Abstract

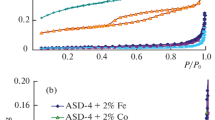

Scalable synthesis of aluminum fumarate (Al_FA) metal organic framework (MOF) in aqueous medium and the effect of drying on the crystallinity, apparent activation energy and thermal lifetime are presented. The oven dried (Al_FA_A) at 100 °C (760 mmHg) for 3 h is characterized by Fourier transform infrared spectrophotometer, differential scanning calorimeter, thermogravimetric analyzer, X-ray diffractometer, particle size analyzer, scanning electron microscope (SEM-EDAX) and Brunauer–Emmett–Teller (BET) analysis. The BET surface area, micropore volume (Vpore) and mean pore diameter of Al_FA_A are 937 m2 g−1, 0.38 cm3 g−1 and 1.6 nm, respectively. The Al_FA_A MOF is thermally stable up to 400 °C when compared to aluminum fumarate dried in vacuum oven at 100 °C (25 mmHg) for 3 h (Al_FA_C) which is stable only up to 350 °C. The thermal degradation kinetics for Al_FA_A and Al_FA_C are reported for the first time using model-free approach. For the reaction extent α = 0.2–0.4, a progressive increase in the apparent activation energy for thermal degradation (Ea–D) for Al_FA_A is noted and found to be 205–220 kJ mol−1 and is constant after α = 0.4. The material Al_FA_C shows Ea–D from 160 to 173 kJ mol−1 for α values from 0.2 to 0.7. The difference in the Ea–D values between these materials is attributed to the structural changes and change in the crystalline nature of MOFs. During thermal degradation of Al_FA MOFs, gases like CO, CO2, H2O, CH2=CH2 and CH≡CH are evolved.

Graphic abstract

Similar content being viewed by others

References

Christoph Kiener UM, Schubert M. Metal Organic Frameworks based on aluminium fumarate, the preparation thereof, shaped bodies comprising such frameworks and uses therefor. 2013.

Liu Y-Y, Leus K, Grzywa M, Weinberger D, Strubbe K, Vrielinck H, et al. Synthesis, structural characterization, and catalytic performance of a vanadium-based Metal-Organic Framework (COMOC-3). Eur J Inorg Chem. 2012;16:2819–27. https://doi.org/10.1002/ejic.201101099.

Kaskel S. The chemistry of metal–organic frameworks, synthesis, characterization and applications. Weinheim: Wiley-VCH Verlag GmbH & Co. KGaA; 2016.

Rowsell JLC, Yaghi OM. Metal–organic frameworks: a new class of porous materials. Microporous Mesoporous Mater. 2004;73(1–2):3–14. https://doi.org/10.1016/j.micromeso.2004.03.034.

Martin-Dominguez V, Estevez J, Ojembarrena F, Santos V, Ladero M. Fumaric acid production: a biorefinery perspective. Fermentation. 2018;4(2):33. https://doi.org/10.3390/fermentation4020033.

Jiang HL, Feng D, Liu TF, Li JR, Zhou HC. Pore surface engineering with controlled loadings of functional groups via click chemistry in highly stable metal-organic frameworks. J Am Chem Soc. 2012;134(36):14690–3. https://doi.org/10.1021/ja3063919.

Li H, Wang K, Sun Y, Lollar CT, Li J, Zhou H-C. Recent advances in gas storage and separation using metal–organic frameworks. Mater Today. 2018;21(2):108–21. https://doi.org/10.1016/j.mattod.2017.07.006.

Sarawade P, Tan H, Polshettiwar V. Shape- and morphology-controlled sustainable synthesis of Cu Co, and in metal organic frameworks with high CO2 capture capacity. ACS Sustain Chem Eng. 2012;1(1):66–74. https://doi.org/10.1021/sc300036p.

Makhseed S, Samuel J. Hydrogen adsorption in microporous organic framework polymer. Chem Commun (Camb). 2008;36:4342–4. https://doi.org/10.1039/b805656k.

Rowsell JL, Yaghi OM. Strategies for hydrogen storage in metal–organic frameworks. Angew Chem Int Ed Engl. 2005;44(30):4670–9. https://doi.org/10.1002/anie.200462786.

Abanades Lazaro I, Abanades Lazaro S, Forgan RS. Enhancing anticancer cytotoxicity through bimodal drug delivery from ultrasmall Zr MOF nanoparticles. Chem Commun (Camb). 2018;54(22):2792–5. https://doi.org/10.1039/c7cc09739e.

