Abstract

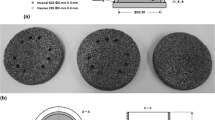

A thermal energy storage system combined with renewable energy sources or waste heat recovery will increase the dispatchability of the energy system. It also helps to reduce the gap between supply and demand. Among available techniques, latent heat thermal energy storage systems have been an attractive area of research. Selecting a phase change and construction material is vital in designing any storage system. In the present study, corrosion characterization was performed for erythritol used in the experimental prototype. The use of erythritol to develop a storage system requires understanding its corrosion behavior with storage container material and piping system to ensure the safety of construction and enhance the system's life. Corrosion rates were determined in stainless steel and mild steel sample by gravimetric tests, measuring the mass loss after 2000 h of immersion at 140 °C in two different test conditions. Simultaneously, surface morphology and corrosion products were analyzed by scanning electron microscopy (SEM) and energy-dispersive X-ray scanning (EDX). The experimental result confirms that stainless steel shows better corrosion resistance than mild steel for selected phase change material. SEM and EDX analysis shows no significant changes in the structure after 2000 h of immersion. Corrosion rates for open and closed crucible stainless steel sample have been observed at 0.003 mm y−1 and 0.004 mm y−1, respectively, whereas mild steel sample was more affected by PCM in both the open and closed crucible tests, giving 0.0221 mm y−1 and 0.0392 mm y−1. The study shows that further research is required in different operating conditions.

Similar content being viewed by others

References

Sarbu I, Dorca A. Review on heat transfer analysis in thermal energy storage using latent heat storage systems and phase change materials. Int J Energy Res. 2018;43(1):29–64.

Gil A, Medrano M, Martorell I, Lázaro A, Dolado P, Zalba B, et al. State of the art on high temperature thermal energy storage for power generation. Part 1-Concepts, materials and modellization. Renew Sustain Energy Rev. 2010;14:31–55.

Zalba B, Marín JM, Cabeza LF, Mehling H. Review on thermal energy storage with phase change: Materials, heat transfer analysis and applications. Appl Therm Eng. 2003;23(3):251–83.

Sharma A, Tyagi VV, Chen CR, Buddhi D. Review on thermal energy storage with phase change materials and applications. Renew Sustain Energy Rev. 2009;13:318–45.

Zhao Y, Zhang X, Xu X, Zhang S. Development, characterization and modification study of eutectic fatty alcohol for cold energy storage application. J Therm Anal Calorim. 2021;146:1133–47. https://doi.org/10.1007/s10973-020-10114-1.

Dinesh R, Hussain SI, Roseline AA, Kalaiselvam S. Experimental investigation on heat transfer behavior of the novel ternary eutectic PCM embedded with MWCNT for thermal energy storage systems. J Therm Anal Calorim. 2021;145:2935–49. https://doi.org/10.1007/s10973-020-09726-4.

Beemkumar N, Yuvarajan D, Arulprakasajothi M, Elangovan K, Arunkumar T. Control of room temperature fluctuations in the building by incorporating PCM in the roof. J Therm Anal Calorim. 2021;143:3039–46. https://doi.org/10.1007/s10973-019-09226-0.

Deng Z, Zhang C, Sun Q, Wu L, Yao F, Xu D. Experimental study on melting performance of phase change material-based finned heat sinks by a comprehensive evaluation. J Therm Anal Calorim. 2021;144:869–82. https://doi.org/10.1007/s10973-020-09508-y.

Bakirci K, Yuksel B. Simulation study of solar-source heat pump system with sensible energy storage. J Therm Anal Calorim. 2021;146:1853–64. https://doi.org/10.1007/s10973-020-10091-5.

Ghoghaei MS, Mahmoudian A, Mohammadi O, Shafii MB, Jafari Mosleh H, Zandieh M, et al. A review on the applications of micro-/nano-encapsulated phase change material slurry in heat transfer and thermal storage systems. J Therm Anal. 2021;145:245–68. https://doi.org/10.1007/s10973-020-09697-6.

Tyagi VV, Panwar NL, Rahim NA, Kothari R. Review on solar air heating system with and without thermal energy storage system. Renew Sustain Energy Rev Elsevier Ltd. 2012;16:2289–303.

