Abstract

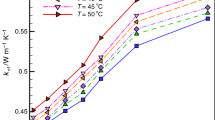

In this study, the thermal behavior of a hybrid nanofluid including nanoparticles of multi-walled carbon nanotube (\(\mathrm{MWCNT}\) ) and \({\mathrm{ZrO}}_{2}\) was discussed. The nanoparticles of \(\mathrm{MWCNT}\) and \({\mathrm{ZrO}}_{2}\) at the mass fraction 40:60 were added to pure water with CMC surfactant to prepare samples at 0.009, 0.018, 0.036, 0.072 and 0.14 vol%. The thermal conductivity of \(\mathrm{MWCNT}-{\mathrm{ZrO}}_{2}/\mathrm{water}\) \(\left( {{\text{k}}_{{{\text{ZrO}}_{2} - {\text{MWCNT}}/{\text{water}}}} } \right)\) was measured at temperature range of 20–50 °C and compared with \({\mathrm{k}}_{\mathrm{water}}\) to investigate the effectiveness of adding \(\mathrm{MWCNT}-{\mathrm{ZrO}}_{2}\) nanoparticles to the base fluid by evaluating the parameter of thermal conductivity ratio \(\left( {{\text{TCR = }}\frac{{{\text{k}}_{{{\text{ZrO}}_{2} - {\text{MWCNT}}/{\text{water}}}} }}{{{\text{k}}_{{{\text{water}}}} }}} \right)\). The results showed that an increase in temperature results in a higher \(\mathrm{TCR}\). The use of \(\mathrm{MWCNT}-{\mathrm{ZrO}}_{2}\) led to an increase in thermal conductivity up to 15.4%. To boost the amount of improvement, the sonication time increased from 30 to 60 min. The best sonication time was 50 min so that \(\mathrm{MWCNT}\) and \({\mathrm{ZrO}}_{2}\) nanoparticles could enhance \({\mathrm{k}}_{\mathrm{water}}\) by 59.6%. To estimate TCR, the response surface methodology was used, which based on linear regression, provides a function consisting of independent variables, and it was found for the best function with an error of less than 1.52% and by providing R2 = 0.998, can estimate TCR very well. Then artificial intelligence was used, and it was determined that the neural network consisting of eight neurons with a maximum error of less than 0.4% could predict TCR.

Similar content being viewed by others

Abbreviations

- ANN:

-

Artificial neural network

- CMC:

-

Carboxy methyl cellulose

- DLS:

-

Dynamic light scattering

- EG:

-

Ethylene glycol

- k:

-

Thermal conductivity \(\left( {{\text{W}}{{{\text m}^{-1} {\text K}^{-1}}}} \right)\)

- MF:

-

Mass fraction

- MOD:

-

Margin of deviation

- MSE:

-

Mean square error

- MWCNT:

-

Multi-walled carbon nanotubes

- RSM:

-

Response surface methodology

- STP*:

-

Sonication time parameter \(\mathrm{STP}=\frac{\mathrm{STP}-30}{60-30}\)

- T:

-

Temperature (℃)

- T∗ :

-

Dimensionless temperature \(\left({\mathrm{T}}^{*}=\frac{T-20}{50-20}\right)\)

- TCR:

-

Thermal conductivity ratio \(\left(\frac{{\mathrm{k}}_{\mathrm{nf}}}{{\mathrm{k}}_{\mathrm{bf}}}\right)\)

- XRD:

-

X-ray diffraction

- ρ:

-

Density \(\left({\mathrm{kg}}{{\mathrm\,{\text{m}}}^{-3}}\right)\)

- \(\Phi\) :

-

Volume fraction

- \(\upmu\) :

-

Viscosity (Pa.s)

- \(\sigma\) :

-

Surface tension \(\left( {{\text{N\,}}{\text{m}^{-1}}} \right)\)

- \(\mathrm{bf}\) :

-

Base fluid

- \(\mathrm{nf}\) :

-

Nanofluid

- \(\mathrm{np}\) :

-

Nanoparticle

References

Mahian O, Bellos E, Markides CN, Taylor RA, Alagumalai A, Yang L, Qin C, Lee BJ, Ahmadi G, Safaei MR, Wongwises S. Recent advances in using nanofluids in renewable energy systems and the environmental implications of their uptake. Nano Energy. 2021;86:106069.

Sangeetha A, Shanmugan S, Alrubaie AJ, Jaber MM, Panchal H, Attia MEH, Elsheikh AH, Mevada D, Essa FA. A review on PCM and nanofluid for various productivity enhancement methods for double slope solar still: future challenge and current water issues. Desalination. 2023;551:116367.

