Abstract

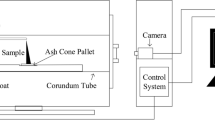

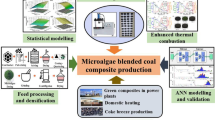

In this work, a comprehensive and systematic study on synergistic effect and kinetics of three coal ranks (anthracite coal, bituminous coal, and waste coal), and three biomass materials (wheat straw, sawdust, groundnut) were performed under different blending ratios. The kinetic parameters of coal and biomass devolatilization were estimated by means of thermogravimetric analysis (TGA) at 10, 20, 30 and 40 Kmin−1. These kinetic parameters were subsequently validated using Artificial Neural Network (ANN) Model. Further, for fitting the experimental data, a numerical approach to distributed activation energy model (DAEM) has been evaluated and the experimental findings were compared with simulated data. Subsequently, the kinetic and thermodynamic parameters were estimated and compared with three model-free methods viz., KAS, OFW, and Friedman. The results from TG study indicate that the interactions between the waste coal with higher rank coal and biomass samples present an inhibitive effect during the devolatilization process. Furthermore, the values of activation energy were found in the range of 270, 250, 149 kJmol−1 by using OFW, KAS and Friedman model, respectively. Additionally, the thermodynamic parameters viz., enthalpy (ΔH), Gibbs free energy (ΔG) and entropy (ΔS) were estimated as 275.2 kJ mol−1, 184.5 kJmol−1, and 59.7 Jmol−1, respectively.

Similar content being viewed by others

References

IEA. Coal reserves in India, survey. 2020. https://www.iea.org/countries/india.

Nag D, Karmakar S, Burgula L, Dash J, Dash PS, Ghorai S. Use of organic polymers for improvement of coking potential of poor coking coal. Int J Coal Prep Util. 2019. https://doi.org/10.1080/19392699.2019.1686365.

Sahoo M, Bhowmick T, Mishra V, Pal S, Sharma M, Chakravarty S. Significance of coal quality on thermoplastic properties: a case study. Int J Coal Prep Util. 2019. https://doi.org/10.1080/19392699.2019.1678470.

Zhang D, Liu P, Lu X, Wang L, Pan T. Upgrading of low rank coal by hydrothermal treatment: Coal tar yield during pyrolysis. Fuel Process Technol. 2015;141(1):117–22.

Xu C, Hu S, Xiang J, Zhang L, Sun L, Shuai C, Chen Q, He L. Interaction and kinetic analysis for coal and biomass co-gasification by TG–FTIR. Bioresour Technol. 2014;154:313–21.

Routray A, Das D, Parhi PK, Padhy MK. Characterization, stabilization, and study of mechanism of coal-water slurry using Sapindous Mukorossi as an additive. Energy Sour A Recovery Util Environ Eff. 2018;40(20):2502–3.

Pekel E, Akkoyunglu MC, Akkoyunglu MT, Pusat S. Decision tree regression model to predict low-rank coal moisture content during convective drying process. Int J Coal Prep Util. 2020. https://doi.org/10.1080/19392699.2020.1737527.

Bong JT, Loy ACM, Chin BLF, Lam MK, Tang DKH, Lim HY. Artificial neural network approach for co-pyrolysis of Chlorella vulgaris and peanut shell binary mixtures using microalgae ash catalyst. Energy. 2020;207:118289.

Naqvi SR, Tariq R, Hameed Z, Ali I, Taqvi SA, Naqvi M. Pyrolysis of high-ash sewage sludge: Thermo-kinetic study using TGA and artificial neural networks. Fuel. 2018;233:529–38.

Dwivedi KK, Prabhansu KMK, Chatterjee PK. Thermal degradation, characterization and kinetic modeling of different particle size coal through TGA. Therm Sci Eng Prog. 2020;18:100523.

Damartzis T, Vamvuka D, Sfakiotakis S, Zabaniotou A. Thermal degradation studies and kinetic modeling of cardoon (Cynara cardunculus) pyrolysis using thermogravimetric analysis (TGA). Bioresour Technol. 2011;102:6230–8.

Ken BS, Aich S, Saxena VK, Nandi BK. Combustion behavior of KOH desulphurized coals assessed by TGA-DTG. Energy Sour A Recovery Util Environ Eff. 2018;40(20):2458–66.

Seo DK, Park SS, Kim YT, Hwang J, Yu T. Study of coal pyrolysis by thermo-gravimetric analysis (TGA) and concentration measurements of the evolved species. J Anal Appl Pyrol. 2011;92:209–16.

Patel M, Oyedun AO, Kumar A, Gupta R. Predicting the biomass conversion performance in a fluidized bed reactor using isoconversional model-free method. Can J Chem Eng. 2019;97:1263–73.

International Energy Agency (IEA). Global Energy Review 2020. https://www.iea.org/reports/global-energy-review-2020/renewables.

