Abstract

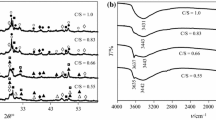

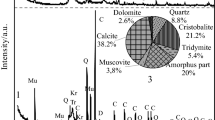

The influence of temperature and duration on the formation of cuspidine during hydrothermal synthesis was investigated in the CaO–SiO2·nH2O and CaO–silica gel waste–CaF2–H2O systems. The reaction was carried out in the temperature range of 95–200 °C for 4–48 h. In the system with amorphous silica, cuspidine was determined to form at 130 °C within 12 h. At higher temperatures (150–200 °C) its formation started earlier (within 4 h). Portlandite reacted completely in the temperature range of ~ 170–200 °C; meanwhile, a part of fluorite remained unreacted up to 200 °C. The surface area of the obtained synthetic cuspidine sample (200 °C, 12 h) was 56.9 m2 g–1. In the CaO–silica gel waste–CaF2–H2O system, cuspidine formed within 4 h and it was the main compound in the synthesis products with an admixture of katoite, which formed due to the presence of aluminium ions in the waste material. The SEM images showed that synthetic cuspidine samples from both systems exhibited a scaffold-like structure. The mineralogical composition of the synthesised products remained stable up to 48 h. The synthetic products were investigated by XRD, STA, FT-IR, BET and SEM analysis methods.

Similar content being viewed by others

References

Soliman NK, Moustafa AF. Industrial solid waste for heavy metals adsorption features and challenges; a review. J Mater Res Technol. 2020;9:10235–53.

Waste statistics - Statistics Explained [Internet]. [cited 2022]. Available from: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics#Total_waste_generation

Dreveton A. Manufacture of aluminium fluoride of high density and anhydrous hydrofluoric acid from fluosilicic acid. Procedia Eng Elsevier Ltd. 2012;46:255–65.

Dambrauskas T, Baltakys K, Grineviciene A, Rudelis V. The effect of various hydroxide and salt additives on the reduction of fluoride ion mobility in industrial waste. Sustainability. 2021;13:1–17. https://doi.org/10.3390/su13031554.

Rudelis V, Dambrauskas T, Grineviciene A, Baltakys K. The prospective approach for the reduction of fluoride ions mobility in industrial waste by creating products of commercial value. Sustainability. 2019;11:634.

Deshmukh P, Bhatt J, Peshwe D, Pathak S. Determination of silica activity index and XRD, SEM and EDS studies of amorphous SiO2 extracted from rice husk ash. Trans Indian Inst Met. 2012;65:63–70. https://doi.org/10.1007/s12666-011-0071-z.

Gineika A, Dambrauskas T, Baltakys K. Synthesis and characterisation of wollastonite with aluminium and fluoride ions. Ceram Int. 2021;47:22900–10.

Watanabe T, Fukuyama H, Nagata K. Stability of Cuspidine (3CaO 2SiO2 CaF2) and Phase Relations in the CaO–SiO2–CaF2 System. ISIJ Int. 2021;42:489–97.

Galuskina IO, Lazic B, Armbruster T, Galuskin EV, Gazeev VM, Zadov AE, et al. Kumtyubeite Ca5(SiO4)2F2:a new calcium mineral of the humite group from Northern Caucasus, Kabardino-Balkaria. Russia Am Mineral GeoScienceWorld. 2009;94:1361–70.

Smirnova RF, Rumanova IM, Belov NV. Crystal structure of cuspidine. Zap Vsesoyuznogo Mineral Obs. 1955;84:159–69.

Saburi S, Kawahara A, Henmi C, Kusachi I, Kihara K. The refinement of the crystal structure of cuspidine. Mineral J. 1977;8:286–98.

Merlino S, Perchiazzi N. Modular mineralogy in the cuspidine group of minerals. Can Miner. 1988;26:933–43.

Seo MD, Bin SC, Wang H, Cho JW, Kim SH. Non-isothermal melt crystallization of cuspidine in CaO–SiO2–CaF2 based glasses. J Non Cryst Solids. 2015;412:58–65.

Ogorodova LP, Vigasina MF, Kononov OV, Koshlyakova NN, Ksenofontov DA, Khanin DA, et al. Thermodynamic properties of natural cuspidine. Geochem Int. 2018;56:865–9. https://doi.org/10.1134/S0016702918080098.

Cruz-Ramírez A, Romo-Castañeda J, Hernández-Pérez MDLÁ, Vargas-Ramírez M, Romero-Serrano A, Hallen-López M. An application of infrared analysis to determine the mineralogical phases formation in fluxes for thin slab casting of steel. J Fluor Chem Elsevier. 2011;132:323–6.

Jia Y, Qiao H, Guo N, Zheng Y, Yang M, Huang Y, et al. Electronic structure and photoluminescence properties of Eu2+-activated Ca4Si2O7F2. Opt Mater (Amst). 2011;33:1803–7.

