Abstract

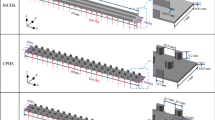

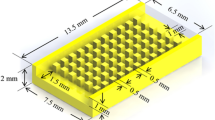

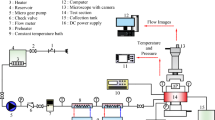

The electronic devices are facing the challenge of high heat flux. To improve the thermal and hydraulic performance of micro heat sinks with ribbed pin-fins and single heating input, the geometrical parameters, including shapes, arrangements, width and height, are numerically investigated. The results show that the micro heat sinks with arc ribbed pin-fins exhibit the best comprehensive performance comparing with triangle and rectangle ribbed pin-fins. Meanwhile, even for the single heating input, the staggered ribs arrangement exhibits better comprehensive performance than that of the in-line ribs arrangement the same Reynolds number. Moreover, the average Nu number increases first and then decreases with the increase in the rib width. At Re = 1342, the average Nusselt number of Dp/D0 = 1/2 can reach up 44.3, which is 1.8 times of Dp/D0 = 3/2. Increasing the Hp/H0 plays a positive effect on improving thermal performance but with higher pressure loss. At higher Hp/H0, increasing Hp/H0 does not show obvious effect on reduction total thermal resistance under the same pump power. To better balance the thermal resistance and pressure drop, the value of Dp/D0 and Hp/H0 should be chosen properly.

Similar content being viewed by others

References

He Z, Yan Y, Zhang Z. Thermal management and temperature uniformity enhancement of electronic devices by micro heat sinks: a review. Energy. 2021. https://doi.org/10.1016/j.energy.2020.119223.

He Z, Yan Y, Feng S, Yang Z, Zhang L, Zhang Z. Multi-objective optimizations on thermal and hydraulic performance of symmetric and asymmetric bionic Y-shaped fractal networks by genetic algorithm coupled with CFD simulation. Int Commun Heat Mass Transf. 2021. https://doi.org/10.1016/j.icheatmasstransfer.2021.105261.

Yan Y, Yan H, Yin S, Zhang L, Li L. Single/multi-objective optimizations on hydraulic and thermal management in micro-channel heat sink with bionic Y-shaped fractal network by genetic algorithm coupled with numerical simulation. Int J Heat Mass Transf. 2019. https://doi.org/10.1016/j.ijheatmasstransfer.2018.09.120.

Tuckerman D, Pease R. High-performance heat sinking for VLSI. IEEE Electr Dev Lett. 1981. https://doi.org/10.1109/EDL.1981.25367.

Bahiraei M, Heshmatian S. Electronics cooling with nanofluids: a critical review. Energy Convers Manag. 2018. https://doi.org/10.1016/j.enconman.2018.07.047.

Zhang Z, Cai J, Chen F, Li H, Zhang W, Qi W. Progress in enhancement of CO2 absorption by nanofluids: a mini review of mechanisms and current status. Renew Energy. 2018. https://doi.org/10.1016/j.renene.2017.11.031.

Junankar AA, Parate SR, Dethe PK, Dhote NR, Gadkar DG, Gadkar DD, Gajbhiye SA. A review: enhancement of turning process performance by effective utilization of hybrid nanofluid and MQL. Mater Today Proc. 2020. https://doi.org/10.1016/j.matpr.2020.05.603.

Ellahi R, Hassan M, Zeeshan A, Khan AA. The shape effects of nanoparticles suspended in HFE-7100 over wedge with entropy generation and mixed convection. Appl Nanosci. 2016;6:641–51. https://doi.org/10.1007/s13204-015-0481-z.

Feng S, Yan Y, Li H, He Z, Zhang L. Temperature uniformity enhancement and flow characteristics of embedded gradient distribution micro pin fin arrays using dielectric coolant for direct intra-chip cooling. Int J Heat Mass Transf. 2020. https://doi.org/10.1016/j.ijheatmasstransfer.2020.120235.

