Abstract

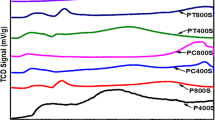

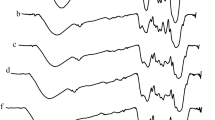

Heterogeneous acid catalysts derived from residues of the guarana (Paullinia cupana) industry were synthesized using the traditional method of carbonization/sulfonation and one-pot hydrothermal carbonization/sulfonation. These residues present physicochemical properties that are suitable for synthesis of solid acid catalysts. The sulfonated-based carbon catalysts were characterized by X-ray diffraction, thermogravimetry, infrared spectroscopy (FTIR), EDS-coupled scanning electron microscopy for elementary mapping, low-temperature N2 sorption and Boehm titration. The catalytic activity was tested by reaction of esterification of oleic acid with methanol with catalyst loading of 5% by mass, molar ratio oleic acid/methanol 1:12 at 100 ºC for 1 h. The catalyst, produced via the traditional method, showed a yield of 93%, and the one-pot hydrothermal catalyst a yield of 96%. In the reuse tests, the hydrothermal sample was stable for four cycles, with a yield of 78%, and the traditional sample showed a sharp reduction in yields. The best activity of the one-pot hydrothermal catalyst was also tested in a free fatty acid (FFA) esterification reaction in cooking oil residues. The effects of reaction time, methanol to oil ratio, catalyst concentration and temperature on conversion were investigated. The results show maximum FFA conversion of 63% using 5% by mass catalyst, 2 h, molar ratio oil/methanol 1:12 and 75 °C. The use of this industrial waste for the production of catalysts can help to avoid accumulation of materials that are usually inadequately disposed of. In addition, its production is cheap, fast and simple and has excellent catalytic activity.

Similar content being viewed by others

References

O ONU. 9.7 billion on Earth by 2050, but growth rate slowing, says new UN population report. In: United Nations. 2019. https://news.un.org/en/story/2019/06/1040621. Accessed 20 Jul 2019.

Kumar Mishra R, Mohanty K. Effect of low-cost catalysts on yield and properties of fuel from waste biomass for hydrocarbon-rich oil production. Mater Sci Energy Technol. 2020;3:526–35.

Chong CT, Loe TY, Wong KY, Ashokkumar V, Lam SS, Chong WT, et al. Biodiesel sustainability: The global impact of potential biodiesel production on the energy–water–food (EWF) nexus. Environ Technol Innovation. 2021;22: 101408.

Athar M, Zaidi S. A review of the feedstocks, catalysts, and intensification techniques for sustainable biodiesel production. J Environ Chem Eng. 2020;8(6): 104523.

Munir M, Ahmad M, Mubashir M, Asif S, Waseem A, Mukhtar A, et al. A practical approach for synthesis of biodiesel via non-edible seeds oils using trimetallic based montmorillonite nano-catalyst. Bioresour Technol. 2021;328: 124859.

Mahmoud HR, El-Molla SA, Ibrahim MM. Biodiesel production via stearic acid esterification over mesoporous ZrO2/SiO2 catalysts synthesized by surfactant-assisted sol-gel auto-combustion route. Renewable Energy. 2020;160:42–51.

Ishak N, Estephane J, Dahdah E, Chalouhi LM, Nassreddine S, el Khoury B, et al. Outstanding activity of a biodiesel coated K2O/fumed silica catalyst in the transesterification reaction. J Environ Chem Eng. 2021;9(1): 104665.

Li J, Liang X. Magnetic solid acid catalyst for biodiesel synthesis from waste oil. Energy Convers Manage. 2017;141:126–32.

Mazivila SJ, Borges NW. Detection of illegal additives in Brazilian S-10/common diesel B7/5 and quantification of Jatropha biodiesel blended with diesel according to EU 2015/1513 by MIR spectroscopy with DD-SIMCA and MCR-ALS under correlation constraint. Fuel. 2021;285: 119159.

da Costa JM, de Andrade Lima LRP. Transesterification of cotton oil with ethanol for biodiesel using a KF/bentonite solid catalyst. Fuel. 2021;293: 120446.

