Abstract

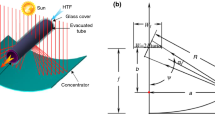

Parabolic trough solar collectors (PTSCs) or parabolic trough collectors have caught the interest of scientists and renewable energy enthusiasts due to their wide range of operating temperatures between 100 and 700 °C and their potential for power production as well as industrial process heating. More PTSCs have been constructed than all other concentrated sun-producing apparatuses put together. One of the most important functional components of the PTSC is the space for heat collection, also known as the absorber tube and transporting fluids. To increase its thermal potential, numerous investigations on the fluids in the absorber tube flow have been conducted. Better fluid thermo-physical properties are required to improve heat transfer and the system's overall efficiency. Examining different heat transfer fluids (HTF) that have been used for PTSC absorber tube/receiver tube is the goal of the current review. The usage of novel HTFs like nanofluids is also investigated, along with conventional fluids like thermic fluid and water. Review of the performance of the PTSC with various fluids using experiments and numerical methods are presented.. There are many difficulties with once-through PTSCs since two-phase flow circumstances make them worse and can occasionally cause tube bending. Summarized comparisons of several studies looking at the stability, manufacturing methods, and effects of hybrid nanofluids on PTSC thermal properties are summarized. For HTF inside the absorber tube, hybrid nanofluids and nanofluids may be used to enhance the thermal and optical characteristics of PTSC. It also demonstrates that metal oxide hybrid nanofluids are discovered to be more successful and efficient in enhancing thermal conductivity causing heat transfer augmentation than oxide nanofluids. This research, in our opinion, will encourage scientists and manufacturers to choose appropriate working fluids for PTSC applications.

Similar content being viewed by others

Abbreviations

- CFD:

-

Computational fluid dynamics

- CNT:

-

Carbon nanotube

- CPC:

-

Compound parabolic concentrator

- CTC:

-

Circular trough collectors

- CSP:

-

Concentrated solar power

- DSC:

-

Differential scanning calorimeter

- DSG:

-

Direct steam generation

- GNP:

-

Graphene nanoparticles

- HDH:

-

Humidification and dehumidification

- HTF:

-

Heat transfer fluid

- LFR:

-

Linear Fresnel reflector

- MWCNT:

-

Multi-wall carbon nanotube

- Nm:

-

Nano-meter

- PTC:

-

Parabolic trough collector

- PTSC:

-

Parabolic trough solar collector

- SDC:

-

Solar dish concentrator

- TES:

-

Thermal energy storage

- h:

-

Flow-induced heat transfer coefficient

- K:

-

Thermal conductivity

- Nu:

-

Nusselt number

- Pr:

-

Prandtl number

- Re:

-

Reynolds number

- T:

-

Temperature

References

Cheng ZD, He YL, Xiao J, Tao YB, Xu RJ. Three-dimensional numerical study of heat transfer characteristics in the receiver tube of parabolic trough solar collector. Int Commun Heat Mass Transf. 2010;37:782–7. https://doi.org/10.1016/j.icheatmasstransfer.2010.05.002.

Qiu Y, Li M, He Y, Tao W. Thermal performance analysis of a parabolic trough solar collector using supercritical CO2 as heat transfer fluid under non-uniform solar flux. Appl Therm Eng. 2016;115:1255–65. https://doi.org/10.1016/j.applthermaleng.2016.09.044.

Ray S, Tripathy AK, Sahoo SS, Bindra H. Performance analysis of receiver of parabolic trough solar collector: effect of selective coating, vacuum and semitransparent glass cover. Int J Energy Res. 2018;42:4235–49. https://doi.org/10.1002/er.4137.

Khanna S, Kedare SB, Singh S. Deflection and stresses in absorber tube of solar parabolic trough due to circumferential and axial flux variations on absorber tube supported at multiple points. Sol Energy. 2014;99:134–51. https://doi.org/10.1016/j.solener.2013.11.005.

Khanna S, Singh S, Kedare SB. Explicit expressions for temperature distribution and deflection in absorber tube of solar parabolic trough concentrator. Sol Energy. 2015;114:289–302. https://doi.org/10.1016/j.solener.2015.01.044.

Bhuyan U, Sahoo SS, Satapathy PK, Parida PK. Heat loss modelling and analysis of parabolic trough solar collector using computational approach. Aust J Mech Eng. 2019;17:24–37. https://doi.org/10.1080/14484846.2018.1507336.

Tripathy AK, Ray S, Sahoo SS, Chakrabarty S. Structural analysis of absorber tube used in parabolic trough solar collector and effect of materials on its bending: a computational study. Sol Energy. 2018;163:471–85. https://doi.org/10.1016/j.solener.2018.02.028.

