Abstract

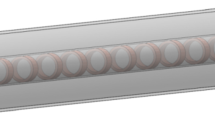

In the present study, the nanofluid flow and heat transfer in a shell and tube heat exchanger have been simulated in three dimensions. The hot fluid is the combustion gaseous product of a diesel engine, and the coolant is considered the shell of pure water, seawater, and CuO-water nanofluid with \(\varphi =\) 2 and 4%. The present study aims to reduce the temperature of exhaust gases from the heat exchanger, which is used at the inlet of the diesel engine gas recirculation system. The velocities of the hot gases and the coolant liquid based on Reynolds numbers, (respectively, Regas and Rewater), various fluids, and the volume fraction of the nanofluid \(\left( \varphi \right)\) are studied in this research. Moreover, the effect of twisted tape and baffle on the thermal performance of the heat exchanger is investigated. Examination of the base fluid shows that the change of the base fluid from pure water to seawater decreases the thermal efficiency of the heat exchanger by 3% and also increases the outlet gas temperature. Also, the pressure drop due to seawater is 16% higher than that of pure water. According to the results, the effect of twisted tape on improving thermal performance is higher than baffles. The analysis of thermal performance shows that the maximum convective heat transfer coefficient is obtained in the condition that the twisted tape with TR = 4 is used in the shell part, which is 119 W m−2 K−1. According to the results, the use of nanoparticles in the base fluid with twisted tape, despite the increase in heat transfer, reduces the thermal performance. The use of nanoparticles in seawater also increases heat transfer; however, it considerably increases the friction factor.

Similar content being viewed by others

Abbreviations

- A 0 :

-

Cross-sectional area [m2]

- C P :

-

Specific heat capacity [J Kg−1 K−1]

- D h :

-

Hydraulic diamete [m]

- \(\bar{P}\) :

-

Pressure [Pa]

- d f :

-

Diameter of the base fluid molecule [m]

- d s :

-

Diameter of the nanoparticle molecule [m]

- k b :

-

Boltzmann constant [J K−1]

- h :

-

Heat transfer coefficient [W m−2 K−1]

- Re :

-

ReReynolds number

- L :

-

Length of the heat exchanger [m]

- Nu :

-

Nusselt number

- Pe :

-

Péclet number

- T:

-

Temperature [K]

- f :

-

Friction factor

- k :

-

Thermal conductivity [W m−1 K−1]

- u:

-

Velocity [m s−1]

- η :

-

Thermal performance

- µ :

-

Viscosity [Pa s]

- ρ :

-

Density [kg m−3]

- φ :

-

Volume fraction

- ave:

-

Average

- f :

-

Fluid

- in :

-

Inlet

- nf :

-

Nanofluid

- out :

-

Outlet

- s :

-

Solid

- t :

-

Turbulence

- w:

-

Wall

- LM :

-

Logarithmic mean temperature difference

References

Tian XX, Kalbasi R, Jahanshahi R, Qi C, Huang HL, Rostami S. Competition between intermolecular forces of adhesion and cohesion in the presence of graphene nanoparticles: Investigation of graphene nanosheets/ethylene glycol surface tension. J Mol Liq. 2020;311:113329.

Kalbasi R. Introducing a novel heat sink comprising PCM and air - Adapted to electronic device thermal management. Int J Heat Mass Transf. 2021;169:120914.

Toghraie D. Numerical thermal analysis of water’s boiling heat transfer based on a turbulent jet impingement on heated surface. Physica E. 2016;84:454–65.

Afshari F. Experimental and numerical investigation on thermoelectric coolers for comparing air-to-water to air-to-air refrigerators. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09500-6.

Mohebbi R, Amiri Delouei A, Jamali A, et al. Pore-scale simulation of non-Newtonian power-law fluid flow and forced convection in partially porous media: thermal lattice Boltzmann method. Phys Stat Mech Appl. 2019;525:642–56.

Afra B, Nazari M, Kayhani MH, et al. An immersed boundary-lattice Boltzmann method combined with a robust lattice spring model for solving flow–structure interaction problems. Appl Math Model. 2018;55:502–21.

Karimnejad S, Amiri Delouei A, Nazari M, et al. Immersed boundary thermal lattice Boltzmann method for the moving simulation of non-isothermal elliptical particles. J Therm Anal Calorim. 2019;138:4003–17. https://doi.org/10.1007/s10973-019-08329-y.