Rashidi S, Eskandarian M, Mahian O, Poncet S. Combination of nanofluid and inserts for heat transfer enhancement. J Therm Anal Calorim. 2019;135(1):437–60.

Rubbi F, Das L, Habib K, Aslfattahi N, Saidur R, Rahman MT. State-of-the-art review on water-based nanofluids for low temperature solar thermal collector application. Sol Energy Mater Sol Cells. 2021;230:111220.

Liu C, Qiao Y, Du P, Zhang J, Zhao J, Liu C, Huo Y, Qi C, Rao Z, Yan Y. Recent advances of nanofluids in micro/nano scale energy transportation. Renew Sustain Energy Rev. 2021;149:111346.

Ren Y, Wang H, Zhang T, Ma L, Ye P, Zhong Y, Hu Y. Designed preparation of CoS/Co/MoC nanoparticles incorporated in N and S dual-doped porous carbon nanofibers for high-performance Zn-air batteries. Chin Chem Lett. 2021;32(7):2243–8.

Mustafa J, Alqaed S, Sharifpur M. Economic and thermo-hydraulic features of multiphase nanofluids in a heat exchanger equipped with novel turbulators: a numerical study. Eng Anal Boundary Elem. 2022;144:55–66.

Cardenas Contreras EM, Bandarra Filho EP. Heat transfer performance of an automotive radiator with MWCNT nanofluid cooling in a high operating temperature range. Appl Therm Eng. 2022;207:118149.

Sepehrnia M, Mohammadzadeh K, Hemmati Rozbahani M, Ghiasi MJ, Amani M. Experimental study, prediction modeling, sensitivity analysis, and optimization of rheological behavior and dynamic viscosity of 5W30 engine oil based SiO2/MWCNT hybrid nanofluid. Ain Shams Eng J. 2023;2023:102257.

Shoeibi S, Rahbar N, Abedini Esfahlani A, Kargarsharifabad H. Improving the thermoelectric solar still performance by using nanofluids– Experimental study, thermodynamic modeling and energy matrices analysis. Sustain Energy Technol Assess. 2021;47:101339.

Mustafa J, Abdullah MM, Ahmad MZ, Husain S, Sharifpur M. Numerical study of two-phase turbulence nanofluid flow in a circular heatsink for cooling LEDs by changing their location and dimensions. Eng Anal Boundary Elem. 2023;149:248–60.

Mustafa J, Alqaed S, Sharifpur M, Alharthi MA. Combined simulation of molecular dynamics and computational fluid dynamics to predict the properties of a nanofluid flowing inside a micro-heatsink by modeling a radiator with holes on its fins. J Mol Liq. 2022;362:119727.

Xu K, Zheng S, Li Y, Chu H, Xiong Q, Mei Z, Zhao Q, Yang L, Li S, Pan F. Constructing low-valent Ni nanoparticles for highly selective CO2 reduction. Chin Chem Lett. 2022;33(1):424–7.

Tian J, Liu D, Li J, Sun D, Liu H, Wang H, Tang Y. Cu/Cu2O nanoparticles co-regulated carbon catalyst for alkaline Al-air batteries. Chin Chem Lett. 2021;32(8):2427–32.

Wang Z, Chen C, Liu H, Hrynshpan D, Savitskaya T, Chen J, Chen J. Enhanced denitrification performance of Alcaligenes sp. TB by Pd stimulating to produce membrane adaptation mechanism coupled with nanoscale zero-valent iron. Sci Total Environ. 2020;708:135063.

Yan S-R, Kalbasi R, Karimipour A, Afrand M. Improving the thermal conductivity of paraffin by incorporating MWCNTs nanoparticles. J Therm Anal Calorim. 2020;145:2809–16.

Boroomandpour A, Toghraie D, Hashemian M. A comprehensive experimental investigation of thermal conductivity of a ternary hybrid nanofluid containing MWCNTs- titania-zinc oxide/water-ethylene glycol (80:20) as well as binary and mono nanofluids. Synth Met. 2020;268:116501.

Çolak AB. A novel comparative analysis between the experimental and numeric methods on viscosity of zirconium oxide nanofluid: developing optimal artificial neural network and new mathematical model. Powder Technol. 2021;381:338–51.

Ordóñez F, Chejne F, Pabón E, Cacua K. Synthesis of ZrO2 nanoparticles and effect of surfactant on dispersion and stability. Ceram Int. 2020;46(8):11970–7.

