Abstract

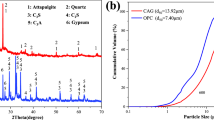

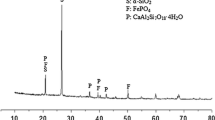

Recycled clay brick powder (RCBP) was used to replace partially cement to prepare composite cementitious materials, and the hydration kinetics and microstructure evolution of the composite cementitious materials were investigated by measuring the types of hydration products, hydration heat and microstructure. The results show that RCBP has little effect on the types of hydration products. However, at the later stage of cement hydration, the pozzolanic reaction occurs between RCBP and Ca(OH)2. Meanwhile, RCBP promotes the dispersion and dissolution of cement and provides many nucleation sites for C–S–H gel, increases the effective water-binder ratio and accelerates the heat release of cement hydration, however, the cumulative heat release decreases with the dosage of RCBP. In addition, RCBP can increase porosity at early stage of hydration, but the pozzolanic reaction between RCBP and Ca(OH)2 at the later stage of hydration would produce more hydration products, filling the pores, refining the pore diameter and improving the pore structure. Furthermore, RCBP affects the formation and microstructure of C–(A)–S–H gel, and promotes the formation of spherical C–(A)–S–H gel.

Similar content being viewed by others

References

Shen W, Liu Y, Yan B, et al. Cement industry of China: driving force, environment impact and sustainable development. Renew Sust Energ Rev. 2017;75:618–28. https://doi.org/10.1016/j.rser.2016.11.033.

Zhang C, Yu B, Chen J, et al. Green transition pathways for cement industry in China. Resour Conserv Recy. 2021;166: 105355. https://doi.org/10.1016/j.resconrec.2020.105355.

Schneider M, Romer M, Tschudin M, et al. Sustainable cement production—present and future. Cem Concr Res. 2011;41:642–50. https://doi.org/10.1016/j.cemconres.2011.03.019.

Ding T, Xiao J. Estimation of building-related construction and demolition waste in Shanghai. Waste Mange. 2014;34:2327–34. https://doi.org/10.1016/j.wasman.2014.07.029.

Levy SM, Helene P. Durability of recycled aggregates concrete: a safe way to sustainable development. Ceme Concr Res. 2004;34:1975–80. https://doi.org/10.1016/j.cemconres.2004.02.009.

Pappu A, Saxena M, Asolekar SR. Solid wastes generation in India and their recycling potential in building materials. Build Environ. 2007;42:2311–20. https://doi.org/10.1016/j.buildenv.2006.04.015.

Tang D, Zhang X, Hu S, et al. The reuse of red brick powder as a filler in styrene-butadiene rubber. J Clean Prod. 2020;61: 120966. https://doi.org/10.1016/j.jclepro.2020.120966.

Li LG, Lin ZH, Chen GM, et al. Reutilizing clay brick dust as paste substitution to produce environment-friendly durable mortar. J Clean Prod. 2020;274: 122787. https://doi.org/10.1016/j.jclepro.2020.122787.

Shao J, Zhao Y, Chen X. Study on the pozzolanic reaction of clay brick powder in blended cement pastes. Constr Build Mater. 2019;213:209–15. https://doi.org/10.1016/j.conbuildmat.2019.03.307.

He Z, Shen A, Wu H. Research progress on recycled clay brick waste as an alternative to cement for sustainable construction materials. Constr Build Mater. 2021;274: 122113. https://doi.org/10.1016/j.conbuildmat.2020.122113.

Amakye SY, Abbey SJ, Olubanwo AO. Consistency and mechanical properties of sustainable concrete blended with brick dust waste cementitious materials. SN Appl Sci. 2021. https://doi.org/10.1007/s42452-021-04430-w.

Surya Narayana Raju JNS, Srikanth Reddy S, Raju P, et al. Red brick dust as a partial substitute to cement in conventional concrete. IJRTE. 2019;8:5632–5. https://doi.org/10.35940/ijrte.B1768.078219.

Lin KL, Wu HH, Shie JL, et al. Recycling waste brick from construction and demolition of buildings as pozzolanic materials. Waste Manag Res. 2010;28:653–9. https://doi.org/10.1177/0734242X09358735.

Ouyang X, Wang L, Jiyang Fu. Surface properties of clay brick powder and its influence on hydration and strength development of cement paste. Constr Build Mater. 2021;300: 123958. https://doi.org/10.1016/j.conbuildmat.2021.123958.

Shao J, Gao J, Zhao Y. Characteristics of recycled clay brick powder-cement cementitious system. J Southeast Univ (Natural Science Edition). 2019;49:375–9. https://doi.org/10.3969/j.issn.1001-0505.2019.02.025.

Letelier V, Tarela E, Moriconi G. Mechanical properties of concretes with recycled aggregates and waste brick powder as cement replacement. Proc Eng. 2017;171:627–32. https://doi.org/10.1016/j.proeng.2017.01.396.

