Abstract

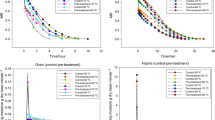

The study aims to determine the effect of pre-treatment applications and optimum drying condition in a hybrid microwave dryer at 350 W + 50 °C, 350 W + 60 °C and 350 W + 70 °C. In terms of color values, the closest value to fresh was found in samples soaked in citric acid pre-treatment at 60 °C. The highest effective diffusivity value was determined in citric acid pre-treated lemon samples at a drying temperature of 70 °C. The highest activation energy was determined in the lemon juice pre-treated samples. The highest specific moisture removal rate (SMER) and lowest specific energy consumption values were determined in natural lemon pre-treatment at 50 °C. The enthalpy values of the lemon juice pre-treatment carried out at 50 °C drying temperature were higher than the other methods. The entropy and Gibbs Free energy values were lower. Considering the energy efficiency values, the method with the highest energy efficiency was determined in the pre-treatment of lemon juice. The highest thermal conductivity and thermal diffusion of the dried samples were determined in the samples immersed in 70 °C citric acid mixture. The highest density values has determined in the samples immersed in 70 °C natural lemon juice. The lowest specific heat was determined at 50 °C drying temperature in the samples with citric acid pre-treatment. Considering all drying processes and pre-treatment applications, it was determined that citric acid pre-treatment increased the evaporation energies of the samples. Drying data was best estimated with the Midilli–Küçük model (R2: 0.9998).

Similar content being viewed by others

Abbreviations

- DS:

-

Dry speed = g moisture g dry base−1

- MR:

-

Moisture ratio

- C:

-

Croma

- WI:

-

Whiteness index

- YI:

-

Yellownes index

- SMER:

-

Specific moisture extraction rate

- SEC:

-

Specific energy consumption

- W:

-

Watt

- Nk.b :

-

Moisture content relative to dry base = g moisture g dry base−1

- Deff :

-

Effective diffusion value = m2 s−1

- Mi :

-

İNitial mass

- Ml :

-

Last mass

- Mt :

-

İNstant moisture content = g moisture g dry base−1

- dt:

-

Minute

- M:

-

İNstant moisture content = g moisture g dry base−1

- Me :

-

Equilibrium moisture content = g moisture g dry base−1

- Mo :

-

Initial moisture content = g moisture g dry base−1

- k, h, j, m:

-

Constant coefficient

- t:

-

Represents the time

- L:

-

Thickness value (m) of the product

- L*:

-

Brightness

- a*:

-

Redness

- b*:

-

Yellowness

- Et :

-

Total energy consumption

- mw :

-

Amount of removed moisture

- Qw :

-

Evaporation energy

- hfg :

-

Evaporation latent energy

- mw :

-

Amount evaporated moisture

- Td :

-

Dry temperature

- ∆H:

-

Entalphy

- Ea :

-

Activation energy

- ln kB:

-

Bolztman constant

- ln hP :

-

Planck constant

- ∆S:

-

Entrophy

- ∆G:

-

Gibbs free energy

- Wx :

-

Uncertainty analysis

References

Aguilar-Hernández MG, Núñez-Gómez D, Forner-Giner MÁ, Hernández F, Pastor-Pérez JJ, Legua P. Quality parameters of Spanish lemons with commercial interest. Foods. 2021;10(62):13–21.

Akpınar-Kavak E, Bicer Y, Çetinkaya F. Modelling of thin layer drying of parsley leaves in a convective dryer and under the open sun. J Food Eng. 2005;75(3):315–308.

Alemrajabi AA, Rezaee F, Mirhosseini M, Esehaghbeygi A. Comparative evaluation of the effects of the electrohydrodynamic, oven, and ambient air on carrot cylindrical slices during the drying process. Dry Technol. 2012;30:96–88.

Alkaç SP, Boran K, Aktaş M, Tokdemir M. Experimental analysis of sliced lemon drying in infrared dryer which is supported with heat pump. Gazi J Eng Sci. 2019;5(2):137–128.

Beigi M. Energy efficiency and moisture diffusivity of apple slices during convective drying. Food Sci Technol. 2016;6(1):154–150.

Boateng ID, Yang XM. Effect of differentdrying methods on productquality, bioactive and toxiccomponents of Ginkgobiloba L. seed. J Sci Food Agri. 2020;101:3297–3290.

Corzo O, Bracho N, Alvarez C. Water effective diffusion coefficient of mango slices at different maturity stages during air drying. J Food Eng. 2008;87(4):484–479.

Ghanem N, Mihoubi D, Bonazzi C, Kechaou N, Boudhrioua N. Drying characteristics of lemon by-product (Citrus limon. v. lunari): effects of drying modes on quality attributes kinetics. Waste Biomass Valoriz. 2020;11:322–303.