Sahoo SS, Singh SS, Banerjee R. Thermal hydraulic simulation of absorber tubes in linear fresnel reflector solar thermal system using RELAP. Ren Energy. 2016;86:507–16. https://doi.org/10.1016/j.renene.2015.08.050.

Sahoo SS, Singh SS, Banerjee R. Steady sate hydrothermal analysis of absorber tubes used in Linear Fresnel Reflector solar thermal system. Sol Energy. 2013;87:84–95. https://doi.org/10.1016/j.solener.2012.10.002.

Sahoo SS, Varghese SM, Kumar CS, Viswanathan SP, Singh S, Banerjee R. Experimental investigation and computational validation of heat loss from the cavity receiver used in Linear Fresnel reflector solar thermal system. Renew Energy. 2013;55:18–23. https://doi.org/10.1016/j.renene.2012.11.036.

Sahoo SS, Singh S, Banerjee R. Analysis of heat loss from a trapezoidal cavity used for Linear Fresnel Reflector system. Sol Energy. 2012;86:1313–22. https://doi.org/10.1016/j.solener.2012.01.023.

Avargani VM, Norton B, Rahimi A. An open-aperture partially-evacuated receiver for more uniform reflected solar flux in circular-trough reflectors: comparative performance in air heating applications. Renew Energy. 2021;176:11–24. https://doi.org/10.1016/j.renene.2021.05.072.

Prakash M, Kedare SB, Nayak JK. Numerical study of natural convection loss from open cavities. Int J Therm Sci. 2012;51:23–30. https://doi.org/10.1016/j.ijthermalsci.2011.08.012.

Karimi R, Gheinani TT, Avargani VM. A detailed mathematical model for thermal performance analysis of a cylindrical cavity receiver in a solar parabolic dish collector system. Renew Energy. 2018;125:768–82. https://doi.org/10.1016/j.renene.2018.03.015.

Madadi V, Tavakoli T, Amir R. First and second thermodynamic law analyses applied to a solar dish collector. J Non-Equilib Thermodyn. 2014;39:183–97. https://doi.org/10.1515/jnet-2014-0023.

Avargani VM, Rahimi A, Tavakoli T. Exergetic optimization and optimum operation of a solar dish collector with a cylindrical receiver. J Energy Eng. 2016;142:04015049–51. https://doi.org/10.1061/(ASCE)EY.1943-7897.0000322.

Soltani S, Bonyadi M, Avargani VM. A novel optical-thermal modeling of a parabolic dish collector with a helically baffled cylindrical cavity receiver. Energy. 2019;168:88–98. https://doi.org/10.1016/j.energy.2018.11.097.

Karimi R, Gheinani TT, Avargani VM. Coupling of a parabolic solar dish collector to finned-tube heat exchangers for hot air production: an experimental and theoretical study. Sol Energy. 2019;187:199–211. https://doi.org/10.1016/j.solener.2019.05.050.

Avargani VM, Rahimi A, Divband M, Zamani MA. Optical analysis and heat transfer modeling of a helically baffled cavity receiver under solar flux non-uniformity and windy conditions. Therm Sci Eng Prog. 2020;20:100719. https://doi.org/10.1016/j.tsep.2020.100719.

Tagle-Salazar PD, Nigam KDP, Rivera-Solorio CI. Parabolic trough solar collectors: a general overview of technology, industrial applications, energy market, modeling, and standards. Green Process Synth. 2020;9:595–649. https://doi.org/10.1515/gps-2020-0059.

Coccia G, Di G, Sotte M. Design, manufacture, and test of a prototype for a parabolic trough collector for industrial process heat. Renew Energy. 2015;74:727–36. https://doi.org/10.1016/j.renene.2014.08.077.

Benoit H, Sprea L, Gauthier D, Flamant G. Review of heat transfer fluids in tube-receivers used in concentrating solar thermal systems: properties and heat transfer coefficients. Renew Sustain Energy Rev. 2016;55:298–315. https://doi.org/10.1016/j.rser.2015.10.059.

Aslfattahi N, Saidur R, Arifutzzaman A, Sadri R, Bimbo N, Sabri MFM, et al. Experimental investigation of energy storage properties and thermal conductivity of a novel organic phase change material/MXene as a new class of nanocomposites. J Energy Storage. 2020;27:101115. https://doi.org/10.1016/j.est.2019.101115.

Xiao P, Guo L, Zhang X. Investigations on heat transfer characteristic of molten salt flow in helical annular duct. Appl Therm Eng. 2015;88:22–32. https://doi.org/10.1016/j.applthermaleng.2014.09.021.