Lemos MS, Yokoyama L, Viana MM, Dweck J. A study of coke and char formation during pyrolysis of rice husk. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08196-7.

Kelebopile L, Sun R, Liao J. Fly ash and coal char reactivity from Thermogravimetric (TGA) experiments. Fuel Process Technol. 2011;92:1178–86.

De CB, De FP, Herce C, Verdone N. Double gaussian distributed activation energy model for coal devolatilization. Energy Fuels. 2012;26(10):6153–9.

Jain AA, Mehra A, Ranade VV. Processing of TGA data: analysis of isoconversional and model fitting methods. Fuel. 2016;165:490–8.

Dwivedi KK, Shrivastav P, Karmakar MK, Pramanick AK, Chatterjee PK. A comparative study on pyrolysis characteristics of bituminous coal and low-rank coal using thermogravimetric analysis (TGA). Int J Coal Prep Util. 2019;39:1–11.

Ahmad SM, Mehmood MA, Ayed OS, Guangbin Y, Luo H, Ibrahim M. Kinetic analysis and pyrolytic behavior of Para grass (Urochloa mutica) for its bioenergy potential. Bioresour Technol. 2017;224:708–13.

ASTM, D-5373. Standard method for instrumental determination of carbon, hydrogen, and nitrogen in laboratory samples of coal and coke. West Conshohocken: ASTM International; 2014.

Channiwala SA, Parikh PP. A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel. 2002;81:1051–63.

Chen C, Ma X, He Y. Co-pyrolysis characteristics of microalgae Chlorella vulgaris and coal through TGA. Bioresour Technol. 2012;117:264–73.

Kumari N, Saha S, Sahu G, Chauhan V, Roy R, Datta S, Chavan SD. Comparison of CO2 gasification reactivity and kinetics: petcoke, biomass and high ash coal. Biomass Conv Bioref. 2020. https://doi.org/10.1007/s13399-020-00882-z.

Aboyade AO, Carrier M, Meyer EL, Knoetze JH, Gorgens JF. Model fitting kinetic analysis and characterization of the devolatilization of coal blends with corn and sugarcane residues. Thermochim Acta. 2012;530:95–106.

Biagini E, Lippi F, Petarc L, Tognotti L. Devolatilization rate of biomasses and coal-biomass blends: an experimental investigation. Fuel. 2002;81:1041–50.

Kissinger H. Variation of peak temperature with heating rate in differential thermal analysis. J Res Natl Bur Stand. 1956;7(4):217–21.

Akahira T, Sunose T. Method of determining activation deterioration constant of electrical insulating materials. Resour Rep Chiba Inst Technol (Sci Technol). 1971;16:22–31.

Murray P, White J. Kinetics of the thermal dehydration of clays. Part IV. Interpretation of the differential thermal analysis of the clay minerals. Trans J Br Cer Soc. 1955;54:204–38.

Flynn JH. The temperature integral-its use and abuse. Thermochim Acta. 1997;300:83–92.

Ozawa T. A new method of analyzing thermogravimetric data. Bulletin Chem Soc Japan. 1965;38:1881–6.

Doyle CD. Estimating isothermal life from thermo-gravimetric data. J Appl Poly Sci. 1962;6:639–42.

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry: application to a phenolic plastic. J Poly Sci Part C: Poly Symp. 1964;6:183–95.

Soria A, Garcia LM, Blanco L, Garcia N, Ruiz U. Evaluating the accuracy of the distributed activation energy model for biomass devolatilization curves obtained at high heating rates. Energy Convers Manag. 2014;86:1045–9.

Bhavanam A, Sastry RC. Kinetic study of solid waste pyrolysis using distributed activation energy model. Bioresour Technol. 2015;178:126–31.

Fletcher TH, Kerstein AR, Pugmire RJ, Grant DM. Chemical percolation model for devolatilization. Temperature and heating rate effects on product yields. Energy Fuels. 1990;4(1):54–60.

Bi H, Wang C, Lin Q, Jiang X, Jiang C, Bao L. Pyrolysis characteristics, artificial neural network modeling and environmental impact of coal gangue and biomass by TG-FTIR. Sci Total Environ. 2021;751:142293.

Naqvi SR, Hameed Z, Tariq R, Taqvi SA, Ali I, Niazi MBK, Noor T, Hussain A, Iqbal N, Shahbaz M. Synergistic effect on co-pyrolysis of rice husk and sewage sludge by thermal behavior, kinetics, thermodynamic parameters and artificial neural network. Waste Manag. 2019;85:131–40.

Eyring H. The activated complex in chemical reactions. J Chem Phy. 1935;3(2):107–15.

Chaves AP, Ruiz AS. Considerations on the kinetics of froth flotation of ultrafine coal contained in tailings. Int J Coal Prep Util. 2009. https://doi.org/10.1080/19392690903558371.

Ding L, Dai Z, Guo Q, Yu G. Effects of in-situ interactions between steam and coal on pyrolysis and gasification characteristics of pulverized coals and coal water slurry. Appl Energy. 2017;187:627–39.

