Abstract

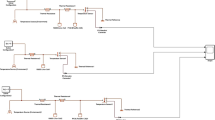

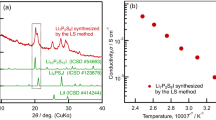

Devices of solar water desalination confront many problems including the low thermal properties of phase change materials (PCMs) such as heat transfer, storage of heat capacity, charging and discharging capability. Thus, these properties need to be improved by using a simple and novel procedure. So, incorporation and dispersion of hybrid nano-powders inside PCMs is considered a simple and novel procedure to improve the thermal properties of solar water desalination devices. The present article is focused on incorporating different nano-powders of MWCNTs and Al2O3 inside PCMs to improve the thermal characteristics of solar water desalination applications. Different nano-powders of MWCNTs and Al2O3 have been incorporated as: (i) 1.0 mass% Al2O3, (ii) 1.0 mass% MWCNTs, and (iii) hybrid 1.0 mass% of Al2O3 + 1.0 mass% MWCNTs, inside a constant amount of 250 gm RT-65HC paraffin wax. An innovative prototype was designed and produced to measure the thermal characteristics of solar water desalination devices. Various analyses have been carried out to study the influence of nano-powders scattering on the morphological, microstructural observations, chemical and thermal characteristics, including SEM, XRD, FT-IR, TGA, DSC, thermal conductivity, and infrared thermography. Microstructural observations showed that the excellent dispersion of nano-powders was at hybrid nano-additives of 1.0 mass% MWCNTs + 1.0 mass% Al2O3 inside PCMs. The uniform scattering of hybrid 1.0 mass% MWCNTs + 1.0 mass% Al2O3 inside PCMs assists to eliminate any defects. Finally, thermal characteristics of hybrid nano-additives phase change materials (NAPCMs) were improved specially in thermal stability, latent heat temperature, and thermal conductivity at 89%, 80%, and 32.8%, respectively.

Similar content being viewed by others

References

Feng D, Feng Y, Qiu L, Li P, Zang Y, Zou H, Yu Z, Zhang X. Review on nanoporous composite phase change materials: fabrication, characterization, enhancement, and molecular simulation. Renew Sustain Energy Rev. 2019;109:578–605.

Cunha JPD, Eames P. Thermal energy storage for low and medium temperature applications using phase change materials—a review. Appl Energy. 2016;177:227–38.

Qian T, Li J, Feng W, Nian H. Enhanced thermal conductivity of form-stable phase change composite with singlewalled carbon nanotubes for thermal energy storage. Sci Rep. 2017;7(44710):1–10.

Jaguemont J, Omar N, Van den Bossche P, Van Mierlo J. Phasechange materials (PCM) for automotive applications: a review. Appl Therm Eng. 2017;132:308–20.

Parameshwaran R, Deepak K, Saravanan R, Kalaiselvam S. Preparation, thermal and rheological properties of hybrid nanocomposite phase change material for thermal energy storage. Appl Energy. 2014;115:320–30.

Li M, Chen Q, Yang C. The effect of the geometry and content of the modified carbon nanotubes on the thermal properties of the composite phase-change materials. J Therm Anal Calorim. 2020;143:103.

Selvaraj V, Morri B, Nair LM, Krishnan H. Experimental investigation on the thermophysical properties of beryllium oxide-based nanofluid and nano-enhanced phase change material. J Therm Anal Calorim. 2019;137:1527–36.

Akeiber H, Nejat P, Majid MZA, Wahid MA, Jomehzadeh F, Zeynali Famileh I, et al. A review on phase change material (PCM) for sustainable passive cooling in building envelopes. Renew Sustain Energy Rev. 2016;60:1470–97.

Ranjbar S, Masoumi H, Khoshkhoo RH, Mirfendereski M. Experimental investigation of stability and thermal conductivity of phase change materials containing pristine and functionalized multi-walled carbon nanotubes. J Therm Anal Calorim. 2019;140:2505.

Babapoor A, Karimi G. Thermal properties measurement and heat storage analysis of paraffnnanoparticles composites phase change material: comparison and optimization. Appl Therm Eng. 2015;90:945–51.