Shin D, Banerjee D. Enhanced thermal properties of SiO2 nanocomposite for solar thermal energy storage applications. Int J Heat Mass Transf. 2015;84:898–902. https://doi.org/10.1016/j.ijheatmasstransfer.2015.01.100.

Asadi A, Asadi M, Rezaniakolaei A, Rosendahl LA, Afrand M, Wongwises S. Heat transfer efficiency of Al2O3-MWCNT/thermal oil hybrid nanofluid as a cooling fluid in thermal and energy management applications: an experimental and theoretical investigation. Int J Heat Mass Transf. 2018;117:474–86. https://doi.org/10.1016/j.ijheatmasstransfer.2017.10.036.

Chieruzzi M, Miliozzi A, Crescenzi T, Torre L, Kenny JM. a new phase change material based on potassium nitrate with silica and alumina nanoparticles for thermal energy storage. Nanoscale Res Lett. 2015;10:273. https://doi.org/10.1186/s11671-015-0984-2.

Chieruzzi M, Cerritelli GF, Miliozzi A, Kenny JM. Effect of nanoparticles on heat capacity of nanofluids based on molten salts as PCM for thermal energy storage. Nanoscale Res Lett. 2013;8:1–9. https://doi.org/10.1186/1556-276X-8-448.

Chen YY, Zhao CY. Thermophysical properties of Ca (NO3) 2-NaNO3-KNO3 mixtures for heat transfer and thermal storage. Sol Energy. 2017;146:172–9.

Sharma M, Jilte R. A review on passive methods for thermal performance enhancement in parabolic trough solar collectors. Int J Energy Res. 2021;45:4392–966. https://doi.org/10.1002/er.6212.

Avargani VM, Rahimi A, Divband M. Coupled optical and thermal analyses of a new type of solar water heaters using parabolic trough reflectors. Sustain Energy Technol Assess. 2020;40:100780. https://doi.org/10.1016/j.seta.2020.100780.

Avargani VM, Divband M. Performance evaluation of a solar water heating system with glass-covered parabolic trough concentrators, under different system tracking modes. J Therm Anal Calorim. 2022;147:4873–88. https://doi.org/10.1007/s10973-021-10845-9.

Sabiha MA, Saidur R, Mekhilef S, Mahian O. Progress and latest developments of evacuated tube solar collectors. Renew Sustain Energy Rev. 2015;51:1038–54. https://doi.org/10.1016/j.rser.2015.07.016.

Faizal M, Saidur R, Mekhilef S. Potential of size reduction of flat-plate solar collectors when applying Al2O3 nanofluid. Adv Mater Res. 2014;832:149–53. https://doi.org/10.4028/www.scientific.net/AMR.832.149.

Fernández-García A, Zarza E, Valenzuela L, Pérez M. Parabolic-trough solar collectors and their applications. Renew Sustain Energy Rev. 2010;14:1695–721. https://doi.org/10.1016/j.rser.2010.03.012.

Mahian O, Kianifar A, Kalogirou SA, Pop I, Wongwises S. A review of the applications of nanofluids in solar energy. Int J Heat Mass Transf. 2013;57:582–94. https://doi.org/10.1016/j.ijheatmasstransfer.2012.10.037.

Bellos E, Tzivanids C, Symeou C, Antonopoulos KA. Energetic, exergetic and financial evaluation of a solar driven absorption chiller – A dynamic approach. Energy Convers Manag. 2017;137:34–48. https://doi.org/10.1016/j.enconman.2017.01.041.

Silva R, Javier F, Pérez-garcía M. Process heat generation with parabolic trough collectors for a vegetables preservation industry in Southern Spain. Energy Procedia. 2014;48:1210–6. https://doi.org/10.1016/j.egypro.2014.02.137.

Giglio A, Lanzini A, Leone P, Rodríguez MM, Zarza E. Direct steam generation in parabolic-trough collectors: A review about the technology and a thermo-economic analysis of a hybrid system. Renew Sustain Energy Rev. 2017;74:453–73. https://doi.org/10.1016/j.rser.2017.01.176.

Selvakumar P, Somasundaram P, Thangavel P. Performance study on evacuated tube solar collector using therminol D-12 as heat transfer fluid coupled with parabolic trough. Energy Convers Manag. 2014;85:505–10. https://doi.org/10.1016/j.enconman.2014.05.069.

Raade JW, Padowitz D. Development of molten salt heat transfer fluid with low melting point and high thermal stability. ASME J Sol Energy Eng. 2011;133:031013. https://doi.org/10.1115/1.4004243.

