Abstract

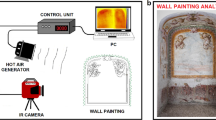

Conservation of artworks is of paramount importance nowadays around the world. Clever conservation by using non-destructive testing techniques is highly appreciated by restorers and art historians. Among these, a special set-up working into the infrared region is the flying spot laser thermography technique that uses a punctual stimulus to transfer the heat from the source into the artwork. In this way, the precious surface is gently heated by avoiding any type of damage, such as color changes and/or shrinkage and warpage effects. To the best of our knowledge, the flying spot laser thermography technique, in the configuration proposed, has been used here for the first time in the cultural heritage field. It was applied in combination with terahertz inspection, an emergent technique in the field of art research, completely non-invasive and safe for the operator. The target to be inspected was a panel painting executed by following the rules dictated by the art master Cennino Cennini. Results demonstrated how such an integrated approach is plausible to provide robust information concerning invisible defects to the naked eye.

Similar content being viewed by others

References

Conde-Contreras M, Bante-Guerra J, Hernandez-Garcia E, Hernandez AM, Trujillo S, Quintana P, Alvarado-Gil JJ. Thermographic analysis of surface damage in teeth. In: Proceedings of SPIE—The international society for optical engineering—Progress in Biomedical Optics and Imaging—Lasers in Dentistry XIV, USA : San Josè (CA), 2008, vol. 6843, Article number 68430C.

Schlichting J, Maierhofer C, Kreutzbruck M. Defect sizing by local excitation thermography. Quant Infr Therm J. 2011;8(1):51–63.

Cheng C, Fan W, Cao J, Ryu S-G, Ji J, Grigoropoulos CP, Wu J. Heat transfer across the interface between nanoscale solids and gas. ACS Nano. 2011;5(12):10102–7.

Schlichting J, Maierhofer C, Kreutzbruck M. Crack sizing by laser excited thermography. NDT&E Int. 2012;45(1):133–40.

Rudlin J, Cerniglia D, Scafidi M. Inspection of laser powder deposited layers. In: 52nd Annual conference of the british institute of non-destructive testing 2013—BINDT 2013, Telford: UK, 2013. pp. 569–582 Code 107049.

Santospirito SP, Łopatka R, Cerniglia D, Słyk K, Luo B, Panggabean D, Rudlin J. Defect detection in laser powder deposition components by laser thermography and laser ultrasonic inspections. In: Proceedings of SPIE—The international society for optical engineering— Frontiers in ultrafact optics: biomedical, scientific, and industrial applications XIII, San Francisco (CA): USA, 2013, vol. 8611, Article number 86111N.

Santospirito SP, Słyk K, Luo B, Łopatka R, Gilmour O, Rudlin J. Detection of defects in laser powder deposition (LPD) components by pulsed laser transient thermography. In: Proceedings of SPIE—The international society for optical engineering— Thermosense: thermal infrared applications XXXV, Baltimore (MD), USA, 2013, vol. 8705, Article number 87050X.

Basheer M, Pv N, Ravindran P, Balasubramaniam K. A thermographic approach for surface crack depth evaluation through 3D finite element modeling. In: 41st Annual review of progress in quantitative nondestructive evaluation (QNDE 2014), Boise, USA, 2014, vol. 1650 (AIP Conference Proceedings), Code 111794.

Montinaro N, Cerniglia D, Pitarresi G. Defect detection in additively manufactured titanium prosthesis by flying laser scanning thermography. Proced Struct Integr. 2018;12:165–72.

Montinaro N, Cerniglia D, Pitarresi G. A numerical and experimental study through laser thermography for defect detection on metal additive manufactured parts. Frat ed Integr Strut. 2018;12(43):231–40.

Cerniglia D, Montinaro N. Defect detection in additively manufactured components: laser ultrasound and laser thermography comparison. Proced Struct Integr. 2018;8:154–62.

Shi Q, Liu J, Liu W, Wang F, Wang Y. Barker-coded modulation laser thermography for CFRP laminates delamination detection. Infrared Phys Technol. 2019;98:55–61.

Yu S, Sui H, Zhu H, Netzelmann U, Müller D. Laser line generation for optimized interaction with hidden defects in active thermography. In: Proceedings of 2019 IEEE Far East NDT new technology and application Forum (FENDT 2019), Qingdao, China, 2019, pp. 213–217, Article number 8962578.

Montinaro N, Cerniglia D, Pitarresi G. Evaluation of vertical fatigue cracks by means of flying laser thermography. J Nondestr Eval. 2019;38(2):48.

Hwang S, An Y-K, Sohn H. Continuous-wave line laser thermography for nonitoring of rotating wind turbine blades. Struct Health Monit. 2019;18(4):1010–21.

Puthiyaveettil N, Thomas KR, Unnikrishnakurup S, Myrach P, Ziegler M, Balasubramaniam K. Laser line scanning thermography for surface breaking crack detection: modeling and experimental study. Infrared Phys Technol. 2020;104:103141.

Roemer J. The concept of laser spot thermography test rig with real-time data processing. Int J Multiphys. 2020;14(1):31–8.

