Abstract

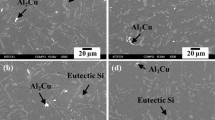

In the present work, the thermal properties and heat treatment effect of an ingot metallurgy hypereutectic Al–Mg–Si alloy with extra Si are studied. The alloy is produced by gravity casting using 99.8% pure Al, 98.5% Si, and 99.9% pure Mg pellets. Thermal diffusivity, thermal conductivity, specific heat, and thermal expansion analyses are performed both after solid solution and after various aging treatments. The heat flow curve reveals a correlation between the precipitation reactions and the thermal diffusivity behaviors. In particular, the thermal characteristics of the Al–Mg–Si alloy are determined by the precipitation of the β″ and β′ phases, and the precipitation and re-dissolving of Si. Interestingly, the effect of Si precipitation upon the thermal diffusivity and expansion is greater than that of meta-stable β-phase precipitation.

Similar content being viewed by others

References

Mondolfo LF. Aluminum alloys: structure and properties. Amsterdam: Elsevier; 2013.

Werinos M, Antrekowitsch H, Ebner T, Prillhofer R, Curtin WA, Uggowitzer PJ, et al. Design strategy for controlled natural aging in Al–Mg–Si alloys. Acta Mater. 2016;118:296–305.

Gómora CM, Ambriz RR, Zuno-Silva J, Jaramillo D. Heat sink effect on 6061 aluminum alloy welds with different partial aging conditions. J Mater Eng Perform. 2020;29:4339–50.

Wong M, Owen I, Sutcliffe CJ, Puri A. Convective heat transfer and pressure losses across novel heat sinks fabricated by selective laser melting. Int J Heat Mass Transf. 2009;52:281–8.

Lin Z, Wang S, Huo J, Hu Y, Chen J, Zhang W, et al. Heat transfer characteristics and LED heat sink application of aluminum plate oscillating heat pipes. Appl Therm Eng Elsevier. 2011;31:2221–9.

Nguyen T, Mochizuki M, Mashiko K, Saito Y. Use of heat pipe/heat sink for thermal managenlent of high performance CPUs. Sixt IEEE SEMI-THERMTM Symp. IEEE; 2000. p. 2–5.

Buchanan K, Colas K, Ribis J, Lopez A, Garnier J. Analysis of the metastable precipitates in peak-hardness aged Al-Mg-Si(-Cu) alloys with differing Si contents. Acta Mater. 2017;132:209–21.

Edwards GA, Stiller K, Dunlop GL, Couper MJ. The precipitation sequence in Al–Mg–Si alloys. Acta Mater. 1998;46:3893–904.

Matsuda K, Uetani Y, Sato T, Ikeno S. Metastable phases in an Al-Mg-Si alloy containing copper. Metall Mater Trans a-Physical Metall Mater Sci. 2001;32:1293–9.

Weng Y, Jia Z, Ding L, Pan Y, Liu Y, Liu Q. Effect of Ag and Cu additions on natural aging and precipitation hardening behavior in Al-Mg-Si alloys. J Alloys Compd. 2017;695:2444–52.

JIM. Microstructure and properties of aluminum alloys. Japan: Japan Institute of light metals; 1991.

Sakurai T, Eto T. Aluminum alloys: their physical and mechanical properties. Proc 3rd Int Conf Aluminum, Ed by L Arnberg, O Lohne, E Nes N Ryum (Norwegian Inst Technol SINTEF Metall Trondheim, 1992) Vol 1992. p. 208.

Chen H, Lu J, Kong Y, Li K, Yang T, Meingast A, et al. Atomic scale investigation of the crystal structure and interfaces of the B′ precipitate in Al-Mg-Si alloys. Acta Mater. 2020;185:193–203.

Kimura T, Nakamoto T, Mizuno M, Araki H. Effect of silicon content on densification, mechanical and thermal properties of Al-xSi binary alloys fabricated using selective laser melting. Mater Sci Eng A Elsevier. 2017;682:593–602.

Gupta AK, Lloyd DJ, Court SA. Precipitation hardening in Al-Mg-Si alloys with and without excess Si. Mater Sci Eng A. 2001;316:11–7.

Choi S-W, Kim Y-M, Kim Y-C, Kang C-S. Effects of alloying elements on mechanical and thermal characteristics of Al-6wt-%Si-0.4wt-%Mg–(Cu) foundry alloys. Mater Sci Technol. 2019;35:1365–71.

Kim Y-M, Choi S-W, Kim Y-C, Kang C-S, Hong S-K. Influence of the precipitation of secondary phase on the thermal diffusivity change of Al-Mg2Si Alloys. Appl Sci. 2018;8:2039.

Kim Y, Kim Y, Choi S. Effect of precipitation and dissolution of Si on the thermal diffusivity in the Al-Si alloy system. Korean J Mater Res. 2020;30:474–9.

Novák P, Nová K. Oxidation behavior of Fe-Al, Fe-Si and Fe-Al-Si intermetallics. Materials (Basel). 2019;12:1748.

Weng Y, Ding L, Xu Y, Jia Z, Sun Q, Chen F, et al. Effect of In addition on the precipitation behavior and mechanical property for Al-Mg-Si alloys. J Alloys Compd. 2022;895:162685.

Ninive PH, Løvvik OM, Strandlie A. Density functional study of the β phase in Al-Mg-Si alloys. Metall Mater Trans A Phys Metall Mater Sci. 2014;45:2916–24.

Kim YM, Choi SW, Hong SK. The behavior of thermal diffusivity change according to the heat treatment in Al-Si binary system. J Alloys Compd. 2016;687:54–8.

Kim Y, Choi S. Effect of additional cu and natural aging treatment on thermal diffusivity in the Al-Mg-Si Alloy. J Korea Foundary Assoc. 2021;41:528–34.

Tritt TM. Thermal conductivity: theory, properties and applications 1st edition, Kluwer Academic/Plemum Publishers; 2004.

Rosenbaum HS, Turnbull D. Metallographic investigation of precipitation of silicon from aluminum. Acta Metall. 1959;7:664–74.

ASM. ASM Ready Reference: Thermal properties of metals. Acta Mater. ASM International; 2002.

Acknowledgements

This study has been conducted with the support of the Korea Institute of Industrial Technology as "Development of core technologies of AI based self-power generation and charging for next-generation mobility (KITECH EH-23-0013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kim, YM., Choi, SW. & Kim, YC. Effects of Si additions and heat treatment on the thermal characteristics of Al–Si–Mg alloys. J Therm Anal Calorim 148, 10749–10756 (2023). https://doi.org/10.1007/s10973-023-12429-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12429-1