Abstract

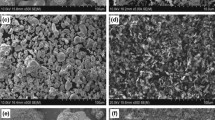

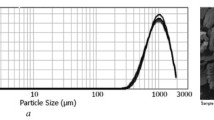

Metallic diamond (MD) is a new alloy class which hardness was found to surpass any current alloys at more than a twofold factor, up to 2500 HV (kgf mm−2). The alloy design employs simple metallurgical principles at the so-called Lattice Occupancy Project aided by Diamoy 1.0 software. The most important aspect of the alloy project considers the maximization of chromium equivalent values by selecting metallic elements for promoting body-centred cubic structures. Forming these alloys into parts is challenging, whereas powder metallurgy techniques appear as valid processing routes. The work studies the sintering behaviour of MD-4 and 5 alloy powders, being the hardest MD ones. High energy milled powder compacts were sintered in a dilatometer up to 1500 °C for 1 h under Ar-10%H2 atmosphere. Alloy MD-5 has shown intense shrinkage starting at 1150 °C, contrasting to marginal sintering of alloy MD-4. The latter has undergone transformations from 400 °C with strong expansion, which seems to block most of the sintering retraction at higher temperatures. Alloy powder MD-5 is a good candidate as a raw material for tool parts production by powder metallurgy, which can compete with cemented carbide hard tools.

Similar content being viewed by others

References

Gao MC, Yeh JW, Liaw PK, Zhang Y. High-entropy alloys. Fundamentals and applications. Switzerland: Springer International Publishing; 2016.

Miracle DB, Senkov ON. A critical review of high entropy alloys and related concepts. Acta Mater. 2017;122:448–511.

George EP, Raabe D, Ritchie RO. High-entropy alloys. Nat Rev Mater. 2019;4:515–34.

Gorsse S, et al. Database on the mechanical properties of high entropy alloys and complex concentrated alloys. Data Brief. 2018;21:2664–78.

Senkov ON, et al. Development and exploration of refractory high entropy alloys—a review. J Mater Res. 2018;33(19):3092–128.

Brandi SD, Schön CG. A Thermodynamic study of a constitutional diagram for duplex stainless steels. J Phase Equilib Diffus. 2017;38:268–75.

Chen J, et al. A review on fundamental of high entropy alloys with promising high–temperature properties. J Alloy Compd. 2018;760:15–30.

Wan Y, et al. WReTaMo refractory high-entropy alloy with high strength at 1600 °C. Adv Eng Mater. 2022;24:2100765.

Chen S, Qi C, Liu J, Zhang J, Wu Y. Recent advances in W-containing refractory high-entropy alloys—an overview. Entropy. 2022;24(11):1553.

Guruvidyathri K, et al. Topologically close-packed phase formation in high entropy alloys: a review of calphad and experimental results. JOM. 2017;69:11.

Ruixuan L, et al. High-throughput calculations for high-entropy alloys: a brief review. Front Mater. 2020;7:290.

Restivo TAG, Restivo GMG. Development of ultra-hard multi-component alloys. J Mater Res. 2021;36:1316–27.

Restivo TAG. Ligas metálicas multi-elementares de extrema dureza tratáveis por processos térmicos e químicos e respectivo projeto, preparação e tratamento. Patent BR102019025461-0, INPI, 02/12/2019.

Hu Q, et al. Parametric study of amorphous high-entropy alloys formation from two new perspectives: atomic radius modification and crystalline structure of alloying elements. Sci Rep. 2017. https://doi.org/10.1038/srep39917.

Ryu SH, Yu J. A new equation for the Cr equivalent in 9 to 12 pct Cr steels. Met and Mat Trans A. 1998;29A:1573–8.

Nonato RBP, Restivo TAG. Software solution for ultra-hard metal alloy design. Engenharia, Gestão e Inovação, vol. 3. 1st ed. Belo Horizonte: Editora Poisson; 2022. p. 179–87.

Nonato R, Restivo T, et al. Software creation for ultra-hard metal alloy design. In: Ulhôa JLR, et al., editors. Engenharia: a máquina que constrói o futuro, vol. 9. 1st ed. Piracanjuba: Editora Conhecimento Livre; 2022. p. 168–81.

Restivo TAG, Castanho SRHM, Tenorio JAS. TG/DTA-MS evaluation of methane cracking and coking on doped nickel-zirconia based cermets. J Therm Anal Calorim. 2014;118:75–81.

Restivo TAG, Castanho SRHM. Cu-Ni-YSZ anodes for solid oxide fuel cell by mechanical alloying processing. Int J Mater Res. 2010;101:128–32.

Bermingham MJ, et al. Microstucture of cast titanium alloys. Mater Forum. 2007;31:84–9.

Ghosh G. Thermodynamic and kinetic modeling of the Cr-Ti-V system. J Phase Equilib. 2002;23(4):310–28.

Yang Y, Mao H, Chen H-L, Selleby M. An assessment of the Ti-V-O system. J Alloy Compd. 2017;722:365–74.

Hanyaloglu SC, Aksakal B, Bolton JD. Production and indentation analysis of WC/Fe–Mn as an alternative to cobalt-bonded hardmetals. Mater Charact. 2001;47:315–22.

Acknowledgements

The authors acknowledge the research councils CNPq (proj. 408406/2021-6), CatalisaICT Sebrae (proj. 29083*128) and FAPESP (proj. 2020/09736-3) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guisard Restivo, T.A., Pires Nonato, R.B., Rossoni Figueira, R. et al. Sintering of metallic diamond alloy powders. J Therm Anal Calorim 148, 13003–13009 (2023). https://doi.org/10.1007/s10973-023-12260-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12260-8