Abstract

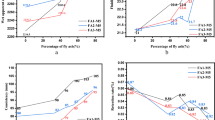

Random stacking of waste foundry sand will cause great environmental pollution, so it is necessary to recycle the waste foundry sand produced by resin-bonded sand technology by hot-reclamation to eliminate the residual resin on its surface. The study of thermodynamics analysis of resin binder for casting in combustion decomposition process can provide theoretical support for thermal reclamation. In this paper, TG–DTA technology was applied to measure TG, TGA, DTG curves of the three kinds of resin binders at 0–800 °C (furan resin binder, phenolic urethane resin binder and alkaline phenolic resin binder). The ignition point, reaction peak temperature, activation energy, mode function and other parameters of the three resin binders were calculated by the curves, and conclusions are as follows: (1) Furan resin binder, phenolic urethane resin binder and alkaline phenolic resin binder were heated to 800 °C in air at a heating rate of 15 °C min−1, and their residual mass was 9.8%, 2.7% and 33.7%, respectively; (2) the highest activation energy of furan resin binder, phenolic urethane resin binder and alkaline phenolic resin binder was 82.35 kJ mol−1, 90.77 kJ mol−1 and 335.77 kJ mol−1, respectively; (3) the reaction mode of three resin binders in each stage is Acceleratory α-time(n = 1), f(α) = α, G(α) = lnα.

Similar content being viewed by others

References

Anonymous. Casting production. Mod Cast. 2018;2019(109):23–4.

Peng W, Yuancai L, Hongjiang L, et al. Development of a new instrument for measurement of high temperature mechanical properties of resin-bonded sand. China Foundry. 2017;14(4):286–91.

Peng W, Yuancai L, Long Z, et al. Research on testing method of resin-bonded sand high temperature compressive strength. China Foundry. 2016;13(5):335–41.

Deng A, Tikalsky PJ. Geotechnical and leaching properties of flowable fill incorporating waste foundry sand. Waste Manage. 2008;28(11):2161–70.

Bastian KC, Alleman JE. Microtox characterization of foundry sand residuals. Waste Manage. 1998;18(4):227–34.

Mastella MA, Gislon ES, Pelisser F, et al. Mechanical and toxicological evaluation of concrete artifacts containing waste foundry sand. Waste Manage. 2014;34(8):1495–500.

China foundry association.T/CFA 0310021–2019 Specification conditions for foundry enterprise. 2004 (in Chinese)

Manoharan T, Laksmanan D, Mylsamy K, et al. Engineering properties of concrete with partial utilization of used foundry sand. Waste Manage. 2017;71:454–60.

Lu Y, Shi G, Chen X, Bai L. Conventional sintered brick comprises foundry waste, binder, and reinforcing agent, where the foundry waste is composed of sand treated ash, waste black sand and electric furnace ash: CN109942279 - A. 2019 (in Chinese)

Oberleitne R. Fluidised bed for thermal regeneration of used foundry sand - has synthetic resin binder removed by heat and uses regenerated sand heat to warm used sand entering the bed: DE4012158-A. 1990

Dai W; Luo G; Zhu Y. Reclaiming method for cast waste sand hot plasmas: CN105328115A. 2016 (in Chinese)

Severo JA, Modolo RC, Espinosa MCAM, et al. Thermal regeneration of waste foundry phenolic sand in a lab scale fluidized bed. Matéria (Rio de Janeiro). 2018;23(1):1–14.

Fan ZT, Liu FC, Long W, et al. A new low-cost method of reclaiming mixed foundry waste sand based on wet-thermal composite reclamation. China Foundry. 2014;11(5):402–7.

Holtzer M, Rafał D, Kmita A. Influence of a reclaimed sand addition to moulding sand with furan resin on its impact on the environment. Water Air Soil Pollut. 2016;227(1):16.

Łucarz M, Drożyński D. Influence of the reclamation method of spent moulding sands on the possibility of creating favourable conditions for gases flow in a mould. Archives of Metallurgy and Materials. 2017;62(1):359–64.

Svidró JT, Diószegi A, Svidró J, Ferenczi T. The effect of different binder levels on the heat absorption capacity of moulding mixtures made by the phenolic urethane cold-box process. J Therm Anal Calorim. 2017;130(3):1769.

Svidró JT, Diószegi A, Svidró J, Ferenczi T. Thermophysical aspects of reclaimed moulding sand addition to the epoxy-SO2 coremaking system studied by Fourier thermal analysis. J Therm Anal Calorim. 2017;130:1779–89.

Lucarz M. Method of selecting the reclamation temperature of spent moulding sands with organic binders. Archives of Foundry Engineering. 2018;18(1):65–70.

Łucarz M, Grabowska B, Grabowski G. Determination of parameters of the moulding sand reclamation process, on the thermal analysis bases. Arch Metall Mater. 2014;59(3):1023–7.

