Abstract

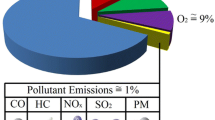

Low-temperature combustion in diesel engines gained prominence because of their ability to meet the current emission standards without NOx and PM trade-off. Among the low-temperature combustion concepts, premixed charge compression ignition (PCCI) offers an in-cylinder emission reduction with minimal to zero engine modifications. This work reviews the role of premixed charge compression ignition (PCCI) of low-carbon and oxygen-rich fuels on diesel powertrains' performance. This review covers the fundamentals and significance of PCCI combustion with low-carbon oxygen-rich fuels of both renewable and synthetic origins. Various strategies employed for achieving PCCI combustion, in-cylinder, and external charge preparation are discussed in this review. The effect of a single injection, multiple split injections, injection pressure, and injection duration on PCCI combustion in diesel engines is discussed at length. Low-temperature combustion depends on the chemical kinetics of combustion. The present review discusses the numerical works carried out with detailed chemical kinetics of various conventional and alternative fuels. Challenges in PCCI combustion, such as wall-wetting in early direct injections, combustion phasing, narrow load range, and engine knock for conventional and unconventional fuels, are presented. Bottlenecks in the present PCCI technology, advantages of using alternative fuels for PCCI combustion, and the scope of future work are presented at the end of this review.

Graphic abstract

Similar content being viewed by others

References

Berggren C, Magnusson T. Reducing automotive emissions-the potentials of combustion engine technologies and the power of policy. Energy Policy. 2012;41:636–43.

Mclaren J, Miller J, O’shaughnessy E, Wood E, Shapiro E. Emissions associated with electric vehicle charging: Impact of electricity generation mix, charging infrastructure availability, and vehicle type. 2016.

Elgowainy A, Burnham A, Wang M, Molburg J, Rousseau A. Well-to-wheels energy use and greenhouse gas emissions analysis of plug-in hybrid electric vehicles. 2009.

Messagie M, Boureima F, Matheys J, Sergeant N, Timmermans J-M, Macharis C, et al. Environmental performance of a battery electric vehicle: a descriptive life cycle assessment approach. World Electr Veh J. 2011;4:782–6.

Singh AP, Agarwal AK. Diesoline, diesohol, and diesosene fuelled HCCI engine development. J Energy Resour Technol, Trans ASME. 2016;138:1–13.

Natarajan S, Shankar SA, Sundareswaran AUM. Early injected PCCI engine fuelled with bio ethanol and diesel blends—An experimental investigation. Energy Proced. 2017;105:358–66.

Srihari S, Thirumalini S, Prashanth K. An experimental study on the performance and emission characteristics of PCCI-DI engine fuelled with diethyl ether-biodiesel-diesel blends. Renew Energy. 2017;107:440–7.

Pandey S, Bhurat S, Chintala V. Combustion and emissions behaviour assessment of a partially premixed charge compression ignition (PCCI) engine with diesel and fumigated ethanol. Energy Proced. 2019;160:590–6. https://doi.org/10.1016/j.egypro.2019.02.210.

Kook S, Bae C. Combustion control using two-stage diesel fuel injection in a single-cylinder PCCI engine. SAE technical paper 2004–01–0938. 2004.

de Ojeda W, Zoldak P, Espinosa R, Kumar R. Development of a fuel injection strategy for partially premixed compression ignition combustion. SAE Int J Eng. 2009;2:1473–88.

Kook S, Park S, Bae C. Influence of early fuel injection timings on premixing and combustion in a diesel engine. Energy Fuels. 2008;22:331–7.

Neely GD, Sasaki S, Leet JA. Experimental investigation of PCCI-DI combustion on emissions in a light-duty diesel engine. SAE technical papers 2004–01–0121. 2004.

Agarwal AK, Singh AP, Maurya RK. Evolution, challenges and path forward for low temperature combustion engines. Prog Energy Combust Sci. 2017;61:1–56.

Kook S, Bae C, Miles PC, Choi D, Pickett LM. The influence of charge dilution and injection timing on low-temperature diesel combustion and emissions. SAE technical paper 2005–01–3837. 2005.

Neely GD, Sasaki S, Huang Y, Leet JA, Stewart DW. New diesel emission control strategy to meet us tier 2 emissions regulations. SAE technical paper 2005–01–1091. 2005.

Shim E, Park H, Bae C. Comparisons of advanced combustion technologies (HCCI, PCCI, and dual-fuel PCCI) on engine performance and emission characteristics in a heavy-duty diesel engine. Fuel. 2020;262:116436.

Fang Q, Fang J, Zhuang J, Huang Z. Influences of pilot injection and exhaust gas recirculation (EGR) on combustion and emissions in a HCCI-DI combustion engine. Appl Therm Eng. 2012;48:97–104.

Liu H, Yao M, Zhang B, Zheng Z. Influence of fuel and operating conditions on combustion characteristics of a homogeneous charge compression ignition engine. Energy Fuels. 2009;23:1422–30.

Aceves SM, Flowers D, Martinez-Frias J, Espinosa-Loza F, Pitz WJ, Dibble R. Fuel and additive characterization for HCCI combustion. SAE technical paper 2003–01–1814. 2003.

Mei D, Yue S, Zhao X, Hielscher K, Baar R. Effects of center of heat release on combustion and emissions in a PCCI diesel engine fuelled by DMC-diesel blend. Appl Therm Eng. 2017;114:969–76.

Pandey SK, Sarma Akella SR, Ravikrishna RV. Novel fuel injection strategies for PCCI operation of a heavy-duty turbocharged diesel engine. Appl Therm Eng. 2018;143:883–98.

D’Ambrosio S, Ferrari A. Effects of exhaust gas recirculation in diesel engines featuring late PCCI type combustion strategies. Energy Convers Manag. 2015;105:1269–80.

