Abstract

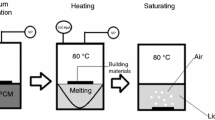

The pristine attapulgite (Atta) was pretreated by thermal and acid activation process in order to improve the loading capacity of phase change material (PCM). A series of pretreated Atta-based composite PCM was prepared combined with different kind of fatty acids. The XRD, FT-IR and XRF results shown that the pretreated process increased the purity of Atta as well as the SEM micrographs and BET results indicated that the porosity of Atta slightly increased after pretreating. What`s more, XRD and FT-IR results of the composites PCMs shown good chemical compatibility. DSC results indicated that the composite PCMs of AH-Atta/Lauric acid (LA), AH-Atta/Palmitic acid (SA) and AH-Atta/Docosanoic acid (DA) melted at 42.8 °C, 1.4 °C and 75.2 °C with the latent heat of 94.6 J g−1, 107.5 J g−1 and 84.6 J g−1 at the maximum loading of 51.0%, 50.8% and 51.3%, respectively. In addition, TGA results and 200 thermal cycles test results proved the good thermal stability and reliability of the samples. Based all above results, the prepared composite PCMs have good potential application in energy conservation buildings at different function temperature.

Similar content being viewed by others

References

Chu S, Majumdar A. Opportunities and challenges for a sustainable energy future. Nature. 2012;488:294–303.

Aftab W, Huang X, Wu W, Liang Z, Mahmood A, Zou R. Nanoconfined phase change materials for thermal energy applications. Energy Environ Sci. 2018;11:1392–424.

Qiu J, Fan X, Shi Y, Zhang S, Jin X, Wang W, Tang B. PEG/3D graphene oxide network form-stable phase change materials with ultrahigh filling content. J Mater Chem A. 2019;7:21371–7.

He M, Yang L, Lin W, Chen J, Mao X, Ma Z. Preparation, thermal characterization and examination of phase change materials (PCMs) enhanced by carbon-based nanoparticles for solar thermal energy storage. J Energy Storage. 2019;25:100874.

Ye R, Lin W, Fang X, Zhang Z. A numerical study of building integrated with CaCl2 ·6H2O/expanded graphite composite phase change material. Appl Therm Eng. 2017;126:480–8.

Li TX, Wu DL, He F, Wang RZ. Experimental investigation on copper foam/hydrated salt composite phase change material for thermal energy storage. Int J Heat Mass Transf. 2017;115:148–57.

Xu T, Li Y, Chen J, Liu J. Preparation and thermal energy storage properties of LiNO3–KCl–NaNO3/expanded graphite composite phase change material. Sol Energy Mater Sol Cells. 2017;169:215–21.

Zhang Q, Liu J. Sebacic acid/CNT sponge phase change material with excellent thermal conductivity and photo-thermal performance. Sol Energy Mater Sol Cells. 2018;179:217–22.

Yang J, Jia Y, Bing N, Wang L, Xie H, Yu W. Reduced graphene oxide and zirconium carbide co-modified melamine sponge/paraffin wax composites as new form-stable phase change materials for photothermal energy conversion and storage. Appl Therm Eng. 2019;163:114412.

Guo X, Huang Y, Cao J. Performance of a thermal energy storage composite by incorporating diatomite stabilized paraffin as phase change material. Energy Build. 2018;158:1257–65.

Wen R, Liu Y, Yang C, Zhu X, Huang Z, Zhang X, Gao W. Enhanced thermal properties of stearic acid/carbonized maize straw composite phase change material for thermal energy storage in buildings. J Energy Storage. 2021;36:102420.

Zhang Q, Luo Z, Guo Q, Wu G. Preparation and thermal properties of short carbon fibers/erythritol phase change materials. Energy Convers Manage. 2017;136:220–8.

Min X, Fang M, Huang Z, Liu Y, Huang Y, Wen R, Qian T, Wu X. Enhanced thermal properties of novel shape-stabilized PEG composite phase change materials with radial mesoporous silica sphere for thermal energy storage. Sci Rep. 2015;5:12964.

Shen Q, Ouyang J, Zhang Y, Yang H. Lauric acid/modified sepiolite composite as a form-stable phase change material for thermal energy storage. Appl Clay Sci. 2017;146:14–22.

Wen R, Zhang X, Huang Z, Fang M, Liu Y, Wu X, Min X, Gao W, Huang S. Preparation and thermal properties of fatty acid/diatomite form-stable composite phase change material for thermal energy storage. Sol Energy Mater Sol Cells. 2018;178:273–9.

Qian T, Li J, Min X, Deng Y, Guan W, Ning L. Diatomite: a promising natural candidate as carrier material for low, middle and high temperature phase change material. Energy Convers Manag. 2015;98:34–45.

Han J, Liu S. Myristic acid-hybridized diatomite composite as a shape-stabilized phase change material for thermal energy storage. RSC Adv. 2017;7:22170–7.

Xu B, Ma H, Lu Z, Li Z. Paraffin/expanded vermiculite composite phase change material as aggregate for developing lightweight thermal energy storage cement-based composites. Appl Energy. 2015;160:358–67.

Jiesheng L, Yuanyuan Y, Xiang H. Research on the preparation and properties of lauric acid/expanded perlite phase change materials. Energy Build. 2016;110:108–11.

