Abstract

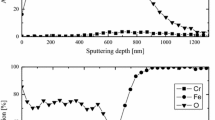

The article concerns high-temperature corrosion of steel S235. Samples were oxidized in air for 480 s. The experiment was carried out at the following temperatures: 1100 °C or 1200 °C. The emissivity factor of the scale was measured with a thermal camera. The emissivity of the oxidation layer formed at the lower temperature was 0.65, and for the layer oxidized at the higher temperature, it was 0.59. The formed scale had a tree-layer structure, which included: Fe2O3, Fe3O4, FeO. The thickness and structure of the scale were compared, both in cross section and on their surface. The oxide scale formed at 1200 °C was twice as thick as that formed at 1100 °C. The scale layer with the lowest oxidation state at the higher temperature was 60.5% and at the lower temperature 54.4%. The scale surface formed at 1100 °C consisted of several phases and was delaminated, whereas the surface of oxidized layer at 1200 °C was compact and homogeneous.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

2021. World steel in figures. World Steel Association. 2021. https://www.worldsteel.org/steel-by-topic/statistics/World-Steel-in-Figures.html. Accessed 2 Feb 2021.

Wang SQ, Wei MX, Wang F, Cui XH, Chen KM. Effect of morphology of oxide scale on oxidation wear in hot working die steels. Mater Sci Eng A. 2009. https://doi.org/10.1016/j.msea.2008.10.032.

Utsunomiya H, Nakagawa T, Matsumoto R. Mechanism of oxide scale to decrease friction in hot steel rolling. Procedia Manuf. 2018. https://doi.org/10.1016/j.promfg.2018.07.168.

Kalasin N, Yenchum S, Nilsonthi T. Adhesion behaviour of scales on hot-rolled steel strips produced from continuous casting slabs. Mater Today Proc. 2018. https://doi.org/10.1016/j.matpr.2017.10.111.

Dobrzański LA, Dobrzańska-Danikiewicz AD. Obróbka powierzchni materiałów inżynierskich. Gliwice: Open Access Library Scientific International Journal of the World Academy of Materials; 2011.

Mrowec S, Werber T. Korozja gazowa metali. Katowice: Wydawnictwo “Śląsk”; 1975.

Arshed M, Siddique M, Anwar-ul-Islam M, Hussain N, Shahid KA, Butt NM. Study of oxidation of alloy 1.4306 S (SS-304L) in air and steam at 1200 °C using the Mössbauer technique. J Radioanal Nucl Chem. 1997. https://doi.org/10.1007/BF02034603.

Ishida T, Harayama Y, Yaguchi S. Oxidation of 304 stainless steel in high-temperature steam. J Nucl Mater. 1986. https://doi.org/10.1016/0022-3115(86)90198-4.

Bittel JT, Sjodahl LH, White JF. Oxidation of 304L stainless steel by steam and by air. Corrosion. 1969. https://doi.org/10.5006/0010-9312-25.1.7.

Jonsson T, Karlsson S, Hooshyar H, Sattari M, Liske J, Svensson JE, Johansson LG. Oxidation after breakdown of the chromium-rich scale on stainless steels at high temperature: internal oxidation. Oxid Met. 2016. https://doi.org/10.1007/s11085-016-9610-7.

Ardigo-Besnard MR, Popa I, Chevalier S. Effect of spinel and perovskite coatings on the long term oxidation of a ferritic stainless steel in H2/H2O atmosphere. Corr Sci. 2019. https://doi.org/10.1016/j.corsci.2018.12.034.

Chiromawa IM, Shaari A, Razali R, Taura LS, Lawal A. Structural stabilities, electronic structure, optical and elastic properties of ternary Fe2SiO4 spinel: an ab initio study. Mater Today Commun. 2020. https://doi.org/10.1016/j.mtcomm.2020.101665.

Ray PK, Akinc M, Kramer MJ. Formation of multilayered scale during the oxidation of NiAl–Mo alloy. Appl Surf Sci. 2014. https://doi.org/10.1016/j.apsusc.2014.01.148.

