Abstract

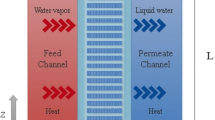

Local parameter evaluation needs so much computing effort and reduces the fastness of code capability. Hence, in this paper a comparison of local and averaged of various model parameters is made in order of finding which parameters could be replaced by averaged value with negligible effect on performance evaluation of a direct contact membrane distillation (DCMD) for solar desalination purposes. In this regard, a one-dimensional model of a DCMD is introduced in which all fluid and membrane properties are evaluated locally as well as temperature-dependent. Then each parameter is replaced by the mean value and the accuracy of developed model is compared by experimental data. Results show that it is possible to alternatively implement mean value without noticeably accuracy loss. In addition, because the experimental data are in laboratory scale a large-scale simulation is also done. A comparison of results shows that for large-scale simulation, it is also possible to use average value parameters instead of local evaluations while the speed of simulation increases significantly and no noticeably accuracy loss occurs.

Similar content being viewed by others

Abbreviations

- A:

-

Cross-sectional area [m2]

- AD:

-

Average deviation

- B:

-

Mass flux coefficient of membrane [kg m−2 Pa−1 s−1]

- D:

-

Diffusion coefficient of water [m2 s−1]

- H:

-

Specific enthalpy [J kg−1], height and thickness [m]

- \(h_{t}\) :

-

Convective heat transfer coefficient [W m−2 K−1]

- J:

-

Vapor flux [kg m−2 s−1]

- K:

-

Membrane/vapor thermal conductivity [W m−1 K−1]

- L:

-

Channel length [m]

- M :

-

Molecular mass [kg mol−1]

- \(\dot{m}\) :

-

Channel mass flow rate [kg s−1]

- P:

-

pressure [Pa]

- Q :

-

Flow rate [lit min−1]

- \(q_{\rm m}\) :

-

Membrane heat flux [W m−2]

- R:

-

Gas constant [J K−1 mol−1]

- r:

-

Membrane [μm] pore size

- s:

-

Salinity [ppm]

- T:

-

Temperature [°C]

- \(z^{*}\) :

-

Non-dimensional axial position

- \(\delta\) :

-

Thickness of membrane [\(\upmu{\rm m}\)]

- \(\varepsilon\) :

-

Channel aspect ratio

- \(\in\) :

-

Porosity of membrane

- \(\lambda\) :

-

Water conductivity [W m−1 K−1]

- \(\mu\) :

-

Water viscosity [Pa s]

- \(\tau\) :

-

Tortuosity of membrane

- a:

-

Air

- ave:

-

Average

- b:

-

Bulk

- f:

-

Feed

- in:

-

Inlet

- m:

-

Membrane

- p:

-

Permeate

- s:

-

Solid

- sw:

-

Seawater

- v:

-

Vapor

- w:

-

Water

References

Kiss AA, Kattan Readi OM. An industrial perspective on membrane distillation processes. J Chem Technol Biotechnol. 2018;93(8):2047–55.

Hausmann A, et al. Performance assessment of membrane distillation for skim milk and whey processing. J Dairy Sci. 2014;97(1):56–71.

Al-Obaidani S, et al. Potential of membrane distillation in seawater desalination: thermal efficiency, sensitivity study and cost estimation. J Membr Sci. 2008;323(1):85–98.

Saffarini RB, Summers EK, Arafat HA. Technical evaluation of stand-alone solar powered membrane distillation systems. Desalination. 2012;286:332–41.

Hausmann A, et al. Integration of membrane distillation into heat paths of industrial processes. Chem Eng J. 2012;211:378–87.

Walton J, et al. Solar and waste heat desalination by membrane distillation. Desalin Water Purif Res Develop Prog Rep. 2004;81:20.

Mericq J-P, Laborie S, Cabassud C. Vacuum membrane distillation of seawater reverse osmosis brines. Water Res. 2010;44(18):5260–73.

Ji X, et al. Membrane distillation-crystallization of seawater reverse osmosis brines. Sep Purif Technol. 2010;71(1):76–82.

Drioli E, et al. Integrated membrane operations in desalination processes. Desalination. 1999;122(2–3):141–5.

Wu HY, Wang R, Field RW. Direct contact membrane distillation: An experimental and analytical investigation of the effect of membrane thickness upon transmembrane flux. J Membr Sci. 2014;470:257–65.

Alkhudhiri A, Darwish N, Hilal N. Membrane distillation: a comprehensive review. Desalination. 2012;287:2–18.

Khayet M. Membranes and theoretical modeling of membrane distillation: a review. Adv Coll Interface Sci. 2011;164(1–2):56–88.

Ali A, et al. Optimization of module length for continuous direct contact membrane distillation process. Chem Eng Process. 2016;110:188–200.

Ali A, et al. Designing and optimization of continuous direct contact membrane distillation process. Desalination. 2018;426:97–107.

Khalifa A, et al. Experimental and theoretical investigations on water desalination using direct contact membrane distillation. Desalination. 2017;404:22–34.

Manawi YM, et al. A predictive model for the assessment of the temperature polarization effect in direct contact membrane distillation desalination of high salinity feed. Desalination. 2014;341:38–49.