Chowdhury MA. Metal–organic-frameworks for biomedical applications in drug delivery, and as MRI contrast agents. J Biomed Mater Res A. 2017;105(4):1184–94. https://doi.org/10.1002/jbm.a.35995.

Hoskins BF, Robson R. Design and construction of a new class of scaffolding-like materials comprising infinite polymeric frameworks of 3D-linked molecular rods. A reappraisal of the zinc cyanide and cadmium cyanide structures and the synthesis and structure of the diamond-related frameworks [N(CH3)4][CuIZnII(CN)4] and CuI[4,4’,4’’,4’’’-tetracyanotetraphenylmethane]BF4.xC6H5NO2. J Am Chem Soc. 2002;112(4):1546–54. https://doi.org/10.1021/ja00160a038.

Henschel A, Gedrich K, Kraehnert R, Kaskel S. Catalytic properties of MIL-101. Chem Commun (Camb). 2008;35:4192–4. https://doi.org/10.1039/b718371b.

Horcajada P, Surble S, Serre C, Hong DY, Seo YK, Chang JS, et al. Synthesis and catalytic properties of MIL-100(Fe), an iron(III) carboxylate with large pores. Chem Commun (Camb). 2007;27:2820–2. https://doi.org/10.1039/b704325b.

Liu TF, Feng D, Chen YP, Zou L, Bosch M, Yuan S, et al. Topology-guided design and syntheses of highly stable mesoporous porphyrinic zirconium metal–organic frameworks with high surface area. J Am Chem Soc. 2015;137(1):413–9. https://doi.org/10.1021/ja5111317.

Herbst A, Khutia A, Janiak C. Bronsted instead of Lewis acidity in functionalized MIL-101Cr MOFs for efficient heterogeneous (nano-MOF) catalysis in the condensation reaction of aldehydes with alcohols. Inorg Chem. 2014;53(14):7319–33. https://doi.org/10.1021/ic5006456.

Jiang J, Gandara F, Zhang YB, Na K, Yaghi OM, Klemperer WG. Superacidity in sulfated metal–organic framework-808. J Am Chem Soc. 2014;136(37):12844–7. https://doi.org/10.1021/ja507119n.

Yuan S, Feng L, Wang K, Pang J, Bosch M, Lollar C, et al. Stable metal–organic frameworks: stable metal-organic frameworks: design, synthesis, and applications (Adv. Mater. 37/2018). Adv Mater. 2018;30:37. https://doi.org/10.1002/adma.201870277.

Dhakshinamoorthy A, Asiri AM, Garcia H. Metal–Organic Framework (MOF) compounds: photocatalysts for redox reactions and solar fuel production. Angew Chem Int Ed Engl. 2016;55(18):5414–45. https://doi.org/10.1002/anie.201505581.

Li H, Yang Y, He C, Zeng L, Duan C. Mixed-ligand Metal–Organic Framework for two-photon responsive photocatalytic C–N and C–C coupling reactions. ACS Catal. 2018;9(1):422–30. https://doi.org/10.1021/acscatal.8b03537.

Qin JS, Yuan S, Lollar C, Pang J, Alsalme A, Zhou HC. Stable metal–organic frameworks as a host platform for catalysis and biomimetics. Chem Commun (Camb). 2018;54(34):4231–49. https://doi.org/10.1039/c7cc09173g.

Lu XF, Liao PQ, Wang JW, Wu JX, Chen XW, He CT, et al. An Alkaline-stable, metal hydroxide mimicking Metal–Organic Framework for efficient electrocatalytic oxygen evolution. J Am Chem Soc. 2016;138(27):8336–9. https://doi.org/10.1021/jacs.6b03125.

Logvinenko V, Sapianik A, Pishchur D, Fedin V. Thermal decomposition of inclusion compounds and metal–organic frameworks on the basis of heterometallic complex [Li2Zn2(bpdc)3]. J Therm Anal Calorim. 2019;138(6):4453–61. https://doi.org/10.1007/s10973-019-08173-0.

Logvinenko V, Zavakhina M, Bolotov V, Pishchur D, Dybtsev D. Some basic correlations in the thermal (kinetic) stability of inclusion compounds on the basis of microporous metal–organic frameworks. J Therm Anal Calorim. 2017;130(1):335–42. https://doi.org/10.1007/s10973-017-6317-1.