Ma J, Shi M, Hoang TKA, Yao Z, Sun A. A facile preparation of nitrogen-doped porous carbons from renewable as efficient catalysts for oxygen reduction reaction. J Solid State Chem. 2020;291: 121609.

Aslan V, Eryilmaz T. Polynomial regression method for optimization of biodiesel production from black mustard (Brassica nigra L.) seed oil using methanol, ethanol, NaOH, and KOH. Energy. 2020;209:118386.

Gebremariam SN, Marchetti JM. Techno-economic feasibility of producing biodiesel from acidic oil using sulfuric acid and calcium oxide as catalysts. Energy Convers Manage. 2018;171:1712–20.

Su CH. Recoverable and reusable hydrochloric acid used as a homogeneous catalyst for biodiesel production. Appl Energy. 2013;104:503–9.

Krzyżyńska B, Malaika A, Ptaszyńska K, Tolińska A, Kirszensztejn P, Kozłowski M. Modified activated carbons for esterification of acetic acid with ethanol. Diamond Relat Mater. 2020;101: 107608.

Foroutan R, Mohammadi R, Ramavandi B. Waste glass catalyst for biodiesel production from waste chicken fat: Optimization by RSM and ANNs and toxicity assessment. Fuel. 2021;291: 120151.

Huang J, Zou Y, Yaseen M, Qu H, He R, Tong Z. Fabrication of hollow cage-like CaO catalyst for the enhanced biodiesel production via transesterification of soybean oil and methanol. Fuel. 2021;290: 119799.

Nisar J, Razaq R, Farooq M, Iqbal M, Khan RA, Sayed M, et al. Enhanced biodiesel production from Jatropha oil using calcined waste animal bones as catalyst. Renewable Energy. 2017;101:111–9.

Bedir Ö, Doğan TH. Use of sugar industry waste catalyst for biodiesel production. Fuel. 2021;286: 119476.

Quah RV, Tan YH, Mubarak NM, Khalid M, Abdullah EC, Nolasco-Hipolito C. An overview of biodiesel production using recyclable biomass and non-biomass derived magnetic catalysts. J Environ Chem Eng. 2019;7(4): 103219.

Balajii M, Niju S. Banana peduncle—A green and renewable heterogeneous base catalyst for biodiesel production from Ceiba pentandra oil. Renew Energy. 2020;146:2255–69.

Hamza M, Ayoub M, Shamsuddin R bin, Mukhtar A, Saqib S, Zahid I, et al. A review on the waste biomass derived catalysts for biodiesel production. Environ Technol Innovation. 2021;21:101200.

Akinfalabi SI, Rashid U, Ngamcharussrivichai C, Nehdi IA. Synthesis of reusable biobased nano-catalyst from waste sugarcane bagasse for biodiesel production. Environ Technol Innovation. 2020;18: 100788.

Tang ZE, Lim S, Pang YL, Shuit SH, Ong HC. Utilisation of biomass wastes based activated carbon supported heterogeneous acid catalyst for biodiesel production. Renew Energy. 2020;158.

Ngaosuwan K, Goodwin JG, Prasertdham P. A green sulfonated carbon-based catalyst derived from coffee residue for esterification. Renew Energy. 2016;86:262–9.

Araujo RO, Chaar J da S, Queiroz LS, da Rocha Filho GN, da Costa CEF, da Silva GCT, et al. Low temperature sulfonation of acai stone biomass derived carbons as acid catalysts for esterification reactions. Energy Convers Manage. 2019;196:821–30.