Schofield R, et al. Factors affecting flux in membrane distillation. Desalination. 1990;77:279–94.

Abu Al-Rub FA, Banat F, Beni-Melhim K. Parametric sensitivity analysis of direct contact membrane distillation. Separation Sci Technol. 2002;37(14):3245–71.

Bahmanyar A, Asghari M, Khoobi N. Numerical simulation and theoretical study on simultaneously effects of operating parameters in direct contact membrane distillation. Chem Eng Process. 2012;61:42–50.

Bouchrit R, et al. Direct contact membrane distillation: Capability to treat hyper-saline solution. Desalination. 2015;376:117–29.

Lee J-G, et al. Performance modeling of direct contact membrane distillation (DCMD) seawater desalination process using a commercial composite membrane. J Membr Sci. 2015;478:85–95.

Hayer H, Bakhtiari O, Mohammadi T. Simulation of momentum, heat and mass transfer in direct contact membrane distillation: a computational fluid dynamics approach. J Ind Eng Chem. 2015;21:1379–82.

Hwang HJ, et al. Direct contact membrane distillation (DCMD): experimental study on the commercial PTFE membrane and modeling. J Membr Sci. 2011;371(1–2):90–8.

Rezakazemi M. CFD simulation of seawater purification using direct contact membrane desalination (DCMD) system. Desalination. 2018;443:323–32.

El Kadi K, Janajreh I, Hashaikeh R. Numerical simulation and evaluation of spacer-filled direct contact membrane distillation module. Appl Water Sci. 2020;10(7):1–17.

Al-Turki YA, et al. Flat sheet direct contact membrane distillation desalination system using temperature-dependent correlations: thermal efficiency via a multi-parameter sensitivity analysis based on Monte Carlo method. J Therm Anal Calorimetry. 2021;144(6):2641–52.

Curcio E, Drioli E. Membrane distillation and related operations—a review. Sep Purif Rev. 2005;34(1):35–86.

Summers EK, Arafat HA. Energy efficiency comparison of single-stage membrane distillation (MD) desalination cycles in different configurations. Desalination. 2012;290:54–66.

Hitsov I, et al. Modelling approaches in membrane distillation: a critical review. Sep Purif Technol. 2015;142:48–64.

Khayet M, Velázquez A, Mengual JI. Modelling mass transport through a porous partition: effect of pore size distribution. J Non-Equilib Thermodyn. 2004;29(3):279–99.

Rao G, Hiibel SR, Childress AE. Simplified flux prediction in direct-contact membrane distillation using a membrane structural parameter. Desalination. 2014;351:151–62.

Lawson KW, Lloyd DR. Membrane distillation. J Membr Sci. 1997;124(1):1–25.

Khayet M, Godino M, Mengual J. Modelling transport mechanism through a porous partition. J Non-Equilib Thermodyn. 2001;26(1):1–14.

Phattaranawik J, Jiraratananon R. Direct contact membrane distillation: effect of mass transfer on heat transfer. J Membr Sci. 2001;188(1):137–43.

Muzychka Y, Yovanovich M. Laminar forced convection heat transfer in the combined entry region of non-circular ducts. J Heat Transfer. 2004;126(1):54–61.

Sharqawy MH, Lienhard JH, Zubair SM. Thermophysical properties of seawater: a review of existing correlations and data. Desalin Water Treat. 2010;16(1–3):354–80.

Nayar KG, Sharqawy MH, Banchik LD. Thermophysical properties of seawater: a review and new correlations that include pressure dependence. Desalination. 2016;390:1–24.

Jamieson D, et al. Physical properties of sea water solutions: heat capacity. Desalination. 1969;7(1):23–30.

Martı́nez-Dı́ez L, Vazquez-Gonzalez MI. Temperature and concentration polarization in membrane distillation of aqueous salt solutions. J Membr Sci. 1999;156(2):265–73.

Abdulrazzaq T, Togun H, Goodarzi M, Kazi S, Ariffin M, Adam N, Hooman K. Turbulent heat transfer and nanofluid flow in an annular cylinder with sudden reduction. J Therm Anal Calorimetry. 2020;141(1):373–85.

Ahmadi MH, Mohseni-Gharyehsafa B, Ghazvini M, Goodarzi M, Jilte RD, Kumar R. Comparing various machine learning approaches in modeling the dynamic viscosity of CuO/water nanofluid. J Therm Anal Calorim. 2020;139(4):2585–99.

Bahiraei M, Jamshidmofid M, Goodarzi M. Efficacy of a hybrid nanofluid in a new microchannel heat sink equipped with both secondary channels and ribs. J Mol Liq. 2019;273:88–98. https://doi.org/10.1016/j.molliq.2018.10.003.

Bahmani MH, Sheikhzadeh G, Zarringhalam M, Akbari OA, Alrashed AA, Shabani GAS, Goodarzi M. Investigation of turbulent heat transfer and nanofluid flow in a double pipe heat exchanger. Adv Powder Technol. 2018;29(2):273–82. https://doi.org/10.1016/j.apt.2017.11.013.