Artur B. Studies on thermal decomposition of phenol binder using TG/DTG/DTA and Ftir-Drifts techniques in temperature range 20–500 °C. China Foundry. 2018;15(2):145–51.

Zhang G, Wu H, Peng Z, et al. TG/DTA and XRD study on structure and chemical transformation of the Cs–P–W oxides. J Therm Anal Calorim. 2017;128(2):947–56.

Pouretedal HR, Damiri S, Ravanbod M, et al. The kinetic of thermal decomposition of PETN, pentastite and pentolite by TG/DTA non-isothermal methods. J Therm Anal Calorim. 2017;129(1):521–9.

Mahzoun Y, Oshita K, Takaoka M, et al. Prediction of ignition loss and heating value of sewage sludge by thermo gravimetry and differential thermal analysis (TG-DTA). J Jpn Soc Civ Eng Ser G. 2017;73(7):375–84.

Ravishankar S, Balu AR, Balamurugan S, et al. TG–DTA analysis, structural, optical and magnetic properties of PbS thin films doped with Co2+ ions. J Mater Sci Mater Electron. 2018;29(7):6051–8.

Ptáček P, Kubátová D, Havlica J, et al. Isothermal kinetic analysis of the thermal decomposition of kaolinite: the thermogravimetric study. Thermochim Acta. 2010;501(1):24–9.

Wu D, Zhang W, Fu B, Hu G. Chemical structure and gas products of different rank coals during pyrolysis. J Therm Anal Calorim. 2018;136(5):2017–31.

Slezak R, Krzystek L, Ledakowicz S. CO2 gasification of char from spent mushroom substrate in TG-MS system. J Therm Anal Calorim. 2019;140(5):2337–45.

Zhao B, Jin J, Li S, Liu D, Zhang R, Yang H. Co-pyrolysis characteristics of sludge mixed with Zhundong coal and sulphur contaminant release regularity. J Therm Anal Calorim. 2019;138(2):1623–32.

Xiao Y, Song G, Lyu Q. Experimental study on the effect of pyrolysis temperature on the NO emission and conversion during combustion. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-10093-3.

Janković B, Manić N, Stojiljković D. The gaseous products characterization of the pyrolysis process of various agricultural residues using TGA–DSC–MS techniques. J Therm Anal Calorim. 2019;139(5):3091–106.

Zhang H, Xian S, Zhu Z, Guo X. Release behaviors of sulfur-containing pollutants during combustion and gasification of coals by TG-MS. Journal of Thermal Analysis and Calorimetry. 2020(ahead-of-print)

Fan F, Yang Z, Xing X. Study on the pyrolysis properties of corn straw by TG–FTIR and TG–GC/MS. J Therm Anal Calorim. 2020;143:3783–91.

Wang C, Li L, Chen R, Ma X, Lu M, Ma W, et al. Thermal conversion of tobacco stem into gaseous products. J Therm Anal Calorim. 2019;137(3):811–23.

Vyazovkin S, Burnham AK, Criado JM, et al. ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520(1):1–19.

Yang RT, Steinberg M. Reaction kinetics and differential thermal analysis. J Phys Chem. 1976;80(9):965–8.

Chen J, Liu J, He Y, Huang L, Sun S, Sun J, Chang K, Kuo J, Huang S, Ning X. Investigation of co-combustion characteristics of sewage sludge and coffee grounds mixtures using thermogravimetric analysis coupled to artificial neural networks modeling. Bioresour Technol. 2017;225:234–45.

Fernandez-Lopez M, Pedrosa-Castro GJ, Valverde JL, Sanchez-Silva L. Kinetic analysis of manure pyrolysis and combustion processes. Waste Manage. 2016;58:230–40.

Ozawa T. Kinetics of non-isothermal crystallization. Polymer. 1971;12(3):150–8.

Sun G, Zhang G, Liu J, et al. Thermogravimetric and mass-spectrometric analyses of combustion of spent potlining under N2/O2 and CO2/O2 atmospheres. Waste Manage. 2019;87:237–49.

Cai Z, Ma X, Fang S, Yu Z, Lin Y. Thermogravimetric analysis of the cocombustion of eucalyptus residues and paper mill sludge. Appl Therm Eng. 2016;106:938–43.

Starink MJ. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta. 2003;404(1):163–76.

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci Polym Symp. 1964;6(1):183–95.

Wan P, Zhou J, Li Y, Yin Y, Huang D, Xiaoyuan J, Shen Xu. Experimental Study on Gas Evolution Process of Binders in Foundry Industry based on TG-MS. Proc Manufact. 2019;37:311–8.

Bin Peng. Research of reducing the content of carbon monoxide in the mainstream smoke of cigarette. Jiangnan University. 2005 (in Chinese)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51775205).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wan, P., Zhou, J., Li, Y. et al. Kinetic analysis of resin binder for casting in combustion decomposition process. J Therm Anal Calorim 147, 6323–6336 (2022). https://doi.org/10.1007/s10973-021-10902-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10902-3