Abstract

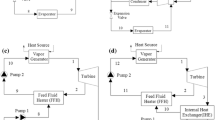

The choice of refrigerant and expander is always one of the main concerns of researchers using organic Rankine cycles. The problem of using the organic Rankine cycle becomes more complicated when there are two waste heat sources with different temperatures in a system, such as exhaust gas and jacket water heat sources in an internal combustion engine. Hence, in this paper, a thermoeconomic program is developed using four types of volumetric expanders, including piston, screw, scroll and root, and eight different organic fluids in the series double cascade-evaporator organic Rankine cycle. The studied organic fluids were selected to cover a wide range of pressure levels in the series double cascade-evaporator organic Rankine cycle, including R245 FA, R123, n-pentane, acetone, n-heptane, benzene, n-octane and toluene. In the present study, 16 different pairs of expanders were examined for a cohort of 8 dissimilar fluids, resulting in an aggregate of 128 distinctive cases. In each of the 128 different cases, the important parameters, including power production, exergetic efficiency, total investment cost, net present value and levelized cost of electricity generation, are calculated. Also, the Pareto method is used to select the best organic fluid and expander pair. The results show the fluids with lower critical temperatures performed better due to the pressure ratio limit. The lowest cost of the expander compared to the total cost was 4.98%, related to the pair of root–scroll expanders, and the highest cost of 48.21% was related to the piston–screw expander pair. The lowest total investment cost was 377,478$ for the n-pentane and the piston–scroll expander pair. The screw expander costs more than other expanders, especially when in the low-pressure cycle. According to the optimization results, the optimal pair of expanders for the series double cascade-evaporator organic Rankine cycle system is scroll–scroll with n-pentane as the working fluid. Additionally, the exergetic efficiency, payback period and total investment cost values in this case are 0.3945, 4.089 years and 385,786$, respectively.

Similar content being viewed by others

Abbreviations

- \(C\) :

-

Cost ($)

- \(d\) :

-

Diameter (mm)

- \({\dot{\text{E}}\text{x}}\) :

-

Exergy rate (kW)

- \(f\) :

-

Friction factor

- \(F\) :

-

Correction factor

- \(h\) :

-

Specific enthalpy (kJ kg−1)

- \(\dot{I}\) :

-

Irreversible loss (kW)

- \(k\) :

-

Thermal conductivity (W m−1·K−1)

- \(L\) :

-

Length of the tube (m)

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- \({\text{Nu}}\) :

-

Nusselt number

- \(\Pr\) :

-

Prandtl number

- \(\dot{Q}\) :

-

Heat rate (kW)

- \({\text{Re}}\) :

-

Reynolds number

- \(\dot{s}\) :

-

Entropy (kJ kg−1·K−1)

- \(U\) :

-

Total heat transfer coefficient (W m−2·K−1)

- \(v\) :

-

Velocity (m s2−1)

- \(\dot{W}\) :

-

Power (kW)

- c :

-

Cold side

- cond :

-

Condenser

- Cr :

-

Critical

- d :

-

Destruction

- e :

-

Output

- Eva :

-

Evaporator

- ex :

-

Exergy

- exh :

-

Exhaust heat source

- exp :

-

Expander

- FIX:

-

Fixed manufacturing costs

- gen :

-

Generation

- h :

-

Hot side

- i :

-

Input

- in :

-

Inlet

- is :

-

Isentropic

- jw :

-

Jacket water heat source

- net :

-

Net

- out :

-

Outlet

- p :

-

Pump

- PI:

-

Property taxes and liability insurance

- s :

-

Shell side

- t :

-

Tube side

- th:

-

Thermal

- \({\text{w}}\) :

-

Water

- 0:

-

Dead state

- COM:

-

Cost of manufacture

- DMS:

-

Direct manufacturing costs

- DRORC:

-

Double-stage regenerative organic Rankine cycle

- DORC:

-

Dual-loop organic Rankine cycle

- EEDI:

-

Energy efficiency design index

- GE:

-

General expenses

- GHG:

-

Greenhouse gas

- GWP:

-

Global warming potential

- HX:

-

Heat exchanger

- ICE:

-

Internal combustion engine

- LCOE:

-

Levelized cost of electricity

- MO:

-

Maintenance overhead

- MS:

-

Materials and services

- NPV:

-

Net present value

- ODP:

-

Ozone depletion potential

- ORC:

-

Organic Rankine cycle

- PBP:

-

Payback period (year)

- PDORC:

-

Parallel two-stage organic Rankine cycle

- ROI:

-

Return on investment

- RORC:

-

Regenerative organic Rankine cycle

- SB:

-

Salaries and benefits

- SIC:

-

Specific investment cost ($ kW−1)

- SORC:

-

Solar organic Rankine cycle

- SDCORC:

-

Series double cascade-evaporator organic Rankine cycle

- STORC:

-

Series two-stage organic Rankine cycle

- TIC:

-

Total investment cost ($)

- TPC:

-

Total production cost

- TSORC:

-

Two-stage organic Rankine cycle

- WB:

-

Wages and benefits

- WHRS:

-

Waste heat recovery system

- \(\eta\) :

-

Efficiency (%)

- \(\lambda\) :

-

Convective coefficient

- \(\mu\) :

-

Dynamic viscosity (Pa.s)

References

Capuano L. International energy outlook 2018 (IEO2018), vol. 2018. Washington: US Energy Information Administration (EIA); 2018. p. 21.

Khodadadi F, Deymi-Dashtebayaz M, Lakzian E. Parametric analysis of combined power and freshwater producing system for natural gas engine heat recovery. Energy Convers Manag. 2020;225: 113464.

Deymi-Dashtebayaz M, Rezapour M, Farahnak M. Modeling of a novel nanofluid-based concentrated photovoltaic thermal system coupled with a heat pump cycle (CPVT-HP). Appl Therm Eng. 2022;201: 117765.

Deymi-Dashtebayaz M, Maddah S, Goodarzi M. Investigation of the effect of using various HFC refrigerants in geothermal heat pump with residential heating applications. J Therm Anal Calorim. 2020;141:361–72.

Deymi-Dashtebayaz M, Dadpour D, Khadem J. Using the potential of energy losses in gas pressure reduction stations for producing power and fresh water. Desalination. 2021;497: 114763.

Asadi M, Deymi-Dashtebayaz M, Alavi S. Emergy and eco-exergy analysis of different scenarios in waste heat recovery applications for electricity and fresh water generation. J Therm Anal Calorim. 2022;147:1–19.

Catapano F, et al. Development and experimental testing of an integrated prototype based on stirling, ORC and a latent thermal energy storage system for waste heat recovery in naval application. Appl Energy. 2022;311: 118673.

Zhai H, Shi L, An Q. Influence of working fluid properties on system performance and screen evaluation indicators for geothermal ORC (organic Rankine cycle) system. Energy. 2014;74:2–11.

Rodríguez CEC, et al. Exergetic and economic comparison of ORC and Kalina cycle for low temperature enhanced geothermal system in Brazil. Appl Therm Eng. 2013;52(1):109–19.

Sui H, Wu J, He L, Li X. Conversion of low-grade heat from FCC absorption-stabilization system to electricity by organic Rankine cycles: simulation and optimization. J Eng Thermophys. 2017;26(2):216–33.

Gao H, Liu C, He C, Xu X, Wu S, Li Y. Performance analysis and working fluid selection of a supercritical organic Rankine cycle for low grade waste heat recovery. Energies. 2012;5(9):3233–47.

Yang M-H, Yeh R-H. Economic performances optimization of an organic Rankine cycle system with lower global warming potential working fluids in geothermal application. Renew Energy. 2016;85:1201–13.

Yang M-H, Yeh R-H. Thermodynamic and economic performances optimization of an organic Rankine cycle system utilizing exhaust gas of a large marine diesel engine. Appl Energy. 2015;149:1–12.