Lin SC, Al-Kayiem HH. Evaluation of copper nanoparticles - paraffn wax compositions for solar thermal energy storage. Sol Energy. 2016;132:267–78.

Lin Y, Jia Y, Alva G, Fang G. Review on thermal conductivity enhancement, thermal properties and applications of phase change materials in thermal energy storage. Renew Sustain Energy Rev. 2018;82:2730–42.

Li TX, Lee JH, Wang RZ, Kang YT. Enhancement of heat transfer for thermal energy storage application using stearic acid nanocomposite with multi-walled carbon nanotubes. Energy. 2013;55:752–61.

Li T, Lee JH, Wang R, Kang YT. Heat transfer characteristics of phase change nanocomposite materials for thermal energy storage application. Int J Heat Mass Tran. 2014;75:1–11.

Manikandan S, Selvam C, Praful PPS, Lamba R, Kaushik S, Zhao D, et al. A novel technique to enhance thermal performance of a thermoelectric cooler using phase-change materials. J Therm Anal Calorim. 2019;140:1003.

Ma L, Guo C, Ou R, Wang Q, Li L. Synthesis and characterization of the n-butyl palmitate as an organic phase change material. J Therm Anal Calorim. 2018;136:2033–9.

Tian H, Du L, Wei X, Deng S, Wang W, Ding J. Enhanced thermal conductivity of ternary carbonate salt phase change material with Mg particles for solar thermal energy storage. Appl Energy. 2017;204:525–30.

Huang X, Alva G, Jia Y, Fang G. Morphological characterization and applications of phase change materials in thermal energy storage: a review. Renew Sustain Energy Rev. 2017;72:128–45.

Murshed SMS, Castro CAN. A critical review of traditional and emerging techniques and fluids for electronics cooling. Renew Sustain Energy Rev. 2017;78:821–33.

Arora N, Gupta M. An updated review on application of nanofluids in flat tubes radiators for improving cooling performance. Renew Sustain Energy Rev. 2020;134: 110242.

Sardarabadi H, Heris SZ, Ahmadpour A, Fard MP. Experimental investigation of a novel type of two-phase closed thermosyphon flled with functionalized carbon nanotubes/water nanofluids for electronic cooling application. Energy Convers Manag. 2019;188:321–32.

Bafakeeh O, Shewakh W, Abu-Oqail A, Abd-Elaziem W, Abdel Ghafaar M, Abu-Okail M. Synthesis and characterization of hybrid fiber-reinforced polymer by adding ceramic nanoparticles for aeronautical structural applications. Polymers. 2021;13:4116.

Prabhu B, ValanArasu A. Stability analysis of TiO2–Ag nanocomposite particles dispersed paraffn wax as energy storage material for solar thermal systems. Renew Energy. 2020;152:358–67.

Karaipekli A, Bicer A, Sarı A, Tyagi VV. Thermal characteristics of expanded perlite/paraffin composite phase change material with enhanced thermal conductivity using carbon nanotubes. Energy Convers Manag. 2017;15(134):373–81.

Shah KW. A review on enhancement of phase change materials-A nanomaterials perspective. Energy Build. 2018;175:57–68.

Chieruzzi M, Miliozzi A, Crescenzi T, Torre L, Kenny JM. A new phase change material based on potassium nitrate with silica and alumina nanoparticles for thermal energy storage. Nanoscale Res Lett. 2015;10(1):273.

Liang W, Wang L, Zhu H, Pan Y, Zhu Z, Sun H, et al. Enhanced thermal conductivity of phase change material nanocomposites based on MnO2 nanowires and nanotubes for energy storage. Sol Energy Mater Sol Cells. 2018;180:158–67.

Tao YB, He YL. A review of phase change material and performance enhancement method for latent heat storage system. Renew Sustain Energy Rev. 2018;31(93):245–59.

Swami VM, Autee AT, Anil T. Experimental analysis of solar fish dryer using phase change material. J Energy Storage. 2018;20:310–5.