Farabi MSA, Ibrahim ML, Rashid U, Taufiq-Yap YH. Esterification of palm fatty acid distillate using sulfonated carbon-based catalyst derived from palm kernel shell and bamboo. Energy Convers Manage. 2019;181:562–70.

Li M, Chen D, Zhu X. Preparation of solid acid catalyst from rice husk char and its catalytic performance in esterification. Chin J Catal. 2013;34(9):1674–82.

Marques LLM, Ferreira EDF, de Paula MN, Klein T, de Mello JCP. Paullinia cupana: a multipurpose plant—a review. Rev Bras. 2019;29(1):77–110.

Silva MP, Thomazini M, Holkem AT, Pinho LS, Genovese MI, Fávaro-Trindade CS. Production and characterization of solid lipid microparticles loaded with guaraná (Paullinia cupana) seed extract. Food Res Int. 2019;123:144–52.

Giglio A del, Giglio A del. Using Paullinia cupana (Guarana) to Treat Fatigue and Other Symptoms of Cancer and Cancer Treatment. In: Bioactive Nutraceuticals and Dietary Supplements in Neurological and Brain Disease. Elsevier. 2015;57–63.

Santana ÁL, Macedo GA. Health and technological aspects of methylxanthines and polyphenols from guarana: A review. J Funct Foods. 2018;47:457–68.

Lopes FCR, Pereira JC, Tannous K. Thermal decomposition kinetics of guarana seed residue through thermogravimetric analysis under inert and oxidizing atmospheres. Bioresour Technol. 2018;270:294–302.

Ke L, Wu Q, Zhou N, Xiong J, Yang Q, Zhang L, et al. Lignocellulosic biomass pyrolysis for aromatic hydrocarbons production: Pre and in-process enhancement methods. Renew Sustain Energy Rev. 2022;165: 112607.

Bandgar PS, Jain S, Panwar NL. A comprehensive review on optimization of anaerobic digestion technologies for lignocellulosic biomass available in India. Biomass Bioenerg. 2022;161: 106479.

Arora A, Nandal P, Singh J, Verma ML. Nanobiotechnological advancements in lignocellulosic biomass pretreatment. Mater Sci Energy Technol. 2020;3:308–18.

Krishnan SG, Pua FL, Syed Jaafar SN. Synthesis and characterization of local biomass supported magnetic catalyst for esterification reaction. Mater Today Proc. 2020;31:161–5.

Ibrahim SF, Asikin-Mijan N, Ibrahim ML, Abdulkareem-Alsultan G, Izham SM, Taufiq-Yap YH. Sulfonated functionalization of carbon derived corncob residue via hydrothermal synthesis route for esterification of palm fatty acid distillate. Energy Convers Manage. 2020;210: 112698.

Santos EM, Teixeira AP de C, da Silva FG, Cibaka TE, Araújo MH, Oliveira WXC, et al. New heterogeneous catalyst for the esterification of fatty acid produced by surface aromatization/sulfonation of oilseed cake. Fuel. 2015 ;150:408–14.

Roslan NA, Zainal Abidin S, Abdullah N, Osazuwa OU, Abdul Rasid R, Yunus NM. Esterification reaction of free fatty acid in used cooking oil using sulfonated hypercrosslinked exchange resin as catalyst. Chem Eng Res Des. 2021.

Guo M, Jiang W, Chen C, Qu S, Lu J, Yi W, et al. Process optimization of biodiesel production from waste cooking oil by esterification of free fatty acids using La3+/ZnO-TiO2 photocatalyst. Energy Convers Manage. 2021;229: 113745.

Al-Sakkari EG, Abdeldayem OM, El-Sheltawy ST, Abadir MF, Soliman A, Rene ER, et al. Esterification of high FFA content waste cooking oil through different techniques including the utilization of cement kiln dust as a heterogeneous catalyst: A comparative study. Fuel. 2020;279: 118519.

