Abstract

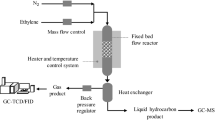

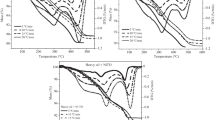

Combustion kinetic data of the coke present in FCC catalysts and additives are important for developing industrial regenerator simulations. In this work, the Ozawa–Flynn–Wall kinetic model was applied to evaluate the impact of the modifications carried out with zinc oxide in a beta zeolite (BEA) on coke combustion activation energy values. The catalysts were coked by catalytic cracking of n-hexane, containing 2-methylthiophene at a temperature of 500 °C and mass hourly space velocity of 0.17 s−1. The catalysts showed an average coke formation of 23% by mass. The activation energy in the coke combustion in the catalysts was 108.1 kJ mol−1 (H-BEA), 114.7 kJ mol−1 (ZnO/H-BEA2), and 122.3 kJ mol-1 (ZnO/H-BEA8). A directly proportional relationship was observed between the coke content formed, the activation energy of the combustion of this coke, and the type of coke formed (types I and II) with the zinc content in the catalysts. The incorporation of zinc at different levels in zeolite beta increased the adsorption capacity and the number of strong acid sites of the catalysts, increasing the interaction between the coke formed and the catalyst, favoring the formation of different types of coke under the reaction conditions studied.

Similar content being viewed by others

References

Bryden K, Singh U, Berg M, Brandt S, Schiller R, Cheng W-C. Fluid catalytic cracking (FCC): catalysts and additives. Published online: https://doi.org/10.1002/0471238961.fluidnee.a01.pub2, Willey (2015).

Calderón EHJ, Tipantuña AEP, Mullo PFH, Cháfuel DAH, Ruiz W, Stahl U, Bermudez J. Natural and activated allophane catalytic activity based on the microactivity test in ASTM norm 3907/D3907M-2019. Appl Sci. 2020;10:3035.

Ng SH, Heshka NE, Zheng Y, Ling H, Wang J, Liu Q, Little E, Ding F, Wang H. Virgin heavy gas oil from oil sands bitumen as FCC feed. Catalysts. 2020;10:277.

Argyle MD, Bartholomew CH. Heterogeneous catalyst deactivation and regeneration: a review. Catalysts. 2015;5:145–269.

Wang W, Zhang C, Chen G, Zhang R. Influence of CeO2 addition to Ni–Cu/HZSM-5 catalysts on hydrodeoxygenation of bio-oil. Appl Sci. 2019;9:1257.

Vergara HR, Brijaldo MH, Martinez JJ, Rojas HA, Pedraza J, Passos FB, Pereira da Costa L, Gonzalez-Vera D, Osorio-Vargas P. Effect of metal content on ethanol decomposition over Ni-Co catalysts supported on La-Ce oxides. Materials. 2020;13:759.

Cerqueira HS, Caeiro G, Costa L, Ribeiro F. Deactivation of FCC catalysts. J Mol Catal A Chem. 2008;292:1–13.

Bai P, Etim UJ, Yan Z, Mintova S, Zhang Z, Zhong Z, Gao X. Fluid catalytic cracking technology: current status and recent discoveries on catalyst contamination. Catal Rev. 2019;61:333–405.

Vogt ETC, Weckhuysen BM. Fluid catalytic cracking: recent developments on the grand old lady of zeolite catalysis. Chem Soc Rev. 2015;44:7342–70.

Amblard B, Singh R, Gorgzboe E, Raynal L. CFD modeling of the coke combustion in an industrial FCC regenerator. Chem Eng Sci. 2017;170:731–42.

Sadeghbeigi R. Fluid catalytic cracking handbook: an expert guide to the practical operation, design, and optimization of FCC units. 4th ed. New York: Elsevier; 2020.

Santos RC, Almeida D, Pontes DA, Lam YL, Pontes LAM. Thiophene cracking on zinc modified beta zeolite. Mol Catal. 2019;470:112–9.

Al-Majnouni KA, Supronowicz W, Aldugman T, Al-Yassir N, Al-Zenaidi A, Nagengast J, Matuszyk T. Dynamic and steady state evolution of active sites in H-ZSM5. Catalysts. 2020;10:425.