Promvonge P, Chompookham T, Kwankaomeng S, Thianpong C. Enhanced heat transfer in a triangular ribbed channel with longitudinal vortex generators. Energy Convers Manag. 2010. https://doi.org/10.1016/j.enconman.2009.12.035.

Awais M, Bhuiyan AA. Enhancement of thermal and hydraulic performance of compact finned-tube heat exchanger using vortex generators (VGs): a parametric study. Int J Therm Sci. 2019. https://doi.org/10.1016/j.ijthermalsci.2019.02.041.

Amini Y, Akhavan S, Izadpanah E. A numerical investigation on the heat transfer characteristics of nanofluid flow in a three-dimensional microchannel with harmonic rotating vortex generators. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08402-6.

Dezan DJ, Yanagihara JI, Jenovencio G, Salviano LO. Parametric investigation of heat transfer enhancement and pressure loss in louvered fins with longitudinal vortex generators. Int J Therm Sci. 2019. https://doi.org/10.1016/j.ijthermalsci.2018.09.039.

Raihan MFB, Al-Asadi MT, Thompson HM. Management of conjugate heat transfer using various arrangements of cylindrical vortex generators in micro-channels. Appl Therm Eng. 2021. https://doi.org/10.1016/j.applthermaleng.2020.116097.

Lorenzini D, Green C, Sarvey TE, Zhang X, Hu Y, Fedorov AG, Bakir MS, Joshi Y. Embedded single phase microfluidic thermal management for non-uniform heating and hotspots using microgaps with variable pin fin clustering. Int J Heat Mass Transf. 2016. https://doi.org/10.1016/j.ijheatmasstransfer.2016.08.040.

Feng S, Yan Y, Li H, Yang Z, Li L, Zhang L. Theoretical and numerical investigation of embedded microfluidic thermal management using gradient distribution micro pin fin arrays. Appl Therm Eng. 2019;153:748–60. https://doi.org/10.1016/j.applthermaleng.2019.03.017.

He Z, Yan Y, Xu F, Yang Z, Cui H, Wu Z, et al. Combustion characteristics and thermal enhancement of premixed hydrogen/air in micro combustor with pin fin arrays. Int J Hydrog Energy. 2020. https://doi.org/10.1016/j.ijhydene.2019.12.093.

He Y, Liu L, Li P, Ma L. Experimental study on heat transfer enhancement characteristics of tube with cross hollow twisted tape inserts. Appl Therm Eng. 2018. https://doi.org/10.1016/j.applthermaleng.2017.12.029.

Li P, Liu Z, Liu W, Chen G. Numerical study on heat transfer enhancement characteristics of tube inserted with centrally hollow narrow twisted tapes. Int J Heat Mass Transf. 2015. https://doi.org/10.1016/j.ijheatmasstransfer.2015.04.103.

Razavi SE, Osanloo B, Sajedi R. Application of splitter plate on the modification of hydro-thermal behavior of PPFHS. Appl Therm Eng. 2015. https://doi.org/10.1016/j.applthermaleng.2015.01.046.

Sajedi R, Osanloo B, Talati F, Taghilou M. Splitter plate application on the circular and square pin fin heat sinks. Microelectron Reliab. 2016;62:91–101. https://doi.org/10.1016/j.microrel.2016.03.026.

Ghachem K, Aich W, Kolsi L. Computational analysis of hybrid nanofluid enhanced heat transfer in cross flow micro heat exchanger with rectangular wavy channels. Case Stud Therm Eng. 2021. https://doi.org/10.1016/j.csite.2020.100822.

Chiam ZL, Lee PS, Singh PK, Mou N. Investigation of fluid flow and heat transfer in wavy micro-channels with alternating secondary branches. Int J Heat Mass Transf. 2016. https://doi.org/10.1016/j.ijheatmasstransfer.2016.05.097.

