Abstract

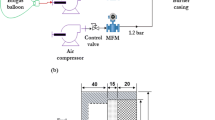

Natural gas fired porous burners are increasingly utilized in heating appliances. In this study, a pot containing water is heated by a porous burner to analyze its heat transfers behavior. Dimensions of the aluminum pot are chosen according to a reference standard. A test rig for silicon carbide burner is designed and fabricated, including air and natural gas lines. The cooking pot is heated in working firing rates and for the test selected pot-burner gap D = 1.5 cm, resulted in maximum thermal efficiency of 29% coincided with minimum CO and NOx emission of 4 and 2.2 ppm, respectively. The main contribution of the study is to evaluate the side and bottom convection heat transfers to assess total thermal performance of a porous media burner. The side and bottom convection fractions are 28% and 58%, while surface and flame radiation are 2% and 12% measured in peak efficient case. In another test, the system was undergone the same heating power in which different equivalence ratios were applied to the burner. The best φ to result in ηmax = 23.9% was found to be φ = 0.998. Considering the pot-water system, the majority of heat absorbed is devoted to convection. The modular system can apply to different low power burners with the adjustable gap between burner surface and pot bottom gaining attention of researchers and also the industrial section. Measuring, differentiating and evaluating the balance between convective and radiative portions of the heat received by pot, is the main idea of this research to obtain a thorough insight of role of each mode on thermal efficiency and pollutants emission. Besides, proper equivalence ratio and distance gap are also presented to get an appropriate design of burner-pot system. As the masses, materials and dimensions are chosen according to standard, the results could be used by researchers in this area.

Similar content being viewed by others

Change history

08 May 2023

A Correction to this paper has been published: https://doi.org/10.1007/s10973-023-12173-6

Abbreviations

- A:

-

Area [m2]

- C:

-

Specific heat capacity [J kg−1 K−1]

- D:

-

Diameter [m]

- F:

-

Shape factor

- h:

-

Convective heat transfer coefficient [W m−2 K−1]

- H:

-

Distance gap [m]

- k:

-

Thermal conductivity [W m−1 K−1]

- m:

-

Mass [kg]

- Nu:

-

Nusselt number

- Q:

-

Heat transfer [J]

- Re:

-

Reynolds number

- t:

-

Time [s]

- T:

-

Temperature

- Vf :

-

Fuel consumption [m3

- ε:

-

Emissivity

- η:

-

Efficiency

- φ:

-

Equivalence ratio

- B:

-

Burner

- g:

-

Combustion gas

- p:

-

Pot

- s:

-

Surface of burner

- w:

-

Water

- conv:

-

Convection

- FR:

-

Firing rate [W m−2]

- LHV:

-

Lower heating value

- ppm:

-

Part per million

References

de Soete G. Stability and propagation of combustion waves in inert porous media. Symp (Int) Combust. 1967;11(1):959–66. https://doi.org/10.1016/S0082-0784(67)80222-4.

Chafin C, Koenig M, Matthews RDK, Hall MJ, Nichol SP and Lim IG. Experimental Investigation of Premixed Combustion Within Highly Porous Media. NewYork: ASME/JSME Thermal Engineering Joint, 219–224 (1991).

Howell JR, Buckius RO, Fundamentals of Engineering Thermodynamics. New York: McGraw–Hill 888(1992).

Trimis D, Durst F. Combustion in a porous medium-advances and applications. Combust Sci Technol. 1996;121:153–68.

Shakiba SA, Ebrahimi R, Shams M, Yazdanfar Z (2015) Effects of foam structure and material on the performance of premixed porous ceramic burner Proceedings of the Institution of Mechanical Engineers. Part A: J Power Energy.229:176–191

Al-attab KA, Ho JC, Zainal ZA. Experimental investigation of submerged flame in packed bed porous media burner fueled by low heating value producer gas. Experimental Thermal Fluid Sci. 2015;62:1–8. https://doi.org/10.1016/j.expthermflusci.2014.11.007.

Chaelek A, Grare UM, Jugjai S. Self-aspirating/air-preheating porous medium gas burner. Appl Thermal Eng. 2019;153:181–9. https://doi.org/10.1016/j.applthermaleng.2019.02.109.

Habib R, Yadollahi B, Saeed A, Doranehgard MH, Li LKB, Karimi N. Unsteady ultra-lean combustion of methane and biogas in a porous burner – An experimental study. Applied Thermal Eng. 2021;182:116099. https://doi.org/10.1016/j.applthermaleng.2020.116099.

Khanna V, Goel R, Ellzey JL. Measurements of emissions and radiation for methane combustion within a porous medium burner. Combust Sci Technol. 1994;99:133–42.

Mujeebu MA, Abdullah MZ, Bakar MA, Mohamad AA, Abdullah MK. A review of investigations on liquid fuel combustion in porous inert media. Prog Energy Combust Sci. 2009;35:216–30.

Mujeebu MA, Abdullah MZ, Bakar MA, Mohamad AA, Abdullah MK. Applications of porous media combustion technology–a review. Appl Energy. 2009;86(9):1365–75.

