Abstract

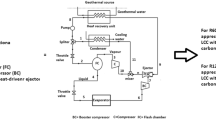

This paper presents a thermodynamic analysis of a novel dual-ejector transcritical CO2 refrigeration system for applications in warm climate. Dual-ejector flow-pressurization and flow-splitting for higher ambient temperature operation are implemented to improve the performance. The proposed system is compared with various previously published CO2 systems including B1 (Standard CO2 booster system), B2 (CO2 booster system with parallel compression), B3 (CO2 booster system with flooded LT evaporator), B4 (CO2 booster system with work recovery expander), B5 (CO2 booster system with parallel compression integrated with flooded LT evaporator and work recovery expander) and also with a multi-stage ejector system. The investigation is carried out at ambient temperatures ranging from 34 to 43 °C. Ambient temperature and gas-cooler pressure were found to have a significant effect on the effective flow area of the ejectors. The COP of the proposed system is found to be 32% higher than B5 and 26% higher than the multi-ejector system. Exergy analysis is also carried out to comprehend system response to various parameters including extent of flow-splitting and change in inter-cooler pressure. The ejector Ej-2 was found to have the highest contribution to irreversibility accounting for an increment of 30% with the increase in ambient temperature from 34 to 43 °C. A detailed analysis of the ejector performance is also presented. Mixing chamber diameter is found to be an important parameter affecting the energetic and exergetic performance of the ejector. An enhancement of 29.63% in pressure lift and reduction of 61.11% in the irreversibility contribution of the ejector is possible by increasing the mixing chamber diameter from 0.012 to 0.015 m.

Similar content being viewed by others

Abbreviations

- a :

-

Speed of sound (m s−1)

- \(\alpha \) :

-

Void fraction

- A :

-

Area (m2)

- d :

-

Diameter (m)

- h :

-

Enthalpy (J kg−1)

- V :

-

Velocity (m s−1)

- v :

-

Specific volume (m3 kg−1)

- \(\eta \) :

-

Efficiency

- m :

-

Mass flow rate (kg s−1)

- Q :

-

Cooling load (kW)

- c pj :

-

Specific heat capacity at constant pressure (J kg−1 K−1)

- C :

-

Capital cost ($)

- C pv :

-

Volumetric heat capacity of vapour (J m−3 K−1)

- C pl :

-

Volumetric heat capacity of liquid (J m−3 K−1)

- CO2 :

-

Carbon dioxide

- COP:

-

Coefficient of performance

- C1, C2, C3:

-

Compressor 1, 2 and 3

- ω :

-

Entrainment ratio

- β :

-

Thermal expansion coefficient (K−1)

- PL:

-

Pressure lift generated by the ejector

- ρ :

-

Density (kg m−3)

- W :

-

Work (kW)

- P :

-

Pressure (kPa)

- p r :

-

Pressure ratio

- r :

-

Quality

- s :

-

Entropy (J kg−1 K−1)

- AC:

-

Air-conditioning

- Ex:

-

Exergy destruction

- SEER:

-

Seasonal energy efficiency ratio

- TEWI:

-

Total environmental warming impact

- HFC:

-

Hydrofluorocarbon

- HCFC:

-

Hydrochlorofluorocarbon

- Ej-1, 2:

-

Ejector 1 and 2

- R-1, 2:

-

Receiver 1 and 2

- BPV:

-

By-pass valve

- Exp-1, 2, 3:

-

Expansion valve 1, 2 and 3

- Wrec:

-

Work recovered by ejectors (kW)

- Wrec_max:

-

Maximum work recovered by ejectors (kW)

- T :

-

Temperature (°C)

- LF:

-

Load factor

- min:

-

Minimum fraction of design load

- p :

-

Motive

- suc:

-

Suction

- int:

-

Inter-cooler

- e :

-

Evaporators

- GC:

-

Gas cooler

- gco:

-

Gas cooler outlet

- amb:

-

Ambient

- mn:

-

Motive nozzle

- sn:

-

Suction nozzle

- mni:

-

Motive nozzle inlet

- sni:

-

Suction nozzle inlet

- d :

-

Diffuser

- eff:

-

Effective

- m :

-

Mixing chamber

- mo:

-

Mixing chamber outlet

- do:

-

Diffuser outlet

- s :

-

Suction

- sv:

-

Saturated vapour

- sl:

-

Saturated liquid

- LT:

-

Low temperature

- MT:

-

Medium temperature

- ds:

-

Isentropic diffuser

- fan:

-

Fan

- w :

-

After shock wave

References

Yari M. Performance analysis and optimization of a new two-stage ejector-expansion transcritical CO2 refrigeration cycle. Int J Therm Sci. 2009;48(10):1997–2005.

Gullo P, Elmegaard B, Cortella G. Energy and environmental performance assessment of R744 booster supermarket refrigeration systems operating in warm climates. Int J Refrig. 2016;64:61–79.

