Abstract

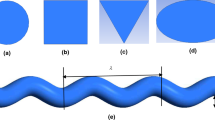

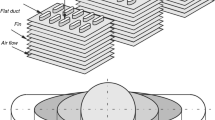

In various industrial applications, especially those that focus on heat transfer, curved ducts present an interesting equipment. The flow behavior inside curved ducts is more complex compared to straight ducts, particularly in the presence of nanofluids. Hence, the present paper reports a numerical investigation of a nanofluid two-phase flow according to the Buongiorno model in a curved duct with abruptly expanded cross section. It deals with a toroidal duct with a circular cross-section abruptly expanded through which an Alumina-water nanofluid flows. The nanofluid penetrates the duct with a constant initial velocity at a cold constant temperature. Moreover, the lateral surface of the expanded part of the duct is maintained at a hot temperature, however, the rest of the duct boundaries are assumed to be adiabatic. The aim of the present study is to visualize the impact of the phenomenon of inertia (10 ⩽ Re ⩽ 200), mass diffusion (0.1 ⩽ Le ⩽ 100) and alumina nanoparticles concentration (0 ⩽ φ0 ⩽ 0.1) on the hydrodynamic, thermal and mass behavior of the nanofluid inside the expanded curved ducts under Brownian and thermophoretic diffusions. The nanofluid flow is governed by the mathematical model of Buongiorno including the mass, momentum, energy and nanoparticles equations and solved by the Galerkin finite element method. The numerical results have indicated that, in addition to the presence of Dean’s vortices, the enlarged configuration of the current duct leads to the emergence of vortices resulting from flow reattachment. Moreover, the heat transfer rate increases with higher Reynolds numbers. Furthermore, the addition of alumina nanoparticles enhances the heat transfer with a percentage of 15% compared to pure water. Additionally, there is a relative decrease in the heat transfer rate due to nanoparticles’ thermophoretic migration. On the other hand, the increase in the Lewis number does not significantly influence this heat transfer rate, although it does promote a more homogeneous distribution of nanoparticles.

Similar content being viewed by others

Data availability

Not applicable.

Abbreviations

- a 1 :

-

Radius of restricted duct/m

- a 2 :

-

Radius of expanded duct/m

- Cp:

-

Specific heat/J kg−1 K−1

- D :

-

Diameter of restricted duct/m

- D B :

-

Brownian motion coefficient/m2 s−1

- De:

-

Dean number/–

- d p :

-

Nanoparticles diameter/m

- D T :

-

Thermophoresis coefficient/m2 s−1

- k :

-

Thermal conductivity/W m−1 K−1

- K B :

-

Boltzmann coefficient/J K−1

- Le:

-

Lewis number/–

- N B :

-

Brownian motion parameter/–

- N T :

-

Thermophoresis parameter/–

- Nu:

-

Nusselt number/–

- P :

-

Dimensionless pressure/–

- p :

-

Pressure/Pa

- Pr:

-

Prandtl number/–

- q w :

-

Heat flux/W/m−2 K−1

- R :

-

Dimensionless radial coordinate/–

- R c :

-

Average curvature radius/m

- Re:

-

Reynolds number/–

- Ri:

-

Richardson number/–

- S :

-

Lateral area of expanded duct/m2

- t :

-

Time/s

- T :

-

Temperature/K

- u 0 :

-

Inlet velocity/m s−1

- u r :

-

Radial velocity/ m s−1

- U R :

-

Dimensionless radial velocity/–

- u z :

-

Vertical velocity/ m s−1

- U Z :

-

Dimensionless vertical velocity/–

- u θ :

-

Axial velocity/m s−1

- U θ :

-

Dimensionless axial velocity/–

- V :

-

Magnitude velocity/m s−1

- x :

-

x-Cartesian coordinate/m

- y :

-

y-Cartesian coordinate/m

- Z :

-

Dimensionless vertical coordinate/–

- z :

-

Vertical coordinate/m

- α :

-

Thermal diffusivity/m2 s−1

- β :

-

Thermal expansion coefficient/K−1

- Θ:

-

Dimensionless temperature/–

- θ :

-

Axial coordinate/rd

- μ :

-

Viscosity/Pa s

- ρ :

-

Density/kg m−3

- τ :

-

Dimensionless time/–

- φ :

-

Volume fraction or concentration/–

- φ 0 :

-

Mean concentration/–

- Φ:

-

Dimensionless concentration/–

- ϕ :

-

Cross section angle coordinate/rd

- Ω:

-

Computational domain

- f:

-

Base fluid

- p:

-

Nanoparticles

- nf:

-

Nanofluid

- h:

-

Hot

- c:

-

Cold

- ave:

-

Average

References

Yasuo M, Wataru N. Study on forced convective heat transfer in curved pipes: (1st report, laminar region). Int J Heat Mass Transf. 1965;8(1):67–82.