Bodnar J-L, Nicolas J-L, Mouhoubi K, Detalle V. Stimulated infrared thermography applied to thermophysical characterization of cultural heritage mural paintings. EPJ Appl Phys. 2012;60(2):p1–6.

Gaverina L, Bensalem M, Bedoya A, González J, Sommier A, Battaglia J-L, Salazar A, Mendioroz A, Oleaga A, Batsale J-C, Pradere C. Constant velocity flying spot for the estimation of in-plane thermal diffusivity on anisotropic materials. Int J Therm Sci. 2019;145:106000.

Gaverina L, Batsale J-C, Sommier A, Pradere C. Pulsed flying spot with the logarithmic parabolas method for the estimation of in-plane thermal diffusivity fields on heterogeneous and anisotropic materials. J Appl Phys. 2017;121(11):115105.

Gaverina L, Sommier A, Battaglia J-L, Batsale J-C, Pradere C. Pulsed flying spot elliptic method for the estimation of the thermal diffusivity field of orthotropic materials. Int J Therm Sci. 2018;125:142–8.

Jansen C, Wietzke S, Peters O, Scheller M, Vieweg N, Salhi M, Krumbholz N, Jördens C, Hochrein T, Koch M. Terahertz imaging: application and perspectives. Appl Opt. 2010;49(19):E48–57.

Skry AS, Bianca Jackson J, Bakunov MI, Menu M, Mourou GA. Terahertz time-domain imaging of hidden defects in wooden artworks: application to a Russian icon painting. Appl Opt. 2014;53(6):1033–8.

Chulkov AO, Gaverina L, Pradere C, Batsale JC, Vavilov VP. Water detection in honeycomb composite structures using terahertz thermography. Russ J Nondestruct+. 2015;51(8):520–3.

Bensalem M, Sommier A, Mindeguia JC, Batsale JC, Pradere C. Terahertz measurement of the water content distribution in wood materials. J Infrared Millim Te. 2018;39:195–209.

Romano M, Chulkov A, Sommier A, Balageas D, Vavilov V. Broadband sub-terahertz camera based on photothermal conversion and IR thermography. J Infrared Millim Te. 2016;37:448–61.

Frezzato F. Cennino Cennini’s Il libro dell’arte A new English translation and commentary with Italian transcription. J Am Inst Conserv. 2016;55(3):186–8.

Sfarra S, Theodorakeas P, Ibarra-Castanedo C, Avdelidis NP, Paoletti A, Paoletti D, Hrissagis K, Bendada A, Koui M, Maldague X. Evaluation of defects in panel paintings using infrared, optical and ultrasonic techniques. Insight. 2012;54(1):21–7.

Laureti S, Sfarra S, Malekmohammadi H, Burrascano P, Hutchins DA, Senni L, Silipigni G, Maldague XPV, Ricci M. The use of pulse-compression thermography for detecting defects in paintings. NDT&E Int. 2018;98:147–54.

Del Barrio EP, Dauvergne JL, Pradere C. Thermal characterization of materials using Karhunen-Loève decomposition techniques–Part I Orthotropic materials. Inverse Probl Sci En. 2012;20:1115–43.

Toullier T, https://tel.archives-ouvertes.fr/tel-02389051/document, Accessed on 30 October 2021.

Sfarra S, Yao Y, Zhang H, Perilli S, Scozzafava M, Avdelidis NP, Maldague XPV. Precious walls built in indoor environments inspected numerically and experimentally within long-wave infrared (LWIR) and radio regions. J Therm Anal Calorim. 2019;137:1083–111.

Sfarra S, Regi M, Tortora M, Casieri C, Perilli S, Paoletti D. A multi-technique nondestructive approach for characterizing the state of conservation of ancient bookbindings. J Therm Anal Calorim. 2018;132:1367–87.

Yao Y, Sfarra S, Ibarra-Castanedo C, You R, Maldague XPV. The multi-dimensional ensemble empirical mode decomposition (MEEMD)—An advanced tool for thermographic diagnosis of mosaics. J Therm Anal Calorim. 2017;128:1841–58.

Altenburg SJ, Straße A, Gumenyuk A, Maierhofer C. In-situ monitoring of a laser metal deposition (LMD) process: comparison of MWIR, SWIR and high-speed NIR thermography. Quant Infr Therm J. 2020. https://doi.org/10.1080/17686733.2020.1829889.

Author information

Authors and Affiliations

Contributions

SS, LG, CP, AS, J-CB were involved in conceptualization, visualization, validation, writing—original draft preparation, writing—review and editing; LG, CP, AS, J-CB contributed to methodology; LG, CP, AS were involved in software and data curation; SS, LG, CP, AS contributed to formal analysis and investigation; SS, CP, AS, J-CB contributed to resources, supervision, project administration and funding acquisition. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sfarra, S., Gavérina, L., Pradere, C. et al. Integration study among flying spot laser thermography and terahertz technique for the inspection of panel paintings. J Therm Anal Calorim 147, 8279–8287 (2022). https://doi.org/10.1007/s10973-021-11181-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-11181-8