Abstract

In this paper, the simultaneous impacts of using nanofluid and ultrasonic vibrations in a double-pipe heat exchanger are experimentally investigated. The vibrating heat exchanger is designed so that the ultrasonic waves with the power of 60 watts and frequency of 40 kHz are applied to its body at equal length distances in a uniform and effective manner. Water-based Al2O3 nanofluid is used in this research. The available empirical correlation has been used to confirm the accuracy of the measurements and validate the results. The effective thermal parameters have been tested in three cases using water, nanofluids, and ultrasonic-excited nanofluids as the working flow of the double-pipe heat exchanger. These tests have been performed in a relatively wide range of flow rate (113–257 lh−1), Reynolds number (3230–7431), inlet hot fluid temperature (40–60 °C), and nanoparticle volume fraction (0.4–0.8%). The results indicate the positive effect of adding nanoparticles and applying ultrasonic vibrations, especially at higher inlet hot fluid temperatures and higher nanofluids concentrations. The nanoparticles are more effective at high-flow rates, whereas the ultrasonic vibration is highlighted at low-flow rates. Also, the effectiveness-NTU analysis carried out for the current heat exchanger shows that using nanofluid and ultrasonic-excited nanofluid instead of water can increase the efficiency of the thermal system up to 18.3% and 42.3%, respectively.

Similar content being viewed by others

Abbreviations

- \(A\) :

-

Area (m2)

- \(D\) :

-

Pipe’s diameter (m)

- \(f\) :

-

Friction factor

- \(h\) :

-

Convection coefficient (W m−2 K−1)

- \(k\) :

-

Thermal conductivity (W m−1 K−1)

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- \(M\) :

-

Molecular mass

- \(N\) :

-

Avogadro number

- \({\text{Nu}}\) :

-

Nusselt number

- \(\Pr\) :

-

Prandtl number

- \(\dot{q}\) :

-

Heat transfer rate (W)

- Q :

-

Volumetric flow rate

- \({\text{Re}}\) :

-

Reynolds number

- \(U\) :

-

Overall heat transfer coefficient (W m−2 K−1)

- \(\varepsilon \) :

-

Efficiency

- θ :

-

Temperature (°C)

- \(\mu\) :

-

Dynamic viscosity (Pa s)

- \(\rho\) :

-

Density (kgm−3)

- \({\sigma }_{\mathrm{b}}\) :

-

Boltzmann constant

- \(\psi \) :

-

Volumetric percentage of nanoparticles

- \({\Omega }_{\mathrm{p}}\) :

-

Isobaric heat capacity (J kg−1 K−1)

- \({\Omega }_{\mathrm{r}}\) :

-

Capacity ratio

- ave:

-

Average

- \(c\) :

-

Cold

- \(h\) :

-

Hot

- \(i\) :

-

Inlet

- \(o\) :

-

Outlet

- nf:

-

Nanofluid

- np:

-

Nanoparticle

- wf:

-

Water fluid

- CFF:

-

Cold fluid flow

- CPVC:

-

Chlorinated polyvinyl chloride

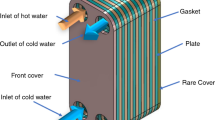

- DPHX:

-

Double-pipe heat exchanger

- HX:

-

Heat exchanger

- HFF:

-

Hot fluid flow

- HTE:

-

Heat transfer enhancement

- HTR:

-

Heat transfer rate

- LMTD:

-

Logarithmic mean temperature difference

- MWCNT:

-

Multi-walled carbon nanotube

- NTU:

-

Number of transfer units

References

Wang W, Zhang Y, Lee KS, Li B. Optimal design of a double pipe heat exchanger based on the outward helically corrugated tube. Int J Heat Mass Transf. 2019;135:706–16.

Corcoles JI, Moya-Rico JD, Molina AE, Almendros-Ibanez JA. Numerical and experimental study of the heat transfer process in a double pipe heat exchanger with inner corrugated tubes. Int J Therm Sci. 2020;158:106526.

Uzzan M, Leinen K, Labuza TP. Temperature profiles within a double-pipe heat exchanger with countercurrent turbulent flow of Newtonian fluids: derivation, validation, and application to food processing. J Food Sci. 2004;69:433–40.

Rennie TJ, Raghavan VG. Numerical analysis of the lethality and processing uniformity in a double-pipe helical heat exchanger. Chem Eng Process Process Intensif. 2010;49:672–9.