Logvinenko VA, Sapchenko SA, Fedin VP. Thermal decomposition of inclusion compounds on the base of the metal–organic framework [Zn4(dmf)(ur)2(ndc)4]. J Therm Anal Calorim. 2014;117(2):747–53. https://doi.org/10.1007/s10973-014-3827-y.

Haque MA, Chaudhary RG, Paliwal LJ. Synthesis, structural, morphological, and thermal decomposition kinetics of Iron(II) coordination polymer of sebacoyl bis (isonicotinoylhydrazone). Inorg Chim Acta. 2017;462:298–307. https://doi.org/10.1016/j.ica.2017.03.042.

Bagade R, Sonkusare V, Potbhare AK, Gomaji Chaudhary R, Husain R, Juneja HD. Fabrication of microflower-shaped mesoporous Fe(II) chelate polymer for photocatalytic performance under visible light. Mater Today Proc. 2019;15:566–74. https://doi.org/10.1016/j.matpr.2019.04.122.

Bagade R, Chaudhary RG, Potbhare A, Mondal A, Desimone M, Dadure K, et al. Microspheres/custard-apples copper(II) chelate polymer: characterization, docking, antioxidant antibacterial assay. ChemistrySelect. 2019;4(20):6233–44. https://doi.org/10.1002/slct.201901115.

Siva Kaylasa Sundari S, Shamim Rishwana S, Dhanalakshmi J, Ramani R, Vijayakumar CT. Nanoporous Metal Organic Frameworks: effect of thermal history on crystallinity and thermal stability. Chapter No. 15, Multidisciplinary Science and Advanced Technologies. Nova Science Publishers. 2021; ISBN: 978-1-5-53618-959-9.

Chughtai AH, Ahmad N, Younus HA, Laypkov A, Verpoort F. Metal–organic frameworks: versatile heterogeneous catalysts for efficient catalytic organic transformations. Chem Soc Rev. 2015;44(19):6804–49. https://doi.org/10.1039/c4cs00395k.

Lee J, Farha OK, Roberts J, Scheidt KA, Nguyen ST, Hupp JT. Metal–organic framework materials as catalysts. Chem Soc Rev. 2009;38(5):1450–9. https://doi.org/10.1039/b807080f.

Asgari A, Ghani K, Keshavarz MH, Mousaviazar A, Khajavian R. Ammonium nitrate-MOF-199: a new approach for phase stabilization of ammonium nitrate. Thermochim Acta. 2018;667:148–52. https://doi.org/10.1016/j.tca.2018.07.018.

Domán A, Madarász J, László K. In situ evolved gas analysis assisted thermogravimetric (TG-FTIR and TG/DTA–MS) studies on non-activated copper benzene-1,3,5-tricarboxylate. Thermochim Acta. 2017;647:62–9. https://doi.org/10.1016/j.tca.2016.11.013.

Kleist W, Maciejewski M, Baiker A. MOF-5 based mixed-linker metal–organic frameworks: synthesis, thermal stability and catalytic application. Thermochim Acta. 2010;499(1–2):71–8. https://doi.org/10.1016/j.tca.2009.11.004.

Łyszczek R. Synthesis, structure, thermal and luminescent behaviors of lanthanide—pyridine-3,5-dicarboxylate frameworks series. Thermochim Acta. 2010;509(1–2):120–7. https://doi.org/10.1016/j.tca.2010.06.010.

Jeremias F, Fröhlich D, Janiak C, Henninger SK. Advancement of sorption-based heat transformation by a metal coating of highly-stable, hydrophilic aluminium fumarate MOF. RSC Adv. 2014;4(46):24073–82. https://doi.org/10.1039/c4ra03794d.

Karmakar S, Dechnik J, Janiak C, De S. Aluminium fumarate metal–organic framework: a super adsorbent for fluoride from water. J Hazard Mater. 2016;303:10–20. https://doi.org/10.1016/j.jhazmat.2015.10.030.

Chaudhary RG, Juneja HD, Gharpure MP. Thermal degradation behaviour of some metal chelate polymer compounds with bis(bidentate) ligand by TG/DTG/DTA. J Therm Anal Calorim. 2012;112(2):637–47. https://doi.org/10.1007/s10973-012-2616-8.

Mani MR, Chellaswamy R, Marathe YN, Pillai VK. Enhanced nucleation of polypropylene by metal–organic frameworks (MOFs) based on aluminium dicarboxylates: influence of structural features. RSC Adv. 2016;6(3):1907–12. https://doi.org/10.1039/c5ra22764j.