Abdul Mujeebu M, Abdullah MZ, Abu Bakar MZ, Mohamad AA, Muhad RMN, Abdullah MK. Combustion in porous media and its applications – A comprehensive survey. J Environ Manage. 2009;90(8):2287–312. https://doi.org/10.1016/j.jenvman.2008.10.009.

Avdic F, Adzic M, Durst F. Small scale porous medium combustion system for heat production in households. Appl Energy. 2010;87:2148–55.

Muthukumar P, Shyamkumar PI. Development of novel porous radiant burners for LPG cooking applications. Fuel. 2013;112:562–6.

Panigrahy S, Mishra NK, Mishra SC, Muthukumar P. Numerical and experimental analyses of LPG (liquefied petroleum gas) combustion in a domestic cooking stove with a porous radiant burner. Energy. 2016;95:404–14.

Kaushik LK, Muthukumar P. Thermal and economic performance assessments of waste cooking oil /kerosene blend operated pressure cook-stove with porous radiant burner. Energy. 2020;206:102–18.

Ghorashi SA, Hashemi SA, Hashemi SM, Mollamahdi M. Experimental study on pollutant emissions in the novel combined porous-free flame burner. Energy. 2018;162:517–25.

Omidi M, Emami MD. Experimental investigation of premixed combustion and thermal efficiency in a porous heating burner. Int J Energy Res. 2020;45:1948–58.

Dehaj MS, Ebrahimi R, Shams M, Farzaneh M. Experimental analysis of natural gas combustion in a porous burner. Experiment Thermal Fluid Sci. 2017;84:134–43. https://doi.org/10.1016/j.expthermflusci.2017.01.023.

Hoda SN, Nassab SAG, Ebrahim JJ. Three dimensional numerical simulation of combustion and heat transfer in porous radiant burners. Inter J Thermal Sci. 2019;145:12900729.

Sobhani S, Mohaddes D, Boigne E, Muhunthan P, Ihme M. Modulation of heat transfer for extended flame stabilization in porous media burners via topology gradation. Proceed Combustion Institute. 2019;37(4):5697–704. https://doi.org/10.1016/j.proci.2018.05.155.

Song F, Wen Z, Fang Y, Wang E, Liu X. Combustion wave propagation of a modular porous burner with annular heat recirculation. J Thermal Sci. 2020;29(1):98–107. https://doi.org/10.1007/s11630-019-1162-0.

Caetano NR, Lorenzini G, Lhamby AR, Guillet VMM, Klunk MA, Rocha LAO. Experimental assessment of thermal radiation behavior emitted by solid porous material. Inter J Heat Technol. 2020;38(1):1–8. https://doi.org/10.18280/ijht.380101.

Chen X, Li J, Zhao D, Rashid M, Zhou X, Wang N. Effects of porous media on partially premixed combustion and heat transfer in meso-scale burners fuelled with ethanol. Energy. 2021;224:120191. https://doi.org/10.1016/j.energy.2021.120191.

Bubnovich V, Hernandez H, Toledo M, Flores C. Experimental investigation of flame stability in the premixed propane-air combustion in two-section porous media burner. Fuel. 2021;291:120117.

Laguillo S, Ochoa JS, Tizné E, Pina A, Ballester J, Ortiz A. CO emissions and temperature analysis from an experimental and numerical study of partially premixed methane flames impinging onto a cooking pot. Journal of Natural Gas Science and Engineering. 2021;88:103771.

Wichangarm M, Matthujak A, Sriveerakul T, Sucharitpwatskul S, Phongthanapanich S. Investigation on thermal efficiency of LPG cooking burner using computational fluid dynamics. Energy. 2020;203:117849.

Feng XB, Xu HJ. Modeling the propane combustion process within a micro-catalytic porous combustor by using the lattice Boltzmann method. J Therm Anal Calorim. 2020;139:2659–77.

Kaushik LK, Muthukumar P. Thermal and economic performance assessments of waste cooking oil /kerosene blend operated pressure cook-stove with porous radiant burner. Energy. 2020;206:118102.

Yuen WW. RAD-NNET, a neural network based correlation developed for a realistic simulation of the non-gray radiative heat transfer effect in three-dimensional gas-particle mixtures. International J Heat Mass Transfer. 2009;52(13–14):3159–68. https://doi.org/10.1016/j.ijheatmasstransfer.2009.01.041.

Lytle D, Webb BW. Air jet impingement heat transfer at low nozzle-plate spacings. Inter J Heat and Mass Transfer. 1994;37(12):1687–97. https://doi.org/10.1016/0017-9310(94)90059-0.

MacCarty N, Bryden KM (2013) A heat transfer model for conceptual design of a biomass cookstove for developing countries. Proceedings of the ASME 2013 International Design Engineering Technical Conference & Computers and Information in Engineering Conference, August 4–7, Portland, Oregon, USA

World Health Organization. WHO guidelines for indoor air quality: selected pollutants. Geneva: Switzerland World Health Organization; 2010.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Soltanian, H., Targhi, M.Z. & Maerefat, M. Experimental investigation and heat transfer analysis of a natural gas fueled porous burner in domestic application. J Therm Anal Calorim 147, 13523–13534 (2022). https://doi.org/10.1007/s10973-022-11511-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11511-4