Abstract

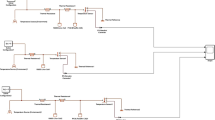

The dynamic response characteristic is an important performance indicator of the proton exchange membrane fuel cell (PEMFC), which has a great influence on the durability and reliability. The cooling capacity is an important factor that affects the stability of the PEMFC output after the change. This research proposes to apply the micro-heat pipe array (MHPA) to the thermal management of PEMFC. A novel MHPA-PEMFC stack is designed, and four cases involving comparative dynamic response experiments are studied. The results show that compared with the traditional air-cooled PEMFC, the MHPA-PEMFC significantly reduces the maximum step voltage, dynamic internal resistance and step temperature, shortens the temperature response time and improves the internal temperature uniformity. In the case where the output current stepped up from 10 to 30 A, the maximum step voltage and the maximum dynamic impedance of MHPA-PEMFC are lower than those of PEMFC by 0.449 V and 0.037 Ω, respectively. The maximum step temperature has been reduced by 4.44 °C, and the temperature response time has been reduced by 180 s. The research results provide a basis for using MHPA in PEMFC thermal management applications.

Similar content being viewed by others

Abbreviations

- MHPA:

-

Micro-heat pipe array

- TMS:

-

Thermal management system

- PEMFC:

-

Proton exchange membrane fuel cells

- E r :

-

Theoretical reversible voltage (V)

- H t :

-

Total heat transfer coefficient (W ºC−1)

- I :

-

Output current (A)

- n :

-

Number

- P e :

-

The power output (W)

- R d :

-

Nominal dynamic internal resistance (Ω)

- t :

-

Time (s)

- T :

-

Temperature (K)

- V :

-

Output voltage (V)

- △V :

-

Step voltage (V)

- △T :

-

Step temperature (ºC)

- αV :

-

Voltage response rate (V s-1)

- ε V :

-

Voltage fluctuation rate

- ε T :

-

Temperature fluctuation rate

- τ V :

-

Voltage response time (s)

- τ T :

-

Temperature response time(s)

- a :

-

Ambient

- i :

-

Transient moment

- max:

-

Maximum

- min:

-

Minimum

- s :

-

Steady state

- T :

-

Temperature

- V :

-

Voltage

References

Pourkiaei SM, Ahmadi MH, Hasheminejad SM. Modeling and experimental verification of a 25W fabricated PEM fuel cell by parametric and GMDH-type neural network. Mech Ind. 2016;17:105. https://doi.org/10.1051/meca/2015050.

Zhang G, Kandlikar SG. A critical review of cooling techniques in proton exchange membrane fuel cell stacks. Int J Hydrogen Energy. 2012;37:2412–29. https://doi.org/10.1016/j.ijhydene.2011.11.010.

Jradi M, Riffat S. Tri-generation systems: energy policies, prime movers, cooling technologies, configurations and operation strategies. Renew Sustain Energy Rev. 2014;32:396–415. https://doi.org/10.1016/j.rser.2014.01.039.

Chen H, Pei P, Song M. Lifetime prediction and the economic lifetime of proton exchange membrane fuel cells. Appl Energy. 2015;142:154–63. https://doi.org/10.1016/j.apenergy.2014.12.062.

Weydahl H, Møller-Holst S, Hagen G, Børresen B. Transient response of a proton exchange membrane fuel cell. J Power Sour. 2007;171:321–30. https://doi.org/10.1016/j.jpowsour.2007.06.073.

Cho J, Kim H, Min K. Transient response of a unit proton-exchange membrane fuel cell under various operating conditions. J Power Sour. 2008;185:118–28. https://doi.org/10.1016/j.jpowsour.2008.06.073.

Lee Y, Kim B, Kim Y. Effects of self-humidification on the dynamic behavior of polymer electrolyte fuel cells. Int J Hydrogen Energy. 2009;34:1999–2007. https://doi.org/10.1016/j.ijhydene.2008.12.042.

Yan Q, Toghiani H, Causey H. Steady state and dynamic performance of proton exchange membrane fuel cells (PEMFCs) under various operating conditions and load changes. J Power Sour. 2006;161:492–502. https://doi.org/10.1016/j.jpowsour.2006.03.077.

Zhang Z, Jia L, Wang X, Ba L. Effects of inlet humidification on PEM fuel cell dynamic behaviors. Int J Energy Res. 2011;35:376–88. https://doi.org/10.1002/er.1692.

Tang Y, Yuan W, Pan M, Li Z, Chen G, Li Y. Experimental investigation of dynamic performance and transient responses of a kW-class PEM fuel cell stack under various load changes. Appl Energy. 2010;87:1410–7. https://doi.org/10.1016/j.apenergy.2009.08.047.

Meng H. Numerical investigation of transient responses of a PEM fuel cell using a two-phase non-isothermal mixed-domain model. J Power Sour. 2007;171:738–46. https://doi.org/10.1016/j.jpowsour.2007.06.029.

Mohamed WANW, Talib SFA, Zakaria IA, Mamat AMI, Daud WRW. Effect of dynamic load on the temperature profiles and cooling response time of a proton exchange membrane fuel cell. J Energy Inst. 2018;91:349–57. https://doi.org/10.1016/j.joei.2017.02.006.

