Abstract

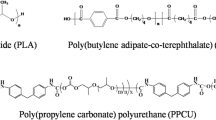

A bioplastics film with excellent physical and barrier properties was prepared with Poly(butylene adipate-co-terephthalate) (PBAT), thermoplastic starch (TPS), and poly(propylene carbonate) (PPC). PBAT/TPS/PPC blend films were investigated through rheological measurements, tensile tests, scanning electron microscopy, mechanical dynamic analysis, and barrier properties. The content of PPC controlled the morphology and continuity development of the PBAT/TPS/PPC blend. With an increase in PPC, the TPS demonstrated better dispersion in the system, and the PBAT and PPC became the continuous phase. Compared with PBAT/TPS films, an increase in PPC led to a decrease in the water contact angle of the films, and water vapor permeability, oxygen permeability, and carbon dioxide permeability of PBAT/TPS/PPC films decreased by 53.1%, 74.4%, and 78.9%, respectively. The addition of PPC increased the dispersion of starch in the film and accelerated degradation of the film. PBAT/TPS/PPC films demonstrated good mechanical properties and excellent barrier properties, indicating that they have potential for use as degradable and cost-effective alternatives to traditional plastics in the packaging industry.

Similar content being viewed by others

References

Li Z, Li W, Zhang H, Dong L. Thermal, rheological and mechanical properties of poly(propylene carbonate)/methyl methacrylate–butadiene–styrene blends. Iran Polym J. 2015;24(10):861–70. https://doi.org/10.1007/s13726-015-0374-8.

Siracusa V, Blanco I. Bio-polyethylene (Bio-PE), bio-polypropylene (Bio-PP) and bio-poly (ethylene terephthalate)(bio-PET): recent developments in bio-based polymers analogous to petroleum-derived ones for packaging and engineering applications. Polymers. 2020;12(8):1641. https://doi.org/10.3390/polym12081641.

Yu X, Chen L, Jin Z, Jiao A. Research progress of starch-based biodegradable materials: a review. J Mater Sci. 2021;56(19):11187–208. https://doi.org/10.1007/s10853-021-06063-1.

Credou J, Berthelot T. Cellulose: from biocompatible to bioactive material. J Mater Chem B. 2014;2(30):4767–88. https://doi.org/10.1039/c4tb00431k.

Ahmed J, Varshney SK. Polylactides—chemistry, properties and green packaging technology: a review. Int J Food Prop. 2011;14(1):37–58. https://doi.org/10.1080/10942910903125284.

Park SJ, Kim TW, Kim MK, Lee SY, Lim SC. Advanced bacterial polyhydroxyalkanoates: towards a versatile and sustainable platform for unnatural tailor-made polyesters. Biotechnol Adv. 2012;30(6):1196–206. https://doi.org/10.1016/j.biotechadv.2011.11.007.

Swain SN, Biswal SM, Nanda PK, Nayak PL. Biodegradable soy-based plastics: opportunities and challenges. J Polym Environ. 2004;12(1):35–42. https://doi.org/10.1023/B:Jooe.0000003126.14448.04.

Ma X, Yu J, Zhao A. Properties of biodegradable poly(propylene carbonate)/starch composites with succinic anhydride. Compos Sci Technol. 2006;66(13):2360–6. https://doi.org/10.1016/j.compscitech.2005.11.028.

Dammak M, Fourati Y, Tarrés Q, Delgado-Aguilar M, Mutjé P, Boufi S. Blends of PBAT with plasticized starch for packaging applications: mechanical properties, rheological behaviour and biodegradability. Ind Crops Prod. 2020. https://doi.org/10.1016/j.indcrop.2019.112061.

Lendvai L, Apostolov A, Karger-Kocsis J. Characterization of layered silicate-reinforced blends of thermoplastic starch (TPS) and poly(butylene adipate-co-terephthalate). Carbohydr Polym. 2017;173:566–72. https://doi.org/10.1016/j.carbpol.2017.05.100.

