Abstract

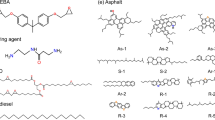

Epoxy asphalt has emerged as a high-performance pavement material. However, research on its curing mechanism and kinetics remains limited. This study aimed to investigate the kinetic equation of the epoxy asphalt curing system using non-isothermal differential scanning calorimetry for better understanding and prediction of the curing reaction. The results revealed that the epoxy asphalt system in this study is autocatalytic, with the conversion rate increasing as the heating rate rises. Additionally, this research employed Density Function Theory to simulate the surface electrostatic potential distribution of the curing agent and epoxy resin in epoxy asphalt. This approach identified potential active sites for chemical reactions, confirming the likelihood of a cross-linking reaction between carbon–carbon double bonds in the oleylamine curing agent. This cross-linking reaction contributes to the formation of a network structure in the cured epoxy resin system, resulting in superior mechanical properties for the cured epoxy asphalt. The study utilized transition state theory to simulate the ring-opening reaction between the primary amine group in oleylamine and epoxy resin. Finally, the above conclusions were verified using in situ infrared spectroscopy, and the microstructure of the epoxy asphalt at different curing times was observed using in situ fluorescence microscopy. In conclusion, this research provides valuable insights into the curing mechanism and kinetics of epoxy asphalt, offering guidance for future applications and development in the field of pavement materials.

Similar content being viewed by others

Data availability

All data to reproduce the findings in this study will be available upon request to the corresponding author.

References

Sha A, Liu Z, Jiang W, Qi L, Hu L, Jiao W, et al. Advances and development trends in eco-friendly pavements. J Road Eng. 2021;1:1–42.

Yousefi A, Behnood A, Nowruzi A, Haghshenas H. Performance evaluation of asphalt mixtures containing warm mix asphalt (WMA) additives and reclaimed asphalt pavement (RAP). Constr Build Mater. 2021;268: 121200.

Xie H, Li C, Wang Q. A critical review on performance and phase separation of thermosetting epoxy asphalt binders and bond coats. Constr Build Mater. 2022;326: 126792.

Yi X, Chen H, Wang H, Shi C, Yang J. The feasibility of using epoxy asphalt to recycle a mixture containing 100% reclaimed asphalt pavement (RAP). Constr Build Mater. 2022;319: 126122.

Li C, Gong J, Zhao R, Xi Z, Wang Q, Xie H. Laboratory performance of recycled polyethylene modified epoxy asphalt binders. Int J Pavement Eng. 2022. https://doi.org/10.1080/10298436.2022.2101055.

Zhang F, Zhang L, Muhammad Y, Cai Z, Guo X, Guo Y, et al. Study on preparation and properties of new thermosetting epoxy asphalt. Constr Build Mater. 2021;311: 125307. https://doi.org/10.1016/j.conbuildmat.2021.125307.

Chen Y, Hossiney N, Yang X, Wang H, You Z. Application of epoxy-asphalt composite in asphalt paving industry: A review with emphasis on physicochemical properties and pavement performances. Adv Mater Sci Eng. 2021;2021:1–35.

Zhang L, Zhang F, Huang K, Zhou S, Guo Y. Preparation and performance of graphene nanoplatelets-modified epoxy asphalt. J Perform Constr Facil. 2021;35(6):04021083.

Min Z, Wang Q, Xie Y, Xie J, Zhang B. Influence of polyethylene glycol (PEG) chain on the performance of epoxy asphalt binder and mixture. Constr Build Mater. 2021;272: 121614.

Huang W, Qian Z, Chen G, Yang J. Epoxy asphalt concrete paving on the deck of long-span steel bridges. Chin Sci Bull. 2003;48(21):2391–4.

Liu X, Zhou C, Cao Q, Chen L, Feng D. Experimental study on properties of epoxy binder and epoxy bonding chips layer for steel bridge deck pavement. Road Mater Pavement Design. 2021;23(11):2451–65.

Yin C, Zhang H, Pan Y. Cracking mechanism and repair techniques of epoxy asphalt on steel bridge deck pavement. Transp Res Rec. 2016;2550(1):123–30.

Huang W, Guo W, Wei Y. Thermal effect on rheological properties of epoxy asphalt mixture and stress prediction for bridge deck paving. J Mater Civ Eng. 2019;31(10):04019222.

Lv Q, Huang M, Huang WD. A conception of application epoxy asphalt mixture on airport pavement. Adv Mater Res. 2014;838:1240–4.

Jamshidi A, White G, Kurumisawa K. Functional and field performance of epoxy asphalt technology–state-of-the-art. Road Mater Pavement Design. 2023;24(4):881–918.

Jamshidi A, White G, Kurumisawa K. Rheological characteristics of epoxy asphalt binders and engineering properties of epoxy asphalt mixtures–state-of-the-art. Road Mater Pavement Design. 2022;23(9):1957–80.