Abu-Okail M, Shewakh W, Brisha AM, Abdelraouf YA, Abu-Oqail A. Effect of GNPs content at various compaction pressures and sintering temperatures on the mechanical and electrical properties of hybrid Cu/Al2O3/xGNPs nanocomposites synthesized by high energy ball milling. Ceram Int. 2020;46:18037–45.

Keller TM, Qadri SB, Little CA. Carbon nanotube formation in situ during carbonization in shaped bulk solid cobalt nanoparticle compositions. J Mater Chem. 2004;14(20):3063. https://doi.org/10.1039/b402936d.

Fan L-W, Zhu Z-Q, Zeng Y, Xiao Y-Q, Liu X-L, Wu Y-Y, Ding Q, Yu Z-T, Cen K-F. Transient performance of a PCM-based heat sink with high aspect-ratio carbon nanofllers. Appl Therm Eng. 2015;75:532–40. https://doi.org/10.1016/j.applthermaleng.2014.10.050.

Arshad A, Jabbal M, Yan Y. Preparation and characteristics evaluation of mono and hybrid nanoenhanced phase change materials (NePCMs) for thermal management of microelectronics. Energy Convers Manag. 2020;205:112444–50.

Abd Elaziz M, Essa F, Elsheikh H. Utilization of ensemble random vector functional link network for freshwater prediction of active solar stills with nanoparticles. Sustain Energy Technol Assess. 2021;47:101405.

Elsheikh A, Sharshir H, Mostafa M, Essa F, Ali M. Applications of nanofluids in solar energy: a review of recent advances. Renew Sustain Energy Rev. 2018;82:3483–502.

Essa F, Alawee W, Mohammed S, Dhahad H, Abdullah A, Omara Z. Experimental investigation of convex tubular solar still performance using wick and nanocomposites. Case Stud Therm Eng. 2021;27:101368.

Zou D, Ma X, Liu X, Zheng P, Hu Y. Thermal performance enhancement of composite phase change materials (PCM) using graphene and carbon nanotubes as additives for the potential application in lithium-ion power battery. Int J Heat Mass Tran. 2018;120:33–41. https://doi.org/10.1016/j.ijheatmasstransfer.2017.12.024.

Xie H, Wang J, Xi T, Liu Y, Ai F, Wu Q. Thermal conductivity enhancement of suspensions containing nanosized alumina particles. J Appl Phys. 2002;4568:4572–91.

Murshed S, Leong K, Yang C. Investigations of thermal conductivity and viscosity of nanofluids. Int J Therm Sci. 2008;560:568–647.

Nourani M, Hamdami N, Keramat J, Moheb A, Shahedi M. Thermal behavior of parafn-nano-Al2O3 stabilized by sodium stearoyl lactylate as a stable phase change material with high thermal conductivity. Renew Energy. 2016;88:474–82. https://doi.org/10.1016/j.renene.2015.11.043.

Nourani M, Hamdami N, Keramat J, Moheb A, Shahedi M. Preparation of a stable nanocomposite phase change material (NCPCM) using sodium stearoyl lactylate (SSL) as the surfactant and evaluation of its stability using image analysis. Renew Energy. 2016;93:404–11. https://doi.org/10.1016/j.renene.2016.02.073.

Li X, Zhou Y, Nian H, Zhang X, Dong O, Ren X, Zeng J, Hai C, Shen Y. Advanced nanocomposite phase change material based on calcium chloride hexahydrate with aluminum oxide nanoparticles for thermal energy storage. Energy Fuels. 2017;31(6):6560–7. https://doi.org/10.1021/acs.energyfuels.7b00851.

Putra N, Rawi S, Amin M, Kusrini E, Kosasih EA, Mahlia TMI. Preparation of beeswax/multi-walled carbon nanotubes as novel shape-stable nanocomposite phase-change material for thermal energy storage. J Energy Storage. 2019;21:32–9. https://doi.org/10.1016/j.est.2018.11.007.

Zou D, Ma X, Liu X, Zheng P, Hu Y. Thermal performance enhancement of composite phase change materials (PCM) using graphene and carbon nanotubes as additives for the potential application in lithium-ion power battery. Int J Heat Mass Transf. 2018;120:33–41. https://doi.org/10.1016/j.ijheatmasstransfer.2017.12.024.