Zhai X, Wang W, Zhang H, Dai Y, Dong H, Hou H. Effects of high starch content on the physicochemical properties of starch/PBAT nanocomposite films prepared by extrusion blowing. Carbohydr Polym. 2020;239: 116231. https://doi.org/10.1016/j.carbpol.2020.116231.

Jian J, Xiangbin Z, Xianbo H. An overview on synthesis, properties and applications of poly(butylene-adipate-co-terephthalate)–PBAT. Adv Ind Eng Polym Res. 2020;3(1):19–26. https://doi.org/10.1016/j.aiepr.2020.01.001.

Girdthep S, Worajittiphon P, Leejarkpai T, Molloy R, Punyodom W. Effect of silver-loaded kaolinite on real ageing, hydrolytic degradation, and biodegradation of composite blown films based on poly (lactic acid) and poly (butylene adipate-co-terephthalate). Eur Polym J. 2016;82:244–59.

Stagner JA, Alves VD, Narayan R. Application and performance of maleated thermoplastic starch-poly(butylene adipate-co-terephthalate) blends for films. J Appl Polym Sci. 2012;126(S1):E135–42. https://doi.org/10.1002/app.34876.

Xing Q, Buono P, Ruch D, Dubois P, Wu L, Wang W-J. Biodegradable UV-blocking films through core-shell lignin–melanin nanoparticles in poly(butylene adipate-co-terephthalate). ACS Sustain Chem Eng. 2019;7(4):4147–57. https://doi.org/10.1021/acssuschemeng.8b05755.

Venkatesan R, Rajeswari N. Preparation, mechanical and antimicrobial properties of SiO2/poly (butylene adipate-co-terephthalate) films for active food packaging. Silicon. 2019;11(5):2233–9.

Nunes EdCD, de Souza AG, Rosa DdS. Use of a chain extender as a dispersing agent of the CaCO3 into PBAT matrix. J Compos Mater. 2019;54(10):1373–82. https://doi.org/10.1177/0021998319880282.

Raquez JM, Nabar Y, Narayan R, Dubois P. Novel high-performance talc/poly[(butylene adipate)-co-terephthalate] hybrid materials. Macromol Mater Eng. 2008;293(4):310–20. https://doi.org/10.1002/mame.200700352.

Muthuraj R, Misra M, Mohanty AK. Biodegradable compatibilized polymer blends for packaging applications: a literature review. J Appl Polym Sci. 2018;135(24):45726.

Wei D, Wang H, Xiao H, Zheng A, Yang Y. Morphology and mechanical properties of poly(butylene adipate-co-terephthalate)/potato starch blends in the presence of synthesized reactive compatibilizer or modified poly(butylene adipate-co-terephthalate). Carbohydr Polym. 2015;123:275–82. https://doi.org/10.1016/j.carbpol.2015.01.058.

Avérous L. Biodegradable multiphase systems based on plasticized starch: a review. J Macromol Sci, Part C Polym Rev. 2004;44(3):231–74. https://doi.org/10.1081/mc-200029326.

Rodriguez Gonzalez FJ, Ramsay BA, Favis BD. Rheological and thermal properties of thermoplastic starch with high glycerol content. Carbohydr Polym. 2004;58(2):139–47. https://doi.org/10.1016/j.carbpol.2004.06.002.

Hablot E, Dewasthale S, Zhao Y, Zhiguan Y, Shi X, Graiver D, et al. Reactive extrusion of glycerylated starch and starch–polyester graft copolymers. Eur Polym J. 2013;49(4):873–81. https://doi.org/10.1016/j.eurpolymj.2012.12.005.

Cyras VP, Manfredi LB, Ton-That M-T, Vázquez A. Physical and mechanical properties of thermoplastic starch/montmorillonite nanocomposite films. Carbohydr Polym. 2008;73(1):55–63. https://doi.org/10.1016/j.carbpol.2007.11.014.

Zuo Y, Gu J, Yang L, Qiao Z, Zhang Y. Study on the preparation of maleated thermoplastic starch by reactive extrusion. J Thermoplast Compos Mater. 2014;29(3):397–409. https://doi.org/10.1177/0892705713518809.