Zhang HL, Baeyens J, Degrève J, Cacères G. Concentrated solar power plants: review and design methodology. Renew Sustain Energy Rev. 2013;22:466–81. https://doi.org/10.1016/j.rser.2013.01.032.

Wang Y, Liu Q, Lei J, Jin H. A three-dimensional simulation of a parabolic trough solar collector system using molten salt as heat transfer fluid. Appl Therm Eng. 2014;70:462–76. https://doi.org/10.1016/j.applthermaleng.2014.05.051.

Bauer T, Pfleger N, Laing D, Eck M, Kaesche S. 20 high-temperature molten salts for solar power application. Molten Salts Chem. 2013;2013:415–38. https://doi.org/10.1016/B978-0-12-398538-5.00020-2.

Coscia K, Elliott T, Mohapatra S, Oztekin A, Neti S. Binary and ternary nitrate solar heat transfer fluids. ASME J Sol Energy Eng. 2013;135:021011. https://doi.org/10.1115/1.4023026.

Chen M, Shen Y, Zhu S, Li P. Digital phase diagram and thermophysical properties of KNO3-NaNO3-Ca(NO3)2 ternary system for solar energy storage. Vacuum. 2017;145:225–33. https://doi.org/10.1016/j.vacuum.2017.09.003.

Fernández AG, Ushak S, Galleguillos H, Pérez FJ. Development of new molten salts with LiNO3 and Ca(NO3)2 for energy storage in CSP plants. Appl Energy. 2014;119:131–40. https://doi.org/10.1016/j.apenergy.2013.12.061.

Vignarooban K, Xu X, Arvay A, Hsu K, Kannan AM. Heat transfer fluids for concentrating solar power systems - a review. Appl Energy. 2015;146:383–96. https://doi.org/10.1016/j.apenergy.2015.01.125.

Zhao CY, Wu ZG. Thermal property characterization of a low melting-temperature ternary nitrate salt mixture for thermal energy storage systems. Sol Energy Mater Sol Cells. 2011;95:3341–6. https://doi.org/10.1016/j.solmat.2011.07.029.

Chieruzzi M, Miliozzi A, Crescenzi T, Torre L, Kenny JM. A new phase change material based on potassium nitrate with silica and alumina nanoparticles for thermal energy storage. Nanoscale Res Lett. 2015. https://doi.org/10.1186/s11671-015-0984-2.

Chen YY, Zhao CY. Thermophysical properties of Ca(NO3)2-NaNO3-KNO3 mixtures for heat transfer and thermal storage. Sol Energy. 2017;146:172–9. https://doi.org/10.1016/j.solener.2017.02.033.

Yarmand H, Gharehkhani S, Shirazi SFS, Goodarzi M, Amiri A, Sarsam WS, et al. Study of synthesis, stability and thermo-physical properties of graphene nanoplatelet/platinum hybrid nanofluid. Int Commun Heat Mass Transf. 2016;77:15–21. https://doi.org/10.1016/j.icheatmasstransfer.2016.07.010.

Wei B, Zou C, Li X. Experimental investigation on stability and thermal conductivity of diathermic oil based TiO2 nanofluids. Int J Heat Mass Transf. 2017;104:537–43. https://doi.org/10.1016/j.ijheatmasstransfer.2016.08.078.

Ilyas SU, Pendyala R, Narahari M. Stability and thermal analysis of MWCNT-thermal oil-based nanofluids. Colloids Surf A Physicochem Eng Asp. 2017;527:11–22. https://doi.org/10.1016/j.colsurfa.2017.05.004.

Wang T, Mantha D, Reddy RG. Novel low melting point quaternary eutectic system for solar thermal energy storage. Appl Energy. 2013;102:1422–9. https://doi.org/10.1016/j.apenergy.2012.09.001.

Bradshaw RW, Brosseau DA. Low-melting point inorganic nitrate salt heat transfer fluid. United States Pat US 7,588,694 B1 2009. pp. 1–9.

Peng Q, Yang X, Ding J, Wei X, Yang J. Design of new molten salt thermal energy storage material for solar thermal power plant. Appl Energy. 2013;112:682–9. https://doi.org/10.1016/j.apenergy.2012.10.048.

Good P, Zanganeh G, Ambrosetti G, Barbato MC, Pedretti A, Steinfeld A. Towards a commercial parabolic trough CSP system using air as heat transfer fluid. Energy Procedia. 2014;49:381–5. https://doi.org/10.1016/j.egypro.2014.03.041.

Bellos E, Tzivanidis C, Antonopoulos KA, Daniil I. The use of gas working fluids in parabolic trough collectors – an energetic and exergetic analysis. Appl Therm Eng. 2016;109:1–14. https://doi.org/10.1016/j.applthermaleng.2016.08.043.