Kanda T, Hakozaki T, Uchimoto T, Hatano J, Kitayama N, Sono H. PCCI operation with early injection of conventional diesel fuel. SAE technical paper 2005–01–0378. 2005.

Xin Q, Pinzon CF. Improving the environmental performance of heavy-duty vehicles and engines: key issues and system design approaches. Altern Fuels Adv Veh Technol Improv Environ Perform. 2014. https://doi.org/10.1533/9780857097422.2.279.

Yin L, Lundgren M, Wang Z, Stamatoglou P, Richter M, Andersson Ö, et al. High efficient internal combustion engine using partially premixed combustion with multiple injections. Appl Energy. 2019;233–234:516–23.

Horibe N, Harada S, Ishiyama T, Shioji M. Improvement of premixed charge compression ignition-based combustion by two-stage injection. Int J Engine Res. 2009;10:71–80.

Jung Y, Hwang J, Bae C. Assessment of particulate matter in exhaust gas for biodiesel and diesel under conventional and low temperature combustion in a compression ignition engine. Fuel. 2016;165:413–24.

Fang Q, Fang J, Zhuang J, Huang Z. Effects of ethanol-diesel-biodiesel blends on combustion and emissions in premixed low temperature combustion. Appl Therm Eng. 2013;54:541–8.

Kiplimo R, Tomita E, Kawahara N, Yokobe S. Effects of spray impingement, injection parameters, and EGR on the combustion and emission characteristics of a PCCI diesel engine. Appl Therm Eng. 2012;37:165–75.

Kim Y, Kim H, Kim K, Lee D, Lee K. A study of the characteristics of mixture formation and combustion in a PCCI engine using an early multiple injection strategy. Energy Fuels. 2008;22:1542–8.

Jain A, Singh AP, Agarwal AK. Effect of fuel injection parameters on combustion stability and emissions of a mineral diesel fuelled partially premixed charge compression ignition (PCCI) engine. Appl Energy. 2017;190:658–69.

Kim YJ, Kim KB, Lee KH. Effect of a 2-stage injection strategy on the combustion and flame characteristics in a PCCI engine. Int J Automot Technol. 2011;12:639–44.

Mancaruso E, Vaglieco BM. Characterization of PCCI combustion in a single cylinder CI engine fuelled with RME and bio-ethanol. SAE technical papers 2013–01–1672. 2013.

Mohammadi A, Kee SS, Ishiyama T, Kakuta T, Matsumoto T. Implementation of ethanol diesel blend fuels in PCCI combustion. SAE technical papers 2005–01–3712. 2005.

Murugesa Pandian M, Anand K. Comparison of different low temperature combustion strategies in a light duty air cooled diesel engine. Appl Therm Eng. 2018;142:380–90.

Park Y, Bae C. Influence of EGR and pilot injection on PCCI combustion in a single-cylinder diesel engine. SAE technical papers 2011–01–1823. 2011.

Park Y, Bae C. Effects of single and double post injections on diesel PCCI combustion. SAE technical papers 2013–01–0010. 2013.

Shimazaki N, Tsurushima T, Nishimura T. Dual mode combustion concept with premixed diesel combustion by direct injection near top dead center. SAE technical paper 2003–01–0742. 2003.

Simescu S, Ryan TW, Neely GD, Matheaus AC, Surampudi B. Partial pre-mixed combustion with cooled and uncooled EGR in a heavy-duty diesel engine. SAE technical paper 2002–01–0963. 2002.

Singh AP, Jain A, Agarwal AK. Fuel-injection strategy for PCCI engine fuelled by mineral diesel and biodiesel blends. Energy Fuels Am Chem Soc. 2017;31:8594–607.

Soloiu V, Moncada JD, Gaubert R, Muiños M, Harp S, Ilie M, et al. LTC (low-temperature combustion) analysis of PCCI (premixed charge compression ignition) with n-butanol and cotton seed biodiesel versus combustion and emissions characteristics of their binary mixtures. Renew Energy. 2018;123:323–33.

Sun C, Kang D, Bohac SV, Boehman AL. Impact of fuel and injection timing on partially premixed charge compression ignition combustion. Energy Fuels Am Chem Soc. 2016;30:4331–45.

Torregrosa AJ, Broatch A, Novella R, Gomez-Soriano J, Mónico LF. Impact of gasoline and diesel blends on combustion noise and pollutant emissions in premixed charge compression ignition engines. Energy. 2017;137:58–68.

Valentino G, Corcione FE, Iannuzzi SE, Serra S. Experimental study on performance and emissions of a high speed diesel engine fuelled with n-butanol diesel blends under premixed low temperature combustion. Fuel. 2012;92:295–307.

Vanegas A, Won H, Peters N. Influence of the nozzle spray angle on pollutant formation and combustion efficiency for a PCCI diesel engine. SAE technical paper 2009–01–1445. 2009.

Ying W, li H, Longbao Z, Wei L. Effects of DME pilot quantity on the performance of a DME PCCI-DI engine. Energy Convers Manag. 2010;51:648–54.

Xu L, Treacy M, Zhang Y, Aziz A, Tuner M, Bai X-S. Comparison of efficiency and emission characteristics in a direct-injection compression ignition engine fuelled with iso-octane and methanol under low temperature combustion conditions. Appl Energy. 2022;312:118714.

Singh AP, Kumar V, Agarwal AK. Evaluation of comparative engine combustion, performance and emission characteristics of low temperature combustion (PCCI and RCCI) modes. Appl Energy. 2020;278:115644.

Egüz U, Leermakers N, Somers B, de Goey P. Modelling of PCCI combustion with FGM tabulated chemistry. Fuel. 2014;118:91–9.

Nakagome K, Shimazaki N, Niimura K, Kobayashi S. Combustion and emission characteristics of premixed lean diesel combustion engine. SAE technical paper 970898. 1997.