Zhang X, et al. Multi-objective optimisation and fast decision-making method for working fluid selection in organic Rankine cycle with low-temperature waste heat source in industry. Energy Convers Manag. 2018;172:200–11.

Feng Y, Hung T, Zhang Y, Li B, Yang J, Shi Y. Performance comparison of low-grade ORCs (organic Rankine cycles) using R245fa, pentane and their mixtures based on the thermoeconomic multi-objective optimization and decision makings. Energy. 2015;93:2018–29.

Yang F, Zhang H, Song S, Bei C, Wang H, Wang E. Thermoeconomic multi-objective optimization of an organic Rankine cycle for exhaust waste heat recovery of a diesel engine. Energy. 2015;93:2208–28.

Özahi E, Tozlu A, Abuşoğlu A. Thermoeconomic multi-objective optimization of an organic Rankine cycle (ORC) adapted to an existing solid waste power plant. Energy Convers Manag. 2018;168:308–19.

Asadi M, Deymi-Dashtebayaz M, Amiri-Rad E. Comparing the profitability of waste heat electricity generation of internal combustion engines: an exergoeconomic analysis through optimization of two different organic Rankine cycle scenarios. Appl Therm Eng. 2022;211:118443.

Mago PJ, Chamra LM, Srinivasan K, Somayaji C. An examination of regenerative organic Rankine cycles using dry fluids. Appl Therm Eng. 2008;28(8–9):998–1007.

Pei G, Li J, Ji J. Analysis of low temperature solar thermal electric generation using regenerative organic Rankine cycle. Appl Therm Eng. 2010;30(8–9):998–1004.

Xi H, Li M-J, Xu C, He Y-L. Parametric optimization of regenerative organic Rankine cycle (ORC) for low grade waste heat recovery using genetic algorithm. Energy. 2013;58:473–82.

Li T, Zhu J, Hu K, Kang Z, Zhang W. Implementation of PDORC (parallel double-evaporator organic Rankine cycle) to enhance power output in oilfield. Energy. 2014;68:680–7.

Roy JP, Misra A. Parametric optimization and performance analysis of a regenerative organic Rankine cycle using R-123 for waste heat recovery. Energy. 2012;39(1):227–35.

Karimi S, Mansouri S. A comparative profitability study of geothermal electricity production in developed and developing countries: exergoeconomic analysis and optimization of different ORC configurations. Renew Energy. 2018;115:600–19.

Franco A. Power production from a moderate temperature geothermal resource with regenerative organic Rankine cycles. Energy Sustain Dev. 2011;15(4):411–9.

Wang Z, Hu Y, Xia X, Zuo Q, Zhao B, Li Z. Thermo-economic selection criteria of working fluid used in dual-loop ORC for engine waste heat recovery by multi-objective optimization. Energy. 2020;197: 117053.

Wang SK, Hung TC. Renewable energy from the sea-organic Rankine cycle using ocean thermal energy conversion. In: Proceedings of the international conference on energy and sustainable development: issues and strategies (ESD 2010). 2010. pp. 1–8.

Shu G, Liu L, Tian H, Wei H, Liang Y. Analysis of regenerative dual-loop organic Rankine cycles (DORCs) used in engine waste heat recovery. Energy Convers Manag. 2013;76:234–43.

Yang F, et al. Performance analysis of waste heat recovery with a dual loop organic Rankine cycle (ORC) system for diesel engine under various operating conditions. Energy Convers Manag. 2014;80:243–55.

Li T, Zhang Z, Lu J, Yang J, Hu Y. Two-stage evaporation strategy to improve system performance for organic Rankine cycle. Appl Energy. 2015;150:323–34.

Imran M, Usman M, Park B-S, Lee D-H. Volumetric expanders for low grade heat and waste heat recovery applications. Renew Sustain Energy Rev. 2016;57:1090–109.

Dumont O, Parthoens A, Dickes R, Lemort V. Experimental investigation and optimal performance assessment of four volumetric expanders (scroll, screw, piston and roots) tested in a small-scale organic Rankine cycle system. Energy. 2018;165:1119–27.