Güler P, Doğan İ. Comparıson of ohmıc and conventıonal blanchıng pre-treatments for convectıve dryıng of lemon. KSU J Eng Sci. 2022;25(1):26–17.

Horuz E, Bozkurt H, Karataş H, Maskan M. Simultaneous application of microwave energy and hot air to whole drying process of apple slices: drying kinetics, modeling, temperature profile and energy aspect. Heat Mass Transf. 2018;54:436–425.

Hsu CL, Chen W, Weng YM, Tseng CY. Chemical composition, physical properties, and antioxidant activities of yam flours as affected by different drying methods. Food Chem. 2003;83(1):92–85.

Huang SR, Yang JI, Lee YC. Interactions of heat and mass transfer in steam reheating of starchy foods. J Food Eng. 2013;114:174–82.

Jideani VA, Mpotokwana SM. Modeling of water absorption of Botswana bambara varieties using Peleg’s equation. J Food Eng. 2009;92(2):188–182.

Kumar C, Millar GJ, Karim MA. Effective diffusion and evaporative cooling in convective drying of food material. Dry Technol. 2015;33(2):237–227.

Lewicki PP, Das-Gupta DK. Osmotic dehydration of fruits and vegetables in hand book of industrial drying, vol. 1, 2nd Edition, Mujumdar, Marcel Dekker, AS, editors. New York. 1995, pp. 713–691.

Midilli A, Küçük H, Yapar Z. A new model for single-layer drying. Dry Technol. 2002;20(7):1513–1503.

Moffat RJ. Describing the uncertainties in experimental results. Exp Therm Fluid Sci. 1988;1(1):17–23.

Morais RMSC, Morais AMMB, Dammak I, Bonilla J, Sobral PJA, Laguerre JC, Afonso MJ, Ramalhosa ECD. Functional dehydrated foods for health preservation. J. Food Qual. 2018; 29–1. https://doi.org/10.1155/2018/1739636

Motevali A, Abbaszadeh A, Minaei S, Khoshtaghaza MH, Ghobadian B. Effective moisture diffusivity, activation energy and energy consumption in thin-layer drying of jujube (Zizyphus jujube Mill). J Agric Sci Technol. 2012;14(3):532–523.

Mujumdar AS, Law CL. Drying technology: trends and applications in postharvest processing. Food Bioprocess Technol. 2010;3:852–843.

Page G. Factors influencing the maximum rates of air drying shelled corn in thin layer. Master’s Thesis, İnstitute of science, Purdue University, West Lafayette, IN, USA. 1949; 65–1.

Pathare PB, Opara UL, Al-Said FA. Colour measurement and analysis in fresh and processed foods: a review. Food Bioprocess Technol. 2013;6:60–36.

Perusello C, Cocco V, Masson M, De-Castilhos F. Determination of thermophysical properties of yacon (Smallanthus sonchifolius) to be used in a finite element simulation. Int J Heat Mass Transf. 2013;67:1163–9.

Pixton SW, Warburton S. Determination of moisture content and equilibrium relative humidity of dried fruit-Sultanas. J Stored Prod Res. 1973;8(4):270–263.

Plou E, Lopez-Malo A, Barbosa-Canovas GV, Welti-Chanes J, Swanson BG. Polyphenoloxidase activitiy and color of blanced and high hydrostatic pressure treated banana puree. J Food Sci. 1999;64:45–42.

Purohit P, Kumar A, Kandpal TC. Solar drying vs. open sun drying: a frame work for financial evaluation. Sol Energy. 2006;80(12):1579–1568.

Ramallo LA, Mascheroni RH. Quality evoluation of pineapple fruit during drying process. Food Bioprod Process. 2012;99:283–275.

Rhim JW, Wu Y, Weller CL, Schnepf M. Physical characteristics of a composite film of soy protein ısolate and propyleneglycol alginate. J Food Sci. 1999;64(1):152–149.

Ruiz-Lopez II, Rodriquez-Jimenes GC, Garcia-Alvarado MA. Moisture and temperature evolution during food drying: effect of variable properties. J Food Eng. 2014;63(1):117–24.

Sadeghi M, Kesbi OM, Mireei SA. Mass transfer characteristics during convective, microwave and combined microwave convective drying of lemon slices. J Sci Food Agric. 2013;93:478–471.

Salim NSM, Gariepy Y, Raghavan V. Hot air drying and microwave-assisted hot air drying of broccoli stalk slices (Brassica oleracea L. Var. Italica). J Food Proces Preserv. 2017;41(3):9–1.