Dean WR. XVI. Note on the motion of fluid in a curved pipe. Lond Edinb Dublin Philos Mag J Sci. 1927;4(20):208–23.

Dean WR. Fluid motion in a curved channel. Proc R Soc Lond Ser A Contain Pap Math Phys Character. 1928;121(787):402–20.

Dean WR, Hurst JM. Note on the motion of fluid in a curved pipe. Mathematika. 1959;6(1):77–85.

Williams GS, Hubbell CW, Fenkell GH. Experiments at detroit, Mich., on the effect of curvature upon the flow of water in pipes. Trans Am Soc Civ Eng. 1902;47(1):1–196.

Grindley JH, Gibson AH. On the frictional resistances to the flow of air through a pipe. Proc R Soc Lond Ser A Contain Pap Math Phys Character. 1908;80(536):114–39.

Eustice J. Flow of water in curved pipes. Proceed R Soc Lond Ser A Contain Pap Math Phys Character. 1910;84(568):107–18.

Eustice J. Experiments on streamline motion in curved pipes. Proc R Soc Lond Ser A Contain Pap Math Phys Character. 1911;85(576):119–31.

Ito H. Theory on laminar flow through curved pipes of elliptic and rectangular cross-section. Rep Inst High Speed Mech Tohoku Univ Sendai Jpn. 1951;1:1–16.

Stonemetz RE. Liquid cavitation studies in circular pipe bends. Washington, D.C.: National Aeronautics and Space Administration; 1965.

McConalogue DJ, Srivastava RS. Motion of a fluid in a curved tube. Proc R Soc Lond Ser A Math Phys Sci. 1968;307(1488):37–53.

Mullinix BF. Streamline motion of a viscous, incompressible fluid in a curved pipe with an elliptical cross section. Army missile command redstone arsenal al systems research directorate 1969;0129.

Sugiyama S, Hayashi T, Yamazaki K. Flow characteristics in the curved rectangular channels: visualization of secondary flow. Bull JSME. 1983;26(216):964–9.

Hille P, Vehrenkamp R, Schulz-Dubois EO. The development and structure of primary and secondary flow in a curved square duct. J Fluid Mech. 1985;151:219–41.

Bovendeerd PHM, Van Steenhoven AA, Van de Vosse FN, Vossers G. Steady entry flow in a curved pipe. J Fluid Mech. 1987;177:233–46.

Bara B, Nandakumar K, Masliyah J. An experimental and numerical study of the Dean problem: flow development towards two-dimensional multiple solutions. J Fluid Mech. 1992;244:339–76.

Li Y, Wang X, Zhou B, Yuan S, Tan SK. Dean instability and secondary flow structure in curved rectangular ducts. Int J Heat Fluid Flow. 2017;68:189–202.

Yee G, Chilukuri R, Humphrey JAC. Developing flow and heat transfer in strongly curved ducts of rectangular cross section. 1980; 285–291.

Wang L, Cheng KC. Flow transitions and combined free and forced convective heat transfer in rotating curved channels: the case of positive rotation. Phys Fluids. 1996;8(6):1553–73.

Gyves TW, Irvine TF Jr. Laminar conjugated forced convection heat transfer in curved rectangular channels. Int J Heat Mass Transf. 2000;43(21):3953–64.

Choi HK, Park SO. Mixed convection flow in curved annular ducts. Int J Heat Mass Transf. 1994;37(17):2761–9.

Yanase SRNM, Mondal RN, Kaga Y. Numerical study of non-isothermal flow with convective heat transfer in a curved rectangular duct. Int J Therm Sci. 2005;44(11):1047–60.

Mondal RN, Kaga Y, Hyakutake T, Yanase S. Effects of curvature and convective heat transfer in curved square duct flows. J Fluids Eng. 2006;128:1013–22.

Chandratilleke TT, Nadim N, Narayanaswamy R. Vortex structure-based analysis of laminar flow behaviour and thermal characteristics in curved ducts. Int J Therm Sci. 2012;59:75–86.

Mondal RN, Islam MS, Uddin MK. Unsteady solutions with convective heat transfer through a curved duct flow. Procedia Eng. 2013;56:141–8.