Al-Sulaiman FA, Zubair MI, Atif M, Gandhidasan P, Al-Dini SA, Antar MA. Humidification dehumidification desalination system using parabolic trough solar air collector. Appl Therm Eng. 2015;75:809–16. https://doi.org/10.1016/j.applthermaleng.2014.10.072.

Biencinto M, González L, Valenzuela L, Zarza E. A new concept of solar thermal power plants with large-aperture parabolic- trough collectors and CO2 as working fluid. Energy Convers Manag. 2019;199:112030. https://doi.org/10.1016/j.enconman.2019.112030.

Islam MK, Hasanuzzaman M, Rahim NA. RSC Modelling and analysis of the effect of different parameters on a parabolic-trough concentrating solar system. RSC Adv. 2015. https://doi.org/10.1039/C4RA12919A.

Vutukuru R, Pegallapati AS, Maddali R. Suitability of various heat transfer fluids for high temperature solar thermal systems. Appl Therm Eng. 2019;159:113973. https://doi.org/10.1016/j.applthermaleng.2019.113973.

Pacio J, Singer C, Wetzel T, Uhlig R. Thermodynamic evaluation of liquid metals as heat transfer fluids in concentrated solar power plants. Appl Therm Eng. 2013;60:295–302. https://doi.org/10.1016/j.applthermaleng.2013.07.010.

Sarafraz MM, Arjomandi M. Demonstration of plausible application of gallium nano-suspension in microchannel solar thermal receiver: experimental assessment of thermo- hydraulic performance of microchannel. Int Commun Heat Mass Transf. 2018;94:39–46. https://doi.org/10.1016/j.icheatmasstransfer.2018.03.013.

Paul TC, Morshed AKMM, Fox EB, Khan JA. Thermal performance of Al2O3 nanoparticle enhanced ionic liquids (NEILs) for concentrated solar power (CSP) applications. Int J Heat Mass Transf. 2015;85:585–94. https://doi.org/10.1016/j.ijheatmasstransfer.2015.01.071.

Sanada Y, Akiba I, Hashida S, Sakurai K, et al. Composition dependence of the micellar architecture made from poly(ethylene glycol)-block-poly(partially benzyl-esterified aspartic acid). J Phys Chem B. 2012;116:8241–50. https://doi.org/10.1021/jp300936d.

Moens L, Blake DM. Advanced heat transfer and thermal storage fluids. Conference paper NREL/CP-510-37083 2005.

Wittmar A, Ruiz-Abad D, Ulbricht M. Dispersions of silica nanoparticles in ionic liquids investigated with advanced rheology. J Nanoparticle Res. 2012;14:1–10. https://doi.org/10.1007/s11051-011-0651-1.

Wang B, Wang X, Lou W, Hao J. Ionic liquid-based stable nanofluids containing gold nanoparticles. J Colloid Interface Sci. 2011;362:5–14. https://doi.org/10.1016/j.jcis.2011.06.023.

Perissi I, Bardi U, Caporali S, Fossati A, Lavacchi A. Ionic liquids as diathermic fluids for solar trough collectors’ technology: a corrosion study. Sol Energy Mater Sol Cells. 2008;92:510–7. https://doi.org/10.1016/j.solmat.2007.11.007.

Liu J, Ye Z, Zhang L, Fang X, Zhang Z. Solar energy materials & solar cells A combined numerical and experimental study on graphene/ionic liquid nano fluid based direct absorption solar collector. Sol Energy Mater Sol Cells. 2015;136:177–86. https://doi.org/10.1016/j.solmat.2015.01.013.

Hoffmann JF, Vaitilingom G, Henry JF, Chirtoc M, Olives R, Goetz V, Py X. Temperature dependence of thermophysical and rheological properties of seven vegetable oils in view of their use as heat transfer fluids in concentrated solar plants. Sol Energy Mater Sol Cells. 2018;178:129–38. https://doi.org/10.1016/j.solmat.2017.12.037.

Aberoumand S, Jafarimoghaddam A. Tungsten (III) oxide (WO3) – Silver/transformer oil hybrid nanofluid: preparation, stability, thermal conductivity and dielectric strength. Alex Eng J. 2018;57:169–74. https://doi.org/10.1016/j.aej.2016.11.003.

Hemmat Esfe M, Abbasian Arani AA, Rezaie M, Yan WM, Karimipour A. Experimental determination of thermal conductivity and dynamic viscosity of Ag–MgO/water hybrid nanofluid. Int Commun Heat Mass Transf. 2015;66:189–95. https://doi.org/10.1016/j.icheatmasstransfer.2015.06.003.