Hernando H, Moreno I, Fermoso J. Biomass catalytic fast pyrolysis over hierarchical ZSM-5 and Beta zeolites modified with Mg and Zn oxides. Biomass Conv Bioref. 2017;7:289–304.

Duan W, Yu Q, Liu J, Wu T, Yang F, Qin Q. Experimental and kinetic study of steam gasification of low-rank coal in molten blast furnace slag. Energy. 2016;111:859–68.

Thiagarajan J, Srividhya PK, Balasubramanian P. Thermochemical behaviors and co-gasification kinetics of palm kernel shells with bituminous coal. Biomass Conv Bioref. 2019. https://doi.org/10.1007/s13399-019-00450-0.

Evans MG, Polanyi M. Some applications of transition state method to calculation of reaction velocities, especially in solution. J Chem Soc Faraday Trans. 1935;31:875–94.

Vakalis T, Moustakas K. Modeling the co-combustion of coal and biocoal from the novel process of frictional pyrolysis for reducing the emissions of coal plants. Biomass Convers Bioref. 2020. https://doi.org/10.1007/s13399-020-00671-8.

Mazumder S, Saha P, Reza MT. Co-hydrothermal carbonization of coal waste and food waste: fuel characteristics. Biomass Convers Bioref. 2020. https://doi.org/10.1007/s13399-020-00771-5.

Li S, Chen X, Liu A, Wang L, Yu G. Co-pyrolysis characteristic of biomass and bituminous coal. Biores Technol. 2015;179:414–20.

Ozsin G, Putun AE. Co-pyrolytic behaviors of biomass and polystyrene: Kinetics, thermodynamics and evolved gas analysis. Korean J Chem Eng. 2018;35:428–37.

Lu J, Chen W. Investigation on the ignition and burnout temperatures of bamboo and sugarcane bagasse by thermogravimetric analysis. Appl Energy. 2015;160:49–57.

Thanapal SS, Annamalai K, Ansley RJ, Ranjan D. Co-firing carbon dioxide-torrefied woody biomass with coal on emission characteristics. Biomass Convers Bioref. 2016;6:91–104.

Zhang W, Rezaee M, Bhagavatula A, Li Y, Groppo J, Honaker R. A review of the occurrence and promising recovery methods of rare earth elements from coal and coal by-products. Int J Coal Prep Util. 2015;35:295–330.

Shrivastava P, Khongphakdi P, Palamanit A, Kumar A, Tekasakul P. Investigation of physicochemical properties of oil palm biomass for evaluating potential of biofuels production via pyrolysis processes. Biomass Convers Bioref. 2020. https://doi.org/10.1007/s13399-019-00596-x.

Hernando H, Fermoso J, Moreno I. Thermochemical valorization of camelina straw waste via fast pyrolysis. Biomass Convers Bioref. 2017;7:277–87.

Grant DM, Pugmire RJ, Fletcher TH, Kerstein AR. Chemical model of coal devolatilization using percolation lattice statistics. Energy Fuels. 1989;3(2):175–86.

Yahyaoui R, Jimenez PES, Maqueda LAP, Nahdi K, Luque JMC. Synthesis, characterization and combined kinetic analysis of thermal decomposition of hydrotalcite (Mg6Al2(OH)16CO3·4H2O). Thermochim Acta. 2018;667:177–84.

Xu BH, Liu QF, Ai B, Ding SL, Frost RL. Thermal decomposition of selected coal gangue. J Therm Anal Calorim. 2018;131:1413–22.

Chelgani SC, Hadavandi E, Hower JC. Study relationship between the coal thermoplastic factor with its organic and inorganic properties by the support vector regression method. Int J Coal Prep Util. 2017. https://doi.org/10.1080/19392699.2017.1409215.

Lin X, Luo M, Li S, Yang Y, Chen X, Tian B, Bang Y. The evolutionary route of coal matrix during integrated cascade pyrolysis of a typical low-rank coal. Appl Energy. 2017;199:335–46.

Acknowledgements

Authors are thankful to Director, CSIR-CMERI Durgapur and Director, National Institute of Technology Durgapur, for their support to carry out this research work. The authors extend their gratitude to Dr. Prabhansu, Assistant Professor, Department of Mechanical Engineering, SVNIT Surat, India, for kind cooperation and support during the sample characterization.

Funding

Not Applicable.

Author information

Authors and Affiliations

Contributions

KKD was involved in conceptualization, methodology and writing original draft. AKP was involved in manuscript—review & editing. MKK, AKP and PKC were involved in supervision.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dwivedi, K.K., Pramanick, A.K., Karmakar, M.K. et al. Synergistic effect on co-pyrolysis mechanism and kinetics of waste coal blended with high-rank coal and biomass. J Therm Anal Calorim 147, 8323–8343 (2022). https://doi.org/10.1007/s10973-021-11123-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-11123-4