Kiplimo R, Tomita E, Kawahara N, Yokobe S. Effects of compression ratio and simulated EGR on combustion characteristics and exhaust emissions of a diesel PCCI engine. J Therm Sci Technol. 2011;6:463–74.

Liang X, Zheng Z, Zhang H, Wang Y, Yu H. A review of early injection strategy in premixed combustion engines. Appl Sci. 2019;9(18):3737.

Das P, Subbarao PMV, Subrahmanyam JP. Effect of main injection timing for controlling the combustion phasing of a homogeneous charge compression ignition engine using a new dual injection strategy. Energy Convers Manag. 2015;95:248–58.

Han M, Assanis DN, Bohac SV. Sources of hydrocarbon emissions from low-temperature premixed compression ignition combustion from a common rail direct injection diesel engine. Combust Sci Technol. 2009;181:496–517.

Harada A, Shimazaki N, Sasaki S, Miyamoto T, Akagawa H, Tsujimura K. The effects of mixture formation on premixed lean diesel combustion engine. SAE technical paper 980533. 1998.

Chen L, Yang F, Yang Y, Yang X, Ouyang M. Application of narrow cone angle injectors to achieve advanced compression ignition on a mass-production diesel engine—Control strategy and engine performance evaluation. SAE technical paper 2009–01–2700. 2009.

Eastwood PG, Morris T, Tufail K, Winstanley T, Hardalupas Y, Taylor AMKP. The effects of fuel-injection schedules on emissions of no x and smoke in a diesel engine during partial-premix combustion. SAE technical paper 2007–24–0011. 2007.

Dev S, Chaudhari H, Gothekar S, Juttu S, Harishchandra Walke N, Marathe NV. Review on advanced low temperature combustion approach for BS VI. SAE technical paper 2017–26–0042. 2017.

Iwabuchi Y, Kawai K, Shoji T, Takeda Y. Trial of new concept diesel combustion system-premixed compression-ignited combustion. SAE technical paper 1999–01–0185. 1999.

Jain A, Singh AP, Agarwal AK. Effect of split fuel injection and EGR on NOx and PM emission reduction in a low temperature combustion (LTC) mode diesel engine. Energy. 2017;122:249–64.

kitano k, Nishiumi R, Tsukasaki Y, Tanaka T, Morinaga M. Effect of fuel properties on premixed charge compression ignition combustion in a direct injection diesel engine. SAE technical paper 2003–01–1815. 2003.

Dumitrescu CE, Stuart Neill W, Guo H, Hosseini V, Chippior WL. Fuel property effects on PCCI combustion in a heavy-duty diesel engine. J Eng Gas Turbine Power. 2012. https://doi.org/10.1115/1.4005213.

Park SH, Yoon SH, Lee CS. HC and CO emissions reduction by early injection strategy in a bioethanol blended diesel-fuelled engine with a narrow angle injection system. Appl Energy. 2013;107:81–8.

Su W, Yu W. Effects of mixing and chemical parameters on thermal efficiency in a partly premixed combustion diesel engine with near-zero emissions. Int J Eng Res. 2012;13:188–98.

Takada Y, Ueki S, Saito A, Sawazu N, Nagatomi Y. Improvement of fuel economy by eco-driving with devices for freight vehicles in real traffic conditions. SAE technical paper 2007–01–1323. 2007.

Öztürk E, Can Ö, Usta N, Yücesu HS. Effects of retarded fuel injection timing on combustion and emissions of a diesel engine fueled with canola biodiesel. Eng Sci Technol Int J. 2020;23:1466–75.

Singh M, Sandhu SS. Effect of boost pressure on combustion, performance and emission characteristics of a multicylinder CRDI engine fueled with argemone biodiesel/diesel blends. Fuel. 2021;300:121001.

Colban WF, Miles PC, Oh S. Effect of intake pressure on performance and emissions in an automotive diesel engine operating in low temperature combustion regimes. SAE technical paper 2007–01–4063. 2007.

Geng P, Cao E, Tan Q, Wei L. Effects of alternative fuels on the combustion characteristics and emission products from diesel engines: a review. Renew Sustain Energy Rev. 2017;71:523–34.

Gren L, Malmborg VB, Falk J, Markula L, Novakovic M, Shamun S, et al. Effects of renewable fuel and exhaust after treatment on primary and secondary emissions from a modern heavy-duty diesel engine. J Aerosol Sci. 2021;156:105781.

Apicella B, Mancaruso E, Russo C, Tregrossi A, Oliano MM, Ciajolo A, et al. Effect of after-treatment systems on particulate matter emissions in diesel engine exhaust. Exp Therm Fluid Sci. 2020;116:110107.

Elkelawy M, Bastawissi HAE, el Shenawy EA, Shams MM, Panchal H, Sadasivuni KK, et al. Influence of lean premixed ratio of PCCI-DI engine fueled by diesel/biodiesel blends on combustion, performance, and emission attributes; a comparison study. Energy Convers Manag X. 2021;10:100066.

Shamun S, Shen M, Johansson B, Tuner M, Pagels J, Gudmundsson A, et al. Exhaust PM emissions analysis of alcohol fueled heavy-duty engine utilizing PPC. SAE Int J Eng. 2016;9:2142–52.

Lee S, Jang J, Oh S, Lee Y, Kim J, Lee K. Comparative study on effect of intake pressure on diesel and biodiesel low temperature combustion characteristics in a compression ignition engine. SAE technical paper 2013–01–2533. 2013.

Lu X, Han D, Huang Z. Fuel design and management for the control of advanced compression-ignition combustion modes. Prog Energy Combust Sci. 2011;1:741–83.