Sun C, Fard BE, Karimipour A, Abdollahi A, Bach Q-V. Producing ZrO2/LP107160 NF and presenting a correlation for prediction of thermal conductivity via GMDH method: An empirical and numerical investigation. Physica E. 2021;127:114511.

Sarafraz MM, Kiani T, Hormozi F. Critical heat flux and pool boiling heat transfer analysis of synthesized zirconia aqueous nano-fluids. Int Commun Heat Mass Transfer. 2016;70:75–83.

Askari S, Rashidi A, Koolivand H. Experimental investigation on the thermal performance of ultra-stable kerosene-based MWCNTs and Graphene nanofluids. Int Commun Heat Mass Transfer. 2019;108:104334.

Wu Z, Wang L, Sundén B, Wadsö L. Aqueous carbon nanotube nanofluids and their thermal performance in a helical heat exchanger. Appl Therm Eng. 2016;96:364–71.

Wang Z, Dai L, Yao J, Guo T, Hrynsphan D, Tatsiana S, Chen J. Enhanced adsorption and reduction performance of nitrate by Fe–Pd–Fe3O4 embedded multi-walled carbon nanotubes. Chemosphere. 2021;281:130718.

Huang K, Xu Q, Ying Q, Gu B, Yuan W. Wireless strain sensing using carbon nanotube composite film. Compos B Eng. 2023;256:110650.

Adun H, Kavaz D, Dagbasi M. Review of ternary hybrid nanofluid: synthesis, stability, thermophysical properties, heat transfer applications, and environmental effects. J Clean Prod. 2021;328:129525.

Liu D, Yang N, Zeng Q, Liu H, Chen D, Cui P, Xu L, Hu C, Yang J. Core-shell Ag–Pt nanoparticles: a versatile platform for the synthesis of heterogeneous nanostructures towards catalyzing electrochemical reactions. Chin Chem Lett. 2021;32(11):3288–97.

Hemmat Esfe M, Esfandeh S, Abbasian Arani AA. Proposing a modified engine oil to reduce cold engine start damages and increase safety in high temperature operating conditions. Powder Technol. 2019;355:251–63.

Hemmat Esfe M, Rostamian H, Rejvani M, Emami MRS. Rheological behavior characteristics of ZrO2-MWCNT/10w40 hybrid nano-lubricant affected by temperature, concentration, and shear rate: An experimental study and a neural network simulating. Phys E Low-dimens Syst Nanostruct. 2018;102:160–70.

Tian X-X, Kalbasi R, Qi C, Karimipour A, Huang H-L. Efficacy of hybrid nano-powder presence on the thermal conductivity of the engine oil: an experimental study. Powder Technol. 2020;369:261–9.

Hemmat Esfe M, Karimpour R, Abbasian Arani AA, Shahram J. Experimental investigation on non-Newtonian behavior of Al2O3-MWCNT/5W50 hybrid nano-lubricant affected by alterations of temperature, concentration and shear rate for engine applications. Int Commun Heat Mass Transfer. 2017;82:97–102.

Aghahadi MH, Niknejadi M, Toghraie D. An experimental study on the rheological behavior of hybrid Tungsten oxide (WO3)-MWCNTs/engine oil Newtonian nanofluids. J Mol Struct. 2019;1197:497–507.

Rostami S, Kalbasi R, Talebkeikhah M, Goldanlou AS. Improving the thermal conductivity of ethylene glycol by addition of hybrid nano-materials containing multi-walled carbon nanotubes and titanium dioxide: applicable for cooling and heating. J Therm Anal Calorim. 2020;143:1701–12.

Hemmat Esfe M, Rostamian H, Reza Sarlak M, Rejvani M, Alirezaie A. Rheological behavior characteristics of TiO2-MWCNT/10w40 hybrid nano-oil affected by temperature, concentration and shear rate: An experimental study and a neural network simulating. Phys E Low dimens Syst Nanostruct. 2017;94:231–40.

Chu Y-M, Ibrahim M, Saeed T, Berrouk AS, Algehyne EA, Kalbasi R. Examining rheological behavior of MWCNT-TiO2/5W40 hybrid nanofluid conducting experimental study—challenging of RSM and ANN. J Mol Liq. 2021;333:115969.

Zhu Y, Zamani M, Xu G, Toghraie D, Hashemian M, Alizadeh AA. A comprehensive experimental investigation of dynamic viscosity of MWCNT-WO3/water-ethylene glycol antifreeze hybrid nanofluid. J Mol Liq. 2021;333:115986.