Omidi M, Farhadi M, Jafari M. A comprehensive review on double pipe heat exchangers. Appl Therm Eng. 2017;110:1075–90.

Moya-Rico JD, Molina AE, Córcoles JI, Almendros-Ibáñez JA. Experimental characterization of a double tube heat exchanger with different corrugated tubes and shells. Int J Therm Sci. 2022;179:107640.

Wu Z, Qiu L, Wu C, Zhou D. Study on flow and heat performance of thermal-hydrolyzed sludge in a double-pipe heat exchanger with a series of inner corrugated tubes. Int J Therm Sci. 2021;170:107160.

Luo C, Song KW. Thermal performance enhancement of a double-tube heat exchanger with novel twisted annulus formed by counter-twisted oval tubes. Int J Therm Sci. 2021;164:106892.

Li X, Wang L, Feng R, Wang Z, Liu S, Zhu D. Study on shell side heat transport enhancement of double tube heat exchangers by twisted oval tubes. Int Commun Heat Mass Transf. 2021;124:105273.

Pourahmad S, Pesteei SM, Ravaeei H, Khorasani S. Experimental study of heat transfer and pressure drop analysis of the air/water two-phase flow in a double tube heat exchanger equipped with dual twisted tape turbulator: simultaneous usage of active and passive methods. J Energy Storage. 2021;44:103408.

Moya-Rico JD, Molina AE, Belmonte JF, Córcoles Tendero JI, Almendros-Ibáñez JA. Experimental characterization of a double tube heat exchanger with inserted twisted tape elements. Appl Therm Eng. 2020;174:115234.

Padmanabhan S, Reddy OY, Yadav KVAK, Raja VKB, Palanikumar K. Heat transfer analysis of double tube heat exchanger with helical inserts. Mater Today Proc. 2021;46:3588–95.

Akpinar EK, Bicer Y. Investigation of heat transfer and exergy loss in a concentric double pipe exchanger equipped with swirl generators. Int J Therm Sci. 2005;44:598–607.

Zhao J, Reda SA, Al-Zahrani KS, Singh PK, Amin MT, Tag-Eldin E, Emami F. Hydro-thermal and economic analyses of the air/water two-phase flow in a double tube heat exchanger equipped with wavy strip turbulator. Case Stud Therm Eng. 2022;37:102260.

Eiamsa-ard S, Pethkool S, Thianpong C, Promvonge P. Turbulent flow heat transfer and pressure loss in a double pipe heat exchanger with louvered strip inserts. Int Commun Heat Mass Transfer. 2008;35:120–9.

Sheikholeslami M, Hatami M, Jafaryar M, Farkhadnia F, Ganji DD, GorjiBandpy M. Thermal management of double-pipe air to water heat exchanger. Energy Build. 2015;88:361–6.

Zhang L, Guo H, Wu J, Du W. Compound heat transfer enhancement for shell side of double-pipe heat exchanger by helical fins and vortex generators. Heat Mass Transf. 2012;48:1113–24.

Sanchouli M, Payan S, Payan A, Nada SA. Investigation of the enhancing thermal performance of phase change material in a double-tube heat exchanger using grid annular fins. Case Stud Therm Eng. 2022;34:101986.

Taborek J. Double-pipe and multitube heat exchangers with plain and longitudinal finned tubes. Heat Transfer Eng. 1997;18:34–45.

Amiri DA, Atashafrooz M, Sajjadi H, Karimnejad S. The thermal effects of multi-walled carbon nanotube concentration on an ultrasonic vibrating finned tube heat exchanger. Int Commun Heat Mass Transfer. 2022;135:106098.

Mukesh Kumar PC, Chandrasekar M. CFD analysis on heat and flow characteristics of double helically coiled tube heat exchanger handling MWCNT/water nanofluids. Heliyon. 2019;5:e02030.

Poongavanam GK, Panchabikesan K, Murugesan R, Duraisamy S, Ramalingam V. Experimental investigation on heat transfer and pressure drop of MWCNT—Solar glycol based nanofluids in shot peened double pipe heat exchanger. Powder Technol. 2019;345:815–24.

Rabienataj Darzi AA, Farhadi M, Sedighi K. Heat transfer and flow characteristics of AL2O3–water nanofluid in a double tube heat exchanger. Int Commun Heat Mass Transf. 2013;47:105–12.