Lü W, Luo Y, Hao Z, Zhang X, Wang X, Zhang J. A new dual-emission phosphor Ca4Si2O7F2:Ce3+, Mn2+ with energy transfer for near-UV LEDs. Mater Lett North-Holland. 2012;77:45–7.

Xie M, Zhu G, Li D, Pan R, Zhou X, Xie W. Synthesis and photoluminescence properties of tunable emission phosphors Ca4Si2O7F2:Ce3+. Solid State Sci. 2015;48:193–6.

Talewar RA, Mahamuda S, Vyas A, Rao AS, Moharil SV. Enhancement of 1.54 μm emission in Ce3+–Er3+ codoped Ca4Si2O7F2 phosphor. J Alloys Compd. 2019;775:810–7.

Xu Z, Zhu Y, Fan P, Luo Q, He Z, Liu X, et al. A dual-excited emission phosphor Eu3+/Eu2+ co-doped Ca4Si2O7F2: lattice occupancy and luminescence characterization. J Lumin. 2020;226:117480.

Speakman K, Taylor HFW, Bennett JM, Gard JA. Hydrothermal reactions of γ-dicalcium silicate. J Chem Soc A Inorg, Phys Theor. 1967;2:1052–60.

Mitsuda T, Fukuo K. Synthesis of Kilchoanite. Mineral J. 1969;6:17–35.

Ashraf W, Olek J, Jain J. Microscopic features of non-hydraulic calcium silicate cement paste and mortar. Cem Concr Res Elsevier. 2017;100:361–72.

Ashraf W, Olek J. Carbonation behavior of hydraulic and non-hydraulic calcium silicates: potential of utilizing low-lime calcium silicates in cement-based materials. J Mater Sci. 2016;51:6173–91.

Smalakys G, Siauciunas R. Peculiarities of xonotlite synthesis from the raw materials with different SiO2 activities. J Therm Anal Calorim. 2020;142:1671–9.

Thommes M, Kaneko K, Neimark A V, Olivier JP, Rodriguez-Reinoso F, Rouquerol J, et al. (2015) IUPAC Technical Report Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl Chem, 87(9–10), 1051–1069

Dambrauskas T, Baltakys K, Eisinas A, Kitrys S. The specific surface area and porosity of synthetic and calcined α-C2SH, kilchoanite and hydroxyledgrewite. Powder Technol. 2019;355:504–13.

Kaminskas R, Barauskas I. Autoclaved aerated concrete waste as a Micro-Filler for portland cement. Rev Rom Mater Rom J Mater. 2019;49:244–50.

Wang F, Kong X, Jiang L, Wang D. The acceleration mechanism of nano-C–S–H particles on OPC hydration. Constr Build Mater. 2020;249:118734.

Tajuelo Rodriguez E, Garbev K, Merz D, Black L, Richardson IG. Thermal stability of C–S–H phases and applicability of Richardson and Groves’ and Richardson C–(A)–S–H(I) models to synthetic C–S–H. Cem Concr Res. 2017;93:45–56.

Maddalena R, Li K, Chater PA, Michalik S, Hamilton A. Direct synthesis of a solid calcium-silicate-hydrate (C–S–H). Constr Build Mater. 2019;223:554–65.

Beheri HH, Mohamed KR, El-Bassyouni GT. Mechanical and microstructure of reinforced hydroxyapatite/calcium silicate nano-composites materials. Mater Des. 2013;44:461–8.

Galván-Ruiz M, Hernández J, Baños L, Noriega-Montes J, Rodríguez-García ME. Characterization of calcium carbonate, calcium oxide, and calcium hydroxide as starting point to the improvement of lime for their use in construction. J Mater Civ Eng. 2009;21:694–8.

Zea-Garcia JD, De la Torre AG, Aranda MAG, Santacruz I. Processing and characterisation of standard and doped alite-belite-ye’elimite ecocement pastes and mortars. Cem Concr Res. 2020;127:105911.

Wang Z, Jiang X, Pan M, Shi Y. Nano-scale pore structure and its multi-fractal characteristics of tight sandstone by N2 adsorption/desorption analyses: a case study of Shihezi formation from the sulige gas filed, Ordos basin China. Minerals. 2020;10:377.

Naderi M. Surface area: Brunauer-Emmett-Teller (BET). In: Progress in filtration and separation. 2015. p. 585–608

Myers RJ, L’Hôpital E, Provis JL, Lothenbach B. Effect of temperature and aluminium on calcium (alumino)silicate hydrate chemistry under equilibrium conditions. Cem Concr Res. 2015;68:83–93.

Acknowledgements

This research was supported by the Doctoral Fund of Kaunas University of Technology No. A-410, approved 26 June 2019.

Author information

Authors and Affiliations

Contributions

All authors contributed to the research. Andrius Gineika conceived the idea, carried out the experiment and prepared the manuscript. Kestutis Baltakys supervised the experiment and analysed the obtained data.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gineika, A., Baltakys, K. The effect of hydrothermal treatment conditions and silica source on the formation of cuspidine. J Therm Anal Calorim 148, 3965–3974 (2023). https://doi.org/10.1007/s10973-023-12022-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12022-6