Raquez JM, Nabar Y, Narayan R, Dubois P. In situ compatibilization of maleated thermoplastic starch/polyester melt-blends by reactive extrusion. Polym Eng Sci. 2008;48(9):1747–54. https://doi.org/10.1002/pen.21136.

Wootthikanokkhan J, Kasemwananimit P, Sombatsompop N, Kositchaiyong A, Isarankura na Ayutthaya S, Kaabbuathong N. Preparation of modified starch-grafted poly(lactic acid) and a study on compatibilizing efficacy of the copolymers in poly(lactic acid)/thermoplastic starch blends. J Appl Polym Sci. 2012;126(S1):E389–96. https://doi.org/10.1002/app.36896.

Wang Z, Zhao L, Jin B, Jia S, Han L, Pan H, et al. Effect of maleic anhydride and titanate coupling agent as additives on the properties of poly (butylene adipate-co-terephthalate)/thermoplastic starch films. Polym Bull. 2021. https://doi.org/10.1007/s00289-021-03841-4.

Chang CC, Trinh BM, Mekonnen TH. Robust multiphase and multilayer starch/polymer (TPS/PBAT) film with simultaneous oxygen/moisture barrier properties. J Colloid Interface Sci. 2021;593:290–303. https://doi.org/10.1016/j.jcis.2021.03.010.

Pan H, Hao Y, Zhao Y, Lang X, Zhang Y, Wang Z, et al. Improved mechanical properties, barrier properties and degradation behavior of poly(butylenes adipate-co-terephthalate)/poly(propylene carbonate) films. Korean J Chem Eng. 2017;34(5):1294–304. https://doi.org/10.1007/s11814-017-0066-5.

Chen L, Qin Y, Wang X, Zhao X, Wang F. Plasticizing while toughening and reinforcing poly(propylene carbonate) using low molecular mass urethane: role of hydrogen-bonding interaction. Polymer. 2011;52(21):4873–80. https://doi.org/10.1016/j.polymer.2011.08.025.

Gf Li, Luo WH, Xiao M, Wang SJ, Meng YZ. Biodegradable poly(propylene carbonate)/layered double hydroxide composite films with enhanced gas barrier and mechanical properties. Chin J Polym Sci. 2016;34(1):13–22. https://doi.org/10.1007/s10118-016-1720-9.

Liu Z, Hu J, Gao F, Cao H, Zhou Q, Wang X. Biodegradable and resilient poly(propylene carbonate) based foam from high pressure CO2 foaming. Polym Degrad Stab. 2019;165:12–9. https://doi.org/10.1016/j.polymdegradstab.2019.04.019.

Li J, Lai MF, Liu JJ. Control and development of crystallinity and morphology in poly(β-hydroxybutyrate-co-β-hydroxyvalerate)/poly(propylene carbonate) blends. J Appl Polym Sci. 2005;98(3):1427–36. https://doi.org/10.1002/app.22117.

Fourati Y, Tarres Q, Mutje P, Boufi S. PBAT/thermoplastic starch blends: effect of compatibilizers on the rheological, mechanical and morphological properties. Carbohydr Polym. 2018;199:51–7. https://doi.org/10.1016/j.carbpol.2018.07.008.

Kuwabara K, Gan Z, Nakamura T, Abe H, Doi Y. Crystalline/amorphous phase structure and molecular mobility of biodegradable poly(butylene adipate-co-butylene terephthalate) and related polyesters. Biomacromolecules. 2002;3(2):390–6. https://doi.org/10.1021/bm0156476.

Altayan MM, Al Darouich T, Karabet F. Thermoplastic starch from corn and wheat: a comparative study based on amylose content. Polym Bull. 2020;78(6):3131–47. https://doi.org/10.1007/s00289-020-03262-9.

Liu W, Wang Z, Liu J, Dai B, Hu S, Hong R, et al. Preparation, reinforcement and properties of thermoplastic starch film by film blowing. Food Hydrocoll. 2020. https://doi.org/10.1016/j.foodhyd.2020.106006.