Yang L, Ji W, Mao M, Huang JN. An updated review on the properties, fabrication and application of hybrid-nanofluids along with their environmental effects. J Clean Prod. 2020;257:120408. https://doi.org/10.1016/j.jclepro.2020.120408.

Suresh S, Venkitaraj KP, Selvakumar P, Chandrasekar M. Synthesis of Al2O3-Cu/water hybrid nanofluids using two step method and its thermo physical properties. Colloids Surf A Physicochem Eng Asp. 2011;388:41–8. https://doi.org/10.1016/j.colsurfa.2011.08.005.

Chen LF, Cheng M, Yang DJ, Yang L. Enhanced thermal conductivity of nanofluid by synergistic effect of multi-walled carbon nanotubes and Fe2O3 nanoparticles. Appl Mech Mater. 2014;548–549:118–23. https://doi.org/10.4028/www.scientific.net/AMM.548-549.118.

Timofeeva EV, Gavrilov AN, McCloskey JM, Tolmachev YV, Sprunt S, Lopatina LM, et al. Thermal conductivity and particle agglomeration in alumina nanofluids: Experiment and theory. Phys Rev E Stat Nonlinear Soft Matter Phys. 2007;76:28–39. https://doi.org/10.1103/PhysRevE.76.061203.

Le Ba T, Mahian O, Wongwises S, Szilágyi IM. Review on the recent progress in the preparation and stability of graphene-based nanofluids. J Therm Anal Calorim. 2020;142:1145–72. https://doi.org/10.1007/s10973-020-09365-9.

Suresh S, Venkitaraj KP, Selvakumar P, Chandrasekar M. Effect of Al2O3-Cu/water hybrid nanofluid in heat transfer. Exp Therm Fluid Sci. 2012;38:54–60. https://doi.org/10.1016/j.expthermflusci.2011.11.007.

Sanchez C, Julián B, Belleville P, Popall M. Applications of hybrid organic-inorganic nanocomposites. J Mater Chem. 2005;15:3559–92. https://doi.org/10.1039/b509097k.

Bhosale GH, Borse SL. Pool boiling CHF enhancement with Al2O3-Cuo/H2O hybrid Nan fluid. Int J Eng Res Technol. 2013;2:946–50.

Dhinesh Kumar D, Valan AA. A comprehensive review of preparation, characterization, properties and stability of hybrid nanofluids. Renew Sustain Energy Rev. 2018;81:1669–89. https://doi.org/10.1016/j.rser.2017.05.257.

Cakmak NK, Said Z, Sundar LS, Ali ZM, Tiwari AK. Preparation, characterization, stability, and thermal conductivity of rGO-Fe3O4-TiO2 hybrid nanofluid: an experimental study. Powder Technol. 2020;372:235–45. https://doi.org/10.1016/j.powtec.2020.06.012.

Qiu L, Zhu N, Feng Y, Michaelides EE, Żyła G, Jing D, et al. A review of recent advances in thermophysical properties at the nanoscale: from solid state to colloids. Phys Rep. 2020;843:1–81. https://doi.org/10.1016/j.physrep.2019.12.001.

Paul G, Pal T, Manna I. Thermo-physical property measurement of nano-gold dispersed water based nanofluids prepared by chemical precipitation technique. J Colloid Interface Sci. 2010;349:434–7. https://doi.org/10.1016/j.jcis.2010.05.086.

Gupta M, Singh V, Kumar S, Kumar S, Dilbaghi N, Said Z. Up to date review on the synthesis and thermophysical properties of hybrid nanofluids. J Clean Prod. 2018;190:169–92. https://doi.org/10.1016/j.jclepro.2018.04.146.

Montes MJ. Thermofluidynamic model and comparative analysis of parabolic trough collectors using oil. Water Steam Molten Salt. 2014;132:1–7. https://doi.org/10.1115/1.4001399.

Fritsch A, Frantz C, Uhlig R. Techno-economic analysis of solar thermal power plants using liquid sodium as heat transfer fluid. Sol Energy. 2019;177:155–62. https://doi.org/10.1016/j.solener.2018.10.005.

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, et al. Recent advances in modeling and simulation of nanofluid flows-Part I: fundamentals and theory. Phys Rep. 2019;790:1–48. https://doi.org/10.1016/j.physrep.2018.11.004.

Corcione M. Empirical correlating equations for predicting the effective thermal conductivity and dynamic viscosity of nanofluids. Energy Convers Manag. 2011;52:789–93. https://doi.org/10.1016/j.enconman.2010.06.072.

