Abstract

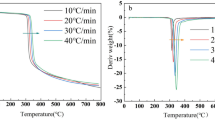

Pyrolysis technology plays an increasingly important role in treating waste circuit boards, recycling metals in circuit boards, and recycling non-metallic components such as resins and glass fibers. However, the pyrolysis mechanism of printed circuit board (PCB) without any electronic components and with a small amount of copper foil is not comprehensive at present. The pyrolysis characteristics and pyrolysis mechanism were studied under different particle size conditions and different heating rates. The study found that the pyrolysis of waste printed circuit board (PCB) resin powder can be divided into four stages: evaporation of residual water on the surface or dissipation of other small molecules, oxidation of side chain groups of epoxy resin, decomposition of tetrabromobisphenol A and decomposition of pyrolysis residues. Kissinger, Flynn–Wall–Ozawa (FWO), Tang and other methods were used to solve the kinetic parameters of thermal decomposition reaction of samples, and it was found that the activation energy and pre-exponential factor of large particles (0.5–0.9 mm) are lower than those of small particles (< 0.5 mm). In addition, the experimental curve determined by z(α) master plots method mainly accords with Mampel power model (P3): \(G\left( \alpha \right) = \alpha^{\frac{1}{2}}\), and random nucleation and subsequent growth model (Avrami-Erofeev A2): \(G\left( \alpha \right) = \left[ { - \ln \left( {1 - \alpha } \right)} \right]^{\frac{1}{2}}\) in the main pyrolysis interval.

Similar content being viewed by others

References

Kumar A, Holuszko ME, Janke T. Characterization of the non-metal fraction of the processed waste printed circuit boards. Waste Manage. 2018;75:94–102.

Premur V, Anić Vučinić A, Vujević D, Bedeković G. The possibility for environmental friendly recycling of printed circuit boards. J Sustain Dev Energy Water Environ Syst. 2016;4:14–22. https://doi.org/10.13044/j.sdewes.2016.04.0002.

Gao Z, Li JZ, Zhang HC. Printed circuit board recycling: a state of art survey. IEEE Trans Electron Packag Manuf. 2004;27:33–42.

Richter H, Lorenz W, Bahadir M. Examination of organic and inorganic xenobiotics in equipped printed circuits. Chemosphere. 1997;35(1):169–79.

Alia L, Abdur R, Anjum KS, Gao XB, ehana S, Javed A. Geochemical modeling, fate distribution, and risk exposure of potentially toxic metals in the surface sediment of the Shyok suture zone, northern Pakistan. Int J Sedim Res. 2021;36(5):656–67.

Hera N, Pieter M, Amir K, Mohd A, Mansoor AS, Simon TA, Faheem A. New insights on the utilization of ultrasonicated mustard seed cake:chemical composition and antagonistic potential for root-knot nematode, Meloidogyne javanica. J Zhejiang Univ Sci B (Biomed Biotechnol). 2021;22(7):563–74.

El-Sikaily A, Helal M. Environmental pollution and diabetes mellitus. World J Meta-Anal. 2021;9(03):234–56.

Timothy IM, Emily S, Sonali S, Vladan N, Robert LB, Stacy B. Brain reward circuitry: the overlapping neurobiology of trauma and substance use disorders. World J Psychiatry. 2021;11(06):222–31.

Quan C, Li AM, Luan JD, Gao NB. Study on the pyrolysis features and the kinetic analysis of the printed circuit board wastes. J Saf Environ. 2008;08(5):55–8. https://doi.org/10.3969/j.issn.1009-6094.2008.05.015.

Zhang YF, Hao B, Guo XJ, Wei LL. Thermogravimetric analysis and kinetic models on pyrolysis of waste printed circuit boards. J Combust Sci Technol. 2008;14(6):506–10. https://doi.org/10.3321/j.issn:1006-8740.2008.06.006.

Evangelopoulos P, Kantarelis E, Yang WH. Investigation of the thermal decomposition of printed circuit boards (PCBs) via thermo-gravimetric analysis (TGA) and analytical pyrolysis (Py–GC/MS). J Anal Appl Pyrol. 2015;115:337–43.

Hung-Lung C, Kuo-Hsiung L, Mei-Hsiu L, Ting-Chien C, Sen-Yi M. Pyrolysis characteristics of integrated circuit boards at various particle sizes and temperatures. J Hazard Mater. 2007;149(1):151–9.

Yao ZT, Xiong JJ, Yu SQ, Su WP, Wu WH, Tang JH. Kinetic study on the slow pyrolysis of nonmetal fraction of waste printed circuit boards (NMF-WPCBs). Waste Manag Res. 2020;38(8):903–10. https://doi.org/10.1177/0734242X19896630.

Gao RT, Zhan L, Guo J, Xu ZM. Research of the thermal decomposition mechanism and pyrolysis pathways from macromonomer to small molecule of waste printed circuit board. J Hazard Mater. 2020;383:121234.1-121234.9. https://doi.org/10.1016/j.jhazmat.2019.121234.

Salimnezhad A, Soltani-Jigheh H, Soorki AA. Effects of oil contamination and bioremediation on geotechnical properties of highly plastic clayey soil. J Rock Mech Geotech Eng. 2021;13(3):653–70.