Chen M, Wang Y, Liu Z. Experimental study on micro-encapsulated phase change material slurry flowing in straight and wavy microchannels. Appl Therm Eng. 2021. https://doi.org/10.1016/j.applthermaleng.2021.116841.

Wan W, Deng D, Huang Q, Zeng T, Huang Y. Experimental study and optimization of pin fin shapes in flow boiling of micro pin fin heat sinks. Appl Therm Eng. 2017. https://doi.org/10.1016/j.applthermaleng.2016.11.182.

Li Y, Gong L, Xu M, Joshi Y. Hydraulic and thermal performances of metal foam and pin fin hybrid heat sink. Appl Therm Eng. 2020. https://doi.org/10.1016/j.applthermaleng.2019.114665.

Woodcock C, Ng’oma C, Sweet M, Wang Y, Peles Y, Plawsky J. Ultra-high heat flux dissipation with Piranha Pin Fins. Int J Heat Mass Transfer. 2019. https://doi.org/10.1016/j.ijheatmasstransfer.2018.09.030.

Zhang Y, Dembla A, Bakir MS. Silicon micropin-fin heat sink with integrated TSVs for 3-D ICs: tradeoff analysis and experimental testing. IEEE T Compon Pack Man. 2013. https://doi.org/10.1109/TCPMT.2013.2267492.

Lee S, Schroder DK, Inc BS, Beaverton OR. 3D IC architecture for high density memories. IEEE Int Memory Workshop. https://doi.org/10.1109/IMW.2010.5488391.

Sidik NAC, Muhamad MNAW, Japar WMAA, Rasid ZA. An overview of passive techniques for heat transfer augmentation in microchannel heat sink. Int Commun Heat Mass Transf. 2017. https://doi.org/10.1016/j.icheatmasstransfer.2017.08.009.

Mohammed HA, Gunnasegaran P, Shuaib NH. Numerical simulation of heat transfer enhancement in wavy microchannel heat sink. Int Commun Heat Mass Transf. 2011. https://doi.org/10.1016/j.icheatmasstransfer.2010.09.012.

Zhao J, Huang S, Gong L, Huang Z. Numerical study and optimizing on micro square pin-fin heat sink for electronic cooling. Appl Therm Eng. 2016. https://doi.org/10.1016/j.applthermaleng.2015.08.105.

Keshavarz F, Mirabdolah Lavasani A, Bayat H. Numerical analysis of effect of nanofluid and fin distribution density on thermal and hydraulic performance of a heat sink with drop-shaped micropin fins. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7711-z.

Marschewski J, Brechbühler R, Jung S, Ruch P, Michel B, Poulikakos D. Significant heat transfer enhancement in microchannels with herringbone-inspired microstructures. Int J Heat Mass Transf. 2016. https://doi.org/10.1016/j.ijheatmasstransfer.2015.12.039.

Yan Y, Yan H, Feng S, Li LX. Thermal-hydraulic performances and synergy effect between heat and flow distribution in a truncated doubled-layered heat sink with Y-shaped fractal network. Int J Heat Mass Transf. 2019. https://doi.org/10.1016/j.ijheatmasstransfer.2019.06.093.

Chiu H, Hsieh R, Wang K, Jang J, Yu C. The heat transfer characteristics of liquid cooling heat sink with micro pin fins. Int Commun Heat Mass Transf. 2017. https://doi.org/10.1016/j.icheatmasstransfer.2017.05.027.

Yang D, Wang Y, Ding G, Jin Z, Zhao J, Wang G. Numerical and experimental analysis of cooling performance of single-phase array microchannel heat sinks with different pin-fin configurations. Appl Therm Eng. 2017. https://doi.org/10.1016/j.applthermaleng.2016.08.211.

Wang W, Zhang Y, Li Y, Han H, Li B. Multi-objective optimization of turbulent heat transfer flow in novel outward helically corrugated tubes. Appl Therm Eng. 2018. https://doi.org/10.1016/j.applthermaleng.2017.12.080.