Prasher R, Song D, Wang J, Phelan P. Measurements of nanofluid viscosity and its implications for thermal applications. Appl Phys Lett. 2006;89:67–70. https://doi.org/10.1063/1.2356113.

De Noni A, Garcia DE, Hotza D. A modified model for the viscosity of ceramic suspensions. Ceram Int. 2002;28:731–5. https://doi.org/10.1016/S0272-8842(02)00035-4.

Novotny V, Meincke PPM, Watson JHP. Effect of size and surface on the specific heat of small lead particles. Phys Rev Lett. 1972;28:901–3. https://doi.org/10.1103/PhysRevLett.28.901.

Angayarkanni SA, Philip J. Review on thermal properties of nanofluids: recent developments. Adv Colloid Interface Sci. 2015;225:146–76. https://doi.org/10.1016/j.cis.2015.08.014.

Riazi H, Murphy T, Webber GB, Atkin R, Tehrani SSM, Taylor RA. Specific heat control of nanofluids: a critical review. Int J Therm Sci. 2016;107:25–38. https://doi.org/10.1016/j.ijthermalsci.2016.03.024.

Abbasi M, Heyhat MM, Rajabpour A. Study of the effects of particle shape and base fluid type on density of nanofluids using ternary mixture formula: a molecular dynamics simulation. J Mol Liq. 2020;305:112831. https://doi.org/10.1016/j.molliq.2020.112831.

Chavan D, Pise A. Experimental investigation of effective viscosity and density of nanofluids. Mater Today Proc. 2019;16:504–15. https://doi.org/10.1016/j.matpr.2019.05.122.

Sundar LS, Sharma KV, Singh MK, Sousa ACM. Hybrid nanofluids preparation, thermal properties, heat transfer and friction factor – a review. Renew Sustain Energy Rev. 2017;68:185–98. https://doi.org/10.1016/j.rser.2016.09.108.

Bakthavatchalam B, Habib K, Saidur R, Saha BB, Irshad K. Comprehensive study on nanofluid and ionanofluid for heat transfer enhancement: a review on current and future perspective. J Mol Liq. 2020;305:112787. https://doi.org/10.1016/j.molliq.2020.112787.

Zhu T, Strycker A, Raible CJ, Vineyard K. Foams for mobility control and improved sweep efficiency in gas flooding 1998. pp. 277–86. https://doi.org/10.2118/39680-ms

Farajzadeh R, Andrianov A, Zitha PLJ. Investigation of immiscible and miscible foam for enhancing oil recovery. Ind Eng Chem Res. 2010;49:1910–9. https://doi.org/10.1021/ie901109d.

Babar H, Ali HM. Towards hybrid nanofluids: Preparation, thermophysical properties, applications, and challenges. J Mol Liq. 2019;281:598–633. https://doi.org/10.1016/j.molliq.2019.02.102.

Saidur R, Leong KY, Mohammed HA. A review on applications and challenges of nanofluids. Renew Sustain Energy Rev. 2011;15:1646–68. https://doi.org/10.1016/j.rser.2010.11.035.

Alirezaie A, Hajmohammad MH, Hassani Ahangar MR, Hemmat EM. Price-performance evaluation of thermal conductivity enhancement of nanofluids with different particle sizes. Appl Therm Eng. 2018;128:373–80. https://doi.org/10.1016/j.applthermaleng.2017.08.143.

Olia H, Torabi M, Bahiraei M, Ahmadi MH, Goodarzi M, Safaei MR. Application of nanofluids in thermal performance enhancement of parabolic trough solar collector: state-of-the-art. Appl Sci. 2019. https://doi.org/10.3390/app9030463.

Mwesigye A, Huan Z, Meyer JP. Thermodynamic optimisation of the performance of a parabolic trough receiver using synthetic oil-Al2O3 nanofluid. Appl Energy. 2015;156:398–412. https://doi.org/10.1016/j.apenergy.2015.07.035.

Shah TR, Ali HM. Applications of hybrid nanofluids in solar energy, practical limitations and challenges: a critical review. Sol Energy. 2019;183:173–203. https://doi.org/10.1016/j.solener.2019.03.012.

Sundar LS, Singh MK, Sousa ACM. Enhanced heat transfer and friction factor of MWCNT-Fe3O4/water hybrid nanofluids. Int Commun Heat Mass Transf. 2014;52:73–83. https://doi.org/10.1016/j.icheatmasstransfer.2014.01.012.

Biswas N, Manna NK, Datta P, Mahapatra PS. Analysis of heat transfer and pumping power for bottom-heated porous cavity saturated with Cu-water nanofluid, vol. 326. Amsterdam: Elsevier; 2018. https://doi.org/10.1016/j.powtec.2017.12.030.