Ahuja A. Augmentation of heat transport in laminar flow of polystyrene suspension I. Experiments and results. J Appl Phys. 1975;46:3408–16.

Hetsroni G, Rozenblit R. Heat transfer to a liquid-solid mixture in a flume. Int J Multiphase Flow. 1994;20:671–89.

Perarasu V, Arivazhagan M, Sivashanmugam P. Experimental and CFD heat transfer studies of Al2O3-water nanofluid in a coiled agitated vessel equipped with propeller. Chin J Chem Eng. 2013;21(11):1232–43.

Choi S, Eastman JA. Enhancing thermal conductivity of fluids with nanoparticles. In: 309 Siginer DA, Wang HP, editors. Developments and applications of non-Newtonian 310 flows, vol 231, no 66. 1995. p. 99–105.

Xuan Y, Roetzel W. Conceptions for heat transfer correlation of nanofluids. Int J Heat Mass Transf. 2003;43(19):3701–7.

Abu-Nada E, Masoud Z, Hijazi A. Natural convection heat transfer enhancement in horizontal concentric annuli using nanofluids. Int Commun Heat Mass Transf. 2008;35(5):657–65.

Shang D-Y, Zhong LC. Heat transfer due to laminar natural convection of nanofluids: theory and calculation. Gewerbestrasse, Switzerland: Springer; 2019.

Bianco V, Manca O, Nardini S, Vafai K. Heat transfer enhancement with nanofluids. 1st ed. New York: CRC Press Taylor & Francis Group; 2015.

Hayat T, Muhammad K, Alsaedi A, Asghar S. Thermodynamics by melting in flow of an Oldroyd-B material. J Braz Soc Mech Sci Eng. 2018;40:1–11.

Muhammad K, Hayat T, Alsaedi A. Heat transfer analysis in slip flow of hybrid nanomaterial (Ethylene Glycol+ Ag+ CuO) via thermal radiation and Newtonian heating. Waves Random Complex Media 2021; 1–21.

Hayat T, Muhammad K, Alsaedi A. Numerical study of melting heat transfer in stagnation-point flow of hybrid nanomaterial (MWCNTs+ Ag+ kerosene oil). Int J Numer Meth Heat Fluid Flow. 2021;31(8):2580–98.

Hayat T, Muhammad K, Alsaedi A. Melting effect in MHD stagnation point flow of Jeffrey nanomaterial. Phys Scr. 2019;94(11):115702.

Pordanjani A, Vahedi S, Rikhtegar F, Wongwises S. Optimization and sensitivity analysis of magneto-hydrodynamic natural convection nanofluid flow inside a square enclosure using response surface methodology. J Therm Anal Calorim. 2018;135:1031–45.

Hussain S, Ahmed SE. Unsteady MHD forced convection over a backward facing step including a rotating cylinder utilizing Fe3O4-water ferrofluid. J Magn Magn Mater. 2019;484:356–66.

Djamila D, Bouzit M, Bouzit F. Effect of the inclination angle of finned cylinder over a BFS on the MHD behavior in the presence of a nanofluid. Metall Mater Eng. 2022;28(2):203–21.

Toumi M, Bouzit M, Bouzit F, Mokhefi A. MHD forced convection using ferrofluid over a backward facing step containing a finned cylinder. Acta Mech Autom. 2022;16(1):70–81.

Aminian E, Moghadasi H, Saffari H. Magnetic field effects on forced convection flow of a hybrid nanofluid in a cylinder filled with porous media: a numerical study. J Therm Anal Calorim. 2020;141:2019–31.

Liu X, et al. Numerical investigation of nanofluid laminar forced convection heat transfer between two horizontal concentric cylinders in the presence of porous medium. J Therm Anal Calorim. 2020;141:2095–108.

Mokhefi A, Bouanini M, Elmir M, Guettaf Y, Spiteri P. 2022 Numerical investigation of mixed convection in an anchor-stirred tank filled with an Al2O3-water nanofluid. Chem Pap. 2022;76(2):967–85.

Mokhefi A, Bouanini M, Elmir M, Spitéri P. Effect of an anchor geometry on the hydrodynamic characteristics of a nanofluid in agitated tank. In: Defect and diffusion forum, vol. 409. Bäch: Trans Tech Publications Ltd.; 2021. p. 179–93.