Pantaleo AM, et al. Thermoeconomic optimisation of small-scale organic Rankine cycle systems based on screw vs. piston expander maps in waste heat recovery applications. Energy Convers Manag. 2019;200: 112053.

Lemort V, Guillaume L, Legros A, Declaye S, Quoilin S. A comparison of piston, screw and scroll expanders for small scale Rankine cycle systems. 2013.

Qiu G, Liu H, Riffat S. Expanders for micro-CHP systems with organic Rankine cycle. Appl Therm Eng. 2011;31(16):3301–7.

Lemmon, E. Thermophysical properties of fluids, CRC, CRC, CO; 2009. Accessed 20 Aug 2023.

Guillaume L. On the design of waste heat recovery organic Rankine cycle systems for engines of long-haul trucks. Liège: Université de Liège; 2017.

Tayyeban E, Deymi-Dashtebayaz M, Gholizadeh M. Investigation of a new heat recovery system for simultaneously producing power, cooling and distillate water. Energy. 2021;229:120775.

Li T, Wang Q, Zhu J, Hu K, Fu W. Thermodynamic optimization of organic Rankine cycle using two-stage evaporation. Renew Energy. 2015;75:654–64.

Baccioli A, Antonelli M, Desideri U. Technical and economic analysis of organic flash regenerative cycles (OFRCs) for low temperature waste heat recovery. Appl Energy. 2017;199:69–87.

Deymi-Dashtebayaz M, Tayyeban E. Multi objective optimization of using the surplus low pressure steam from natural gas refinery in the thermal desalination process. J Clean Prod. 2019;238: 117945.

Shah RK, Sekulic DP. Fundamentals of heat exchanger design. Hoboken: Wiley; 2003.

Bergman TL, Incropera FP, DeWitt DP, Lavine AS. Fundamentals of heat and mass transfer. Hoboken: Wiley; 2011.

Barros JJC, Coira ML, de la Cruz López MP, del Caño Gochi A. Sustainability optimisation of shell and tube heat exchanger, using a new integrated methodology. J Clean Prod. 2018;200:552–67.

Caputo AC, Pelagagge PM, Salini P. Heat exchanger design based on economic optimisation. Appl Therm Eng. 2008;28(10):1151–9.

Sinnott R. Chemical engineering design, vol. 6. Amsterdam: Elsevier; 2014.

Kern DQ. Process heat transfer. New York: Tata McGraw-Hill Education; 1997.

Deymi-Dashtebayaz M, Sulin A, Ryabova T, Sankina Y, Farahnak LM, Nazeri R. Energy, exergoeconomic and environmental optimization of a cascade refrigeration system using different low GWP refrigerants. J Environ Chem Eng. 2021;9:106473.

Kowsari S, Deymi-Dashtebayaz M, Karbasi K, Sheikhani H. Optimal working conditions of various city gate stations for power and hydrogen productio based on energy and eco-exergy analysis. Int J of Hydrogen Energy. 2020;45(43):22513–33.

Turton R, Bailie RC, Whiting WB, Shaeiwitz JA. Analysis, synthesis and design of chemical processes. London: Pearson Education; 2008.

Bowman RA, Mueller AC, Nagle WM. Mean temperature difference in design. Trans ASME. 1940;62(4):283–94.

Ghorbani S, Khoshgoftar-Manesh MH, Nourpour M, Blanco-Marigorta AM. Exergoeconomic and exergoenvironmental analyses of an integrated SOFC–GT–ORC hybrid system. Energy. 2020;206: 118151.

Norani M, Deymi-Dashtebayaz M. Energy, exergy and exergoeconomic optimization of a proposed CCHP configuration under two different operating scenarios in a data center: case study. J Clean Prod. 2022;342: 130971.

Kheiri A, Feidt M, Pelloux-Prayer S. Thermodynamic and economic optimizations of a waste heat to power plant driven by a subcritical ORC (organic Rankine cycle) using pure or zeotropic working fluid. Energy. 2014;78:622–38.