Wataniyakul P, Boonnoun P, Quitain AT, Kida T, Laosiripojana N, Shotipruk A. Preparation of hydrothermal carbon acid catalyst from defatted rice bran. Ind Crops Prod. 2018;117:286–94.

Li X, Lu X, Liang M, Xu R, Yu Z, Duan B, et al. Conversion of waste lignocellulose to furfural using sulfonated carbon microspheres as catalyst. Waste Manage. 2020;108:119–26.

Pan H, Sun J, Liu J, Zhang Y, Zhou S. Preparation of sulfonated carbon derived from orange peel and its application in esterification. Chem Phys Lett. 2021;770: 138395.

Deeba F, Kumar B, Arora N, Singh S, Kumar A, Han SS, et al. Novel bio-based solid acid catalyst derived from waste yeast residue for biodiesel production. Renewable Energy. 2020;159.

Yang YT, Yang XX, Wang YT, Luo J, Zhang F, Yang WJ, et al. Alcohothermal carbonization of biomass to prepare novel solid catalysts for oleic acid esterification. Fuel. 2018;219:166–75.

Xiao Y, Hill JM. Solid acid catalysts produced by sulfonation of petroleum coke: Dominant role of aromatic hydrogen. Chemosphere. 2020;248: 125981.

Basumatary S, Nath B, Das B, Kalita P, Basumatary B. Utilization of renewable and sustainable basic heterogeneous catalyst from Heteropanax fragrans (Kesseru) for effective synthesis of biodiesel from Jatropha curcas oil. Fuel. 2021;286: 119357.

Li J, Zhang H, Cai M, Li L, Li Y, Zhao R, et al. Enhanced catalytic performance of activated carbon-supported ru-based catalysts for acetylene hydrochlorination by azole ligands. App Catal A. 2020;592: 117431.

Guo F, Xiu ZL, Liang ZX. Synthesis of biodiesel from acidified soybean soapstock using a lignin-derived carbonaceous catalyst. Appl Energy. 2012;98.

Lou WY, Guo Q, Chen WJ, Zong MH, Wu H, Smith TJ. A Highly Active Bagasse-Derived Solid Acid Catalyst with Properties Suitable for Production of Biodiesel. ChemSusChem. 2012;5(8).

Endut A, Abdullah SHYS, Hanapi NHM, Hamid SHA, Lananan F, Kamarudin MKA, et al. Optimization of biodiesel production by solid acid catalyst derived from coconut shell via response surface methodology. Int Biodeterior Biodegrad. 2017;124.

Araujo RO, Santos VO, Ribeiro FCP, Chaar J da S, Pereira AM, Falcão NPS, et al. Magnetic acid catalyst produced from acai seeds and red mud for biofuel production. Energy Convers Manage. 2021;228.

Shatesh Kumar, Shamsuddin MR, Farabi MSA, Saiman MI, Zainal Z, Taufiq-Yap YH. Production of methyl esters from waste cooking oil and chicken fat oil via simultaneous esterification and transesterification using acid catalyst. Energy Convers Manage. 2020;226:113366.

Carmo AC, de Souza LKC, da Costa CEF, Longo E, Zamian JR, da Rocha Filho GN. Production of biodiesel by esterification of palmitic acid over mesoporous aluminosilicate Al-MCM-41. Fuel. 2009;88(3):461–8.

Acknowledgements

The authors acknowledge the financial support from Federal University of Amazonas, Amazonas State Research Foundation (FAPEAM)—Process No. 01.02.016301.03414/2021-67, Edital No. 010/2021—CT&I áreas prioritárias. The Coordination for the Development of Higher-level Personnel (CAPES)—finance code 001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ribeiro, F.C.P., Santos, V.O., Araujo, R.O. et al. Determination of the thermal stability of sulfonic groups in heterogeneous acid catalysts derived from residue of guarana amazon biomass. J Therm Anal Calorim 148, 23–35 (2023). https://doi.org/10.1007/s10973-022-11514-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11514-1