Giwa S, Sharifpur M, Goodarzi M, Alsulami H, Meyer J. Influence of base luid, temperature, and concentration on the thermophysical properties of hybrid nanoluids of alumina–ferroluid: experimental data, modeling through enhanced ANN, ANFIS, and curve itting. J Therm Anal Calorim. 2021;143:4149–67.

Homod RZ, Almusaed A, Almssad A, Jaafar MK, Goodarzi M, Sahari KS. Effect of different building envelope materials on thermal comfort and air-conditioning energy savings: a case study in Basra city. Iraq, J Energy Storage. 2021;34:101975.

Bagherzadeh SA, Jalali E, Sarafraz MM, Akbari OA, Karimipour A, Goodarzi M, Bach Q-V. Effects of magnetic field on micro cross jet injection of dispersed nanoparticles in a microchannel. Int J Numer Meth Heat Fluid Flow. 2020;30(5):2683–704. https://doi.org/10.1108/HFF-02-2019-0150.

Bagherzadeh SA, D’Orazio A, Karimipour A, Goodarzi M, Bach QV. A novel sensitivity analysis model of EANN for F-MWCNTs–Fe3O4/EG nanofluid thermal conductivity: outputs predicted analytically instead of numerically to more accuracy and less costs. Physica A: Statist Mech Appl. 2019;521:406–15. https://doi.org/10.1016/j.physa.2019.01.048.

Mat MNH, Asmuin NZ, Basir MFM, Abbas T, Kasihmuddin MSM, Goodarzi M. Influence of nozzle area ratio on the gas-particle low for single-hose dry ice blasting nozzle. J Therm Anal Calorim. 2020 (in Press).

Mat MNH, Asmuin NZ, Basir MFM, Goodarzi M, Abd Rahman MF, Khairulfuaad R, Jabbar BA, Kasihmuddin MSM. Influence of divergent length on the gas-particle flow in dual hose dry ice blasting nozzle geometry. Powder Technol. 2020;364:152–8.

Mat MNH, Asmuin NZ, Basir MFM, Goodarzi M, Hasan NH. Effect of impact force for dual-hose dry blasting nozzle geometry for various pressure and distance: an experimental work. Eur Phys J Plus. 2020;135(2):1–11.

Pordanjani AH, Aghakhani S, Karimipour A, Afrand M, Goodarzi M. Investigation of free convection heat transfer and entropy generation of nanofluid flow inside a cavity affected by magnetic field and thermal radiation. J Therm Anal Calorim. 2019;137(3):997–1019.

Safaei MR, Ranjbarzadeh R, Hajizadeh A, Bahiraei M, Afrand M, Karimipour A. Effects of cobalt ferrite coated with silica nanocomposite on the thermal conductivity of an antifreeze: new nanofluid for refrigeration condensers. Int J Refrig. 2019;102:86–95.

Sarafraz MM, Goodarzi M, Tlili I, Alkanhal TA, Arjomandi M. Thermodynamic potential of a high-concentration hybrid photovoltaic/thermal plant for co-production of steam and electricity. J Therm Anal Calorim. 2021;143:1389–98.

Sarafraz MM, Tian Z, Tlili I, Kazi S, Goodarzi M. Thermal evaluation of a heat pipe working with n-pentane-acetone and n-pentane-methanol binary mixtures. J Therm Anal Calorim. 2020;139(4):2435–45.

Ranjbarzadeh R, Karimipour A, Afrand M, Isfahani AHM, Shirneshan A. Empirical analysis of heat transfer and friction factor of water/graphene oxide nanofluid flow in turbulent regime through an isothermal pipe. Appl Therm Eng. 2017;126:538–47.

Ranjbarzadeh R, Isfahani AM, Afrand M, Karimipour A, Hojaji M. An experimental study on heat transfer and pressure drop of water/graphene oxide nanofluid in a copper tube under air cross-flow: applicable as a heat exchanger. Appl Therm Eng. 2017;125:69–79.

Alsarraf J, Shahsavar A, Khaki M, Ranjbarzadeh R, Karimipour A, Afrand M. Numerical investigation on the effect of four constant temperature pipes on natural cooling of electronic heat sink by nanofluids: a multifunctional optimization. Adv Powder Technol. 2020;31(1):416–32.

Jiang Y, Sulgani MT, Ranjbarzadeh R, Karimipour A, Nguyen TK. Hybrid GMDH-type neural network to predict fluid surface tension, shear stress, dynamic viscosity & sensitivity analysis based on empirical data of iron (II) oxide nanoparticles in light crude oil mixture. Physica A: Statist Mech Appl. 2019;526:120948.

Nguyen Q, Naghieh A, Kalbasi R, Akbari M, Karimipour A, Tlili I. Efficacy of incorporating PCMs into the commercial wall on the energy-saving annual thermal analysis. J Therm Anal Calorim. 2021;143(3):2179–87.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aldabesh, A. A comparison between average and local thermal evaluations to improve the performance of a direct contact membrane distillation for the solar desalination purposes. J Therm Anal Calorim 147, 7459–7470 (2022). https://doi.org/10.1007/s10973-021-10988-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10988-9