Perovi A, Stankovi MZ, Veljkovi VB, Kosti MD, Stamenkovi OS. A further study of the kinetics and optimization of the essential oil hydrodistillation from lavender flowers. Chin J Chem Eng. 2021;29(1):126–30.

He MC, Wang NN, Long XJ, Zhang CJ, Ma CL, Zhong QY, Wang AH, Wang Y, Aneesa P, Shan J. Antimony speciation in the environment: Recent advances in understanding the biogeochemical processes and ecological effects. J Environ Sci. 2019;75(01):14–39.

Fang WZ, Li P, Liu YJ, Wang F, Xu Z, Gao C. A review on graphene oxide two-dimensional macromolecules: from single molecules to macro-assembly. Chin J Polym Sci. 2021;39(03):267–308.

Fernández-Rodríguez J, Erdocia X, Sánchez C, Alriols MG, Labidi J. Lignin depolymerization for phenolic monomers production by sustainable processes. J Energy Chem. 2017;26(04):622–31. https://doi.org/10.1016/j.jechem.2017.02.007.

Maschio G, Koufopanos C, Lucchesi A. Pyrolysis, a promising route for biomass utilization. Elsevier. 1992;42(3):219–31.

Zhang SZ, Wei Y. Pyrolysis characteristics of printed circuit boards based on particles size and temperature rise rate. Chin Soc Environ Sci. 2015;2015:7.

Hu RZ, Shi QZ. Thermal analysis kinetics. Beijing: Science Press; 2001. p. 113–5.

Qiu ZY, Liu C, Fulvio Z. Kinetic theory of geodesic acoustic modes in toroidal plasmas: a brief review. Plasma Sci Technol. 2018;20(09):28–53.

Huang Z, Feng BB, Zhang XR, Lv L, Jiang TQ, Zhao LY, Wang K. Introduction of Thermal Decomposition Kinetic Analysis and Calculation Models. China Printing Packag Study. 2014;6(6):4–17. https://doi.org/10.3969/j.issn.1674-5752.2014.06.002.

Li YF, Duan LB, Cheng L, Yang Y, Li YC, Cheng Y, Song DM. Thermal analysis and crystallization kinetics of polyurethane. J Therm Anal Calorim. 2019;135(5):2843–8. https://doi.org/10.1007/s10973-018-7594-z.

Xie YB. Research on pyrolysis kinetics and products analysis of waste circuit boards. J Environ Eng Technol. 2020;10(2):303–9. https://doi.org/10.12153/j.issn.1674-991X.20190099.

Gao RT, Liu BY, Lu Z, Guo J, Zhang J, Xu ZM. Catalytic effect and mechanism of coexisting copper on conversion of organics during pyrolysis of waste printed circuit boards. J Hazard Mater. 2020;403:123465.

Lu Y, Song QM, Xu ZM. Integrated technology for recovering Au from waste memory module by chlorination process: Selective leaching, extraction, and distillation. J Clean Prod. 2017;161:30–9. https://doi.org/10.1016/j.jclepro.2017.05.033.

Hu X, Gholizadeh M. Biomass pyrolysis: a review of the process development and challenges from initial researches up to the commercialisation stage. J Energy Chem. 2019;39(12):109–43.

Peng WL, Liu QY, Hu GY, Liu Y, Zhu DY, Meng QQ, Guo FT, Wang RL. Mechanisms of carbon isotopic fractionation in the process of natural gas generation: Geochemical evidence from thermal simulation experiment. Pet Explor Dev. 2020;47(05):1042–54.

Tang WJ, Liu YW, Zhang H, Wang CX. New approximate formula for Arrhenius temperature integral. Thermochim Acta. 2003;408(1):39–43.

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N. ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520(1):1–19. https://doi.org/10.1016/j.tca.2011.03.034.

Vyazovkin S, Wight CA. Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data. Thermochim Acta. 1999;340:53–68.

Opfermann JR, Kaisersberger E, Flammersheim HJ. Model-free analysis of thermoanalytical data-advantages and limitations. Thermochim Acta. 2002;391(1):119–27.

Starink MJ. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta. 2003;404(1):163–76.

Zhang SZ, Wei Y. Pyrolysis characteristics of printed circuit boards based on particle size and temperature rise rate. Chin Soc Environ Sci. 2025;2015:7.

Senum GI, Yang RT. Rational approximations of the integral of the Arrhenius function. J Therm Anal. 1977;11(3):445–7.

Yi HH, Yang ZY, Tang XL, Zhao SZ, Gao FY. Variations of apparent activation energy based on thermodynamics analysis of zeolitic imidazolate frameworks including pyrolysis and combustion. Energy. 2018;151:782–98. https://doi.org/10.1016/j.energy.2018.03.107.

Acknowledgements

We acknowledge supports from the Anhui Province Major Scientific and Technological Research Projects (201903a07020019) and the Anhui Province "115" Innovation Industry Team (13th batch).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, D., Ding, G., Chi, W. et al. Research on the pyrolysis kinetics of resin powder on waste printed circuit board with different particle sizes at different heating rates: inspiration for the pyrolysis mechanism. J Therm Anal Calorim 147, 8047–8059 (2022). https://doi.org/10.1007/s10973-021-11102-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-11102-9