He M, Yang L, Lin W, Chen J, Mao X, Ma Z. Preparation, thermal characterization and examination of phase change materials (PCMs) enhanced by carbon-based nanoparticles for solar thermal energy storage. J Energy Storage. 2019;25:100874. https://doi.org/10.1016/j.est.2019.100874.

Ashour M, Mohamed A, Elshalakany AB, Osman T, Khatab A. Rheological behavior of lithium grease with CNTs/GNPs hybrid nanocomposite as an additive. Ind Lubr Tribol. 2018;70:331–8. https://doi.org/10.1108/ILT-10-2017-0305.

Elshalakany AB, Tirth V, El-Kashif E, Hussein H, Hoziefa W. Characterization and mechanical properties of stir-rheo-squeeze cast AA5083/MWCNTs/GNs hybrid nanocomposites developed using a novel preform-billet method. J Mater Res Technol. 2021;1195:1209–10. https://doi.org/10.1016/j.jmrt.2020.12.079.

D8 advance, brukeruk limited, accessed: 01/10/2019. URL:https://www.bruker.com/products/x-ray-diffraction-and-elemental-analysis/x-raydiffraction/d8advance/overview.html.

Ramakrishnan S, Wang X, Sanjayan J, Petinakis E, Wilson J. Development of thermal energy storage cementitious composites (TESC) containing a novel paraffin/hydrophobic expanded perlite composite phase change material. Sol Energy. 2017;626:635–158.

Rufuss D, Iniyan S, Suganthi L, Davies P. Low mass fraction impregnation with graphene oxide (GO) enhances thermo-physical properties of paraffin for heat storage applications. Thermochim Acta. 2017;226:233–655.

Chen P, Gao X, Wang Y, Xu T, Fang Y, Zhang Z. Metal foam embedded in SEBS/paraffin/HDPE form-stable PCMs for thermal energy storage. Sol Energy Mater Sol Cell. 2016;60:65–149.

Kamel B, Tirth V, Algahtani A, Shiba M, Mobasher A, Abu Hashish A, Dabees S. Optimization of the rheological properties and tribological performance of SAE 5w–30 base oil with added MWCNTs. Lubricants. 2021. https://doi.org/10.3390/lubricants9090094.

Kamel B, El-Kashif E, Hoziefa W, Shiba M, Elshalakany AB. The effect of MWCNTsGNs hybrid addition on the tribological and rheological properties of lubricating engine oil. J Dispers Sci Technol. 2020;42:1811–9. https://doi.org/10.1080/01932691.2020.1789470.

Patil P, Shankar H, Sheremet M. Mixed convection of silica-molybdenum disulphide/water hybrid nanoliquid over a rough sphere. Symmetry. 2021;13:236. https://doi.org/10.3390/sym13020236.

Patil P, Kulkarni M. Analysis of MHD mixed convection in a Ag-TiO2 hybrid nanofluid flow past a slender cylinder. Chin J Phys. 2021;406:419–73. https://doi.org/10.1016/j.cjph.2021.07.030.

Patil P, Benawadi S. Mixed convection hybrid nanoliquid flow over an exponentially stretching rough (smooth) surface with the impacts of homogeneous–heterogeneous reactions. Heat Transfer. 2021;8103:8120–50. https://doi.org/10.1002/htj.22268.

Patil P, Benawadi S, Tonannavar J, Shanker B. Homogeneous and heterogeneous reactions in the mixed convection flow of hybrid nanofluid over a slender cylinder. Asia-Pac J Chem Eng. 2022;2022:e2740–817. https://doi.org/10.1002/apj.2740.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bafakeeh, O.T., Shiba, M.S., Elshalakany, A.B. et al. Effect of dispersion hybrid structural properties of MWCNTs and Al2O3 on microstructural and thermal characteristics of PCMs for thermal energy storage in solar water desalination. J Therm Anal Calorim 148, 4087–4104 (2023). https://doi.org/10.1007/s10973-023-11973-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-11973-0