Abstract

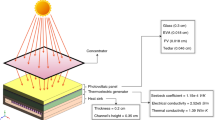

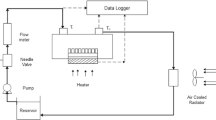

In this paper, in order to improve the cooling power, the thermal effects of using titanium oxide nanoparticles with different concentrations and perforated nozzles with paddle blades are investigated. In this simulation, by presenting a new design for a Si-IGBT power module, three types of paddle blades with a simple nozzle type to pump cooling fluid are evaluated and compared. The boundary condition is that a constant heat flux enters from the top of the module, i.e., IGBT and the Diode. In order to further investigate the thermal effects, an attempt has been made to investigate the temperature of the module under a heat flux of 150 W cm−2, 180 W cm−2, 255 W cm−2, so that the IGBT heat flux is always higher than the Diode input flux. In this robust and three-dimensional simulation extracted from ANSYS-FLUENT commercial software, it was found that turbulent kinetic energy increases with increasing number of nozzle blades. At the same time, increasing the volume fraction of nanoparticles from 0.01 to 0.05 leads to improved heat transfer and ultimately reduces the thermal peak created in the study space. In addition, increasing the transverse mass flow rate improves cooling, which reduces the performance coefficient (COP) of the system.

Similar content being viewed by others

Abbreviations

- COP:

-

Coefficient of performance

- HF:

-

Heat flux, W cm−2

- IGBT:

-

Insulated gate bipolar transistors

- MOT:

-

Maximum operating temperature

- Nu:

-

Nusselt number

- TKE:

-

Turbulence kinetic energy

- T :

-

Temperature (K)

- Out:

-

Outlet

- In:

-

Inlet

- \(\Phi\) :

-

Nanoparticle volume fraction

- P :

-

Pressure (Pa)

- Case 1:

-

Simple nozzel model

- Case 2:

-

Nozzle with multiple holes

- Case 3:

-

Nozzle with 3 vertical blades

- Case 4:

-

Nozzle with 6 vertical blades

- f :

-

Fluid

- s :

-

Solid

- nf:

-

Nano fluid

References

Bahiraei M, Heshmatian S, Goodarzi M, Moayedi H. CFD analysis of employing a novel ecofriendly nanofluid in a miniature pin fin heat sink for cooling of electronic components: effect of different configurations. Adv Powder Technol. 2019;30:2503–16. https://doi.org/10.1016/j.energy.2020.119395.

Zheng LJ, Kang HW. A passive evaporative cooling heat sink method for enhancing low-grade waste heat recovery capacity of thermoelectric generators. Energy Convers Manage. 2022;251:114931. https://doi.org/10.1016/j.enconman.2021.114931.

Gil P. Experimental investigation on heat transfer enhancement of air-cooled heat sink using multiple synthetic jets. Int J Therm Sci. 2021;166:106949. https://doi.org/10.1016/j.ijthermalsci.2021.106949.

Ghanbarpour A, Hosseini MJ, Ranjbar AA, Rahimi M, Bahrampoury R, Ghanbarpour M. Evaluation of heat sink performance using PCM and vapor chamber/heat pipe. Renew Energy. 2021;163:698–719. https://doi.org/10.1016/j.renene.2020.08.154.

Ghasemi SE, Ranjbar AA, Hosseini MJ. Forced convective heat transfer of nanofluid as a coolant flowing through a heat sink: Experimental and numerical study. J Mol Liq. 2021;248:264–70. https://doi.org/10.1016/j.molliq.2017.10.062.

Ghobadi AH, Armin M, Hassankolaei SG, Hassankolaei MG. A new thermal conductivity model of CNTs/C2H6O2–H2O hybrid base nanoliquid between two stretchable rotating discs with Joule heating. Int J Ambient Energy. 2020. https://doi.org/10.1080/01430750.2020.1824942.

Ghasemi SE, Ranjbar AA, Hosseini MJ. Experimental and numerical investigation of circular minichannel heat sinks with various hydraulic diameter for electronic cooling application. Microelectron Reliab. 2017;73:97–105. https://doi.org/10.1016/j.microrel.2017.04.028.

Guowei X, Rui M, Junjie Z, Shun Z, He Y. Thermal performance of an array condenser flat heat pipe for IGBT heat dissipation. Microelectron Reliab. 2020;104:113546. https://doi.org/10.1016/j.microrel.2019.113546.

Tang Z, Liu Q, Li H, Min X. Numerical simulation of heat transfer characteristics of jet impingement with a novel single cone heat sink. Appl Therm Eng. 2017;127:906–14. https://doi.org/10.1016/j.applthermaleng.2017.08.099.

Pan M, Hu M, Wang H. Study of the performance of an integrated liquid cooling heat sink for high-power IGBTs. Appl Thermal Eng. 2021;190:116827. https://doi.org/10.1016/j.applthermaleng.2021.116827.

Gholinia M, Ranjbar AA, Javidan M, Hosseinpour AA. Employing a new micro-spray model and (MWCNTs - SWCNTs) – H2O nanofluid on Si-IGBT power module for energy storage: a numerical simulation. Energy Rep. 2021;7:6844–53. https://doi.org/10.1016/j.egyr.2021.10.047.

Lia Y, Wangb Z, Yanga J, Liua H. Thermal and hydraulic characteristics of microchannel heat sinks with cavities and fins based on field synergy and thermodynamic analysis. Appl Therm Eng. 2020;175:115348. https://doi.org/10.1016/j.applthermaleng.2020.115348.