Mukherjee S, Mishra PC, Chaudhuri P. Thermo-economic performance analysis of Al2O3-water nanofluids—an experimental investigation. J Mol Liq. 2020;299:112200.

Al-Rashed AAAA, Shahsavar A, Entezari S, Moghimi MA, Adio SA, Nguyen TK. Numerical investigation of non-Newtonian water-CMC/CuO nanofluid flow in an offset strip-fin microchannel heat sink: Thermal performance and thermodynamic considerations. Appl Therm Eng. 2019;155:247–58.

Asjad MI, Aleem M, Ahmadian A, Salahshour S, Ferrara M. New trends of fractional modeling and heat and mass transfer investigation of (SWCNTs and MWCNTs)-CMC based nanofluids flow over inclined plate with generalized boundary conditions. Chin J Phys. 2020;66:497–516.

Saqib M, Khan I, Shafie S. Application of Atangana-Baleanu fractional derivative to MHD channel flow of CMC-based-CNT’s nanofluid through a porous medium. Chaos Solitons Fract. 2018;116:79–85.

Abdel-Ghani NT, El-Chaghaby GA, Helal FS. Individual and competitive adsorption of phenol and nickel onto multiwalled carbon nanotubes. J Adv Res. 2015;6(3):405–15.

Mangla O, Roy S. editors. Monoclinic zirconium oxide nanostructures having tunable band gap synthesized under extremely non-equilibrium plasma conditions. Multidisciplinary Digital Publishing Institute Proceedings; 2018.

Müller RH, Hildebrand GE. Zetapotential und Partikelladung in der Laborpraxis(Einführung in die Theorie praktische Messdurchführung Dateninterpretation), Paperback APV. (1996).

ASHRAE A (2021) ASHRAE handbook-fundamentals (SI), American Society of Heating, Refrigerating & Air Conditioning. (2021).

Alnaqi AA, Alsarraf J, Al-Rashed AAAA. Using response surface methodology and artificial neural network to examine the rheological behavior of tungsten trioxide/ethylene glycol nanofluid under various sonication times. J Mol Liq. 2021;337:116022.

Ghafurian MM, Akbari Z, Niazmand H, Mehrkhah R, Wongwises S, Mahian O. Effect of sonication time on the evaporation rate of seawater containing a nanocomposite. Ultrason Sonochem. 2020;61:104817.

Bahrami D, Nadooshan AA, Bayareh M. Numerical study on the effect of planar normal and Halbach magnet arrays on micromixing. Int J Chem React Eng. 2020. https://doi.org/10.1515/ijcre-2020-0080.

Pare A, Ghosh SK. A unique thermal conductivity model (ANN) for nanofluid based on experimental study. Powder Technol. 2021;377:429–38.

Kaladgi AR, Afzal A, Manokar AM, Thakur D, Agbulut U, Alshahrani S, Subbiah R. Integrated Taguchi-GRA-RSM optimization and ANN modelling of thermal performance of zinc oxide nanofluids in an automobile radiator. Case Studies Therm Eng. 2021;26:101068.

Shi L, Zhang S, Arshad A, Hu Y, He Y, Yan Y. Thermo-physical properties prediction of carbon-based magnetic nanofluids based on an artificial neural network. Renew Sustain Energy Rev. 2021;149:111341.

Vicki Wanatasanappan V, Kumar Kanti P, Sharma P, Husna N, Abdullah MZ. Viscosity and rheological behavior of Al2O3-Fe2O3/water-EG based hybrid nanofluid: A new correlation based on mixture ratio. J Mol Liq. 2023;375:121365.

Hajialigol N, Daghigh R. The evaluation of the first and second laws of thermodynamics for the pulsating MHD nanofluid flow using CFD and machine learning approach. J Taiwan Inst Chem Eng. 2023;2023:104782.

Acknowledgements

The authors would like to acknowledge the support of the Deputy for Research and Innovation Ministry of Education, Kingdom of Saudi Arabia for this research through a grant (NU/IFC/2/SERC/-/23) under the Institutional Funding Committee at Najran University, Kingdom of Saudi Arabia.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mustafa, J., Alqaed, S., Abdullah, M.M. et al. A novel hybrid nanofluid including MWCNT and ZrO2 nanoparticles: implementation of response surface methodology and artificial neural network. J Therm Anal Calorim 148, 9619–9632 (2023). https://doi.org/10.1007/s10973-023-12317-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12317-8