Abstract

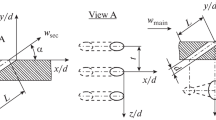

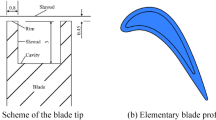

The effect of the curvature of the blade and the existence of pulsation in compressor injection air highlights the importance of pulsating flow analysis on a complete turbine blade. Sinusoidal and square pulsed film cooling on leading-edge (LE), pressure and suction sides (PS and SS) of a complete NASA C3X blade is numerically investigated. The performance of film cooling is studied for five blowing ratios from 0.5 to 2.5 at the frequency of 50 Hz and three of the mainstream Reynolds numbers (Re). The numerical simulations have been performed by the \(SST k{-}\omega\) model. The results showed that film effectiveness is different for the two considered pulse flows. The most value of averaged film effectiveness is obtained on PS, in which its minimum happens at the LE. For the sinusoidal pulse, the average film effectiveness was almost two times more than the square wave. With increasing the blowing ratio, pulsed film cooling effectiveness is reduced at LE and PS but at SS this trend was reversed. The averaged centerline pulsed film effectiveness on the LE and PS at the blowing ratio of 0.5 and for SS at the blowing ratio of 2.5 was maximum. The effect of mainstream Reynolds number variations on pulsed film cooling had the most effect on PS. At LE and SS, at \(Re = 74652\), film effectiveness was the most value while at PS for \(Re = 111978\) the largest effectiveness was obtained.

Similar content being viewed by others

Abbreviations

- D :

-

Hole diameter (m)

- f :

-

Frequency (Hz)

- Gr :

-

Grashof number

- L/D :

-

Length-to-hole diameter ratio

- P :

-

Pressure (Pa)

- PS:

-

Pressure side

- p :

-

Periodicity (s)

- T:

-

Temperature (K)

- t :

-

Time (s)

- x :

-

Stream-wise coordinate (m)

- y :

-

Pitch-wise coordinate (m)

- z :

-

Span-wise coordinate (m)

- u :

-

Velocity \(\left( {ms^{ - 1} } \right)\)

- M :

-

Blowing ratio

- LE:

-

Leading edge

- S :

-

Source term

- SS:

-

Suction side

- K :

-

Thermal conductivity \(\left( {Wm^{ - 1} K^{ - 1} } \right)\)

- \(C_{\text{p}}\) :

-

Specific heat \(\left( {Jkg^{ - 1} K^{ - 1} } \right)\)

- \(C_{\text{ax}}\) :

-

Axial chord length (m)

- Re :

-

Reynolds number

- ɳ :

-

Film cooling effectiveness

- μ :

-

Viscosity (Pa.s)

- ρ :

-

Density \( \left( {kgm^{ - 3} } \right)\)

- ϕ :

-

Phase

- aw :

-

Adiabatic wall index

- f :

-

Cooling flow index

- ins :

-

Instant

- i,j :

-

Index

- m :

-

Mainstream air index

References

Qiu D, Wang C, Luo L, Wang S, Zhao Z, Wang Z. On heat transfer and flow characteristics of jets impinging onto a concave surface with varying jet arrangements. J Therm Anal Calorim. 2020;141(1):57–8. https://doi.org/10.1007/s10973-019-08901-6.

Tian K, Wang J, Liu C, et al. Effect of blockage configuration on film cooling with and without mist injection. Energy. 2018;153:661–70. https://doi.org/10.1016/j.energy.2018.04.050.

Zhou W, Hu H. A novel sand-dune-inspired design for improved film cooling performance. Int J Heat Mass Transf. 2017;110:908–20. https://doi.org/10.1016/j.ijheatmasstransfer.2017.03.091.

Kazemi Kelishami M, Lakzian E. Optimization of the blowing ratio for film cooling on a flat plate. Int J Num Methods Heat Fluid Flow. 2017;27:104–19. https://doi.org/10.1108/HFF-07-2015-0284.

Nemdili F, Azzi A, Jubran BA. Numerical investigation of the influence of hole imperfection on film cooling effectiveness. Int J Num Methods Heat Fluid Flow. 2011;21:46–60. https://doi.org/10.1108/09615531111095067.

