Abstract

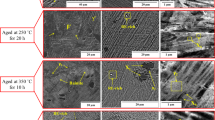

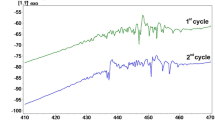

This study proposes to characterize the effect of long-term thermal cycling on transformation temperatures and thermodynamic parameters of polycrystalline CuAlBeCr shape memory alloy. Structural, morphological and thermal characterizations were performed. The samples were submitted up to 1000 cycles using a dual-bath thermal cycler apparatus. The results show that the thermal cycling has a considerable impact on the transformation behavior of the alloy. Up to 500 cycles, the alloy experienced a one-stage reverse martensitic transformation; after this, it was split into two reactions. From 100 cycles, an increase in temperature ranges (\({A}_{\text {f}}-{A}_{\text s}\)) values of the reverse martensitic transformation was observed, associated with the increase in elastic energy. Our study expands the spectrum of knowledge regarding thermal and structural properties, for CuAlBe system alloys, indicating the thermal cycling conditions to which the alloy must be subjected in order to preserve the characteristics required in a given practical application.

Similar content being viewed by others

Data availability

Data will be made available on reasonable request.

References

Mohd Jani J, Leary M, Subic A, Gibson MA. A review of shape memory alloy research, applications and opportunities. Mater Des. 2014. https://doi.org/10.1016/j.matdes.2013.11.084.

Weirich K. Applicability of shape memory alloys in aircraft interiors. Actuators. 2019;8:61. https://doi.org/10.3390/act8030061.

Naresh C, Bose PSC, Rao CSP. Shape memory alloys: a state of art review. IOP Conf Ser Mater Sci Eng. 2016;149: 012054. https://doi.org/10.1088/1757-899X/149/1/012054.

Singh RK, Murigendrappa SM, Kattimani S. Investigation on properties of shape memory alloy wire of Cu-Al-Be doped with zirconium. J Mater Eng Perform. 2020;29:7260–9. https://doi.org/10.1007/s11665-020-05233-7.

Aksu Canbay C, Aydoğdu A. Thermal analysis of Cu-14.82 wt% Al-0.4 wt% Be shape memory alloy. J Therm Anal Calorim. 2013. https://doi.org/10.1007/s10973-012-2792-6.

Hsu CA, Wang WH, Hsu YF, Rehbach WP. The refinement treatment of martensite in Cu–11.38wt.%Al–0.43wt.%Be shape memory alloys. J Alloys Compd. 2009. https://doi.org/10.1016/j.jallcom.2008.06.109.

Mohd Khalil AN, Azmi AI, Murad MN, Mahboob Ali MA. The effect of cutting parameters on cutting force and tool wear in machining Nickel Titanium Shape Memory Alloy ASTM F2063 under Minimum Quantity Nanolubricant. Procedia CIRP. 2018. https://doi.org/10.1016/j.procir.2018.09.002.

Lopez-Ferreño I, Breczewski T, Ruiz-Larrea I, Lopez-Echarri A, Nó ML, San Juan J. Thermal treatments and transformation behavior of Cu-Al-Be shape memory alloys. J Alloys Compd. 2013. https://doi.org/10.1016/j.jallcom.2012.02.006.

Oliveira JP, Zeng Z, Berveiller S, Bouscaud D, Braz Fernandes FM, Miranda RM, Zhou N. Laser welding of Cu-Al-Be shape memory alloys: Microstructure and mechanical properties. Mater Des. 2018. https://doi.org/10.1016/j.matdes.2018.03.066.

Saud SN, Hamzah E, Abubakar T, Ibrahim MK, Bahador A. Effect of a fourth alloying element on the microstructure and mechanical properties of Cu–Al–Ni shape memory alloys. J Mater Res. 2015;30:2258–69. https://doi.org/10.1557/jmr.2015.196.

Bala Narasimha G, Murigendrappa SM. Effect of zirconium on the properties of polycrystalline Cu-Al-Be shape memory alloy. Mater Sci Eng A. 2019. https://doi.org/10.1016/j.msea.2019.04.022.

Candido GVDM, Melo TADA, De Albuquerque VHC, Gomes RM, de Lima SJG, Tavares JMR. Characterization of a CuAlBe Alloy with Different Cr Contents. J Mater Eng Perf. 2012;21(11):2398–406.

Montecinos S, Klímek P, Sláma M, Suarez S, Simison S. Corrosion behavior of a β CuAlBe shape memory alloy containing stress induced martensite. Appl Surf Sci. 2019;466:165–70. https://doi.org/10.1016/j.apsusc.2018.10.047.

Elrasasi TY, Dobróka MM, Daróczi L, Beke DL. Effect of thermal and mechanical cycling on the elastic and dissipative energy in CuAl (11.5 wt%) Ni (5.0 wt%) shape memory alloy. J Alloys Comp. 2013;577:S517–20.

Tong Y, Gu H, James RD, Qi W, Shuitcev AV, Li L. Novel TiNiCuNb shape memory alloys with excellent thermal cycling stability. J Alloys Compd. 2019;782:343–7. https://doi.org/10.1016/j.jallcom.2018.12.219.

Zhang Y, Jiang H, Liu X, Huang L, Yang S, Wang C. Thermal cycle stability of Co64V15Si17Al4 high-temperature shape memory alloy. Mater Lett. 2020;260: 126930. https://doi.org/10.1016/j.matlet.2019.126930.

