Abstract

This study is aimed to investigate the amount of heat transfer, friction factor, and thermal enhancement factor in a tube with different twisted-tape geometries. Six protrusion geometries and one 0° square-cut geometry are applied on the surface of the twisted tape. The main aim is to investigate the effect of the type and the angle of the elements on the rate of heat transfer enhancement. The working fluid is water. Three-dimensional turbulent fluid flow at different Reynolds numbers is solved using the SST k-ω model. Changes in the velocity, temperature, pressure, and turbulence kinetic energy are investigated in the computational domain. The findings demonstrate that, when compared to other situations, triangular elements exhibit the most notable increase in Nusselt number. In addition, as compared to the square elements, triangular elements have the highest friction factor. Moreover, the least rise in Nusselt number and the lowest friction factor are seen in the 0° cut square element. Moreover, that the square with protrusions at 0° has the maximum thermal enhancement factor between protrusion modes, and it is equal to 0.89 and by using the 0° cut, the average thermal enhancement factor equals to 1.01. In contrast, this number equals 0.86 in the twist without elements.

Similar content being viewed by others

Abbreviations

- C p :

-

Specific heat/J Kg−1 k−1

- D :

-

Pipe diameter/mm

- f :

-

Friction factor

- g :

-

Gravity/ms−2

- h :

-

Heat transfer coefficient/W m−2 K−1

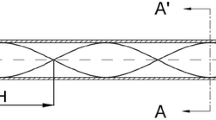

- H :

-

Half pitch of twisted tape/mm

- k :

-

Thermal conductivity/W m−1 k−1

- L :

-

Pipe length/mm

- m :

-

Mass flow rate/kg/s

- p :

-

Pressure/pa

- q":

-

Heat flux on pipes wall/w m−2

- T :

-

Temperature/K

- t :

-

Thickness/mm

- u :

-

Velocity/m s−1

- u i :

-

Mean velocity components in the xi direction/m s−1

- x,y,z :

-

Cartesian coordinates/m

- x i :

-

Cartesian space coordinates (i = 1,2,3)/m

- θ :

-

Angle/degree

- \(\mu\) :

-

Dynamic molecular viscosity

- \(\rho\) :

-

Density/kg m−3

- ƞ :

-

Thermal enhancement factor

- avg:

-

Average

- in:

-

Inlet

- out:

-

Outlet

- Nu:

-

Nusselt number

- Pr:

-

Prandtl number

- Re:

-

Reynolds number

References

Gu H, Chen Y, Wu J, Sunden B. Performance investigation on twisted elliptical tube heat exchangers with coupling-vortex square tube layout. Int J Heat Mass Transf. 2020;151:119473. https://doi.org/10.1016/j.ijheatmasstransfer.2020.119473.

Ranjith and K. Shaji,. Numerical analysis on a double pipe heat exchanger with twisted tape induced swirl flow on both sides. Procedia Technol. 2016;24:436–43. https://doi.org/10.1016/j.protcy.2016.05.060.

Xiang J, Deng L, Zhou C, Zhao H, Huang J, Tao S. Heat transfer performance and structural optimization of a novel micro-channel heat sink. Chinese J Mech Eng. 2022;35(1):38. https://doi.org/10.1186/s10033-022-00704-5.

Liu F, Sun Z, Bian H, Ding M, Meng X. Identification and classification of the flow pattern of hydrogen-air-steam mixture gas under steam condensation. Int J Therm Sci. 2023;183:107854. https://doi.org/10.1016/j.ijthermalsci.2022.107854.

Zhong Q, Chen Y, Zhu B, Liao S, Shi K. A temperature field reconstruction method based on acoustic thermometry. Measurement. 2022;200:111642. https://doi.org/10.1016/j.measurement.2022.111642.

Ahmad S, Abdullah S, Sopian K. A review on the thermal performance of nanofluid inside circular tube with twisted tape inserts. Adv Mech Eng. 2020. https://doi.org/10.1177/1687814020924893.

Farnam M, Khoshvaght-Aliabadi M, Asadollahzadeh MJ. Heat transfer intensification of agitated U-tube heat exchanger using twisted-tube and twisted-tape as passive techniques. Chem Eng Process - Process Intensif. 2018;133:137–47. https://doi.org/10.1016/j.cep.2018.10.002.