Han D, He WF, Asif FZ. Experimental study of heat transfer enhancement using nanofluid in double tube heat exchanger. Energy Procedia. 2017;142:2547–53.

Qi C, Luo T, Liu M, Fan F, Yan Y. Experimental study on the flow and heat transfer characteristics of nanofluids in double-tube heat exchangers based on thermal efficiency assessment. Energy Convers Manag. 2019;197:111877.

Duangthongsuk W, Wongwises S. Heat transfer enhancement and pressure drop characteristics of TiO2–water nanofluid in a double-tube counter flow heat exchanger. Int J Heat Mass Transf. 2009;52:2059–67.

Ravi KH, Dhanasekaran C, Rathnakumar P, Mohamed IS, Sivaganesan S. Biosynthesized zinc nano fluid for helically coiled heat exchanger at constant heat flux. Mater Today Proc. 2022;58:104–13.

Raja S, Sivahari Shankar MS, Mathan KP, Rajaganapathy C. Heat transfer analysis and enhancement in shell and tube heat exchanger using copper oxide Nano particles. Mater Today Proc. 2022;64:1732–7.

Kavitha R, Algani YMA, Kulkarni K, Gupta MK. Heat transfer enhancement in a double pipe heat exchanger with copper oxide nanofluid: an experimental study. Mater Today Proc. 2022;56:3446–9.

Baba MS, Raju AVSR, Rao MB. Heat transfer enhancement and pressure drop of Fe3O4 -water nanofluid in a double tube counter flow heat exchanger with internal longitudinal fins. Case Stud Therm Eng. 2018;12:600–7.

Shahsavar A, Alimohammadi S, Askari IB, Shahmohammadi M, Jamei M, Pouyan N. Two-phase mixture numerical and soft computing-based simulation of forced convection of biologically prepared water-silver nanofluid inside a double-pipe heat exchanger with converging sinusoidal wall: hydrothermal performance and entropy generation analysis. Eng Anal Bound Elem. 2022;143:43–60.

Armstrong M, Sivasubramanian M, Selvapalam N. Experimental investigation on the heat transfer performance analysis in silver nano-coated double pipe heat exchanger using displacement reaction. Mater Today Proc. 2021;45:2482–90.

Zheng D, Du J, Wang W, Klemes JJ, Wang J, Sunden B. Analysis of thermal efficiency of a corrugated double-tube heat exchanger with nanofluids. Energy. 2022;256:124522.

Singh SK, Sarkar J. Improving hydrothermal performance of hybrid nanofluid in double tube heat exchanger using tapered wire coil turbulator. Adv Powder Technol. 2020;31:2092–100.

Nakhchi ME, Hatami M, Rahmati M. Effects of CuO nano powder on performance improvement and entropy production of double-pipe heat exchanger with innovative perforated turbulators. Adv Powder Technol. 2021;32:3063–74.

Gnanavel C, Saravanan R, Chandrasekaran M. Heat transfer enhancement through nano-fluids and twisted tape insert with rectangular cut on its rib in a double pipe heat exchanger. Mater Today Proc. 2020;21:865–9.

Gnanavel C, Saravanan R, Chandrasekaran M. Heat transfer augmentation by nano-fluids and spiral spring insert in double tube heat exchanger—A numerical exploration. Mater Today Proc. 2020;21:857–61.

Gnanavel C, Saravanan R, Chandrasekaran M. Heat transfer augmentation by nano-fluids and circular fin insert in double tube heat exchanger—A numerical exploration. Mater Today Proc. 2020;21:934–9.

Dehbani M, Rahimi M, Rahimi Z. A review on convective heat transfer enhancement using ultrasound. Appl Therm Eng. 2022;208:118273.

Neethu TS, Sabu AS, Mathew A, Wakif A, Areekara S. Multiple linear regression on bioconvective MHD hybrid nanofluid flow past an exponential stretching sheet with radiation and dissipation effects. Int Commun Heat Mass Transf. 2022;135:106115.

Harfouf EL, Wakif A, Mounir A, Hayani S. Heat transfer analysis on squeezing unsteady MHD nanofluid flow between two parallel plates considering thermal radiation, magnetic and viscous dissipations effects a solution by using homotopy perturbation method. Sens Lett. 2020;18:113–21.