Wang Z, Di-Franco F, Seyeux A, Zanna S, Maurice V, Marcus P. Passivation-induced physicochemical alterations of the native surface oxide film on 316l austenitic stainless steel. J Electrochem Soc. 2019;166:C3376–88. https://doi.org/10.1149/2.0321911jes.

Wang X, Van Humbeeck J, Verlinden B, Kustov S. Thermal cycling induced room temperature aging effect in Ni-rich NiTi shape memory alloy. Scr Mater. 2016;113:206–8. https://doi.org/10.1016/j.scriptamat.2015.11.007.

Suresh KS, Bhaumik SK, Suwas S. Effect of thermal and thermo-mechanical cycling on the microstructure of Ni-rich NiTi shape memory alloys. Mater Lett. 2013;99:150–3. https://doi.org/10.1016/j.matlet.2013.03.014.

Churakova, Gunderov, Microstructural and Mechanical Stability of a Ti-50.8 at.% Ni Shape Memory Alloy Achieved by Thermal Cycling with a Large Number of Cycles, Metals (Basel). 10 (2020) 227. doi: https://doi.org/10.3390/met10020227.

Wu S-K, Chang Y-C. Thermal cycling effect on transformation temperatures of different transformation sequences in tini-based shape memory alloys. Materials (Basel). 2019;12:2512. https://doi.org/10.3390/ma12162512.

Meng XL, Li H, Cai W, Hao SJ, Cui LS. Thermal cycling stability mechanism of Ti50.5Ni33.5Cu11.5Pd4.5 shape memory alloy with near-zero hysteresis. Scr Mater. 2015. https://doi.org/10.1016/j.scriptamat.2015.02.030.

Krooß P, Holzweissig MJ, Niendorf T, Somsen C, Schaper M, Chumlyakov YI, Maier HJ. Thermal cycling behavior of an aged FeNiCoAlTa single-crystal shape memory alloy. Scr Mater. 2014;81:28–31. https://doi.org/10.1016/j.scriptamat.2014.02.020.

Duggin M. Further studies of martensitic transformations in gold-copper-zinc and copper-aluminium-nickel alloys. Acta Metall. 1966;14:123–9. https://doi.org/10.1016/0001-6160(66)90293-8.

Dunne D, Ireland K, Gonzalez C, Morin M, Guénin G. Hyperstabilisation of martensite in Cu-Al-Be alloys. Mater Sci Eng A. 2006;438–440:339–42. https://doi.org/10.1016/j.msea.2006.02.139.

Arlic U, Zak H, Weidenfeller B, Riehemann W. Impact of alloy composition and thermal stabilization on martensitic phase transformation structures in CuAlMn shape memory alloys. Mater Res. 2018. https://doi.org/10.1590/1980-5373-mr-2017-0897.

Kainuma R, Takahashi S, Ishida K. Thermoelastic martensite and shape memory effect in ductile Cu-Al-Mn alloys. Metall Mater Trans A. 1996;27:2187–95. https://doi.org/10.1007/BF02651873.

Sedlák P, Seiner H, Landa M, Novák V, Šittner P, Mañosa L. Elastic constants of bcc austenite and 2H orthorhombic martensite in CuAlNi shape memory alloy. Acta Mater. 2005;53:3643–61. https://doi.org/10.1016/j.actamat.2005.04.013.

Cheniti H, Bouabdallah M, Patoor E. High temperature decomposition of the β1 phase in a Cu–Al–Ni shape memory alloy. J Alloys Compd. 2009;476:420–4. https://doi.org/10.1016/j.jallcom.2008.09.003.

J. Van Humbeeck, Cycling effects, fatigue and degradation of shape memory alloys, Le J. Phys. IV. 01 (1991) C4–189-C4–197. doi:https://doi.org/10.1051/jp4:1991429.

Tatar C, Yildirim Z. Phase transformation kinetics and microstructure of NiTi shape memory alloy: effect of hydrostatic pressure. Bull Mater Sci. 2017;40:799–803. https://doi.org/10.1007/s12034-017-1413-1.

Khalil-Allafi J, Amin-Ahmadi B. The effect of chemical composition on enthalpy and entropy changes of martensitic transformations in binary NiTi shape memory alloys. J Alloys Compd. 2009;487:363–6. https://doi.org/10.1016/j.jallcom.2009.07.135.

Acar E, Çalışkan M, Karaca HE. Differential scanning calorimetry response of aged NiTiHfPd shape memory alloys. Appl Phys A. 2019;125:239. https://doi.org/10.1007/s00339-019-2543-7.

He XM, Rong LJ, Yan DS, Li YY. Temperature memory effect of Ni47Ti44Nb9 wide hysteresis shape memory alloy. Scr Mater. 2005;53:1411–5. https://doi.org/10.1016/j.scriptamat.2005.08.022.

Acknowledgements

This research was supported by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brazil (CAPES)—Finance Code 001. The authors also acknowledge the Laboratory of Rapid Solidification (LSR/UFPB) for the general facilities.

Funding

General financial support was received from CAPES. There was no interference with study design and data analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that there are no known conflicts of interest associated with this publication and there has been no significant financial support for this work that could have influenced its outcome.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Silva, D.D.S., Guedes, N.G., Oliveira, D.F. et al. Effects of long-term thermal cycling on martensitic transformation temperatures and thermodynamic parameters of polycrystalline CuAlBeCr shape memory alloy. J Therm Anal Calorim 147, 7875–7881 (2022). https://doi.org/10.1007/s10973-021-11106-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-11106-5