Abstract

Experimental setup has been designed and tested for local heat transfer performance of mPCM slurry flow inside the microchannels under convective boundary condition following unique inverse method. The heat transfer data were collected at ninety-eight precise locations along the flow direction of mPCM slurry inside six microchannels. The experimental setup was validated for both pure water and mPCM slurry with available published literature and found to be in good agreement. The experiments were conducted with mPCM slurry for 5–10% mass concentration and laminar regime (Re = 200–1700) and compared with pure water under the same operating conditions. The effect of mass concentration on the local Nusselt number, average Nusselt number (Nuavg), pressure drop, Stefan number and bulk fluid temperature difference was investigated. The average Nu was enhanced by 12.1% and 28.3% than pure water for mass concentration of 5% and 10% mPCM slurry, respectively. Moreover, a correlation was developed to predict the average Nusselt number in laminar regime for convective boundary condition. The developed correlation predicted experimental data of this study within ± 15%.

Similar content being viewed by others

Abbreviations

- \(A_{{\text{c}}}\) :

-

Cross-sectional area of microchannel

- a :

-

Short side of rectangular cross-section

- b :

-

Long side of rectangular cross-section

- c :

-

Mass concentration of mPCM slurry, %

- C :

-

Specific heat capacity, J kg−1 K−1

- D :

-

Diameter of microchannel

- D h :

-

Hydraulic diameter of microchannel

- h :

-

Heat transfer coefficient

- \(h_{{{\text{fg}}}}\) :

-

Latent heat of phase change

- k :

-

Thermal conductivity, W m−1 K−1

- L :

-

Length of microchannel

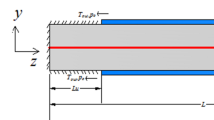

- L u :

-

Length of upstream adiabatic portion

- L d :

-

Length of downstream adiabatic portion

- m :

-

Mass flow rate

- n :

-

Number of microchannels

- \(\Delta P\) :

-

Pressure drop over the length of microchannel

- Q :

-

Heat transfer rate

- T :

-

Temperature, K

- T 1 :

-

Start point at which phase change begins

- T 2 :

-

End point at which phase change completes

- \(\alpha\) :

-

Aspect ratio, b/a

- \(\varphi\) :

-

Volumetric concentration of phase change particles

- \(\rho\) :

-

Density, kg m−3

- \(\mu\) :

-

Dynamic viscosity, kg m−1 s−1

- \(\lambda\) :

-

Heat transfer enhancement (%)

- b :

-

Bulk fluid (mPCM slurry)

- i :

-

Inlet

- o :

-

Outlet

- f :

-

Working fluid

- p :

-

Particles of phase change material

- w :

-

Water

- h :

-

Hot water

- Nu:

-

Nusselt number, hDh/k

- Pr:

-

Prandtl number, \(C_{{\text{b}}} \mu_{{\text{b}}} /k_{{\text{b}}}\)

- Re:

-

Reynolds number, \(\rho_{{\text{b}}} vD_{{\text{h}}} /\mu_{{\text{b}}}\)

- Ste:

-

Stefan number, \(q/mh_{{{\text{fg}}}} - 1\)

References

International Energy Agency, K.e. Statisics, editor. 2020.

Hai T, Sajadi SM, Zain JM, El-Shafay AS, Sharifpur M. The effect of using tubes filled with phase change materials in the air conditioning system of a residential building. J Build Eng. 2022;49: 104079.

Wang T, Wang L, Bai L, Lin G, Bu X, Liu X, Xie G. Experimental study on the performance of a liquid cooling garment with the application of MEPCMS. Energy Convers Manag. 2015;103:943–957.

Abdelrazik AS, Al-Sulaiman FA, Saidur R. Feasibility study for the integration of optical filtration and nano-enhanced phase change materials to the conventional PV-based solar systems. Renew Energy. 2022;187:463–483.

Zhao Y, Zhang X, Xu X, Zhang S. Research progress of phase change cold storage materials used in cold chain transportation and their different cold storage packaging structures. J Mol Liq. 2020;319: 114360.

Shaukat R, Kamran MS, Imran S, Anwar Z, Ali H. Numerical investigation of melting heat transfer during microencapsulated phase change slurry flow in microchannels. J Enhanc Heat Transf. 2019;26(6):551–575.