Aponte Y, Che-Galicia G, De Lasa H. A fluidizable Zn-offretite for selective thiophenic species adsorption. Additive performance under FCC conditions. Fuel. 2016;186:222–34.

Alotibi MF, Alshammari BA, Alotaibi MH, Alotaibi FM, Alshihri SM, Navarro RM, Fierro JL. ZSM-5 zeolite based additive in FCC process: a review on modifications for improving propylene production. Catal Surv Asia. 2019;24:1–10.

Guisnet M, Ribeiro FA. Deactivation and regeneration of zeolite catalysts. 9th ed. Singapore: World Scientific; 2011.

Ochoa A, Ibarra A, Bilbao J, Arandes JM, Castaño P. Assessment of thermogravimetric methods for calculating coke combustion-regeneration kinetics of deactivated catalyst. Chem Eng Sci. 2017;171:459–70.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38:1881–6.

Ortega A. A simple and precise linear integral method for isoconversional data. Thermochim Acta. 2008;474:81–6.

Fernandes VJ, Araujo AS. Kinetic study of HY zeolite regeneration by thermogravimetry. Thermochim Acta. 1995;255:273–80.

Mandal DK, Bhunia H, Bajpai PK, Bhalla VK. Thermal degradation kinetics and estimation of lifetime of radiation grafted polypropylene films. Radiat Phys Chem. 2017;136:1–8.

Cunha JTB, Castro VM, Silva DS, Pontes DA, Santos RC, Pontes LAM. Coke deposition on cracking catalysts study by thermogravimetric analysis. Int J Eng Res Appl. 2020;10:43–7.

Flynn JH, Wall LA. General treatment of the thermogravimetry of polymers. J Res Natl Bur Stand. 1966;70:487–523.

Ozawa T. Some demonstrations of the effect of the heating rate on thermoanalytical curves. J Therm Anal. 1976;9:217–27.

Souza MRO, Silva JMR, Araujo MDS, Almeida JS, Fernandes VJ, Coriolano ACF, Delgado RCOB, Araujo AS. Kinetic study of distillation and cracking of heavy oil on bimodal meso–macroporous materials of silica and aluminosilicates by thermogravimetry. J Therm Anal Calorim. 2022;147:3647–58.

Toop DJ. Theory of life testing and use of thermogravimetric analysis to predict the thermal life of wire enamels. IEEE Trans Electr Insul. 1971;EI-6:2–14.

Yue Y, Guo X, Liu T, Liu H, Wang T, Yuan P, Zhu H, Bai Z, Bao X. Template free synthesis of hierarchical porous zeolite Beta with natural kaolin clay as alumina source. Microporous Mesoporous Mater. 2020;293:109772.

Trník A, Scheinherrová L, Medved I, Černý R. Simultaneous DSC and TG analysis of high-performance concrete containing natural zeolite as a supplementary cementitious material. J Therm Anal Calorim. 2015;121:67–73.

Taufiqurrahmi N, Mohamed AR, Bhatia S. Deactivation and coke combustion studies of nanocrystalline zeolite beta in catalytic cracking of used palm oil. Chem Eng J. 2010;163:413–21.

Epelde E, Ibañez M, Aguayo AT, Gayubo AG, Bilbao J, Castaño P. Differences among the deactivation pathway of HZSM-5 zeolite and SAPO-34 in the transformation of ethylene or 1-butene to propylene. Microporous Mesoporous Mater. 2014;195:284–93.

Ibáñez M, Artetxe M, Lopez G, Elordi G, Bilbao J, Olazar M, Castaño P. Identification of the coke deposited on an HZSM-5 zeolite catalyst during the sequenced pyrolysis-cracking of HDPE. Appl Catal B. 2014;148–149:436–45.

Acknowledgements

The authors acknowledge the financial support provided by Programa de Recursos Humanos da Agência Nacional do Petróleo, Gás Natural e Biocombustíveis—PRH-ANP, and the Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

da Silva, D.S., Andrade, M.L., Araujo, M.D.S. et al. Kinetics of the thermal decomposition of coke formed on ZnO/H-BEA catalyst in the transformation of 2-methylthiophene in n-hexane stream. J Therm Anal Calorim 148, 3479–3486 (2023). https://doi.org/10.1007/s10973-023-11944-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-11944-5