Li X, et al. A magnetic field coupling fractional step lattice Boltzmann model for the complex interfacial behavior in magnetic multiphase flows. Appl Math Model. 2023;117:219–50. https://doi.org/10.1016/j.apm.2022.12.025.

Luo Z-Z, et al. Extraordinary role of Zn in enhancing thermoelectric performance of Ga-doped n-type PbTe. Energy Environ Sci. 2022;15(1):368–75. https://doi.org/10.1039/D1EE02986J.

Azimy H, Azimy N, Isfahani AHM, Bagherzadeh SA, Farahnakian M Analysis of thermal performance and ultrasonic wave power variation on heat transfer of heat exchanger in the presence of nanofluid using the artificial neural network. J Therm Anal Calorim., 2022;1–15

Urkude SS, Farkade HS Heat transfer augmentation techniques in circular tube fitted with swirl flow generator: a review; 3(6):555–560.

Jadhav M, Awari R, Diksha B, Amol B, Mayura M. Review on enhancement of heat transfer by active method. Int J Curr Eng Technol. 2016;6(Special Issue-6):221–225.

Azimy N, Saffarian MR, Noghrehabadi A. Thermal performance analysis of a flat-plate solar heater with zigzag-shaped pipe using fly ash-Cu hybrid nanofluid: CFD approach. Environ Sci Pollut Res, pp. 1–19, 2022.

Keklikcioglu O, Ozceyhan V. A review of heat transfer enhancement methods using coiled wire and twisted tape inserts. In Heat transfer - models, methods and applications. INTECH. 2018. https://doi.org/10.5772/intechopen.74516.

Dong X, Jin X, Li P, Bi Q, Gui M, Wang T. Experimental research on heat transfer and flow resistance properties in spiral twisted tube heat exchanger. Appl Therm Eng. 2020;176:115397. https://doi.org/10.1016/j.applthermaleng.2020.115397.

Guo J, Fan A, Zhang X, Liu W. A numerical study on heat transfer and friction factor characteristics of laminar flow in a circular tube fitted with center-cleared twisted tape. Int J Therm Sci. 2011;50(7):1263–70. https://doi.org/10.1016/j.ijthermalsci.2011.02.010.

Moghaddam HA, et al. Condensation heat transfer and pressure drop characteristics of Isobutane in horizontal channels with twisted tape inserts. Int J Refrig. 2020;118:31–40. https://doi.org/10.1016/j.ijrefrig.2020.06.019.

Hosseinalipour SM, Rostami A, Shahriari G. Numerical study of circumferential temperature difference reduction at the absorber tube of parabolic trough direct steam generation collector by inserting a twisted tape in superheated region. Case Stud Therm Eng. 2020;21:100720. https://doi.org/10.1016/j.csite.2020.100720.

Sarviya RM, Fuskele V. Heat transfer and pressure drop in a circular tube fitted with twisted tape insert having continuous cut edges. J Energy Storage. 2018;19(May):10–4. https://doi.org/10.1016/j.est.2018.07.001.

Abolarin SM, Everts M, Meyer JP. The influence of peripheral u-cut twisted tapes and ring inserts on the heat transfer and pressure drop characteristics in the transitional flow regime. Int J Heat Mass Transf. 2019;132:970–84. https://doi.org/10.1016/j.ijheatmasstransfer.2018.12.051.

Nakhchi ME, Hatami M, Rahmati M. Experimental investigation of heat transfer enhancement of a heat exchanger tube equipped with double-cut twisted tapes. Appl Therm Eng. 2020;180:115863. https://doi.org/10.1016/j.applthermaleng.2020.115863.

Vaisi A, Moosavi R, Lashkari M, Mohsen Soltani M. Experimental investigation of perforated twisted tapes turbulator on thermal performance in double pipe heat exchangers. Chem Eng Process Intensif. 2020;154:108028. https://doi.org/10.1016/j.cep.2020.108028.

Saravanan A, Jaisankar S. Heat transfer augmentation techniques in forced flow V-trough solar collector equipped with V-cut and square cut twisted tape. Int J Therm Sci. 2019;140(February):59–70. https://doi.org/10.1016/j.ijthermalsci.2019.02.030.

Nakhchi ME, Esfahani JA. Performance intensification of turbulent flow through heat exchanger tube using double V-cut twisted tape inserts. Chem Eng Process Process Intensif 2019;141:107533. https://doi.org/10.1016/j.cep.2019.107533.