Mokhefi A, Bouanini M, Elmir M, Spitéri P. Effect of the wavy tank wall on the characteristics of mechanical agitation in the presence of a Al2O3-water nanofluid. Metall Mater Eng. 2021;27(3):301–20.

Akbarinia A, Behzadmehr A. Numerical study of laminar mixed convection of a nanofluid in horizontal curved tubes. Appl Therm Eng. 2007;27(8–9):1327–37.

Choi J, Zhang Y. Numerical simulation of laminar forced convection heat transfer of Al2O3–water nanofluid in a pipe with return bend. Int J Therm Sci. 2012;55:90–102.

Ajeel RK, Sopian K, Zulkifli R, Fayyadh SN, Hilo AK. Assessment and analysis of binary hybrid nanofluid impact on new configurations for curved-corrugated channel. Adv Powder Technol. 2021;32(10):3869–84.

Liu F, Zhang D, Cai Y, Qiu Z, Zhu Q, Zhao J, Tian H. Multiplicity of forced convective heat transfer of nanofluids in curved ducts. Int J Heat Mass Transf. 2019;129:534–46.

Moghadasi H, Aminian E, Saffari H, Mahjoorghani M, Emamifar A. Numerical analysis on laminar forced convection improvement of hybrid nanofluid within a U-bend pipe in porous media. Int J Mech Sci. 2020;179:105659.

Akbarinia A, Laur R. Investigating the diameter of solid particles effects on a laminar nanofluid flow in a curved tube using a two-phase approach. Int J Heat Fluid Flow. 2009;30(4):706–14.

Ghaffari O, Behzadmehr A, Ajam H. Turbulent mixed convection of a nanofluid in a horizontal curved tube using a two-phase approach. Int Commun Heat Mass Transfer. 2010;37(10):1551–8.

Akbari OA, Safaei MR, Goodarzi M, Akbar NS, Zarringhalam M, Shabani GAS, Dahari M. A modified two-phase mixture model of nanofluid flow and heat transfer in a 3-D curved microtube. Adv Powder Technol. 2016;27(5):2175–85.

Buongiorno J. Convective transport in nanofluids. J Heat Transfer. 2006;128:240–50.

Fard MH, Esfahany MN, Talaie MR. Numerical study of convective heat transfer of nanofluids in a circular tube two-phase model versus single-phase model. Int Commun Heat Mass Transf. 2010;37(1):91–7.

Hayat T, Farooq S, Alsaedi A. 2017 Mixed convection peristaltic motion of copper-water nanomaterial with velocity slip effects in a curved channel. Comput Methods Programs Biomed. 2017;142:117–28.

Malvandi A, Ganji D. Mixed convective heat transfer of water/alumina nanofluid inside a vertical microchannel. Powder Technol. 2014;263:37–44.

di Rossi SE, Impiombato AN, Mokhefi A, Biserni C. Theoretical and numerical study on Buongiorno’s model with a couette flow of a nanofluid in a channel with an embedded cavity. Appl Sci. 2022;12(15):7751.

Benygzer C, Bouzit M, Mokhefi A, Khelif F-Z. Unsteady natural convection in a porous square cavity saturated by nanofluid using buongiorno model: variable permeability effect on homogeneous porous medium. CFD Lett. 2022;14(7):42–61.

Brinkman H. 1952The viscosity of concentrated suspensions and solutions. J Chem Phys. 1952;20:571–81.

Maxwell J. A Treatise on Electricity and Magnetism. 1st ed. Cambridge: Oxford University Press; 1881.

Mokeddem M, Laidoudi H, Makinde OD, Bouzit M. 3D Simulation of incompressible poiseuille flow through 180 curved duct of square cross-section under effect of thermal buoyancy. Period Polytech Mech Eng. 2019;63(4):257–69.

Izadi M, Sinaei S, Mehryan SAM, Oztop HF, Abu-Hamdeh N. 2018 Natural convection of a nanofluid between two eccentric cylinders saturated by porous material: Buongiorno’s two-phase model. Int J Heat Mass Transf. 2018;127:67–75.

Acknowledgements

Not applicable.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

DD performed the simulation and showed the results and interpretation, MB proposed the idea of the paper and helped in the interpretation, AM detailed the mathematical formulation and helped in the analyze of the results, FB contributed in the redaction.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Derbal, D., Bouzit, M., Mokhefi, A. et al. Numerical analysis of a nanofluid behavior in an expanded curved duct using the two-phase Buongiorno model. J Therm Anal Calorim 148, 11131–11154 (2023). https://doi.org/10.1007/s10973-023-12423-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12423-7