Yi H, Zhan W, Zhao Y, Zhang X, Jia F, Wang W, Ai Z, Song S. Design of MtNS/SA microencapsulated phase change materials for enhancement of thermal energy storage performances: effect of shell thickness. Sol Energy Mater Sol Cells. 2019;200:109935.

Song S, Dong L, Zhang Y, Chen S, Li Q, Guo Y, Deng S, Si S, Xiong C. Lauric acid/intercalated kaolinite as form-stable phase change material for thermal energy storage. Energy. 2014;76:385–9.

Li C, Fu L, Ouyang J, Tang A, Yang H. Kaolinite stabilized paraffin composite phase change materials for thermal energy storage. Appl Clay Sci. 2015;115:212–20.

Gu XB, Liu P, Bian L, He HC. Enhanced thermal conductivity of palmitic acid/mullite phase change composite with graphite powder for thermal energy storage. Renew Energy. 2019;138:833–41.

Cui M, Mu P, Shen Y, Zhu G, Luo L, Li J. Three-dimensional attapulgite with sandwich-like architecture used for multifunctional water remediation. Sep Purif Technol. 2020;235:116210.

Wang Y, Feng Y, Jiang J, Yao J. Designing of recyclable attapulgite for wastewater treatments: a review. ACS Sustain Chem Eng. 2018;7:1855–69.

Liu W, Wang D, Soomro RA, Fu F, Qiao N, Yu Y, Wang R, Xu B. Ceramic supported attapulgite-graphene oxide composite membrane for efficient removal of heavy metal contamination. J Membr Sci. 2019;591:117323.

Liang W, Wang R, Wang C, Jia J, Sun H, Zhang J, Yang Y, Zhu Z, Li A. Facile preparation of attapulgite-based aerogels with excellent flame retardancy and better thermal insulation properties. J Appl Polym Sci. 2019;136:47849.

Li M, Wu Z, Kao H. Study on preparation, structure and thermal energy storage property of capric–palmitic acid/attapulgite composite phase change materials. Appl Energy. 2011;88:3125–32.

Liang WD, Chen PS, Sun HX, Zhu ZQ, Li A. Innovative spongy attapulgite loaded with n-carboxylic acids as composite phase change materials for thermal energy storage. RSC Adv. 2014;4:38535–41.

Song S, Dong L, Chen S, Xie H, Xiong C. Stearic–capric acid eutectic/activated-attapulgiate composite as form-stable phase change material for thermal energy storage. Energy Convers Manag. 2014;81:306–11.

Bu X, Zhang G, Guo Y. Thermal modified palygorskite: Preparation, characterization, and application for cationic dye-containing wastewater purification. Desalin Water Treat. 2011;30:339–47.

Yang D, Peng F, Zhang H, Guo H, Xiong L, Wang C, Shi S, Chen X. Preparation of palygorskite paraffin nanocomposite suitable for thermal energy storage. Appl Clay Sci. 2016;126:190–6.

Nassir Taha D, SadiSamaka I. Natural Iraqi palygorskite clay as low cost adsorbent for the treatment of dye containing industrial wastewater. J Oleo Sci. 2012;61:729–36.

Sarı A, Bicer A, Karaipekli A, Al-Sulaiman FA. Preparation, characterization and thermal regulation performance of cement based-composite phase change material. Sol Energy Mater Sol Cells. 2018;174:523–9.

Lee J, Wi S, Yun BY, Yang S, Park JH, Kim S. Development and evaluation of gypsum/shape-stabilization phase change materials using large-capacity vacuum impregnator for thermal energy storage. Appl Energy. 2019;241:278–90.

Zhao Y, Min X, Huang Z, Liu YG, Wu X, Fang M. Honeycomb-like structured biological porous carbon encapsulating PEG: a shape-stable phase change material with enhanced thermal conductivity for thermal energy storage. Energy Build. 2018;158:1049–62.

Yang Z, Deng Y, Li J. Preparation of porous carbonized woods impregnated with lauric acid as shape-stable composite phase change materials. Appl Therm Eng. 2019;150:967–76.

Tao S, Wei S. Study on preparation and thermal performance tests of attapulgite-based phase change composites for energy storage. Acta Materiae Compositae Sinica. 2009;26:143–7.

Liu S, Yang H. Stearic acid hybridizing coal–series kaolin composite phase change material for thermal energy storage. Appl Clay Sci. 2014;101:277–81.

Xu B, Li Z. Paraffin/diatomite composite phase change material incorporated cement-based composite for thermal energy storage. Appl Energy. 2013;105:229–37.

Li M, Wu ZS, Kao HT. Study on preparation, structure and thermal energy storage property of capric-palmitic acid/attapulgite composite phase change materials. Appl Energy. 2011;88:3125–32.

Li M, Wu Z, Kao H, Tan J. Experimental investigation of preparation and thermal performances of paraffin/bentonite composite phase change material. Energy Convers Manag. 2011;52:3275–81.

Acknowledgements

This work is financially supported by the National Key Research and Development Program of China (2018YFC1901500).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wen, R., Xu, Y., Xu, Y. et al. Attapulgite: a promising natural mineral as carrier material for fatty acids phase change material. J Therm Anal Calorim 147, 7203–7212 (2022). https://doi.org/10.1007/s10973-021-11046-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-11046-0