Legay M, Gondrexon N, Le Person S, Boldo P, Bontemps A. Enhancement of Heat transfer by ultrasound: review and recent advances. Int J Chem Eng. 2011. https://doi.org/10.1155/2011/670108.

Amiri DA, Sajjadi H, Atashafrooz M, Hesari M, Ben Hamida MB, Arabkoohsar A. Louvered fin-and-flat tube compact heat exchanger under ultrasonic excitation. Fire. 2023;6:13.

Amiri DA, Sajjadi H, Mohebbi R, Izadi M. Ultrasonic vibration technology to improve the thermal performance of CPU Water-cooling systems: experimental investigation. Water. 2022;14:4000.

Rakpakdee W, Tuntarungsri S, Pornnattawut M, Motozawa M, Fukuta M, Chaiworapuek W. Experimental evaluation of heat transfer performance of double vertical coils and shell heat exchanger with altered inlet configuration under low-frequency ultrasound. Appl Therm Eng. 2023. https://doi.org/10.1016/j.applthermaleng.2023.120003.

Legay M, Simony B, Boldo P, Gondrexon N, Le Person S, Bontemps A. Improvement of heat transfer by means of ultrasound: application to a double-tube heat exchanger. Ultrason Sonochem. 2012;19:1194–200.

Legay M, Le Person S, Gondrexon N, Boldo P, Bontemps A. Performances of two heat exchangers assisted by ultrasound. Appl Therm Eng. 2012;37:60–6.

Setareh M, Saffar-Avval M, Abdullah A. Experimental and numerical study on heat transfer enhancement using ultrasonic vibration in a double-pipe heat exchanger. Appl Therm Eng. 2019;159:113867.

Setareh M, Saffar-Avval M, Abdullah A. Heat transfer enhancement in an annulus under ultrasound field: a numerical and experimental study. Int Commun Heat Mass Transf. 2020;114:104560.

Li J, Hou S, Teng D, Shen G. Experimental research on enhanced heat transfer of double-pipe exchanger with audible acoustic field. Int J Heat Mass Transf. 2023;201:123565.

Chen Y, Sun S, Lai Y, Ma C. Influence of ultrasound to convectional heat transfer with fouling of cooling water. Appl Therm Eng. 2016;100:340–7.

Hou T, Chen Y, Wang Z, Ma C. Experimental study of fouling process and antifouling effect in convective heat transfer under ultrasonic treatment. Appl Therm Eng. 2018;140:671–8.

Bergman TL, Lavine AS, Incropera FP, Dewitt DP. Fundamentals of heat and mass transfer. Hoboken: Wiley; 2011.

Kays WM, London AL. Compact heat exchangers. 3rd ed. New York: McGraw-Hill; 1984.

Pak BC, Cho YI. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transf Int J. 1998;11:151–70.

Xuan Y, Roetzel W. Conceptions for heat transfer correlation of nanofluids. Int J Heat Mass Transf. 2000;43:3701–7.

Corcione M. Empirical correlating equations for predicting the effective thermal conductivity and dynamic viscosity of nanofluids. Energy Convers Manag. 2011;52:789–93.

Gnielinski V. New equations for heat and mass transfer in turbulent pipe and channel flow. Int Chem Eng. 1976;16:359–68.

Petukhov BS, Advances in Heat Transfer. In: Irvine TF, Hartnett JP (eds.) Academic Press, New York, 1970.

Moffat RJ. Describing the uncertainties in experimental results. Exp Therm Fluid Sci. 1988;1:3–17.

Albadr J, Tayal S, Alasadi M. Heat transfer through heat exchanger using Al2O3 nanofluid at different concentrations. Case Stud Therm Eng. 2013;1:38–44.

Author information

Authors and Affiliations

Contributions

MH helped in conceptualization, methodology, and validation, AJ worked in formal analysis and investigation, and AA helped in formal analysis and investigation. AAD contibuted to methodology, investigation, and writing—original draft. All authors reviewed the manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hedeshi, M., Jalali, A., Arabkoohsar, A. et al. Nanofluid as the working fluid of an ultrasonic-assisted double-pipe counter-flow heat exchanger. J Therm Anal Calorim 148, 8579–8591 (2023). https://doi.org/10.1007/s10973-023-12102-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12102-7