Xin J, Li M, Li R, Wolcott MP, Zhang J. Green epoxy resin system based on lignin and tung oil and its application in epoxy asphalt. ACS Sustain Chem Eng. 2016;4(5):2754–61.

Ding J, Peng W, Luo T, Yu H. Study on the curing reaction kinetics of a novel epoxy system. RSC Adv. 2017;7(12):6981–7.

El Sawi I, Olivier PA, Demont P, Bougherara H. Investigation of the effect of double-walled carbon nanotubes on the curing reaction kinetics and shear flow of an epoxy resin. J Appl Polym Sci. 2012;126(1):358–66.

Xia W, Wang S, Wang H, Xu T. Thermal effects of asphalt SARA fractions, kinetic parameter calculation using isoconversional method and distribution models. J Therm Anal Calorim. 2021;146:1577–92.

Tziamtzi CK, Chrissafis K. Optimization of a commercial epoxy curing cycle via DSC data kinetics modelling and TTT plot construction. Polymer. 2021;230: 124091. https://doi.org/10.1016/j.polymer.2021.124091.

Li H, Wei W, Zhang C, Xu F, Li X, Jing P, et al. Hot mixing behavior and curing process of epoxy asphalt. J Wuhan Univ Technol-Mater Sci Ed. 2020;35(3):605–10.

Xia W, Xu T. Thermal characteristics, kinetic models, and volatile constituents during the energy conversion of bituminous SARA fractions in air. ACS Omega. 2020;5(33):20831–41.

Roşu D, Caşcaval C, Mustątǎ F, Ciobanu C. Cure kinetics of epoxy resins studied by non-isothermal DSC data. Thermochim Acta. 2002;383(1–2):119–27.

Li B, Chen G, Zhang H, Sheng C. Development of non-isothermal TGA–DSC for kinetics analysis of low temperature coal oxidation prior to ignition. Fuel. 2014;118:385–91.

Sun H, Liu Y, Wang Y, Tan H. Curing behavior of epoxy resins in two-stage curing process by non-isothermal differential scanning calorimetry kinetics method. J Appl Polym Sci. 2014. https://doi.org/10.1002/app.40711.

Hardis R, Jessop JLP, Peters FE, Kessler MR. Cure kinetics characterization and monitoring of an epoxy resin using DSC, Raman spectroscopy, and DEA. Compos A Appl Sci Manuf. 2013;49:100–8. https://doi.org/10.1016/j.compositesa.2013.01.021.

Domínguez JC, Grivel JC, Madsen B. Study on the non-isothermal curing kinetics of a polyfurfuryl alcohol bioresin by DSC using different amounts of catalyst. Thermochim Acta. 2012;529:29–35. https://doi.org/10.1016/j.tca.2011.11.018.

Spackman MA, McKinnon JJ, Jayatilaka D. Electrostatic potentials mapped on Hirshfeld surfaces provide direct insight into intermolecular interactions in crystals. Cryst Eng Comm. 2008;10(4):377–88.

Yin H, Jin H, Wang C, Sun Y, Yuan Z, Xie H, et al. Thermal, damping, and mechanical properties of thermosetting epoxy-modified asphalts. J Therm Anal Calorim. 2014;115(2):1073–80.

Frisch M, Trucks G, Schlegel H, Scuseria G, Robb M, Cheeseman J et al. Gaussian 09, Revis. B. 01, Gaussian. Inc, Wallingford CT. 2009:1–20.

Lu T, Chen F. Multiwfn: a multifunctional wavefunction analyzer. J Comput Chem. 2012;33(5):580–92.

Humphrey W, Dalke A, Schulten K. VMD: visual molecular dynamics. J Mol Graph. 1996;14(1):33–8.

Wang K, Yuan Y, Han S, Yang H. Application of attenuated total reflectance Fourier transform infrared (ATR-FTIR) and principal component analysis (PCA) for quick identifying of the bitumen produced by different manufacturers. Road Mater Pavement Design. 2018;19(8):1940–9.

Tang W, Liu Y, Zhang H, Wang C. New approximate formula for Arrhenius temperature integral. Thermochim Acta. 2003;408(1–2):39–43.

Acknowledgements

The authors express their gratitude for the support from National Natural Science Foundation of China (52078241) (Research on the Interfacial Microstructure and Bonding Failure Mechanism of Cement-asphalt Composite, the National Natural Science Foundation of China (51778142), CCCC Highway Consultants Co., Ltd. (H202010511) (Research on Key Technologies of Advanced Nano Modified Epoxy Asphalt and Its Pavement Performance).

Author information

Authors and Affiliations

Contributions

FZ and XG contributed to conceptualization, methodology, and writing—original draft. ZC contributed to writing—review and editing. LZ contributed to writing—review and editing. KH contributed to writing—review and editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, F., Zhang, L., Guo, X. et al. Study on curing kinetics of epoxy system and DFT simulation. J Therm Anal Calorim 148, 11069–11079 (2023). https://doi.org/10.1007/s10973-023-12401-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12401-z