Wang G, Qi C, Liu M, Li C, Yan Y, Liang L. Effect of corrugation pitch on thermo-hydraulic performance of nanofluids in corrugated tubes of heat exchanger system based on exergy efficiency. Energy Convers Manag. 2019. https://doi.org/10.1016/j.enconman.2019.02.046.

Yang C, Chen M-R, Qian J-Y, Zan W, Jin Z-J, Sunden B. Heat transfer study of a hybrid smooth and spirally corrugated tube. Heat Transf Eng. 2019. https://doi.org/10.1080/01457632.2019.1699292.

Wang W, Zhang Y, Li Y, Han H, Li B. Numerical study on fully-developed turbulent flow and heat transfer in inward corrugated tubes with double-objective optimization. Int J Heat Mass Transf. 2018. https://doi.org/10.1016/j.ijheatmasstransfer.2017.12.079.

He Z, Yan Y, Feng S, Li X, Yang Z. Numerical study of thermal enhancement in a micro-heat sink with ribbed pin-fin arrays. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09739-z.

Ansari D, Kim K-Y. Hotspot thermal management using a microchannel-pinfin hybrid heat sink. Int J Therm Sci. 2018. https://doi.org/10.1016/j.ijthermalsci.2018.07.043.

Klank H, Goranovic G, Kutter JP, Gjelstrup H, Michelsen J, Westergaard CH. PIV measurements in a microfluidic 3D-sheathing structure with three-dimensional flow behaviour. J Micromech Microeng. 2002. https://doi.org/10.1088/0960-1317/12/6/318.

Kumar V, Paraschivoiu M, Nigam KDP. Single-phase fluid flow and mixing in microchannels. Chem Eng Sci. 2011. https://doi.org/10.1016/j.ces.2010.08.016.

Falsetti C, Magnini M, Thome JR. Hydrodynamic and thermal analysis of a micro-pin fin evaporator for on-chip two-phase cooling of high density power micro-electronics. Appl Therm Eng. 2018. https://doi.org/10.1016/j.applthermaleng.2017.10.117.

Khan WA, Culham JR, Yovanovich MM. Optimization of pin-fin heat sinks using entropy generation minimization. IEEE Trans Compon Packag Technol. 2005. https://doi.org/10.1109/TCAPT.2005.848507.

Chai L, Xia GD, Wang HS. Parametric study on thermal and hydraulic characteristics of laminar flow in microchannel heat sink with fan-shaped ribs on sidewalls—part 3: performance evaluation. Int J Heat Mass Transf. 2016. https://doi.org/10.1016/j.ijheatmasstransfer.2016.02.075.

Gong L, Zhao J, Huang S. Numerical study on layout of micro-channel heat sink for thermal management of electronic devices. Appl Therm Eng. 2015. https://doi.org/10.1016/j.applthermaleng.2014.09.048.

Li YF, Xia GD, Ma DD, Jia YT, Wang J. Characteristics of laminar flow and heat transfer in microchannel heat sink with triangular cavities and rectangular ribs. Int J Heat Mass Transf. 2016. https://doi.org/10.1016/j.ijheatmasstransfer.2016.03.022.

Acknowledgements

The authors gratefully acknowledge financial support from Joint Fund of the National Natural Science Foundation of China and China Aerospace Science and Technology Corporation on Advanced Manufacturing Technology for Aerospace Industry (U1737113), Graduate Research and Innovation Foundation of Chongqing (CYB20019), Fundamental Research Funds for the Central Universities (2019CDYGYB022) and Natural Science Foundation of Chongqing (cstc2019jcyj-msxmX0223).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare they have no financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

He, Z., Yan, Y. & Zhang, L. Thermal-hydraulic investigation on micro heat sinks with ribbed pin-fin arrays and single heating input: parametrical study. J Therm Anal Calorim 147, 6489–6505 (2022). https://doi.org/10.1007/s10973-021-10977-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10977-y