Seider WD, Seader JD, Lewin DR. Product and process design principles: synthesis, analysis and evaluation, (with CD). Hoboken: Wiley; 2009.

Kost C, et al. Levelized cost of electricity renewable energy technologies. Fraunhofer Inst Sol Energy Syst ISE. 2013;144:1.

Mainali B, Silveira S. Alternative pathways for providing access to electricity in developing countries. Renew energy. 2013;57:299–310.

Kiani-Moghaddam M, Shivaie M, Weinsier PD. Introduction to multi-objective optimization and decision-making analysis. In: Kiani-Moghaddam M, Shivaie M, Weinsier PD, editors. Modern music-inspired optimization algorithms for electric power systems. Cham: Springer; 2019. p. 21–45.

Kiani-Moghaddam M, Shivaie M, Weinsier PD. Introduction to multi-objective optimization and decision-making analysis. In: Kiani-Moghaddam M, Shivaie M, Weinsier PD, editors. Modern music-inspired optimization algorithms for electric power systems. Cham: Springer; 2019. p. 3–20.

Zhang X, Xu Z. Extension of TOPSIS to multiple criteria decision making with Pythagorean fuzzy sets. Int J Intell Syst. 2014;29(12):1061–78.

Mardani A, Jusoh A, Zavadskas EK. Fuzzy multiple criteria decision-making techniques and applications–two decades review from 1994 to 2014. Expert Syst Appl. 2015;42(8):4126–48.

Kiani-Moghaddam M, Shivaie M, Weinsier PD. Modern music-inspired optimization algorithms for electric power systems. Cham: Springer; 2019.

Saghlatoun S, Zhuge W, Zhang Y. Review of expander selection for small-scale organic Rankine cycle. In: Fluids engineering division summer meeting. vol. 46223; 2019, pp. V01BT10A041.

Bao J, Zhao L. A review of working fluid and expander selections for organic Rankine cycle. Renew Sustain energy Rev. 2013;24:325–42.

Oudkerk J-F, Lemort V. Detailed experimental and model-based analysis of a swash-plate piston expander for ORC application. Front Energy Res. 2020;8:107.

Clemente S, Micheli D, Reini M, Taccani R. Energy efficiency analysis of organic Rankine cycles with scroll expanders for cogenerative applications. Appl Energy. 2012;97:792–801.

Krishna Avadhanula V, Lin C-S. Empirical models for a screw expander based on experimental data from organic Rankine cycle system testing. J Eng Gas Turbines Power. 2014. https://doi.org/10.1115/1.4026303.

Bekiloğlu HE, Bedir H, Anlaş G. Multi-objective optimization of ORC parameters and selection of working fluid using preliminary radial inflow turbine design. Energy Convers Manag. 2019;183:833–47.

Wang S, Liu C, Zhang S, Li Q, Huo E. Multi-objective optimization and fluid selection of organic Rankine cycle (ORC) system based on economic-environmental-sustainable analysis. Energy Convers Manag. 2022;254: 115238.

Kosmadakis G, Manolakos D, Kyritsis S, Papadakis G. Economic assessment of a two-stage solar organic Rankine cycle for reverse osmosis desalination. Renew Energy. 2009;34(6):1579–86.

Kosmadakis G, Manolakos D, Kyritsis S, Papadakis G. Simulation of an autonomous, two-stage solar organic Rankine cycle system for reverse osmosis desalination. Desalin Water Treat. 2009;1(1–3):114–27.

Deymi-Dashtebayaz M, Namanlo SV. Potentiometric and economic analysis of using air and water-side economizers for data center cooling based on various weather conditions. Int J Refrig. 2019;99:213–25.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Asadi, M., Deymi-Dashtebayaz, M. Comparative study and multi-objective optimization of the use of volumetric expanders in a series double cascade-evaporator organic Rankine cycle. J Therm Anal Calorim 148, 11103–11130 (2023). https://doi.org/10.1007/s10973-023-12407-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12407-7