Park SH, Cha J, Kim HJ, Lee CS. Effect of early injection strategy on spray atomization and emission reduction characteristics in bioethanol blended diesel fuelled engine. Energy. 2012;39:375–87.

Kokjohn SL, Hanson RM, Splitter DA, Reitz RD. Experiments and modelling of dual-fuel HCCI and PCCI combustion using in-cylinder fuel blending. SAE Int J Eng. 2010;2:24–39.

Ying W, Wei L, Longbao Z. Advanced combustion operation in a single-cylinder engine. Int J Therm Sci. 2010;49:1303–8.

Wang Y, Liu H, Huang Z, Liu Z. Study on combustion and emission of a dimethyl ether-diesel dual-fuel premixed charge compression ignition combustion engine with LPG (liquefied petroleum gas) as ignition inhibitor. Energy. 2016;96:278–85.

Hwang J, Jung Y, Bae C. Biodiesel PCI combustion for performance and emission improvement in a compression ignition engine. Energy Fuels Am Chem Soc. 2021;35:1523–34.

Zehni A, Saray RK. Comparison of late PCCI combustion, performance and emissions of diesel engine for B20 and B100 fuels by KIVA-CHEMKIN coupling. Renew Energy. 2018;122:118–30.

Sendilvelan S, Bhaskar K. Experimental analysis of PCCI in a diesel engine with different fuel blends. World J Eng. 2018;15:567–74.

Ji Q, Li J, Wang J, Sun P, Wu P. Simulation analysis of the effects of methanol-polyoxymethylene dimethyl ethers blends on combustion and emissions of a PCCI engine. E3S Web Conf. 2021;252:03022.

Hikichi K, Kaneko N, Ogawa H, Miyamoto N. Visualization and analysis of reaction suppression by methanol in a PCCI engine. The proceedings of conference of Hokkaido branch. 2002;42:90–1.

Toshinaga K, Kuribayashi M. A study on PCCI combustion control in medium speed dual-fuel engine. SAE technical papers 2019–01–2176. 2019.

Qian Y, Wu Z, Guo J, Li Z, Jiang C, Lu X. Experimental studies on the key parameters controlling the combustion and emission in premixed charge compression ignition concept based on diesel surrogates. Appl Energy. 2019;235:233–46.

Manente V, Zander CG, Johansson B, Tunestal P. An advanced internal combustion engine concept for low emissions and high efficiency from idle to max load using gasoline partially premixed combustion. SAE technical paper 2010–01–2198. 2010.

Simescu S, Fiveland SB, Dodge LG. An experimental investigation of PCCI-DI combustion and emissions in a heavy-duty diesel engine. SAE technical paper 2004–01–0121. 2004.

Zheng M, Mulenga MC, Reader GT, Wang M, Ting DSK, Tjong J. Biodiesel engine performance and emissions in low temperature combustion. Fuel. 2008;87:714–22.

An Y, Jaasim M, Raman V, Hernández Pérez FE, Im HG, Johansson B. Homogeneous charge compression ignition (HCCI) and partially premixed combustion (PPC) in compression ignition engine with low octane gasoline. Energy. 2018;158:181–91.

Kawano D, Naito H, Suzuki H, Ishii H, Hori S, Goto Y, et al. Effects of fuel properties on combustion and exhaust emissions of homogeneous charge compression ignition (HCCI) engine. SAE technical paper 2004–01–1966. 2004.

Boot MD, Luijten CCM, Somers LMT, Eguz U, van Erp DDTM, Albrecht A, et al. Uncooled EGR as a means of limiting wall-wetting under early direct injection conditions. SAE technical paper 2009–01–0665. 2009.

Boyarski NJ, Reitz RD. Premixed compression ignition (PCI) combustion with modeling-generated piston bowl geometry in a diesel engine. SAE technical paper 2006–01–0198. 2006.

Cheng XB, Hu YY, Yan FQ, Chen L, Dong SJ. Investigation of the combustion and emission characteristics of partially premixed compression ignition in a heavy-duty diesel engine. Proceedings of the institution of mechanical engineers, Part D: Journal of automobile engineering. SAGE publications Ltd; 2014;228:784–98.

Hardy WL, Reitz RD. A study of the effects of high EGR, high equivalence ratio, and mixing time on emissions levels in a heavy-duty diesel engine for PCCI combustion. SAE technical paper 2006–01–0026. 2006.

Jung Y, Bae C, Choi SB, Shin HD. Premixed compression ignition combustion with various injector configurations in a heavy duty diesel engine. Proceedings of the institution of mechanical engineers, Part D: Journal of automobile engineering. SAGE publications Ltd; 2013;227:422–32.

Kathirvelu B, Subramanian S. Performance and emission characteristics of biodiesel blends in a premixed compression ignition engine with exhaust gas recirculation. Environ Eng Res. 2017;22:294–301.

Kim HJ, Park SH, Lee CS. Influence of the fuel spray angle and the injection strategy on the emissions reduction characteristics in a diesel engine. Proceedings of the institution of mechanical engineers, Part D: Journal of automobile engineering. SAGE publications Ltd; 2015;229:563–73.

Korkmaz M, Zweigel R, Niemietz K, Jochim B, Abel D, Pitsch H. Assessment of different included spray cone angles and injection strategies for PCCI diesel engine combustion. SAE technical paper 2017–01–0717. 2017.

Han D, Ickes AM, Bohac SV, Huang Z, Assanis DN. Premixed low-temperature combustion of blends of diesel and gasoline in a high speed compression ignition engine. Proceedings of the combustion institute. 2011;33:3039–46.

Pidol L, Lecointe B, Starck L, Jeuland N. Ethanol-biodiesel-diesel fuel blends: performances and emissions in conventional diesel and advanced low temperature combustions. Fuel. 2012;93:329–38.