Natarajan A, Venkatesh R, Gobinath S, Devakumar L, Gopalakrishnan K. CFD simulation of heat transfer enhancement in circular tube with twisted tape insert by using nanofluids. Mater Today Proc. 2020;21:572–7. https://doi.org/10.1016/j.matpr.2019.06.717.

Varun MO, Garg H, Nautiyal SK, Shukla MK. Heat transfer augmentation using twisted tape inserts: a review. Renew Sustain Energy Rev. 2016;63:193–225. https://doi.org/10.1016/j.rser.2016.04.051.

Kummitha OR, Reddy Bandi VR, Pandey KM. 3D numerical analysis for thermal-hydraulic characteristics of water flow inside a circular tube with twisted tape with helical protrusions. Procedia Eng. 2015;127:1134–1141. https://doi.org/10.1016/j.proeng.2015.11.478.

Bhakta AK, Panday NK, Singh SN. Performance study of a cylindrical parabolic concentrating solar water heater with nail type twisted tape inserts in the copper absorber tube. Energies. 2018. https://doi.org/10.3390/en11010204.

Selvam S, Thiyagarajan P, Suresh S. Experimental studies on effect of bonding the twisted tape with pins to the inner surface of the circular tube. Therm Sci. 2014;18(4):1273–83. https://doi.org/10.2298/TSCI120807036S.

Hayat MZ, Nandan G, Tiwari AK, Sharma SK, Shrivastava R, Singh AK. Numerical study on heat transfer enhancement using twisted tape with trapezoidal ribs in an internal flow. Mater. Today Proc. 2020;46:5412–5419. https://doi.org/10.1016/j.matpr.2020.09.061.

Zheng L, Xie Y, Zhang D. Numerical investigation on heat transfer performance and flow characteristics in circular tubes with dimpled twisted tapes using Al2O3-water nanofluid. Int J Heat Mass Transf. 2017;111:962–81. https://doi.org/10.1016/j.ijheatmasstransfer.2017.04.062.

Murugesan P, Mayilsamy K, Suresh S. Heat transfer and friction factor studies in a circular tube fitted with twisted tape consisting of wire-nails. Chinese J Chem Eng. 2010;18(6):1038–42. https://doi.org/10.1016/S1004-9541(09)60166-X.

Dagdevir T, Ozceyhan V. An experimental study on heat transfer enhancement and flow characteristics of a tube with plain, perforated and dimpled twisted tape inserts. Int J Therm Sci. 2021;159:106564. https://doi.org/10.1016/j.ijthermalsci.2020.106564.

Eiamsa-ard S, Wongcharee K, Sripattanapipat S. 3-D Numerical simulation of swirling flow and convective heat transfer in a circular tube induced by means of loose-fit twisted tapes. Int Commun Heat Mass Transf. 2009;36(9):947–55. https://doi.org/10.1016/j.icheatmasstransfer.2009.06.014.

Janjua MM, Khan NU, Khan WA, Khan WS, Ali HM. Numerical study of forced convection heat transfer across a cylinder with various cross sections. J Therm Anal Calorim. 2021;143(3):2039–52. https://doi.org/10.1007/s10973-020-10297-7.

Pour Razzaghi MJ, Ghassabian M, Daemiashkezari AN, Abdulfattah H, Afrouzi H, Ahmad H. Thermo-hydraulic performance evaluation of turbulent flow and heat transfer in a twisted flat tube: A CFD approach. Case Stud Therm Eng. 2022;35:102107. https://doi.org/10.1016/j.csite.2022.102107.

Hassan MA, Kassem M, Kaood A. Numerical investigation and multi-criteria optimization of the thermal–hydraulic characteristics of turbulent flow in conical tubes fitted with twisted tape insert. Therm Anal Calorim. 2022;147:6847–6868. https://doi.org/10.1007/s10973-021-10998-7

Kalateh MR, Kianifar A, Sardarabadi M. A three-dimensional numerical study of the effects of various twisted tapes on heat transfer characteristics and flow field in a tube: Experimental validation and multi-objective optimization via response surface methodology. Sustain Energy Technol Assess. 2022;50:101798. https://doi.org/10.1016/j.seta.2021.101798.

