Abstract

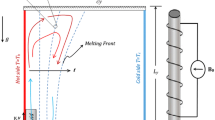

In the present study, the effects of a magnetic field on melting and solidification processes in an isosceles triangular cavity are numerically investigated, using a finite volume method along with an enthalpy-porosity technique. The magnetic field effects (magnitude and direction) on streamlines, isotherms, liquid fraction, and heat transfer are analyzed for Ra = 106 and a wide range of Hartmann number (0 ≤ Ha ≤ 100). As main outcomes, it is observed that contrary to the general trend, the strongest fluid flow stabilization is obtained when the magnetic field is directed parallel to the heated wall. When the magnetic field is horizontally and vertically oriented, the complete melting time is increased by 32.5% and 5.5%, respectively. It is found that the influence of the magnetic field is prominent and reaches a maximum value only during an intermediate stage of melting. Moreover, it is observed that the solidification process is not dependent on the magnetic field direction and magnitude. The complete time of melting at Ha = 100 is almost equal to the time of complete solidification.

Similar content being viewed by others

Abbreviations

- A mush :

-

Mushy zone constant (kg m−3 s−1)

- B :

-

Magnetic field strength (G)

- c p :

-

Specific heat capacity(J kg−1 K−1)

- f :

-

Liquid fraction (−)

- g :

-

Gravitational acceleration (m s−2)

- h :

-

Sensible enthalpy (J kg−1)

- H:

-

Enthalpy (J kg−1)

- Ha:

-

Hartmann number (−), \(Ha = \beta_{l} L\sqrt {\sigma_{l} /\mu_{l} }\)

- k :

-

Thermal conductivity (W m−1 K−1)

- L f :

-

Latent heat of fusion (J kg−1)

- Nu:

-

Nusselt number (−)

- P :

-

Pressure (Pa)

- Pr:

-

Prandtl number (−), \(\Pr = \mu_{l} C_{{\text{p}}} /k_{l}\)

- Ra:

-

Rayleigh number (−), \(Ra = g\rho_{l} \beta_{l} (T_{{\text{H}}} - T_{{\text{m}}} )L^{3} /\mu_{l} \alpha_{l}\)

- t :

-

Time (s)

- T :

-

Temperature (K)

- T m :

-

Melting temperature (K)

- x,y:

-

Cartesian coordinates (m)

- U,V:

-

Velocity components (m.s−1

- μ :

-

Viscosity (kg m−1 s−1)

- σ:

-

Electrical conductivity (A V m−1)

- α :

-

Thermal diffusivity (m2 s−1)

- β :

-

Thermal expansion coefficient (K−1)

- φ :

-

Magnetic field inclination (°)

- ρ :

-

Fluid density (kg m−3)

- μ :

-

Viscosity (kg.m−1 s−1

- C:

-

Cold

- H:

-

Hot

- l:

-

Liquid

- s:

-

Solid

References

Zhou D, Zhao CY, Tian Y. Review on thermal energy storage with phase change materials (PCMs) in building applications. Appl Energy. 2012;92:593–605.

Haddad Z, Iachachene F. Melting characteristics of organic phase change material in a wavy trapezoidal cavity. J Mol Liquids. 2019. https://doi.org/10.1016/j.molliq.2019.112132.

Iachachene F, Haddad Z, Oztop HF, Abu-Nada E. Melting of phase change materials in a trapezoidal cavity: orientation and nanoparticles effects. J Mol Liq. 2019;292:110592.

Ghalambaz M, Zadeh SMH, Mehryan S, Pop I, Wen D. Analysis of melting behavior of PCMs in a cavity subject to a non-uniform magnetic field using a moving grid technique. Appl Math Model. 2020;77:1936–53.

Selimefendigil F, Oztop HF, Chamkha AJ. Natural convection in a CuO–water nanofluid filled cavity under the effect of an inclined magnetic field and phase change material (PCM) attached to its vertical wall. J Therm Anal Calorim. 2019;135:1577–94. https://doi.org/10.1007/s10973-018-7714-9.

Arıcı M, Tütüncüa E, Yıldız Ç, Li D. Enhancement of PCM melting rate via internal fin and nanoparticles. Int J Heat Mass Transf. 2020;156:119845.

Ali FH, Hamzah HK, Egab K, Arıcı M, Shahsavar A. Non-Newtonian nanofluid natural convection in a U-shaped cavity under magnetic field. Int J Mech Sci. 2020;186:105887.

Hussain S, Mehmood K, Sagheer M, et al. Mixed convective magnetonanofluid flow over a backward facing step and entropy generation using extended Darcy–Brinkman–Forchheimer model. J Therm Anal Calorim. 2019;138:3183–203. https://doi.org/10.1007/s10973-019-08347-w.

Hussain S, Jamal M, Maatki C, Ghachem K, Kolsi L. MHD mixed convection of Al2O3–Cu–water hybrid nanofuid in a wavy channel with incorporated fxed cylinder. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-10260-6.

ShafqatMuhammad HJ, Pekmen GB. Impact of fins and inclined magnetic field in double lid-driven cavity with Cu-water nanofluid. In J Therm Sci. 2020. https://doi.org/10.1016/j.ijthermalsci.2020.106707.

Bouabdallah S, Bessaih R. Effect of magnetic field on 3D flow and heat transfer during solidification from a melt. Int J Heat Fluid Flow. 2012;37:154–66.