Kalghatgi GT, Ångström H-E. Advantages of fuels with high resistance to auto-ignition in late-injection, low-temperature, compression ignition combustion. SAE technical paper 2006–01–3385. 2006.

Fang T, Lin YC, Foong TM, Lee CF. Biodiesel combustion in an optical HSDI diesel engine under low load premixed combustion conditions. Fuel. 2009;88:2154–62.

Fang T, Lee CF. Bio-diesel effects on combustion processes in an HSDI diesel engine using advanced injection strategies. Proceedings of the combustion institute. Elsevier Ltd; 2009;32 II:2785–92.

Su J, Zhu H, Bohac SV. Particulate matter emission comparison from conventional and premixed low temperature combustion with diesel, biodiesel and biodiesel-ethanol fuels. Fuel. 2013;113:221–7.

Han D, Ickes AM, Bohac SV, Huang Z, Assanis DN. HC and CO emissions of premixed low-temperature combustion fueled by blends of diesel and gasoline. Fuel. 2012;99:13–9.

Torregrosa AJ, Broatch A, García A, Mónico LF. Sensitivity of combustion noise and NOx and soot emissions to pilot injection in PCCI diesel engines. Appl Energy. 2013;104:149–57.

Kim H, Kim K, Lee K. Reduction in harmful emissions using a two-stage injection-type premixed charge compression ignition engine. Environ Eng Sci. 2009;26:1567–76.

Elumalai PV, Kumar Dash S, Parthasarathy M, Dhineshbabu NR, Balasubramanian D, Nam Cao D, et al. Combustion and emission behaviors of dual-fuel premixed charge compression ignition engine powered with n-pentanol and blend of diesel/waste tire oil included nanoparticles. Fuel. 2022;324:124603.

Alemayehu Getachew, Firew D, NRB, KSK. PCCI combustion for better emissions in diesel engines. In: Jha Kanishka, Gulati P, TUK, editors. Recent advances in sustainable technologies. Singapore: Springer Singapore; 2021. p. 183–94.

Jacobs TJ, Assanis DN. The attainment of premixed compression ignition low-temperature combustion in a compression ignition direct injection engine. Proceedings of the combustion institute. Elsevier Ltd; 2007;31(2):2913–20.

Alriksson M, Denbratt I. Low temperature combustion in a heavy duty diesel engine using high levels of EGR. SAE technical paper 2006–01–0075. 2006.

Noehre C, Andersson M, Johansson B, Hultqvist A. Characterization of partially premixed combustion. SAE technical paper 2006–01–3412. 2006.

Bohac SV, Han M, Jacobs TJ, López AJ, Assanis DN, Szymkowicz PG. Speciated hydrocarbon emissions from an automotive diesel engine and doc utilizing conventional and PCI combustion. SAE technical paper 2006–01–0201. 2006.

Northrop WF, Jacobs TJ, Assanis DN, Bohac SV. Deactivation of a diesel oxidation catalyst due to exhaust species from rich premixed compression ignition combustion in a light-duty diesel engine. Int J Eng Res. 2007;8:487–98.

Sylvain M, Kashdan JT, Gilles B, Thirouard B, Franck V. Formation of unburned hydrocarbons in low temperature diesel combustion. SAE Int J Eng. 2010;2:205–25.

Ekoto IW, Colban WF, Miles PC, Park SW, Foster DE, Reitz RD, et al. UHC and CO emissions sources from a light-duty diesel engine undergoing dilution-controlled low-temperature combustion. SAE Int J Eng. 2010;2:411–30.

Kim D, Ekoto I, Colban WF, Miles PC. In-cylinder CO and UHC imaging in a light-duty diesel engine during PPCI low-temperature combustion. SAE Int J Fuels Lubr. 2009;1:933–56.

Colban WF, Miles PC, Oh S. On the cyclic variability and sources of unburned hydrocarbon emissions in low temperature diesel combustion systems. SAE technical paper 2007–01–1837. 2007.

Bhurat S, Pandey S, Chintala V, Jaiswal M, Kurein C. Effect of novel fuel vaporiser technology on engine characteristics of partially premixed charge compression ignition (PCCI) engine with toroidal combustion chamber. Fuel. 2022. https://doi.org/10.1016/j.fuel.2022.123197.

Petersen BR, Ekoto IW, Miles PC. An investigation into the effects of fuel properties and engine load on UHC and CO emissions from a light-duty optical diesel engine operating in a partially premixed combustion regime. SAE Int J Eng. 2010;3:38–55.

Hildingsson L, Kalghatgi G, Tait N, Johansson B, Harrison A. Fuel octane effects in the partially premixed combustion regime in compression ignition engines. SAE technical paper 2009–01–2648. 2009.

Weall A, Collings N. Investigation into partially premixed combustion in a light-duty multi-cylinder diesel engine fuelled with a mixture of gasoline and diesel. SAE technical paper 2007–01–4058. 2007.

Weall A, Collings N. Gasoline fuelled partially premixed compression ignition in a light duty multi cylinder engine: a study of low load and low speed operation. SAE Int J Eng. 2009;2:1574–86.

Susanth Kishna R, Nanthagopal K, Ashok B, Srinath R, Pranava Kumar M, Bhowmick P. Investigation on pilot injection with low temperature combustion of Calophyllum inophyllum biodiesel fuel in common rail direct injection diesel engine. Fuel. 2019. https://doi.org/10.1016/j.fuel.2019.116144.

Tormos B, Novella R, García A, Gargar K. Comprehensive study of biodiesel fuel for HSDI engines in conventional and low temperature combustion conditions. Renew Energy. 2010;35:368–78.

Northrop WF, Madathil PV, Bohac SV, Assanis DN. Condensational growth of particulate matter from partially premixed low temperature combustion of biodiesel in a compression ignition engine. Aerosol Sci Technol. 2011;45:26–36.