Rahmanian S, Hamzavi A. Effects of pump power on performance analysis of photovoltaic thermal system using CNT nanofluid. Sol Energy. 2020;201:787–97. https://doi.org/10.1016/j.solener.2020.03.061.

Chamsa-ard W, Brundavanam S, Fung CC, Fawcett D, Poinern G. Nanofluid types, their synthesis, properties and incorporation in direct solar thermal collectors: a review. Nanomaterials. 2017. https://doi.org/10.3390/nano7060131.

Bellos E, Tzivanidis C. A review of concentrating solar thermal collectors with and without nanofluids. J Therm Anal Calorim. 2019;135:763–86. https://doi.org/10.1007/s10973-018-7183-1.

Krishna Y, Faizal M, Saidur R, Ng KC, Aslfattahi N. State-of-the-art heat transfer fluids for parabolic trough collector. Int J Heat Mass Transf. 2020. https://doi.org/10.1016/j.ijheatmasstransfer.2020.119541.

Mahmoudi A, Fazli M, Morad MR, Gholamalizadeh E. Thermo-hydraulic performance enhancement of nanofluid-based linear solar receiver tubes with forward perforated ring steps and triangular cross section; a numerical investigation. Appl Therm Eng. 2020;169:114909. https://doi.org/10.1016/j.applthermaleng.2020.114909.

Rostami S, Rostami S, Shahsavar A, Shahsavar A, Kefayati G, Goldanlou AS, et al. Energy and exergy analysis of using turbulator in a parabolic trough solar collector filled with mesoporous silica modified with copper nanoparticles hybrid nanofluid. Energies. 2020. https://doi.org/10.3390/en13112946.

Bilal FR, Arunachala UC, Sandeep HM. Experimental validation of energy parameters in parabolic trough collector with plain absorber and analysis of heat transfer enhancement techniques. J Phys Conf Ser. 2018. https://doi.org/10.1088/1742-6596/953/1/012030.

Hatami M, Geng J, Jing D. Enhanced efficiency in concentrated parabolic solar collector (CPSC) with a porous absorber tube filled with metal nanoparticle suspension. Green Energy Environ. 2018;3:129–37. https://doi.org/10.1016/j.gee.2017.12.002.

Amina B, Miloud A, Samir L, Abdelylah B, Solano JP. Heat transfer enhancement in a parabolic trough solar receiver using longitudinal fins and nanofluids. J Therm Sci. 2016;25:410–7. https://doi.org/10.1007/s11630-016-0878-3.

Waghole DR, Warkhedkar RM, Kulkarni VS, Shrivastva RK. Experimental investigations on heat transfer and friction factor of silver nanofliud in absorber/receiver of parabolic trough collector with twisted tape inserts. Energy Procedia. 2014;45:558–67. https://doi.org/10.1016/j.egypro.2014.01.060.

Bellos E, Tzivanidis C, Antonopoulos KA, Gkinis G. Thermal enhancement of solar parabolic trough collectors by using nanofluids and converging-diverging absorber tube. Renew Energy. 2016;94:213–22. https://doi.org/10.1016/j.renene.2016.03.062.

Biswakarma S, Roy S, Das B, Kumar DB. Performance analysis of internally helically v-grooved absorber tubes using nanofluid. Therm Sci Eng Prog. 2020;18:100538. https://doi.org/10.1016/j.tsep.2020.100538.

Kasaeian A, Daneshazarian R, Rezaei R, Pourfayaz F, Kasaeian G. Experimental investigation on the thermal behavior of nanofluid direct absorption in a trough collector. J Clean Prod. 2017;158:276–84. https://doi.org/10.1016/j.jclepro.2017.04.131.

Bozorg MV, Hossein Doranehgard M, Hong K, Xiong Q. CFD study of heat transfer and fluid flow in a parabolic trough solar receiver with internal annular porous structure and synthetic oil–Al2O3 nanofluid. Renew Energy. 2020;145:2598–614. https://doi.org/10.1016/j.renene.2019.08.042.

Acknowledgements

The corresponding author thankfully acknowledges the financial support from the All India Council of Technical Education Under the Research Promotion Scheme (RPS), the Government of India having research grant 8-46/FDC/RPS (POLICY-1)/2019-20 to carry out this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sarangi, A., Sarangi, A., Sahoo, S.S. et al. A review of different working fluids used in the receiver tube of parabolic trough solar collector. J Therm Anal Calorim 148, 3929–3954 (2023). https://doi.org/10.1007/s10973-023-11991-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-11991-y