Yu C, Cui Y, Zhang H, Gao B, Zeng M, Han L. Comparative study on turbulent flow characteristics and heat transfer mechanism of a twisted oval tube with different twisted tapes. Int J Therm Sci. 2022;174:107455. https://doi.org/10.1016/j.ijthermalsci.2021.107455.

Asadi A, Zaboli M, Mogharrebi AR, Saedodin S, Ganji DD. Numerical analysis of turbulence-inducing elements with various geometries and utilization of hybrid nanoparticles in a double pipe heat exchanger. Alexandria Eng J. 2022;61(5):3633–44. https://doi.org/10.1016/j.aej.2021.08.074.

Sadashiv Kore S, Kumar Chaudhary M, Sarjerao Patil A, Dilip Kolate V. Computational study and enhancement of heat transfer rate by using inserts introduced in a heat exchanger. J Adv Res Fluid Mech Therm Sci. 2023; 103(1):16–29. https://doi.org/10.37934/arfmts.103.1.1629.

Izadi M, Alshehri HM, Hosseinzadeh F, Shokri Rad M, Ben Hamida MB. Numerical study on forced convection heat transfer of TiO2/water nanofluid flow inside a double-pipe heat exchanger with spindle-shaped turbulators. Eng Anal Bound Elem. 2023;150: 612–623. https://doi.org/10.1016/j.enganabound.2023.02.046.

Seyd Eshaghi M, Ameri M, Rasam A, Bidi M. Hydrodynamic and thermal entrance region assessment of turbulent flow through a circular tube with a tight-fit twisted tape insert, considering multifarious operating conditions and pitch ratios. Therm Sci Eng Prog. 2023;38:101647. https://doi.org/10.1016/j.tsep.2022.101647.

Sharifat F, Marchitto A, Solari MS, Toghraie D. Analysis, prediction, and optimization of heat transfer coefficient and friction factor of water-$${\mathrm{Al}}_{\rm 2}{\mathrm{O}}_{\rm 3}$$ nanofluid flow in shell-and-tube heat exchanger with helical baffles (using RSM). Eur Phys J Plus. 2022;137(8):991. https://doi.org/10.1140/epjp/s13360-022-03210-8.

Derikvand M, Solari MS, Toghraie D. Entropy generation and forced convection analysis of ethylene glycol/MWCNTs-Fe3O4 non-Newtonian nanofluid in a wavy microchannel with hydrophobic surfaces. J Taiwan Inst Chem Eng. 2023;143:104707. https://doi.org/10.1016/j.jtice.2023.104707.

Sharma S, Verma K, Hardaha P. Implementation of artificial intelligence in agriculture. J Comput Cogn Eng 2022.

Liu W, Zhao C, Zhou Y, Xu X. Modeling of vapor-liquid equilibrium for electrolyte solutions based on COSMO-RS interaction. J Chem. 2022;2022:1–13. https://doi.org/10.1155/2022/9070055.

Dey P, Jana DK. Evaluation of the convincing ability through presentation skills of pre-service management wizards using AI via T2 linguistic fuzzy logic. J Comput Cogn Eng. 2022.

Chen Z. Research on internet security situation awareness prediction technology based on improved RBF neural network algorithm. J Comput Cogn Eng. 2022;1:103–108. https://doi.org/10.47852/bonviewJCCE149145205514.

Yao Z, et al. Numerical assessment of the impacts of non-Newtonian nanofluid and hydrophobic surfaces on conjugate heat transfer and irreversibility in a silicon microchannel heat-sink. J Taiwan Inst Chem Eng. 2023;142:104642. https://doi.org/10.1016/j.jtice.2022.104642.

Derikvand M, Solari MS, Toghraie D. Numerical investigation of the effect of a porous block and flow injection using non-Newtonian nanofluid on heat transfer and entropy generation in a microchannel with hydrophobic walls. Eur Phys J Plus. 2021;136(8):867. https://doi.org/10.1140/epjp/s13360-021-01846-6.

Hong Y, Zhao L, Huang Y, Li Q, Jiang J, Du J. Turbulent thermal-hydraulic characteristics in a spiral corrugated waste heat recovery heat exchanger with perforated multiple twisted tapes. Int J Therm Sci. 2023;184:108025. https://doi.org/10.1016/j.ijthermalsci.2022.108025.