Lin R, Lee H, Han Y. Experimental studies on hydration–strength–durability of limestone-cement-calcined Hwangtoh clay ternary composite. Constr Build Mater. 2021;269:1290. https://doi.org/10.1016/j.conbuildmat.2020.121290.

Linderoth O, Wadsö L, Jansen D. Long-term cement hydration studies with isothermal calorimetry. Cem Concr Res. 2021;141: 106344. https://doi.org/10.1016/j.cemconres.2020.106344.

Gao X, Yu QL, Brouwers HJH. Properties of alkali activated slag–fly ash blends with limestone addition. Cem Concr Compos. 2015;59:119–28. https://doi.org/10.1016/j.cemconcomp.2015.01.007.

Lura P, Winnefeld F, Klemm S. Simultaneous measurements of heat of hydration and chemical shrinkage on hardening cement pastes. J Therm Anal Calorim. 2010;101:925–32. https://doi.org/10.1007/s10973-009-0586-2.

Kırgız MS. Strength gain mechanism for green mortar substituted marble powder and brick powder for Portland cement. Eur J Environ Civ En. 2016;20:38–63. https://doi.org/10.1080/19648189.2016.1246691.

Gutteridge WA, Dalziel JA. Filler cement: the effect of the secondary component on the hydration of Portland cement: part I. A fine non-hydraulic filler. Cem Concr Res. 1990;20:778–82. https://doi.org/10.1016/0008-8846(90)90011-L.

Castellano CC, Bonavetti VL, Donza HA, et al. The effect of w/b and temperature on the hydration and strength of blast furnace slag cements. Constr Build Mater. 2016;111:679–88. https://doi.org/10.1016/j.conbuildmat.2015.11.001.

Berodier E, Scrivener KL. Understanding the filler effect on the nucleation and growth of C-S–H. J Am Ceram Soc. 2014;97:3764–73. https://doi.org/10.1111/jace.13177.

He X, Zheng Z, Ma M, et al. New treatment technology: the use of wet-milling concrete slurry waste to substitute cement. J Clean Prod. 2020;242: 118347. https://doi.org/10.1016/j.jclepro.2019.118347.

Bullard JW, Jennings HM, Livingston RA, et al. Mechanisms of cement hydration. Cem Concr Res. 2011;41:1208–23. https://doi.org/10.1016/j.cemconres.2010.09.011.

Lura P, Winnefeld F, Fang X. A simple method for determining the total amount of physically and chemically bound water of different cements. J Therm Anal Calorim. 2017;130:653–60. https://doi.org/10.1007/s10973-017-6513-z.

Zhang T, Sun Z, Yang H, et al. Enhancement of triisopropanolamine on the compressive strength development of cement paste incorporated with high content of wasted clay brick powder and its working mechanism. Constr Build Mater. 2021;302: 124052. https://doi.org/10.1016/j.conbuildmat.2021.124052.

Mendes A, Gates WP, Sanjaya JG, et al. NMR, XRD, IR and synchrotron NEXAFS spectroscopic studies of OPC and OPC/slag cement paste hydrates. Mater Struct. 2011;44:1773–91. https://doi.org/10.1617/s11527-011-9737-6.

Chung S, Kim J, Lehmann C, et al. Investigation of phase composition and microstructure of foamed cement paste with different supplementary cementing materials. Cem Concr Compos. 2020;109: 103560. https://doi.org/10.1016/j.cemconcomp.2020.103560.

Yan P, Qin X. The effect of expansive agent and possibility of delayed ettringite formation in shrinkage-compensating massive concrete. Cem Concr Res. 2001;31:335–7. https://doi.org/10.1016/S0008-8846(00)00453-1.

Wu J, Guo L, Qin Y. Preparation and characterization of ultra-high-strength and ultra-high-ductility cementitious composites incorporating waste clay brick powder. J Clean Prod. 2021;312: 127813. https://doi.org/10.1016/j.jclepro.2021.127813.

Guo X, Shi H, Wei X. Pore properties, inner chemical environment, and microstructure of nano-modified CFA-WBP (class C fly ash-waste brick powder) based geopolymers. Cem Concr Compos. 2017;79:53–61. https://doi.org/10.1016/j.cemconcomp.2017.01.007.

Fořt J, Vejmelková E, Koňáková D, et al. Application of waste brick powder in alkali activated aluminosilicates: functional and environmental aspect. J Clean Prod. 2018;194:714–25. https://doi.org/10.1016/j.jclepro.2018.05.181.

Wong CL, Mo KH, Yap SP, et al. Potential use of brick waste as alternate concrete-making materials: a review. J Clean Prod. 2018;195:226–39. https://doi.org/10.1016/j.jclepro.2018.05.193.