Park SH, Kang YJ, Seo HJ, et al. Experimental optimization of a fan-shaped film cooling hole with 30 degrees-injection angle and 6-hole length-to-diameter ratio. Int J Heat Mass Transf. 2019;144:118652. https://doi.org/10.1016/j.ijheatmasstransfer.2019.118652.

Zhou Z, Li H, Wang H, et al. Film cooling of cylindrical holes on turbine blade suction side near leading edge. Int J Heat Mass Transf. 2019;141:669–79. https://doi.org/10.1016/j.ijheatmasstransfer.2019.07.028.

Liu R, Li H, Lin J, You R, Tao Z. An experimental and numerical investigation of film cooling effectiveness on a gas turbine blade tip region. Int J Therm Sci. 2022;177:107544. https://doi.org/10.1016/j.ijthermalsci.2022.107544.

Zhang L, Qian B, Zhang C, Mao J, Fan H. Numerical study on the cooling characteristics of cat-ear-shaped film-cooling holes on turbine blades. Case Stud Therm Eng. 2022;36:102050. https://doi.org/10.1016/j.csite.2022.102050.

Park JS, Lee DH, Rhee DH, et al. Heat transfer and film cooling effectiveness on the squealer tip of a turbine blade. Energy. 2014;72:331–43. https://doi.org/10.1016/j.energy.2014.05.041.

Kukutla PR, Prasad BV, Tarigonda H, Reddy DR. Optimization of film hole row locations of a nozzle guide vane using network approach. J Therm Anal Calorim. 2021;145:2661–74. https://doi.org/10.1007/s10973-020-09841-2.

Zhang SC, Zhang JZ, Yu JJ, Tan XM, Wang LM. Film cooling performance of multi-row casing injection in a turbine-rotor cascade under blade passing. Therm Sci Eng Prog. 2023;16:101672. https://doi.org/10.1016/j.tsep.2023.101672.

Gao WJ, Yue ZF, Li L, et al. Numerical simulation on film cooling with compound angle of blade leading edge model for gas turbine. Int J Heat Mass Transf. 2017;115:839–55. https://doi.org/10.1016/j.ijheatmasstransfer.2017.07.105.

Li HW, Zhang DW, Han F, Guo H, Ding XF. Experimental investigation on the effect of hole diameter on the leading edge region film cooling of a twist turbine blade under rotation conditions. Appl Therm Eng. 2021;184:116386. https://doi.org/10.1016/j.applthermaleng.2020.116386.

Kafaei A, Salmani F, Lakzian E, Wróblewski W, Vlaskin MS, Deng Q. The best angle of hot steam injection holes in the 3D steam turbine blade cascade. Int J Therm Sci. 2022;173:107387. https://doi.org/10.1016/j.ijthermalsci.2021.107387.

Kafaei A, Lakzian E, Ahmadi G, Dykas S. An investigation of finding the best arrangement of hot steam injection holes in the 3D steam turbine blade cascade. J. Therm. Analy, Calori. 2022; 1–18. https://doi.org/10.1007/s10973-022-11242-6

Kukutla PR, Prasad BV. Numerical study on the secondary air performance of the film holes for the combined impingement and film cooled first stage of high pressure gas turbine nozzle guide vane. Int J Turbo Jet-Engines. 2020;37(3):221–40. https://doi.org/10.1515/tjj-2017-0022.

Jung IS, Lee JS, Ligrani PM. Effects of bulk flow pulsations on film cooling with compound angle holes: heat transfer coefficient ratio and heat flux ratio. J Turbomach. 2001;124:142–51. https://doi.org/10.1115/1.1400110.

Liu Y, Luo Y. Transient simulation of pulsed purge film cooling on flow and thermal characteristics of a turbine endwall. Appl Therm Eng. 2019;161:114208. https://doi.org/10.1016/j.applthermaleng.2019.114208.

Rutledge JL, King PI, Rivir RB. Influence of film cooling unsteadiness on turbine blade leading edge heat flux. J Eng Gas Turb Power. 2012;134:071901. https://doi.org/10.1115/1.4005978.

Muldoon F, Acharya S. DNS study of pulsed film cooling for enhanced cooling effectiveness. Int J Heat Mass Transf. 2009;52:3118–27. https://doi.org/10.1016/j.ijheatmasstransfer.2009.01.030.

Hosseini Baghdad Abadi SM, Zirak S, Rajabi Zargar Abadi M. Numerical simulation of the sinusoidal wave pulsed film cooling effectiveness due to the changing cooling injection parameters. Modares Mech Eng. 2019;19(1):191–200.