Anon. Seasonal Thermal Energy Storage. Mech Eng. 1983;105:28–34.

Waseel AM, Sabory NR, Zaheb H, Waseel AK. Central heating by seasonal sensible heat storage of solar thermal energy. Int J Innov Res Sci Stud. 2021;4:100–10.

Mohammadi O, Shafii MB, Shirin-abadi AR, Heydarian R, Ahmadi MH. The impacts of utilizing nano-encapsulated PCM along with RGO nanosheet. Int J. 2021;45:19481–99.

Zandie M, Moghaddas A, Kazemi A, Ahmadi M, Feshkache HN, Ahmadi MH, et al. The impact of employing a magnetic field as well as Fe3O4 nanoparticles on the performance of phase change materials. Eng Appl Comput Fluid Mech. 2022;16:196–214. https://doi.org/10.1080/19942060.2021.2006092.

Sadegh SS, Aghababaei A, Mohammadi O, Mosleh HJ, Shafii MB, Ahmadi MH. An experimental investigation into the melting of phase change material using Fe3O4 magnetic nanoparticles under magnetic field. J Therm Anal Calorim. 2021;146(38):1–92. https://doi.org/10.1007/s10973-020-09958-4.

Abhat A. Low temperature latent heat thermal energy storage: Heat storage materials. Sol Energy. 1983;30:313–32.

Wei G, Wang G, Xu C, Ju X, Xing L, Du X, et al. Selection principles and thermophysical properties of high temperature phase change materials for thermal energy storage: a review. Renew Sustain Energy Rev. 2018;81:1771–86. https://doi.org/10.1016/j.rser.2017.05.271.

Ferrer G, Solé A, Barreneche C, Martorell I, Cabeza LF. Corrosion of metal containers for use in PCM energy storage. Renew Energy. 2015;76:465–9.

del Barrio EP, Godin A, Duquesne M, Daranlot J, Jolly J, Alshaer W, et al. Characterization of different sugar alcohols as phase change materials for thermal energy storage applications. Sol Energy Mater Sol Cells. 2017;159:560–9. https://doi.org/10.1016/j.solmat.2016.10.009.

Patel CP, Thippeswamy PK, Mondal S, Tyagi A.K, Parida SC (Eds) (2020). Effect of different heating/cooling rate on thermophysical properties of sugar alcohol for latent heat energy storage system. India: Bhabha Atomic Research Centre. https://inis.iaea.org/search/searchsinglerecord.aspx?recordsFor=SingleRecord&RN=51088404

Maldonado JM, Fernández ÁG, Cabeza LF. Corrosion assessment of myo-inositol sugar alcohol as a phase change material in storage systems connected to Fresnel solar plants. Molecules. 2019;24(7):1383.

Mojiri A, Grbac N, Bourke B, Rosengarten G. D-mannitol for medium temperature thermal energy storage. Sol Energy Mater Sol Cells. 2018;176:150–6. https://doi.org/10.1016/j.solmat.2017.11.028.

Solé A, Neumann H, Niedermaier S, Martorell I, Schossig P, Cabeza LF. Stability of sugar alcohols as PCM for thermal energy storage. Sol Energy Mater Sol Cells. 2014;126:125–34. https://doi.org/10.1016/j.solmat.2014.03.020.

Ushak S, Marín P, Galazutdinova Y, Cabeza LF, Farid MM, Grágeda M. Compatibility of materials for macroencapsulation of inorganic phase change materials: Experimental corrosion study. Appl Therm Eng. 2016;107:410–9. https://doi.org/10.1016/j.applthermaleng.2016.06.171.

Porisini FC. Salt hydrates used for latent heat storage: Corrosion of metals and reliability of thermal performance. Sol Energy. 1988;41:193–7.

Marín PE, Ushak S, de Gracia A, Grageda M, Cabeza LF. Assessing corrosive behaviour of commercial phase change materials in the 21–25 °C temperature range. J Energy Storage. 2020;32:101711. https://doi.org/10.1016/j.est.2020.101711.

