Abstract

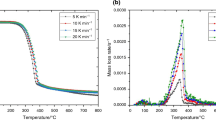

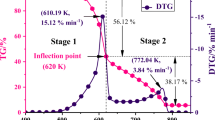

The combustion of wood materials is a complicated process involving multi-physics field coupling heat and mass transfer, with numerous intermediate volatiles from intricate sub-reactions. Both experimental and theoretical aspects of wood sample combustion were investigated in this work. Thermogravimetric analysis (TGA) experiments for Chinese fir wood sample with three different heating rates in a nitrogen atmosphere were carried out. The activation energies were calculated and analyzed. Additionally, bench-scale combustion experiments under the external radiation were conducted using a cone calorimeter. By incorporating appropriate assumptions and simplifying the complicated process, a one-dimension numerical model was developed to explore the micro-scale degradation kinetics and bench-scale combustion characteristics. A multi-scale comprehensive model addressing the pyrolysis and combustion processes was constructed in this study. Utilizing the thermophysical and kinetic parameters derived from the TGA test by employing a multi-parameter optimization algorithm, the combustion process, including variations in mass-loss rate (MLR) and heat release rate (HRR), was simulated. The model demonstrated strong predictive performance in MLR and HRR compared to the experimental data from bench-scale combustion. This research has implications for understanding solid fuel combustion mechanism and simulations.

Similar content being viewed by others

References

Liu H, Li M, Zhao SN, et al. Insights into wood species and aging effects on pyrolysis characteristics and combustion model by multi kinetics methods and model constructions. Renew Energy. 2023;206:784–94.

Li M, Jiang L, Xiao HH, et al. Experimental and theoretical study on horizontal flame spread through arrays of wooden dowels. Fire Mater. 2023;47(2):199–210.

Gašparovič L, Koreňová Z, Jelemenský Ľ. Kinetic study of wood chips decomposition by TGA. Chem Pap. 2010;64(2):174–81.

Liu Q, Zhong Z, Wang S, et al. Interactions of biomass components during pyrolysis: a TG-FTIR study. J Anal Appl Pyrolysis. 2011;90(2):213–8.

Wang S, Guo X, Wang K, et al. Influence of the interaction of components on the pyrolysis behavior of biomass. J Anal Appl Pyrolysis. 2011;91(1):183–9.

Yang H, Yan R, Chen H, et al. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel. 2007;86(12–13):1781–8.

Spearpoint MJ, Quintiere JG. Predicting the piloted ignition of wood in the cone calorimeter using an integral model—effect of species, grain orientation and heat flux. Fire Saf J. 2001;36(4):391–415.

Delichatsios M, Paroz B, Bhargava A. Flammability properties for charring materials. Fire Saf J. 2003;38(3):219–28.

Xu Q, Chen L, Harries KA, et al. Combustion and charring properties of five common constructional wood species from cone calorimeter tests. Constr Build Mater. 2015;96:416–27.

Chung YJ. Comparison of combustion properties of native wood species used for fire pots in Korea. J Ind Eng Chem. 2010;16(1):15–9.

Grexa O, Lübke H. Flammability parameters of wood tested on a cone calorimeter. Polym Degrad Stabill. 2001;74(3):427–32.

Tran HC, White RH. Burning rate of solid wood measured in a heat release rate calorimeter. Fire Mater. 1992;16(4):197–206.

Tsantaridis LD, Östman BAL. Charring of protected wood studs. Fire Mater. 1998;22(2):55–60.

Babrauskas V. Charring rate of wood as a tool for fire investigations. Fire Saf J. 2005;40(6):528–54.

ISO 5660–1:2002. Reaction-to-fire tests—heat release, smoke production and mass loss rate—Part 1: Heat release rate (cone calorimeter method). International Organization for Standardization; Geneva, Switzerland.

Xiao R, Yang W, Cong X, et al. Thermogravimetric analysis and reaction kinetics of lignocellulosic biomass pyrolysis. Energy. 2020;201:117537.

Ankona E, Multanen V, Nisnevitch M, et al. Investigation of pyrolysis kinetics and gaseous compounds emitted during charcoal production from woods commonly used in the Eastern Mediterranean. Biofuel Bioprod Bior. 2021;15(3):646–56.

Zhou A, Tam L-h, Yu Z, et al. Effect of moisture on the mechanical properties of CFRP–wood composite: an experimental and atomistic investigation. Compos Part B Eng. 2015;71:63–73.

Tam L-h, Zhou A, Yu Z, et al. Understanding the effect of temperature on the interfacial behavior of CFRP-wood composite via molecular dynamics simulations. Compos Part B-Eng. 2017;109:227–37.

Li M, Liu L, Jiang L, et al. Application of distributed activation energy models to polymer pyrolysis: effects of distributed model selection, characteristics, validation, and sensitivity analysis. Fuel. 2019;254:115594.

Stoliarov SI, Crowley S, Walters RN, et al. Prediction of the burning rates of charring polymers. Combust Flame. 2010;157(11):2024–34.

Acknowledgements

The authors would like to thank the National Key Research and Development (R&D) Plan of China under Grant No. 2020YFC1522800, the National Natural Science Foundation of China (NSFC, Grants 52176114 and 52111530091), and the Jiangsu Funding Program for Excellent Postdoctoral Talent.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, M., Zhang, D. & Jiang, L. Development of multi-scale pyrolysis and combustion model for fir wood. J Therm Anal Calorim 148, 10549–10555 (2023). https://doi.org/10.1007/s10973-023-12379-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12379-8