mater Chem C. 2023;11 (4)1278–84.

Acknowledgements

Magda Abd El-Rahman extends their appreciation to the Deanship of Scientific Research at King Khalid University, Abha, Saudi Arabia, for funding this work through Large Groups Project under grant number RGP 2/69/44.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sankad, G.C., Priyadarsini, G.D., El-Rahman, M.A. et al. Microfluidics temperature compensation and tracking for drug injection based on mechanically pulsating heat exchanger. J Therm Anal Calorim 148, 12059–12070 (2023). https://doi.org/10.1007/s10973-023-12520-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12520-7