Rovnaník P, Rovnaníková P, Vyšvařil M, et al. Rheological properties and microstructure of binary waste red brick powder/metakaolin geopolymer. Constr Build Mater. 2018;188:924–33. https://doi.org/10.1016/j.conbuildmat.2018.08.150.

Davraz M, Ceylan H, Topçu İB, et al. Pozzolanic effect of andesite waste powder on mechanical properties of high strength concrete. Constr Build Mater. 2018;16:5494–503. https://doi.org/10.1016/j.conbuildmat.2018.01.043.

Karen L. Scrivener, André Nonat, Hydration of cementitious materials, present and future. Cement Concr Res. 2011;41(7):651–65. https://doi.org/10.1016/j.cemconres.2011.03.026.

Ma Z, Tang Q, Wu H, et al. Mechanical properties and water absorption of cement composites with various fineness and contents of waste brick powder from C&D waste. Cem Concr Compos. 2020;114: 103758. https://doi.org/10.1016/j.cemconcomp.2020.103758.

Zou F, Hu C, Wang F, et al. Enhancement of early-age strength of the high content fly ash blended cement paste by sodium sulfate and C–S–H seeds towards a greener binder. J Clean Prod. 2020;244: 118566. https://doi.org/10.1016/j.jclepro.2019.118566.

Böke H, Akkurt S, İpekoğlu B, et al. Characteristics of brick used as aggregate in historic brick-lime mortars and plasters. Cem Concr Res. 2006;36:1115–22. https://doi.org/10.1016/j.cemconres.2006.03.011.

Zhang J, Scherer GW. Comparison of methods for arresting hydration of cement. Cem Concr Res. 2011;41:1024–36. https://doi.org/10.1016/j.cemconres.2011.06.003.

Afroughsabet V, Biolzi L, Monteiro PJM, et al. Investigation of the mechanical and durability properties of sustainable high performance concrete based on calcium sulfoaluminate cement. J Build Eng. 2021;43:102–656. https://doi.org/10.1016/j.jobe.2021.102656.

Zhao Y, Gao J, Xu Z, et al. Combined effect of slag and clay brick powder on the hydration of blended cement. Constr Build Mater. 2021;299: 123996. https://doi.org/10.1016/j.conbuildmat.2021.123996.

Zhao Y, Gao J, Liu C, et al. The particle-size effect of waste clay brick powder on its pozzolanic activity and properties of blended cement. J Clean Prod. 2020;242: 118521. https://doi.org/10.1016/j.jclepro.2019.118521.

Hernandez N, Lizarazo-Marriaga J, Rivas MA. Petrographic characterization of Portlandite crystal sizes in cement pastes affected by different hydration environments. Constr Build Mater. 2018;182:541–9. https://doi.org/10.1016/j.conbuildmat.2018.06.142.

Sun Z, Liu F, Tong T, et al. Hydration of concrete containing hybrid recycled demolition powders. J Mater Civil Eng. 2017;29:04017037. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001842.

Zhao Y, Gao J, Xu Z, et al. Long-term hydration and microstructure evolution of blended cement containing ground granulated blast furnace slag and waste clay brick. Cem Concr Compos. 2021;118: 103982. https://doi.org/10.1016/j.cemconcomp.2021.103982.

Chen G, Gao J, Zhao Y. Research on properties of recycled clay brick powder-limestone powder-cement cementitious material. J Southeast Univ (Natural Science Edition). 2020;50:858–65. https://doi.org/10.3969/j.issn.1001-0505.2020.05.010.

Cui S, Liu P, Cui E, et al. Experimental study on mechanical property and pore structure of concrete for shotcrete use in a hot-dry environment of high geothermal tunnels. Constr Build Mater. 2018;173:124–35. https://doi.org/10.1016/j.conbuildmat.2018.03.191.

Martínez-García C, González-Fonteboa B, Carro-López D, et al. Impact of mussel shell aggregates on air lime mortars Pore structure and carbonation. J Clean Prod. 2019;215:650–68. https://doi.org/10.1016/j.jclepro.2019.01.121.

Acknowledgements

The authors deeply appreciate the financial support provided by the National Natural Science Foundation of China (No. 51578141) and the Jiangsu Key Laboratory of Construction Materials for technical support.

Author information

Authors and Affiliations

Contributions

XL: Conceptualization, Methodology, Funding acquisition, Resources, Investigation, Writing—review & editing. JG: Investigation. XL: Conceptualization, Investigation. SL: Investigation, Writing—review & editing. YZ: Writing– review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Luo, X., Gao, J., Liu, X. et al. Hydration and microstructure evolution of recycled clay brick powder-cement composite cementitious materials. J Therm Anal Calorim 147, 10977–10989 (2022). https://doi.org/10.1007/s10973-022-11343-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11343-2