Xu B, Li BQ, Stock DE. An experimental study of thermally induced convection of molten gallium in magnetic fields. Int J Heat Mass Transfer. 2006;49:2009–19.

Feng Y, Li H, Li L, Zhan F. Investigation of the effect of magnetic field on melting of solid gallium in a bottom-heated rectangular cavity using the lattice Boltzmann method. Numer Heat Transf A. 2016;69:1263–79.

Bondareva NS, Sheremet MA. Natural convection heat transfer combined with melting process in a cubical cavity under the effects of uniform inclined magnetic field and local heat source. Int J Heat Mass Transfer. 2017;108:1057–67.

Krakov MS, Nikiforov IV. To the influence of uniform magnetic field on thermomagnetic convection in square cavity. J Magn Magn Mater. 2002;252:209–11.

Habib HA, Mohammadpourfard M, Zonouzi SA. Numerical investigation of the transient hydrothermal behavior of a ferrofluid flowing throug a helical duct in the presence of nonuniform magnetic field. J Heat Transfer. 2012;136:061702–13.

Sheikholeslami M, Gorji-Bandpy M, Ganji DD, Soleimani S. Effect of a magnetic field on natural convection in an inclined half-annulus enclosure filled with Cu-water nanofluid using CVFEM. Adv Powder Technol. 2013;24:980–91.

Purusothaman A, Oztop HF, Nithyadevi N, Abu-Hamdeh Nidal H. 3D natural convection in a cubical cavity with a thermally active heater under the presence of an external magnetic field. Comput Fluids. 2016;128:30–40.

Dibavar MR, Mohammadpourfardb M, Mohsenic F, Zeinali-Heris S. Numerical study on the effect of non-uniform magnetic fields on melting and solidification characteristics of NEPCMs in an annulus enclosure. Energy Convers Manag. 2018;171:879–89.

Ghalambaz M, Doostanidezfuli A, Zargartalebi H, Chamkha AJ. MHD phase change heat transfer in an inclined enclosure: effect of a magnetic field and cavity inclination. Numer Heat Transf Part A Appl. 2017;71:91–109.

Sheikholeslami M, Mahian O. Enhancement of PCM solidification using inorganic nanoparticles and an external magnetic field with application in energy storage systems. J Clean Prod. 2019;215:963–77.

Mehryan SAM, Tahmasebi A, Izadi M, Ghalambaz M. Melting behavior of phase change materials in the presence of a non-uniform magnetic-field due to two variable magnetic sources. Int J Heat Mass Transf. 2020;149:119184.

Renkun D, Yining W, Javad M, Linghong T, Min Z. Characteristics and control mechanism of melting process under extra magnetic force fields. Appl Therm Eng. 2019. https://doi.org/10.1016/j.applthermaleng.2019.114704.

Mahmoudi A. Analysis of the convective heat transfer characteristics in a two-dimensional cavity subjected to an external magnetic field. Chin J Phys. 2020. https://doi.org/10.1016/j.cjph.2020.10.019.

Ghalambaz M, Zadeh SM, Hashem-Mehryan SAM, Pop I, Wen D. Analysis of melting behavior of PCMs in a cavity subject to a line source magnetic field using a moving grid technique. Appl Math Model. 2019. https://doi.org/10.1016/j.apm.2019.09.015.

Laouer A, Arıcı M, Teggar M, Bouabdallah S, Yıldız Ç, Ismail KAR, Ajarostaghi SSM, Mezaache EH. Effect of magnetic field and nanoparticle concentration on melting of cu-ice in a rectangular cavity under fluctuating temperatures. J Energy Storage. 2021. https://doi.org/10.1016/j.est.2021.102421.

Okada K, Ozoe H. Experimental heat transfer rates of natural convection of molten gallium suppressed under an external magnetic field in either the X, Y, or Z direction. J Heat Transf. 1992;114(1):107. https://doi.org/10.1115/1.2911234.

Lide DR, editor. CRC Handbook of Chemistry and Physics. 84th ed. CRC Press; 2003.

ANSYS FLUENT Theory guide release 15.0, ANSYS Inc., 2013.

Gau C, Viskanta R. Melting and solidification of a pure metal on a vertical wall. J Heat Transf. 1986;108(1):174–81.

Brent AD, Voller VR, Reid KJ. Enthalpy–porosity technique for modeling convection–diffusion phase change: application to the melting of a pure metal. Numer Heat Transf. 1988;13(3):297–318.

Ozoe H, Okada K. The effect of the direction of the external magnetic field on the three-dimensional natural convection in a cubical enclosure. Int J Heat Mass Transf. 1989;32(10):1939–54.

Alboussiere T, Garandet JP, Moreau R. Buoyancy-driven convection with a uniform magnetic field: part 1—Asymptotic analysis. J Fluid Mech. 1983;253:545–63.

Yu X, Zhang J, Ni M. Numerical simulation of the Rayleigh-Benard convectionunder the influence of magnetic fields. Int J Heat Mass Transf. 2018;120:1118–31.

Benzema M, Benkahlaa YK, Ouyahia S. Rayleigh-Bénard MHD convection ofAl2O3–water nanofluid in a square enclosure: magnetic field orientation effect. EnergyProcedia. 2017;139:198–203.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Haddad, Z., Iachachene, F., Zidouni, F. et al. Magnetic field effects on melting and solidification of PCMs in an isosceles triangular cavity. J Therm Anal Calorim 147, 4697–4709 (2022). https://doi.org/10.1007/s10973-021-10857-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10857-5