Liu Q, Zhang Y, Luo J, Zheng J, Cheng Y (2023) Numerical study on heat transfer and flow characteristics of coaxial geothermal heat exchangers with helical finned inner tubes. J Build Eng. 2023; 65:105752. https://doi.org/10.1016/j.jobe.2022.105752.

Tahmasebi A, Abed AM, Aghaei A, Izadi F, Malekshah EH, Aybar HŞ. Investigation into the effect of twisted tape on the thermo-hydraulic performance and entropy generation of turbulent flow of mono and hybrid magnetic nanofluids inside a parabolic solar collector absorber tube by applying two-phase analysis. Eng Anal Bound Elem. 2023;150:318–28. https://doi.org/10.1016/j.enganabound.2023.02.007.

Eiamsa-ard S, Thianpong C, Eiamsa-ard P. Turbulent heat transfer enhancement by counter/co-swirling flow in a tube fitted with twin twisted tapes. Exp Therm Fluid Sci. 2010;34(1):53–62. https://doi.org/10.1016/j.expthermflusci.2009.09.002.

Duan CG, Karelin VY. Abrasive erosion and corrosion of hydraulic machinery. World Sci. 2003.

Nakhchi ME, Esfahani JA. Numerical investigation of rectangular-cut twisted tape insert on performance improvement of heat exchangers. Int J Therm Sci. 2019;138:75–83. https://doi.org/10.1016/j.ijthermalsci.2018.12.039.

Eiamsa-ard S, Wongcharee K, Eiamsa-ard P, Thianpong C. Thermohydraulic investigation of turbulent flow through a round tube equipped with twisted tapes consisting of centre wings and alternate-axes. Exp Therm Fluid Sci. 2010;34(8):1151–61. https://doi.org/10.1016/j.expthermflusci.2010.04.004.

Chen J, et al. A high efficient heat exchanger with twisted geometries for biogas process with manure slurry. Appl Energy. 2020;279:115871. https://doi.org/10.1016/j.apenergy.2020.115871.

Nazer-Nejad M, Saffarian MR, Behbahani-Nejad M. Investigating the possibility of using the underground tunnel for air-conditioning in Tehran. J Brazilian Soc Mech Sci Eng. 2018;40(9):473. https://doi.org/10.1007/s40430-018-1395-y.

Menter FR. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994;32(8):1598–605. https://doi.org/10.2514/3.12149.

Hellsten A. Some Improvements in Mentors’s k-w SST Turbulence Model. In: 29th AIAA Fluid Dynamics Conference, Albuquerque, New Mexico. 1997; pp 1–11

Sivakumar K, Rajan K, Mohankumar T, Naveenchnadran P. Analysis of heat transfer characteristics with triangular cut twisted tape (TCTT) and circular cut twisted tape (CCTT) inserts. Mater Today Proc. 2020;22:375–82. https://doi.org/10.1016/j.matpr.2019.07.212.

Promvonge P, Chompookham T, Kwankaomeng S, Thianpong C. Enhanced heat transfer in a triangular ribbed channel with longitudinal vortex generators. Energy Convers Manag. 2010;51(6):1242–9. https://doi.org/10.1016/j.enconman.2009.12.035.

Mushatet KS, Rishak QA, Fagr MH. Experimental and numerical investigation of swirling turbulent flow and heat transfer due to insertion of twisted tapes of new models in a heated tube. Appl Therm Eng. 2020;171:115070. https://doi.org/10.1016/j.applthermaleng.2020.115070.

Gnanavel C, Saravanan R, Chandrasekaran M. Heat transfer enhancement through nano-fluids and twisted tape insert with rectangular cut on its rib in a double pipe heat exchanger. Mater Today Proc. 2020;21:865–9. https://doi.org/10.1016/j.matpr.2019.07.606.

Bucak H, Yılmaz F. The current state on the thermal performance of twisted tapes: a geometrical categorisation approach. Chem Eng Process Process Intensif. 2020. https://doi.org/10.1016/j.cep.2020.107929.

Acknowledgements

We are grateful to the Research Council of Shahid Chamran University of Ahvaz for financial support (SCU.EM1401.574).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Taheripour, S., Saffarian, M.R., Azimy, N. et al. Numerical evaluation of the effect of using various twisted-tape geometries on heat transfer enhancement and flow characteristics in a tube. J Therm Anal Calorim 148, 7829–7844 (2023). https://doi.org/10.1007/s10973-023-12264-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12264-4