Hao YP, Yang HL, Zhang GB, Zhang HL, Gao G, Dong LS. Rheological, thermal and mechanical properties of biodegradable poly(propylene carbonate)/polylactide/poly(1,2-propylene glycol adipate) blown films. Chin J Polym Sci. 2015;33(12):1702–12. https://doi.org/10.1007/s10118-015-1714-z.

Xing C, Wang H, Hu Q, Xu F, Cao X, You J, et al. Mechanical and thermal properties of eco-friendly poly(propylene carbonate)/cellulose acetate butyrate blends. Carbohydr Polym. 2013;92(2):1921–7. https://doi.org/10.1016/j.carbpol.2012.11.058.

Gavara R, Catalá R, Hernández-Muñoz PM, Hernández RJ. Evaluation of permeability through permeation experiments: isostatic and quasi-isostatic methods compared. Packag Technol Sci. 1996;9(4):215–24.

Krevelen D, Nijenhuis K. Properties determining mass transfer in polymeric systems. Properties of polymers: their correlation with chemical structure: their numerical estimation and prediction from additive group contributions. 2009: 655–702.

Bourtoom T. Edible films and coatings: characteristics and properties. Int Food Res J. 2008;15(3):237–48.

Petersen K, Nielsen PV, Bertelsen G, Lawther M, Olsen MB, Nilsson NH, et al. Potential of biobased materials for food packaging. Trends Food Sci Tech. 1999;10(2):52–68. https://doi.org/10.1016/S0924-2244(99)00019-9.

Biundo A, Hromic A, Pavkov-Keller T, Gruber K, Quartinello F, Haernvall K, et al. Characterization of a poly (butylene adipate-co-terephthalate)-hydrolyzing lipase from pelosinus fermentans. Appl Microbiol Biotechnol. 2016;100(4):1753–64.

Kasuya KI, Ishii N, Inoue Y, Yazawa K, Tagaya T, Yotsumoto T, et al. Characterization of a mesophilic aliphatic–aromatic copolyester-degrading fungus. Polym Degrad Stab. 2009;94(8):1190–6.

Jia H, Zhang M, Weng Y, Zhao Y, Li C, Kanwal A. Degradation of poly(butylene adipate-co-terephthalate) by Stenotrophomonas sp. YCJ1 isolated from farmland soil. J Environ Sci. 2021;103:50–8. https://doi.org/10.1016/j.jes.2020.10.001.

Witt U, Muller RJ, Deckwer WD. Evaluation of the biodegradability of copolyesters containing aromatic compounds by investigations of model oligomers. J Environ Polym Degrad. 1996;4(1):9–20. https://doi.org/10.1007/Bf02083878.

Muller RJ, Witt U, Rantze E, Deckwer WD. Architecture of biodegradable copolyesters containing aromatic constituents. Polym Degrad Stab. 1998;59(1–3):203–8. https://doi.org/10.1016/S0141-3910(97)00186-9.

Wang XW, Wang GX, Huang D, Lu B, Zhen ZC, Ding Y, et al. Degradability comparison of poly(butylene adipate terephthalate) and its composites filled with starch and calcium carbonate in different aquatic environments. J Appl Polym Sci. 2019. https://doi.org/10.1002/app.46916.

Acknowledgements

This work was supported by the Chinese Academy of Sciences (Changchun Branch) (2021SYHZ0042, 2021SYHZ0044), Science and Technology Bureau of Changchun City of China (21SH13, 21KY01), Development and Reform commission of Jilin Province of China (2021C039-2), and the Science and Technology Development Plan of Jilin Province (20210203199SF, 20210509017RQ).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Z., Tian, H., Wang, X. et al. Study on thermal, rheological, mechanical, morphological, and barrier properties of poly(butylene adipate-co-terephthalate)/thermoplastic starch/poly(propylene carbonate) biodegradable blown films. J Therm Anal Calorim 148, 1853–1865 (2023). https://doi.org/10.1007/s10973-022-11858-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11858-8