Loiseau T, Serre C, Huguenard C, Fink G, Taulelle F, Henry M, et al. A rationale for the large breathing of the porous aluminum terephthalate (MIL-53) upon hydration. Chemistry. 2004;10(6):1373–82. https://doi.org/10.1002/chem.200305413.

Sánchez-Sánchez M, Getachew N, Díaz K, Díaz-García M, Chebude Y, Díaz I. Synthesis of metal–organic frameworks in water at room temperature: salts as linker sources. Green Chem. 2015;17(3):1500–9. https://doi.org/10.1039/c4gc01861c.

Alvarez E, Guillou N, Martineau C, Bueken B, Van de Voorde B, Le Guillouzer C, et al. The structure of the aluminum fumarate metal–organic framework A520. Angew Chem Int Ed Engl. 2015;54(12):3664–8. https://doi.org/10.1002/anie.201410459.

Teo HWB, Chakraborty A, Kayal S. Formic acid modulated (fam) aluminium fumarate MOF for improved isotherms and kinetics with water adsorption: cooling/heat pump applications. Microporous Mesoporous Mater. 2018;272:109–16. https://doi.org/10.1016/j.micromeso.2018.06.016.

Sonkusare VN, Chaudhary RG, Bhusari GS, Mondal A, Potbhare AK, Mishra RK, et al. Mesoporous octahedron-shaped tricobalt tetroxide nanoparticles for photocatalytic degradation of toxic dyes. ACS Omega. 2020;5(14):7823–35. https://doi.org/10.1021/acsomega.9b03998.

Kayal S, Chakraborty A, Teo HWB. Green synthesis and characterization of aluminium fumarate metal–organic framework for heat transformation applications. Mater Lett. 2018;221:165–7. https://doi.org/10.1016/j.matlet.2018.03.099.

Tan B, Luo Y, Liang X, Wang S, Gao X, Zhang Z, et al. In situ synthesis and performance of aluminum fumarate Metal–Organic Framework monolithic adsorbent for water adsorption. Ind Eng Chem Res. 2019;58(34):15712–20. https://doi.org/10.1021/acs.iecr.9b03172.

Chaudhary RG, Ali P, Gandhare NV, Tanna JA, Juneja HD. Thermal decomposition kinetics of some transition metal coordination polymers of fumaroyl bis (paramethoxyphenylcarbamide) using DTG/DTA techniques. Arab J Chem. 2019;12(7):1070–82. https://doi.org/10.1016/j.arabjc.2016.03.008.

Chaudhary RG, Juneja HD, Gandhare NV. Evaluation of kinetic parameters from TG/DTG data of chelate polymer compounds of isophthaoylbis(paramethoxyphenylcarbamide). J Chin Adv Mater Soc. 2013;1(4):305–16. https://doi.org/10.1080/22243682.2013.871210.

Vyazovkin S, Wight CA. Estimating realistic confidence intervals for the activation energy determined from thermoanalytical measurements. Anal Chem. 2000;72(14):3171–5. https://doi.org/10.1021/ac000210u.

Acknowledgements

The authors express their sincere thanks to the Management and Principal of Kamaraj College of Engineering and Technology (Autonomous), S.P.G.C. Nagar, K. Vellakulam-625701, Madurai, India for providing all of the facilities to do the work. One of the authors (SKS) thanks DEBEL-DRDO for the financial assistance in the form of Research Fellowship under CARS project. SKS would like to thank Prof. C. Sanjeeviraja and Arunjunai Mahendran for providing guidance in XRD analysis and TG-FTIR studies.

Funding

The fund was received from Defence Bio-Engineering and Electromedical Laboratory, ADE Campus, C.V. Raman Nagar, Bengaluru-560093, Karnataka, India.

Author information

Authors and Affiliations

Contributions

SKS contributed to methodology, writing—original draft preparation. Dr. SSR was involved in validation. Dr. TMK contributed to funding acquisition. Dr. RR was involved in validation and funding acquisition. Dr. RI was involved in funding acquisition. Dr. CTV contributed to supervision, writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or nonfinancial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sundari, S.S.K., Rishwana, S.S., Kotresh, T.M. et al. Effect of structural variation on the thermal degradation of nanoporous aluminum fumarate metal organic framework (MOF). J Therm Anal Calorim 147, 5067–5085 (2022). https://doi.org/10.1007/s10973-021-10899-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10899-9