Kumar Gupta D, Sankar Dasgupta M, Purohit N. Thermodynamic analysis of a CO2 transcritical refrigeration system with ejector for high ambient conditions thermodynamic analysis of a co2 trans-critical refrigeration system with ejector for high ambient conditions. In: The 12th IIR Gustav Lorentzen natural working fluids conference, Edinburgh 2016.

Purohit N, Gupta DK, Dasgupta MS. Energetic and economic analysis of trans-critical CO2 booster system for refrigeration in warm climatic condition. Int J Refrig. 2017;80:182–96.

Gullo P, Tsamos K, Hafner A, Ge Y, Tassou SA. State-of-the-art technologies for transcritical R744 refrigeration systems—A theoretical assessment of energy advantages for European food retail industry. Energy Procedia. 2017;123:46–53.

Gullo P, Hafner A, Cortella G. Multi-ejector R744 booster refrigerating plant and air conditioning system integration—A theoretical evaluation of energy benefits for supermarket applications. Int J Refrig. 2017;75:164–76.

Karampour M, Sawalha S. State-of-the-art integrated CO2 refrigeration system for supermarkets: a comparative analysis. Int J Refrig. 2018;86:239–57.

Shilliday JA. Investigation and optimisation of commercial refrigeration cycles using the natural refrigerant CO2. 2012;218.

Hafner A, Hemmingsen AK. R744 refrigeration technologies for supermarkets in warm climates. Refrig Sci Technol. 2015;2313–20.

Sharma V, Fricke B, Bansal P. Comparative analysis of various CO2 configurations in supermarket refrigeration systems. Int J Refrig. 2014;46:86–99.

Purohit N, Sharma V, Sawalha S, Fricke B, Llopis R, Dasgupta MS. Integrated supermarket refrigeration for very high ambient temperature. Energy. 2018;165:572–90.

Kvalsvik KH, Banasiak K, Hafner A. Integrated CO2 refrigeration and AC unit for hot climates. Refrig Sci Technol. 2017;202–9.

Fritschi H, Tillenkamp F, Löhrer R, Brügger M. Efficiency increase in carbon dioxide refrigeration technology with parallel compression. Int J Low Carbon Technol. 2017;12:171–80.

Amaris C, Tsamos KM, Tassou SA. Analysis of an R744 typical booster onfiguration, an R744 parallel-compressor booster configuration and an R717/R744 cascade refrigeration system for retail food applications. Part 1: thermodynamic analysis. Energy Procedia. 2019;161:259–67.

Gullo P. Innovative fully integrated transcritical R744 refrigeration systems for a HFC-free future of supermarkets in warm and hot climates. Int J Refrig. 2019;108:283–310.

Mitsopoulos G, Syngounas E, Tsimpoukis D, Bellos E, Tzivanidis C, Anagnostatos S. Annual performance of a supermarket refrigeration system using different configurations with CO2 refrigerant. Energy Convers Manag X. 2019. https://doi.org/10.1016/j.ecmx.2019.100006.

Cui Q, Gao E, Zhang Z, Zhang X. Preliminary study on the feasibility assessment of CO2 booster refrigeration systems for supermarket application in China: an energetic, economic, and environmental analysis. Energy Convers Manag. 2020. https://doi.org/10.1016/j.enconman.2020.113422.

Maouris G, Escriva EJ, Acha S, Shah N, Markides CN. CO2 refrigeration system heat recovery and thermal storage modelling for space heating provision in supermarkets: an integrated approach. Appl Energy. 2020. https://doi.org/10.1016/j.apenergy.2020.114722.

Lata M, Gupta DK. Performance evaluation and comparative analysis of trans-critical CO2 booster refrigeration systems with modified evaporative cooled gas cooler for supermarket application in Indian context. Int J Refrig. 2020;120:248–59.

Liu J, Liu Y, Yu J. Performance analysis of a modified dual-ejector and dual-evaporator transcritical CO2 refrigeration cycle for supermarket application. Int J Refrig. 2021;131:109–18.

Pérez BP, Carrillo JA, de La Flor FJ, Lissén JM, Navarro AM. Thermoeconomic analysis of CO2 Ejector-Expansion Refrigeration Cycle (EERC) for low-temperature refrigeration in warm climates. Appl Therm Eng. 2021. https://doi.org/10.1016/j.applthermaleng.2021.116613.

Singh S, Hafner A, Maiya MP, Banasiak K, Neksa P. Multiejector CO2 cooling system with evaporative gascooler for a supermarket application in tropical regions. Appl Therm Eng. 2021. https://doi.org/10.1016/j.applthermaleng.2021.116766.

Flåtten T, Lund H. Equilibrium conditions and sound velocities in two-phase flows. In: SIAM Annual Meeting; 2010.

Cardemil JM, Colle S. A general model for evaluation of vapor ejectors performance for application in refrigeration. Energy Convers Manag. 2012;64:79–86.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sengupta, A., Dasgupta, M.S. Energy and exergy analysis of a novel dual-ejector booster transcritical CO2 refrigeration system for applications in warm climates. J Therm Anal Calorim 148, 2749–2764 (2023). https://doi.org/10.1007/s10973-022-11623-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11623-x