Robinson AJ, Kempers R, Colenbrander J, Bushnell N, Chen R. A single phase hybrid micro heat sink using impinging micro-jet arrays and microchannels. Appl Therm Eng. 2018;136:408–18. https://doi.org/10.1016/j.applthermaleng.2018.02.058.

Yang L, Huang J, Mao M, Ji W. Numerical assessment of Ag-water nanofluid flow in two new microchannel heatsinks: Thermal performance and thermodynamic considerations. Int Commun Heat Mass Transfer. 2020;110:104415. https://doi.org/10.1016/j.icheatmasstransfer.2019.104415.

Oudah SK, Fang R, Tikadar A, Salman AS, Khan JA. An experimental investigation of the effect of multiple inlet restrictors on the heat transfer and pressure drop in a flow boiling microchannel heat sink. Int J Heat Mass Transf. 2020;153:119582. https://doi.org/10.1016/j.ijheatmasstransfer.2020.119582.

Nakharintr L, Naphon P, Wiriyasart S. Effect of jet-plate spacing to jet diameter ratios on nanofluids heat transfer in a mini-channel heat sink. Int J Heat Mass Transf. 2018;116:352–61. https://doi.org/10.1016/j.ijheatmasstransfer.2017.09.037.

Du X, Yang Z, Jin Z, Xia C, Bao D. A comparative study of passive control on flow structure evolution and convective heat transfer enhancement for impinging jet. Int J Heat Mass Transf. 2018;126:256–80. https://doi.org/10.1016/j.ijheatmasstransfer.2018.01.061.

Bahiraei M, Mazaheri N, Moayedi H. Employing V-shaped ribs and nanofluid as two passive methods to improve second law characteristics of flow within a square channel: a two-phase approach. Int J Heat Mass Transf. 2020;151:119419. https://doi.org/10.1016/j.ijheatmasstransfer.2020.119419.

Shahlaei S, Hassankolaei MG. MHD boundary layer of GO–H2O nanoliquid flow upon stretching plate with considering nonlinear thermal ray and Joule heating effect. Heat Transf - Asian Res. 2019;48(8):4152–73.

Wiriyasart S, Naphon P. Heat spreading of liquid jet impingement cooling of cold plate heat sink with different fin shapes. Case Stud Thermal Eng. 2020;20:100638. https://doi.org/10.1016/j.csite.2020.100638.

Ghobadi AH, Hassankolaei MG. Numerical treatment of magneto Carreau nanofluid over a stretching sheet considering Joule heating impact and nonlinear thermal ray. Heat Transf - Asian Res. 2019;48(8):4133–51.

Alnaqi AA, Alsarraf J, Al-Rashed AAAA, Afrand M. Thermal-hydraulic analysis and irreversibility of the MWCNTs-SiO2/EG-H2O non-Newtonian hybrid nanofluids inside a zigzag micro-channels heat sink. Int Commun Heat Mass Transf. 2021;122:105158. https://doi.org/10.1016/j.icheatmasstransfer.2021.105158.

Gholinia M, Kiaeian Moosavi SAH, Gholinia S, Ganji DD. Numerical simulation of nanoparticle shape and thermal ray on a CuO/C2H6O2–H2O hybrid base nanofluid inside a porous enclosure using Darcy’s law. Heat Transf - Asian Res. 2019;48(7):3278–94.

Khandouzi O, Pourfallah M, Yoosefirad E, Shaker B, Gholinia M, Mouloodi S. Evaluating and optimizing the geometry of thermal foundation pipes for the utilization of the geothermal energy: numerical simulation. J Energy Stor. 2021;37:102464. https://doi.org/10.1016/j.est.2021.102464.

Ghobadi AH, Hassankolaei MG. A numerical approach for MHD Al2O3–TiO2/H2O hybrid nanofluids over a stretching cylinder under the impact of shape factor. Heat Transf Asian Res. 2019;48:4262–82.

Pourfattah F, Sabzpooshani M. Thermal management of a power electronic module employing a novel multi-micro nozzle liquid-based cooling system: a numerical study. Int J Heat Mass Transf. 2020;147:118928. https://doi.org/10.1016/j.ijheatmasstransfer.2019.118928.

Gholinia M, Pourfallah M, Chamani HR. Numerical investigation of heat transfers in the water jacket of heavy duty diesel engine by considering boiling phenomenon. Case Stud Thermal Eng. 2018;12:497–509. https://doi.org/10.1016/j.csite.2018.07.003.

Cadek FFA, Fundamental Investigation of Jet Impingement Heat Transfer, University of Cincinnati, 1968.

Huang T, Diao S, Yang Z, Huang Z, Zhang Y. Flow dynamics and heat transfer characteristics analysis for floatation nozzle using large eddy simulation and proper orthogonal decomposition method. Int J Therm Sci. 2020;155:106402. https://doi.org/10.1016/j.ijthermalsci.2020.106402.

Acknowledgements

The authors would like to acknowledge the Department of Mechanical Engineering, Babol Noushirvani University of Technology, Iran.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declare that there is no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gholinia, M., Ranjbar, A.A., javidan, M. et al. CFD analysis of (TiO2)–H2O Nanofluids on Si-IGBT power electronic module with a new micro-nozzle model. J Therm Anal Calorim 147, 11577–11589 (2022). https://doi.org/10.1007/s10973-022-11315-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11315-6