Hosseini Baghdad Abadi SM, Zirak S, Abadi RZ, M. Effect of pulsating injection and mainstream attack angle on film cooling performance of a gas turbine blade. Physics Fluids. 2020;32:117102. https://doi.org/10.1063/5.002911010.

Zaza G, Hammou AD, Benchatti A, Saiah H. Fault detection method on a compressor rotor using the phase variation of the vibration signal. Int J Eng. 2017;30:1176–81. https://doi.org/10.5829/ije.2017.30.08b.09.

Chekardovskiy MN, Chekardovskiy SM, Razboynikov AA, Ponomareva TG. A frequency model of vibrational processes in gas-turbine drives of compressor stations of main gas pipelines. In IOP Conference Series: Materi Sci Eng. 2016;154:012023. https://doi.org/10.1088/1757-899X/154/1/012023.

Kabral R. Turbocharger aeroacoustics and optimal damping of sound. PhD thesis, KTH Royal Instit. Tech. 2017. https://kth.diva-portal.org/smash/get/diva2:1096314/FULLTEXT01.pdf

Hosseini Baghdad Abadi SM, Zirak S, Rajabi Zargar Abadi M. Effect of pulse injection on film cooling performance: Experimental and numerical investigation. Proceed Inst Mech Eng. Part C: J Mech Eng Sci. 2022;236:5705–18. https://doi.org/10.1177/09544062211061263.

Coulthard SM, Volino RJ, Flack KA. Effect of jet pulsing on film cooling—part I: effectiveness and flow-field temperature results. J Turbomach. 2007;129:232–46. https://doi.org/10.1115/1.2437231.

Coulthard SM, Volino RJ, Flack KA. Effect of jet pulsing on film cooling: part 2—heat transfer results. J Turbomach. 2008;129:247–57. https://doi.org/10.1115/1.2437230.

Mohammadpour J, Zolfagharian MM, Mujumdar AS, et al. Heat transfer under composite arrangement of pulsed and steady turbulent submerged multiple jets impinging on a flat surface. Int J Therm Sci. 2014;86:139–47. https://doi.org/10.1016/j.ijthermalsci.2014.07.004.

Zargarabadi MR, Rezaei E, Yousefi-Lafouraki B. Numerical analysis of turbulent flow and heat transfer of sinusoidal pulsed jet impinging on an asymmetrical concave surface. Appl Therm Eng. 2018;128:578–85. https://doi.org/10.1016/j.applthermaleng.2017.09.059.

Qingzong X, Qiang D, Pei W, et al. Computational study of film cooling and flowfields on a stepped vane endwall with a row of cylindrical hole and interrupted slot injections. Int J Heat Mass Transf. 2019;134:796–806. https://doi.org/10.1016/j.ijheatmasstransfer.2019.01.093.

Chen Z, Zhang Z, Li Y, et al. Vortex dynamics based analysis of internal crossflow effect on film cooling performance. Int J Heat Mass Transf. 2019;145:118757. https://doi.org/10.1016/j.ijheatmasstransfer.2019.118757.

Hosseini Baghdad Abadi SM, Zirak S, Rajabi Zargar Abadi M. Numerical investigation of the effect of pulsed injection on film cooling effectiveness of turbine blade under rotation. Heat Transf Res. 2021;52:63–78. https://doi.org/10.1615/HeatTransRes.2021036404.

Jiang Y, Zheng Q, Yue G, et al. Conjugate heat transfer simulation of turbine blade high efficiency cooling method with mist injection. Proceed Inst Mech Eng, Part C: J Mech Eng Sci. 2014;228:2738–49. https://doi.org/10.1177/0954406214522436.

Menter FR. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994;32:1598–605. https://doi.org/10.2514/3.12149.

Hylton LD, Mihelc MS, Turner ER, et al. (1983) Analytical and experimental evaluation of the heat transfer distribution over the surfaces of turbine vanes. NACA Report, CR-168015.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hosseini, S.M., Zirak, S. & Rajabi Zargarabadi, M. Pulsed film cooling on a complete turbine blade: steady, sinusoidal and square injections. J Therm Anal Calorim 148, 9761–9783 (2023). https://doi.org/10.1007/s10973-023-12322-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12322-x