Matsuno F. Blistering and hydraulic removal of scale films of rimmed steel at high temperature. Trans ISIJ. 1980. https://doi.org/10.2355/isijinternational1966.20.413.

Sheasby JS, Boggs WE, Turkdogan ET. Scale growth on steels at 1200 C: rationale of rate and morphology. Met Sci. 1984. https://doi.org/10.1179/msc.1984.18.3.127.

Iordanova I, Surtchev M, Forcey KS, Krastev V. High‐temperature surface oxidation of low‐carbon rimming steel. Surf Interface Anal. 2000. https://doi.org/10.1002/1096-9918(200008)30:1%3c158::AID-SIA744%3e3.0.CO;2-6.

Takeda M, Onishi T, Nakakubo S, Fujimoto S. Physical properties of iron-oxide scales on Si-containing steels at high temperature. Mater Trans. 2009. https://doi.org/10.2320/matertrans.M2009097.

Blazevic DT. Tertiary rolled-in scale: the hot strip mill problem of the 1990s. In: Proceedings of the 37th MWSP Conference. 1996; 33–38.

Wang N, Dong J, Huang W, Li B, Chen M. Growth rate, microstructure and phase composition of oxide scales for three typical steels in simulated continuous casting process. J Iron Steel Res Int. 2014. https://doi.org/10.1016/S1006-706X(14)60185-0.

El Baradie MA. A fuzzy logic model for machining data selection. Int J Mach Tools Manuf. 1997. https://doi.org/10.1016/S0890-6955(95)00094-1.

Chandra-Ambhorn S, Phadungwong T, Sirivedin K. Effects of carbon and coiling temperature on the adhesion of thermal oxide scales to hot-rolled carbon steels. Corr Sci. 2016. https://doi.org/10.1016/j.corsci.2016.11.014.

Zheng L, Hosoi K, Ueda S, Gao X, Kitamura S, Kobayashi Y. Si-rich phases and their distributions in the oxide scale formed on 304 stainless steel at high temperatures. J Nucl Mater. 2018. https://doi.org/10.1016/j.jnucmat.2018.05.018.

Deng GY, Tieu AK, Su LH, Zhu HT, Zhu Q, Zamri WFH, Kong C. Characterizing deformation behaviour of an oxidized high speed steel: effects of nanoindentation depth, friction and oxide scale porosity. Int J Mech Sci. 2019. https://doi.org/10.1016/j.ijmecsci.2019.02.043.

Peng W, Yang Z, Jia G, Hu C, Zhao H, Wu Z, Xu W, Li J, Xiao X, Dong H. Distinct oxidation behaviour attributed to phase constitution transformation at different hot processing temperatures in Fe-10Mn-5.5 Al-0.25 C steel. Corr Sci. 2019. https://doi.org/10.1016/j.corsci.2019.01.045.

Przyłucka A, Cebo-Rudnicka A, Rywotycki M, Augustyn-Nadzieja J, Malinowski Z. Development and verification of the scale growth model during high temperature oxidation for S235 steel. Comput Methods Mater Sci. 2020. https://doi.org/10.7494/cmms.2020.4.0723.

PN-EN 10025-2:2019-11. Hot rolled products of structural steels - Part 2: Technical delivery conditions for non-alloy structured steels.

Malinowski Z. Numerical models of plastic forming and heat exchange. Kraków: Uczelniane Wydawnictwa Naukowo-Dydaktyczne AGH; 2005.

Mrowec S. Kinetyka i mechanizm utleniania metali. Katowice: Wydawnictwo “Śląsk”; 1982.

Funding

The work was realized as a part of fundamental research financed by AGH University of Science and Technology project number 16.16.110.663.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by APB, JAN and MR. The first draft of the manuscript was written by APB, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Przyłucka-Bednarska, A., Augustyn-Nadzieja, J. & Rywotycki, M. Formation of multilayered scale in the process of high-temperature oxidation of steel S235. J Therm Anal Calorim 147, 10235–10243 (2022). https://doi.org/10.1007/s10973-022-11309-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11309-4