Kondle S, Alvarado J, Marsh C. Laminar flow forced convection heat transfer behavior of a phase change material fluid in microchannels. J Heat Transf. 2013;135:0528201–052812.

Punniakodi BMS, Shah N, Rathore VK, Senthil R. Numerical study on melting of phase change material in a horizontal container using multi heat transfer tubes. J Taiwan Inst Chem Eng. 2022;131: 104214.

Lai W-C, Cai Y-T, Cai Y-L. Novel green and sustainable shape-stabilized phase change materials for thermal energy storage. J Taiwan Inst Chem Eng. 2020;117:257–264.

Delgado M, Lázaro A, Mazo J, Zalba B. Review on phase change material emulsions and microencapsulated phase change material slurries: materials, heat transfer studies and applications. Renew Sustain Energy Rev. 2012;16(1):253–273.

Zhang P, Ma ZW, Wang RZ. An overview of phase change material slurries: MPCS and CHS. Renew Sustain Energy Rev. 2010;14(2):598–614.

Gudipaty T, Stamm MT, Cheung LSL, Jiang L, Zohar Y. Cluster formation and growth in microchannel flow of dilute particle suspensions. Microfluid Nanofluidics. 2011;10(3):661–669.

Selimefendigil F, Öztop HF. Modeling and identification of combined effects of pulsating inlet temperature and use of hybrid nanofluid on the forced convection in phase change material filled cylinder. J Taiwan Inst Chem Eng. 2021;119:90–107.

Mo S, Ye J, Jia L, Chen Y. Properties and performance of hybrid suspensions of MPCM/nanoparticles for LED thermal management. Energy J. 2022;239: 122650.

Chai L, Shaukat R, Wang L, Wang HS. A review on heat transfer and hydrodynamic characteristics of nano/microencapsulated phase change slurry (N/MPCS) in mini/microchannel heat sinks. Appl Therm Eng. 2018;135:334.

Huang X, Zhu C, Lin Y, Fang G. Thermal properties and applications of microencapsulated PCM for thermal energy storage: a review. Appl Therm Eng. 2019;147:841–855.

Farid MM, Khudhair AM, Razack SAK, Al-Hallaj S. A review on phase change energy storage: materials and applications. Energy Convers Manag. 2004;45(9–10):1597–615.

Zhou D, Zhao CY, Tian Y. Review on thermal energy storage with phase change materials (PCMs) in building applications. Appl Energy. 2012;92:593–605.

Ran F, Chen Y, Cong R, Fang G. Flow and heat transfer characteristics of microencapsulated phase change slurry in thermal energy systems: a review. Renew Sustain Energy Rev. 2020;134: 110101.

Rao Y, Dammel F, Stephan P, Lin G. Convective heat transfer characteristics of microencapsulated phase change material suspensions in minichannels. Int J Heat Mass Transf. 2007;44(2):175–186.

Rao Y, Dammel F, Stephan P, Lin G. An experimental study on heat transfer and pressure loss of microencapsulated phase change material suspension flowing in rectangular minichannels. J Energy. 2013. https://doi.org/10.1016/j.enconman.2018.06.029

Goel M, Roy SK, Sengupta S. Laminar forced convection heat transfer in microcapsulated phase change material suspensions. Int J Heat Mass Transf. 1994;37(4):593–604.

Yamagishi Y, Takeuchi H, Pyatenko AT, Kayukawa N. Characteristics of microencapsulated PCM slurry as a heat-transfer fluid. AichE J. 1999;45(4):696–707.

Choi E, Cho YI, Lorsch HG. Forced convection heat transfer with phase-change-material slurries: turbulent flow in a circular tube. Int J Heat Mass Transf. 1994;37(2):207–215.

Chen M, Wang Y, Liu Z. Experimental study on micro-encapsulated phase change material slurry flowing in straight and wavy microchannels. Appl Therm Eng. 2021;190: 116841.

Inaba H, Kim M-J, Horibe A. Melting heat transfer characteristics of microencapsulated phase change material slurries with plural microcapsules having different diameters. J Heat Transf. 2004;126(4):558–565.