Northrop W, Bohac S, Assanis D. Premixed low temperature combustion of biodiesel and blends in a high speed compression ignition engine. SAE Int J Fuels Lubr. 2009;2:28–40.

Leermakers CAJ, Luijten CCM, Somers LMT, Kalghatgi GT, Albrecht BA. Experimental study of fuel composition impact on PCCI combustion in a heavy-duty diesel engine. SAE technical paper 2011–01–1351. 2011.

Boot MD, Frijters PJM, Klein-Douwel RJH, Baert RSG. Oxygenated fuel composition impact on heavy-duty diesel engine emissions. SAE technical paper 2007–01–2018. 2007.

Li J, Liu J, Ji Q, Sun P, Wei M, Liu S, et al. Effects of pilot injection strategy on in-cylinder combustion and emission characteristics of PODE/methanol blends. Fuel Process Technol. 2022;228:107168.

Liu J, Wu P, Ji Q, Sun P, Wang P, Meng Z, et al. Experimental study on effects of pilot injection strategy on combustion and emission characteristics of diesel/methanol dual-fuel engine under low load. Energy Pergam. 2022;247:123464.

Elzahaby AM, Elkelawy M, Bastawissi HAE, el Malla SM, Naceb AMM. Kinetic modeling and experimental study on the combustion, performance and emission characteristics of a PCCI engine fueled with ethanol-diesel blends. Egypt J Pet. 2018;27:927–37.

Han X, Yang Z, Wang M, Tjong J, Zheng M. Clean combustion of n-butanol as a next generation biofuel for diesel engines. Appl Energy. 2017;198:347–59.

Kalghatgi G, Hildingsson L, Johansson B. Low NOx and low smoke operation of a diesel engine using gasolinelike fuels. J Eng Gas Turbine Power. 2010. https://doi.org/10.1115/1.4000602.

Park H, Shim E, Bae C. Improvement of combustion and emissions with exhaust gas recirculation in a natural gas-diesel dual-fuel premixed charge compression ignition engine at low load operations. Fuel. 2019;235:763–74.

Parks JE, Prikhodko V, Storey JME, Barone TL, Lewis SA, Kass MD, et al. Emissions from premixed charge compression ignition (PCCI) combustion and affect on emission control devices. Catal Today. 2010;151:278–84.

Manente V, Johansson B, Tunestal P, Cannella WJ. Influence of inlet pressure, EGR, combustion phasing, speed and pilot ratio on high load gasoline partially premixed combustion. SAE technical paper 2010–01–1471. 2010.

Manente V, Tunestal P, Johansson B, Cannella WJ. Effects of ethanol and different type of gasoline fuels on partially premixed combustion from low to high load. SAE technical paper 2010–01–0871. 2010.

Kaiadi M, Johansson B, Lundgren M, Gaynor JA. Experimental investigation on different injection strategies for ethanol partially premixed combustion. SAE technical paper 2013–01–0281. 2013.

Ingesson G, Yin L, Johansson R, Tunestål P. A double-injection control strategy for partially premixed combustion. IFAC-PapersOnLine. 2016;49:353–60.

Benajes J, Molina S, Novella R, de Lima D. Implementation of the partially premixed combustion concept in a 2-stroke HSDI diesel engine fueled with gasoline. Appl Energy. 2014;122:94–111.

An Y, Vedharaj S, Vallinayagam R, Dawood A, Masurier JB, Izadi Najafabadi M, et al. Effect of aromatics on combustion stratification and particulate emissions from low octane gasoline fuels in PPC and HCCI mode. SAE technical paper 2017–24–0086. 2017.

Vallinayagam R, Vedharaj S, An Y, Dawood A, Izadi Najafabadi M, Somers B, et al. Combustion stratification for naphtha from CI combustion to PPC. SAE technical paper 2017–01–0745. 2017.

Laguitton O, Crua C, Cowell T, Heikal MR, Gold MR. The effect of compression ratio on exhaust emissions from a PCCI diesel engine. Energy Convers Manag. 2007;48:2918–24.

Zhao Y, Wang Y, Liu S. Combustion and emission characteristics in a DME premixed charge compression ignition diesel engine. SAE technical paper 2014–01–1292. 2014.

Pedrozo VB, May I, Dalla Nora M, Cairns A, Zhao H. Experimental analysis of ethanol dual-fuel combustion in a heavy-duty diesel engine: an optimisation at low load. Appl Energy. 2016;165:166–82.

Salahi MM, Gharehghani A. Control of combustion phasing and operating range extension of natural gas PCCI engines using ozone species. Energy Convers Manag. 2019. https://doi.org/10.1016/j.enconman.2019.112000.

Alagumalai A. Combustion characteristics of lemongrass (Cymbopogon flexuosus) oil in a partial premixed charge compression ignition engine. Alex Eng J. 2015;54:405–13.

Soloiu V, Duggan M, Ochieng H, Williams D, Molina G, Vlcek B. Investigation of low temperature combustion regimes of biodiesel with n-butanol injected in the intake manifold of a compression ignition engine. J Energy Resour Technol. 2013. https://doi.org/10.1115/1.4023743.

Manente V, Johansson B, Tunestal P. Partially premixed combustion at high load using gasoline and ethanol, a comparison with diesel. SAE technical paper 2009–01–0944. 2009.

How HG, Masjuki HH, Kalam MA, Teoh YH. Influence of injection timing and split injection strategies on performance, emissions, and combustion characteristics of diesel engine fuelled with biodiesel blended fuels. Fuel. 2018;213:106–14.

Tompkins BT, Jacobs TJ. Low-temperature combustion with biodiesel: its enabling features in improving efficiency and emissions. Energy Fuels. 2013;27:2794–803.

Kim MY, Lee JH, Lee CS. Combustion characteristics and NOx emissions of a dimethyl-ether-fuelled premixed charge compression ignition engine. Energy Fuels. 2008;22:4206–12.