Zhao J, Jian Q, Luo L, Huang B, Cao S, Huang Z. Dynamic behavior study on voltage and temperature of proton exchange membrane fuel cells. Appl Therm Eng. 2018;145:343–51. https://doi.org/10.1016/j.applthermaleng.2018.09.030.

Strahl S, Husar A, Puleston P, Riera J. Performance improvement by temperature control of an open-cathode PEM fuel cell system. Fuel Cells. 2014;14:466–78. https://doi.org/10.1002/fuce.201300211.

Liu P, Xu S, Fu J, Liu C. Experimental investigation on the voltage uniformity for a PEMFC stack with different dynamic loading strategies. Energy Convers Manage. 2020;45:26490–500. https://doi.org/10.1016/j.ijhydene.2020.05.070.

Li X, Deng Z, Wei D, Xu C, Cao G. Parameter optimization of thermal-model-oriented control law for PEM fuel cell stack via novel genetic algorithm. Energy Convers Manage. 2011;52:3290–300. https://doi.org/10.1016/j.enconman.2011.05.012.

Soltani M, Mohammad Taghi Bathaee S. Development of an empirical dynamic model for a Nexa PEM fuel cell power module. Energy Convers Manage. 2010;51:2492–500. https://doi.org/10.1016/j.enconman.2010.05.012.

A. Faghri, Integrated bipolar plate heat pipe for fuel cell stacks. US patent 2005, No.0037253.

Faghri A, Guo Z. Integration of heat pipe into fuel cell technology. Heat Transfer Eng. 2008;29:232–8. https://doi.org/10.1080/01457630701755902.

Oro MV, Bazzo E. Flat heat pipes for potential application in fuel cell cooling. Appl Therm Eng. 2015;90:848–57. https://doi.org/10.1016/j.applthermaleng.2015.07.055.

Shirzadi N, Roshandel R, Shafii M. Integration of miniature heat pipes into a proton exchange membrane fuel cell for cooling applications. Heat Transfer Eng. 2016;38:1595–605. https://doi.org/10.1080/01457632.2016.1262722.

Zhao J, Huang Z, Jian B, Bai X, Jian Q. Thermal performance enhancement of air-cooled proton exchange membrane fuel cells by vapor chambers. Energy Convers Manage. 2020;213:112830. https://doi.org/10.1016/j.enconman.2020.112830.

Luo L, Huang B, Bai X, Cheng Z, Jian Q. Temperature uniformity improvement of a proton exchange membrane fuel cell stack with ultra-thin vapor chambers. Appl Energy. 2020;270:115192. https://doi.org/10.1016/j.apenergy.2020.115192.

Huang Z, Jian Q, Zhao J. Experimental study on improving the dynamic characteristics of open-cathode PEMFC stack with dead-end anode by condensation and circulation of hydrogen. Int J Hydrogen Energy. 2020;45:19858–68. https://doi.org/10.1016/j.ijhydene.2020.05.108.

Chen Y, Jian Q, Zhao J, Bai X, Li D, Huang Z. Experimental analysis of dynamic performance of air-cooled PEMFC stack integrated ultrathin vapor chambers under new European driving cycle. Int J Energy Res. 2021;45:20089–103. https://doi.org/10.1002/er.7085.

Huang B, Jian Q, Luo L, Zhao J, Huang Z, Wang X. Cell and stack-level study of steady-state and transient behaviour of temperature uniformity of open-cathode proton exchange membrane fuel cells. Int J Energy Res. 2019. https://doi.org/10.1002/er.4810.

Y.H. Zhao, K.R. Zhang, Y.H. Diao, Heat pipe with micro-pore tubes array and making method thereof and heat exchanging system. US patent 2011, 020377.

Wang G, Quan Z, Zhao Y, Wang H. Performance of a flat-plate micro heat pipe at different filling ratios and working fluids. Appl Therm Eng. 2019;146:459–68. https://doi.org/10.1016/j.applthermaleng.2018.10.014.

Wang L, Quan Z, Zhao Y, Yang M, Zhang J. Experimental investigation on thermal management of proton exchange membrane fuel cell stack using micro heat pipe array. Appl Therm Eng. 2022. https://doi.org/10.1016/j.applthermaleng.2022.118831.

Kim HI, Chan YC, Jin HN, et al. A simple dynamic model for polymer electrolyte membrane fuel cell (PEMFC) power modules: parameter estimation and model prediction[J]. Int J Hydrogen Energy. 2010;35(8):3656–63. https://doi.org/10.1016/j.ijhydene.2010.02.002.

Gertsbakh, Ilya. Measurement uncertainty: error propagation formula. Springer Berlin Heidelberg 2003. https://doi.org/10.1016/10.1007/978-3-662-08583-7_5.

Jung G, Lo K, Su A, Weng F, Tu C, Yang T, Chan S. Experimental evaluation of an ambient forced-feed air-supply PEM fuel cell. Int J Hydrogen Energy. 2008;33:2980–5. https://doi.org/10.1016/j.ijhydene.2008.03.056.

Acknowledgements

This work was supported by the Natural Science Foundation of Inner Mongolia Autonomous Region of China (2020MS05023).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, L., Quan, Z., Zhao, Y. et al. Experimental research on the dynamic response characteristics of proton exchange membrane fuel cell thermal management using micro-heat pipe array. J Therm Anal Calorim 148, 4377–4388 (2023). https://doi.org/10.1007/s10973-023-11988-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-11988-7