Kong M, Alvarado JL, Terrell W, Thies C. Performance characteristics of microencapsulated phase change material slurry in a helically coiled tube. Int J Heat Mass Transf. 2016;101:901–914.

Ho CJ, Chen W-C, Yan W-M, Amani M. Cooling performance of MEPCM suspensions for heat dissipation intensification in a minichannel heat sink. Int J Heat Mass Transf. 2017;115:43–49.

Ho CJ, Chen W-C, Yan W-M. Correlations of heat transfer effectiveness in a minichannel heat sink with water-based suspensions of Al2O3 nanoparticles and/or MEPCM particles. Int J Heat Mass Transf. 2014;69:293–299.

Roberts NS, Al-Shannaq R, Kurdi J, Al-Muhtaseb SA, Farid MM. Efficacy of using slurry of metal-coated microencapsulated PCM for cooling in a micro-channel heat exchanger. Appl Therm Eng. 2017;122:11–18.

Dai H, Chen W. Numerical investigation of heat transfer in the double-layered minichannel with microencapsulated phase change suspension. Int Commun Heat Mass Transf. 2020;119: 104918.

Seyf HR, Zhou Z, Ma HB, Zhang Y. Three dimensional numerical study of heat-transfer enhancement by nano-encapsulated phase change material slurry in microtube heat sinks with tangential impingement. Int J Heat Mass Transf. 2013;56(1–2):561–573.

Ravi G, Alvarado JL, Marsh C, Kessler DA. Laminar flow forced convection heat transfer behavior of a phase change material fluid in finned tubes. Numer Heat Transf A Appl. 2009;55(8):721–738.

Deng X, Wang S, Wang J, Zhang T. Analytical modeling of microchannel heat sinks using microencapsulated phase change material slurry for chip cooling. Procedia Eng. 2017;205:2704–2711.

Song S, Liao Q, Shen W, Ruan Y, Xu J. Numerical study on laminar convective heat transfer enhancement of microencapsulated phase change material slurry using liquid metal with low melting point as carrying fluid. Int J Heat Mass Transf. 2013;62:286–294.

Huang Y, Xuan Y, Li Q. Experimental investigation on convective heat transfer of magnetic phase change microcapsule suspension. Appl Therm Eng. 2012;47:10–17.

Rajabi Far B, Mohammadian SK, Khanna SK, Zhang Y. Effects of pin tip-clearance on the performance of an enhanced microchannel heat sink with oblique fins and phase change material slurry. Int J Heat Mass Transf. 2015;83:136–145.

Yu GX, Sun J, Wang HS, Wen PH, Rose JW. Meshless inverse method to determine temperature and heat flux at boundaries for 2D steady-state heat conduction problems. Exp Therm Fluid Sci. 2014;52:156–163.

Krishnaswamy S, Wang HS, Rose JW. Condensation from gas–vapour mixtures in small non-circular tubes. Int J Heat Mass Transf. 2006;49(9–10):1731–1737.

Shaukat R. Experimental and numerical study on heat transfer and pressure drop during mPCM slurry flow in microchannels. In: School of engineering and materials sciences. United Kingdom: Queen Mary University of London; 2015.

Shaukat R, Anwar Z, Imran S, Noor F, Qamar A. Numerical study of heat transfer characteristics of mPCM slurry during freezing. Arab J Sci Eng. 2021;46:7977–7988.

Acknowledgements

A PhD studentship by the University of Engineering and Technology, Lahore, Pakistan, EU research grant FP7-2010-IRSES-269205 and EPSRC research grant EP/L001233/1 is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

All authors contributed to the revision and upgrading of the manuscript. RS contributed mainly in the experimentation and data analysis. AQ contributed in the formation of correlation development. ZA contributed in the write up of literature review and reviewing of the graphs and figures. SI contributed in writing and grammatically reviewing the manuscript. MA contributed in the writing of the manuscript. HMA contributed in the reviewing of the manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shaukat, R., Qamar, A., Anwar, Z. et al. Experimental study on heat transfer performance of mPCM slurry flow in microchannels. J Therm Anal Calorim 148, 9829–9841 (2023). https://doi.org/10.1007/s10973-023-12353-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12353-4