Zhang J, Qiao X, Wang Z, Guan B, Huang Z. Experimental investigation of low-temperature combustion (LTC) in an engine fuelled with dimethyl ether (DME). Energy Fuels. 2009;23:170–4.

Lilik GK, Boehman AL. Advanced diesel combustion of a high cetane number fuel with low hydrocarbon and carbon moNOxide emissions. Energy Fuels. 2011;25:1444–56.

Srivatsa CV, Mattson J, Depcik C. Exploring the possibility of achieving partially premixed charge compression ignition combustion of biodiesel in comparison to ultra-low sulfur diesel on a high compression ratio engine. Combust Sci Technol. 2021. https://doi.org/10.1080/00102202.2021.1974420.

Yan Y, Zhang YS. The study on PCCI mode of diesel engine fueled with methanol/dimethyl ether. Appl Mech Mater. 2014;607:629–32.

Manente V, Johansson B, Tunestal P. Characterization of partially premixed combustion with ethanol: Egr sweeps, low and maximum loads. J Eng Gas Turbine Power. 2010. https://doi.org/10.1115/ICES2009-76165.

Shen M, Tuner M, Johansson B. Close to stoichiometric partially premixed combustion—the benefit of ethanol in comparison to conventional fuels. SAE technical paper 2013–01–0277. 2013.

Gao T, Divekar P, Asad U, Han X, Reader GT, Wang M, et al. An enabling study of low temperature combustion with ethanol in a diesel engine. J Energy Resour Technol. 2013. https://doi.org/10.1115/ICEF2012-92176.

Divekar P, Yang Z, Ting D, Chen X, Zheng M, Tjong J. Efficiency and emission trade-off in diesel-ethanol low temperature combustion cycles. SAE technical paper 2015–01–0845. 2015.

Nibin M, Raj JB, Geo VE. Experimental studies to improve the performance, emission and combustion characteristics of wheat germ oil fuelled CI engine using bioethanol injection in PCCI mode. Fuel. 2021. https://doi.org/10.1016/j.fuel.2020.119196.

Thiyagarajan S, Sonthalia A, Edwin Geo V, Prakash T, Karthickeyan V, Ashok B, et al. Effect of manifold injection of methanol/n-pentanol in safflower biodiesel fuelled CI engine. Fuel. 2020. https://doi.org/10.1016/j.fuel.2019.116378.

Hunicz J, Matijošius J, Rimkus A, Kilikevičius A, Kordos P, Mikulski M. Efficient hydrotreated vegetable oil combustion under partially premixed conditions with heavy exhaust gas recirculation. Fuel. 2020. https://doi.org/10.1016/j.fuel.2020.117350.

el Shenawy EA, Elkelawy M, Bastawissi HAE, Shams MM, Panchal H, Sadasivuni K, et al. Investigation and performance analysis of water-diesel emulsion for improvement of performance and emission characteristics of partially premixed charge compression ignition (PPCCI) diesel engines. Sustain Energy Technol Assess. 2019. https://doi.org/10.1016/j.seta.2019.100546.

Kumar SA, Sivakumar S. Effect of preheating in premixed charge compression ignition engine using various fuels—an experimental investigation. Mater Today Proc. 2020. https://doi.org/10.1016/j.matpr.2020.09.192.

Hariharan D, Rajan Krishnan S, Kumar Srinivasan K, Sohail A. Multiple injection strategies for reducing HC and CO emissions in diesel-methane dual-fuel low temperature combustion. Fuel. 2021. https://doi.org/10.1016/j.fuel.2021.121372.

Guerry ES, Raihan MS, Srinivasan KK, Krishnan SR, Sohail A. Injection timing effects on partially premixed diesel-methane dual fuel low temperature combustion. Appl Energy. 2016;162:99–113.

Raza M, Chen L, Ruiz R, Chu H. Influence of pentanol and dimethyl ether blending with diesel on the combustion performance and emission characteristics in a compression ignition engine under low temperature combustion mode. J Energy Inst. 2019;92:1658–69.

Jia M, Xie M, Wang T, Peng Z. The effect of injection timing and intake valve close timing on performance and emissions of diesel PCCI engine with a full engine cycle CFD simulation. Appl Energy. 2011;88:2967–75.

Zehni A, Khoshbakhti Saray R, Poorghasemi K. Numerical comparison of PCCI combustion and emission of diesel and biodiesel fuels at low load conditions using 3D-CFD models coupled with chemical kinetics. Appl Therm Eng. 2017;110:1483–99.

Luo Z, Plomer M, Lu T, Som S, Longman DE, Sarathy SM, et al. A reduced mechanism for biodiesel surrogates for compression ignition engine applications. Fuel. 2012;99:143–53.

Chang Y, Jia M, Li Y, Zhang Y, Xie M, Wang H, et al. Development of a skeletal oxidation mechanism for biodiesel surrogate. Proc Combust Inst. 2015;35:3037–44.

Niemeyer KE, Daly SR, Cannella WJ, Hagen CL. Investigation of the LTC fuel performance index for oxygenated reference fuel blends. Fuel. 2015;155:14–24.

Lee Y, Jang K, Han K, Huh KY, Oh S. Simulation of a heavy duty diesel engine fueled with soybean biodiesel blends in low temperature combustion. SAE technical paper 2013–01–1100. 2013.

Brakora J, Reitz R. A comprehensive combustion model for biodiesel-fueled engine simulations. SAE technical paper 2013–01–1099. 2013.

Zehni A, Balazadeh N, Hajibabaei M, Poorghasemi K. Numerical study of the effects of split injection strategy and swirl ratio for biodiesel PCCI combustion and emissions. Propuls Power Res. 2020. https://doi.org/10.1016/j.jppr.2020.11.004.