Sharma A, Chen CR, Lan NV. Solar-energy dryingsystems: a review. Renew Sustain Energy Rev. 2009;13(6–7):1210–1185.

Silva AF, Monteiro M, Resende D, Braga SS, Coimbra MA, Silva AM, Cardoso SM. Inclusion complex of resveratrol with γ-Cyclodextrin as a functional ingredient for lemon juices. Foods. 2020;10(16):13–21.

Soomro AH, Miano TF, Marri A, Kumar D, Khaskheli SG, Arain UF, Baloch AB. Application of pre-treatments on banana slices for improving drying characteristics. Food Sci Qual. 2020;103:41–35.

Surendhar A, Sivasubramanian V, Vidhyeswari D, Deepanraj B. Energy and exergy analysis, drying kinetics, modeling and quality parameters of microwave-dried turmeric slices. J Therm Anal Calorim. 2019;136:197–185.

Tan M, Chua KJ, Mujumdar AS, Chou SK. Effect of osmotic pre-treatment and infrared radiation on drying rate and color changes during drying of potato and pineapple. Dry Technol. 2001;19(9):2207–2193.

Taşkın O, İzli G, İzli N. Physico chemical and morphological properties of European cranberrybush powder manufactured by freeze drying. Int J Fruit Sci. 2021;21(1):1017–1008.

Taşova M, Polatcı H, Gökdoğan O. Effect of osmotic dehydration pre-treatments on physicochemical and energy parameters of Kosia (Nashi) pear slices dried in a convective oven. J Food Process Preserv. 2022;46:e16945.

Taşova M, Polatcı H. Effects on drying models, effective diffusion and thermo-physical properties for chili (Capsicum annuum) pepper of microwave and hot water pretreatments. J Agric Mach Sci. 2021;17(3):86–93.

Taşova M, Polatcı H. Effects on drying models, effective diffusion and thermo-physical properties for chili (Capsicum annuum) pepper of microwave and hot water pretreatments. J Agric Machi Sci. 2011;17(3):86–93.

Torki-Harchegani M, Ghanbarian D, Pirbalouti AG, Sadeghi M. Dehydration behaviour, mathematical modelling, energy efficiency and essential oil yield of peppermint leaves undergoing microwave and hot air treatments. Renew Sustain Energy Rev. 2016;58:418–407.

Tzempelikos DA, Mitrakos D, Vouros AP, Bardakas AV, Filios AE, Margaris DP. Numerical modeling of heat and mass transfer during convective drying of cylindrical quince slices. J Food Eng. 2015;156:10–21.

Wang J, Law CL, Nema PK, Zhao J, Liu Z, Deng L, Xiao H. Pulsed vacuum drying enhances drying kinetics and quality of lemon slices. J Food Eng. 2018;224:129–38.

Yagua CV, Moreira RG. Physical and thermal properties of potato chips during vacuum frying. J Food Eng. 2011;104(2):283–272.

Yağcıoglu A. Agricultural products drying technique. Ege University Faculty of Agriculture Publications. No: 536. Bornova, İzmir (1999).

Yan JK, Wu LX, Qiao ZR, Cai WD, Ma HL. Effect of different drying methods on the product quality and bioactive polysaccharides of bitter gourd (Momordicacharantia L.) slices. Food Chem. 2019;271:596–588.

Yoğurtçu H. Lemon drying in microwave oven: kinetics and modeling. Fırat Univ. J Eng. 2014;26(1):27–33.

Zhang P, Zhou Z. Postharvest ethephon degreening improves fruit color, flavor quality and increases antioxidant capacity in ‘Eureka’ lemon (Citrus Limon (L.) Burm. F.). Sci Hortic. 2019;248:80–70.

Karel M, Saguy I. Effects of water on diffusion in foodsystems. In: Levine H, Slade L, editors. Water relationships in foods. Berlin: Springer; 1991. p. 157–73.

Polatçı H, Taşova M, Ergüneş G, Kırmık G. Drying of mahaleb (Prunus mahaleb) fruit drying kinetics and color change. Akademik Ziraat Dergisi. 2020;9(1):23–32. https://doi.org/10.29278/azd.608757.

Kılıç F, Tabanlıgil-Calam T. Determination of drying and rehydration kinetics of red capia pepper (Capsicum annuum L.), energy analysis of drying process. DEÜ FMD. 2020;22(65):331–42.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aksüt, B., Polatcı, H. & Taşova, M. The effect of pre-treatment and drying temperatures on energy consumption and quality characteristics in drying of lemon (Citrus limon L.) slices. J Therm Anal Calorim 148, 10415–10427 (2023). https://doi.org/10.1007/s10973-023-12362-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12362-3