Groll M, Brost O, Heine D. Corrosion of steels in contact with salt eutectics as latent heat storage materials: Influence of water and other impurities. Heat Recover Syst CHP. 1990;10:567–72.

Cabeza LF, Roca J, Nogueés M, Mehling H, Hiebler S. Long term immersion corrosion tests on metal-PCM pairs used for latent heat storage in the 24 to 29°C temperature range. Mater Corros. 2005;56:33–8.

Moreno P, Miró L, Solé A, Barreneche C, Solé C, Martorell I, et al. Corrosion of metal and metal alloy containers in contact with phase change materials (PCM) for potential heating and cooling applications. Appl Energy. 2014;125:238–45. https://doi.org/10.1016/j.apenergy.2014.03.022.

Vasu A, Hagos FY, Noor MM, Mamat R, Azmi WH, Abdullah AA, et al. Corrosion effect of phase change materials in solar thermal energy storage application. Renew Sustain Energy Rev. 2017;76:19–33.

November R. 2000 TEST METHOD 5 Chapter 1 . Uniform Corrosion General Description Preparation of Fire Chemical Products Coupon Description and Preparation Coupon Degreasing and Initial Cleaning Coupon Immersion End of the Test Exposure Final Coupon Cleaning Control Coupons. Magnesium;1–7. https://www.fs.usda.gov/rm/fire/wfcs/tests/documents/stp_tm05.pdf

Committee ASTM. G01 Standard practice for preparing, cleaning, and evaluating corrosion test specimen. Significance. 2017;90:1–9.

Maldonado JM, Fullana-Puig M, Martín M, Solé A, Fernández ÁG, De Gracia A, et al. Phase change material selection for thermal energy storage at high temperature range between 210°C and 270°C. Energies. 2018;11:1–13.

Cabeza LF, Illa J, Roca J, Badia F, Mehling H, Hiebler S, et al. Immersion corrosion tests on metal-salt hydrate pairs used for latent heat storage in the 32 to 36 8 C temperature range. Mater Corros. 2001;146:140–6.

Holman JP. 2012. Experimental Methods for Engineers. 8th ed. McGraw-Hill Companies, NewYork, p 64

Ferrer G, Solé A, Barreneche C, Martorell I, Cabeza LF. Review on the methodology used in thermal stability characterization of phase change materials. Renew Sustain Energy Rev. 2015;50:665–85. https://doi.org/10.1016/j.rser.2015.04.187.

IYER AP. 2011 The Effect of Silica Nanoparticles on corrosion of steel by molten carbonate eutectics Texas A&M University. http://oaktrust.library.tamu.edu/handle/1969.1/ETD-TAMU-2011-05-9511?show=full)

Oró E, Miró L, Barreneche C, Martorell I, Farid MM, Cabeza LF. Corrosion of metal and polymer containers for use in PCM cold storage. Appl Energy. 2013;109:449–53. https://doi.org/10.1016/j.apenergy.2012.10.049.

Acknowledgements

We are thankful to the central research facility Indian Institute of Technology Delhi (CRF IIT Delhi) for supporting SEM and EDX analysis of corrosion samples. This study was carried out at Centre of Excellence in Thermal Energy Storage, TERI School of Advanced Studies, New Delhi, funded by the Ministry of Education (earlier Ministry of Human Resource Development), Government of India, under the Frontier Areas in Science and Technology (FAST) scheme.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by [CPP], [SN], and [SM]. The first draft of the manuscript was written by [CPP], and all the authors commented on previous version of the manuscript. All author read and approved the final manuscript. Conceptualization was performed by [CPP],[SN],[SM]; methodology by [CPP],[SN]; formal analysis and investigation by [Chhabishwar Prasad Patel]; writing—original draft preparation—by [CPP]; writing—review and editing—by [Som Mondal],[SN]; resources by [SM]; supervision by [SM].

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Patel, C.P., Nikam, S. & Mondal, S. Corrosion assessment of erythritol as a phase change material in latent heat thermal energy storage system. J Therm Anal Calorim 148, 371–381 (2023). https://doi.org/10.1007/s10973-022-11798-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11798-3