Curran HJ, Fisher EM, Glaude P-A, Marinov NM, Pitz WJ, Westbrook CK, et al. Detailed chemical kinetic modeling of diesel combustion with oxygenated fuels. SAE technical paper 2001–01–0653. 2001.

Kokjohn SL, Reitz RD. A computational investigation of two-stage combustion in a light-duty engine. SAE Int J Eng. 2009;1:1083–104.

Peng Z, Liu B, Wang W, Lu L. CFD investigation into diesel PCCI combustion with optimized fuel injection. Energies. 2011;4:517–31.

Shuai S, Abani N, Yoshikawa T, Reitz RD, Park SW. Simulating low temperature diesel combustion with improved spray models. Int J Therm Sci. 2009;48:1786–99.

Opat R, Ra Y, Gonzalez MA, Krieger R, Reitz RD, Foster DE, et al. Investigation of mixing and temperature effects on HC/CO emissions for highly dilute low temperature combustion in a light duty diesel engine. SAE technical paper 2007–01–0193. 2007.

Aniello A, Vergata Rome T, Lorenzo Bartolucci I, Stefano Cordiner I, Vincenzo Mulone I, Sundar Krishnan IR, et al. CFD analysis of diesel-methane dual fuel low temperature combustion at low load and high methane substitution. Proceedings of the ASME 2018 internal combustion engine division fall technical conference Volume 1: Large Bore Engines; Fuels; Advanced Combustion. San Diego, California, USA: ASME; 2018.

Tripathi G, Sharma P, Dhar A. Computational study of diesel injection strategies for methane-diesel dual fuel engine. Clean Eng Technol. 2022;6:100393.

Belgiorno G, di Blasio G, Beatrice C. Parametric study and optimization of the main engine calibration parameters and compression ratio of a methane-diesel dual fuel engine. Fuel. 2018;222:821–40.

Lee Y, Huh KY. Analysis of different modes of low temperature combustion by ultra-high EGR and modulated kinetics in a heavy duty diesel engine. Appl Therm Eng. 2014;70:776–87.

Cao L, Bhave A, Su H, Mosbach S, Kraft M, Dris A, et al. Influence of Injection timing and piston bowl geometry on PCCI combustion and emissions. SAE Int J Eng. 2009;2:1019–33.

Zhang Y, Kong S-C, Reitz RD. Modeling and simulation of a dual fuel (diesel/natural gas) engine with multidimensional CFD. SAE technical paper 2003–01–0755. 2003.

Bartolucci L, Cordiner S, Mulone V, Krishnan SR, Srinivasan KK. A computational investigation of the impact of multiple injection strategies on combustion efficiency in diesel-natural gas dual-fuel lowerature combustion engines. J Energy Resour Technol. 2021. https://doi.org/10.1115/1.4047887.

Jha PR, Srinivasan KK, Krishnan SR. Influence of swirl ratio on diesel-methane dual fuel combustion: A CFD investigation. Proceedings of the ASME 2017 internal combustion engine division fall technical conference. Volume 1: Large bore engines; fuels; advanced combustion. Seattle, Washington, USA: ASME; 2017.

Hampson G, Marchese AJ. Natural gas/diesel RCCI CFD simulations using multi-component fuel surrogates. Int J Powertrains. 2017;6:76–108.

Gao Z, Wagner RM, Sluder CS, Daw CS, Green JB. Using a phenomenological computer model to investigate advanced combustion trajectories in a CIDI engine. Fuel. 2011;90:1907–18.

JU K. Numerical study on premixed charge compression ignition (PCCI) combustion for down-sized diesel engine using converge. SAE technical paper 2020–32–2308. 2020.

Yoshida K, Yamada K, Matsuo N, Tanimura T, Takayama T, Kataoka I. Unsteady numerical analysis on pcci combustion affected by intentional initial fuel concentration distribution. ASME international mechanical engineering congress and exposition, proceedings (IMECE). 2010. p. 555–62.

Mei D, Tu L, Ju Z, Jiang S, Wang X, Yuan Y. Numerical simulation of PCCI combustion in diesel engine with different injection timing. Jiangsu Daxue Xuebao (Ziran Kexue Ban)/Journal of Jiangsu University (Natural Science Edition). 2018;39:7–13.

Panakarajupally RP, Mittal G. Computational investigation of the double-injection strategy on ethanol partially premixed compression ignition. Energy Fuels Am Chem Soc. 2017;31:11280–90.

Li Z, Wang Y, Geng H, Zhen X, Liu M, Xu S, et al. Investigation of injection strategy for a diesel engine with directly injected methanol and pilot diesel at medium load. Fuel. 2020. https://doi.org/10.1016/j.fuel.2019.116958.

Jia M, Li Y, Xie M, Wang T. Numerical evaluation of the potential of late intake valve closing strategy for diesel PCCI (premixed charge compression ignition) engine in a wide speed and load range. Energy. 2013;51:203–15.

Zhang F, Liu HF, Yu J, Yao M. Direct numerical simulation of n-heptane/air auto-ignition with thermal and charge stratifications under partially-premixed charge compression ignition (PCCI) engine related conditions. Appl Therm Eng. 2016;104:516–26.

Acknowledgements

The authors would like to thank Dr. B. Govinda Rao for his kind suggestions and help throughout this work.

Author information

Authors and Affiliations

Contributions

YDB contributed to conceptualization and drafting; ASK contributed to problem definition, the theme of the paper, and proofreading.

Corresponding author

Ethics declarations

Conflict of interest

Authors declare that they do not have any competing interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bharadwaz, Y.D., Kumari, A.S. PCCI combustion of low-carbon alternative fuels: a review. J Therm Anal Calorim 148, 5179–5207 (2023). https://doi.org/10.1007/s10973-023-12108-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12108-1