Khodadadi H, Toghraie D, Karimipour A. Effects of nanoparticles to present a statistical model for the viscosity of MgO-Water nanofluid. Powder Technol. 2019;342:166–80.

Orooji Y, Ghanbari M, Amiri O, Salavati-Niasari M. Facile fabrication of silver iodide/graphitic carbon nitride nanocomposites by notable photo-catalytic performance through sunlight and antimicrobial activity. J Hazard Mater. 2020;389:122079.

Karimi-Maleh H, Kumar BG, Rajendran S, Qin JQ, Vadivel S, Durgalakshmi D, Gracia F, Soto-Moscoso M, Orooji Y, Karimi F. Tuning of metal oxides photocatalytic performance using Ag nanoparticles integration. J Mol Liq. 2020;314:113588.

Ghasemi M, Khataee A, Gholami P, Soltani RDC, Hassani A, Orooji Y. In-situ electro-generation and activation of hydrogen peroxide using a CuFeNLDH-CNTs modified graphite cathode for degradation of cefazolin. J Environ Manage. 2020;267:110629.

Jang J, Lai J, Liu L. The thermal-hydraulic characteristics of staggered circular finned-tube heat exchangers under dry and dehumidifying conditions. Int J Heat Mass Tran. 1998;41:3321–37.

Roetzel W, Lee D. Experimental investigation of leakage in shell-and-tube heat exchangers with segmental baffles. Int J Heat Mass Tran. 1993;36:3765–71.

Lei Y, He Y, Chu P, Li R. Design and optimization of heat exchangers with helical baffles. Chem Eng Sci. 2008;63:4386–95.

Pulkrabek WW. Engineering fundamentals of the internal combustion engine, 2nd Ed.. ASME J Eng Gas Turbines Power. 2004;126(1):198. https://doi.org/10.1115/1.1669459.

Baert RSG, Beckman DE, Veen A. Efficient EGR technology for future HD diesel engine emission targets. 1999-01-0837, SAE Paper; 1999.

Mimura K, Isozaki A. Heat transfer and drop pressure of corrugated tubes. Desalination. 1977;22:131–9.

Jang S-H, Hwang S-J, Park S-K, Choi K-S, Kim H-M. Effects of PM fouling on the heat exchange effectiveness of wave fin type EGR cooler for diesel engine use. Heat Mass Tran. 2011;48:1081–7.

Liu L, Ling X, Peng H. Analysis on flow and heat transfer characteristics of EGR helical baffled cooler with spiral corrugated tubes. Exp Therm Fluid Sci. 2013;44:275–84.

Ghassembaglou N, Torkaman L. Efficient design of exhaust gas cooler in cold EGR equipped diesel engine. Alexandria Eng J. 2016;55:769–78.

Jiaqiang E, Han D, Deng Y, Zuo W, et al. Performance enhancement of a baffle-cut heat exchanger of exhaust gas recirculation. Appl Therm Eng. 2018;134:86–94.

Lin W, Ling Z, Fang X, et al. Numerical investigation on non-Newtonian fluid flowing in heat exchanger with different elliptic aspect ratios and helical angles. Appl Therm Eng. 2018;141:164–73.

Omidi M, Farhadi M, Rabienataj Darzi AA. Numerical study of heat transfer on using lobed cross sections in helical coil heat exchangers: Effect of physical and geometrical parameters. Energ Convers Manag. 2018;176:236–45.

Han H, Wang S, Sun L, et al. Numerical study of thermal and flow characteristics for a fin-and-tube heat exchanger with arc winglet type vortex generators. Int J Refrig. 2019;98:61–9.

Zhang J, Guo S, Li Z, et al. Experimental performance comparison of shell-and-tube oil coolers with overlapped helical baffles and segmental baffles. Appl Therm Eng. 2013;58:336–43.

Mellal M, Benzeguir R, Sahel D, Ameur H. Hydro-thermal shell-side performance evaluation of a shell and tube heat exchanger under different baffle arrangement and orientation. Int J Therm Sci. 2017;121:138–49.

Afshari F, Sözen A, Khanlari A, et al. Effect of turbulator modifications on the thermal performance of cost-effective alternative solar air heater. Renew Energ. 2020;158:297–310.

Karagoz S, Afshari F, Yildirim O, et al. Experimental and numerical investigation of the cylindrical blade tube inserts effect on the heat transfer enhancement in the horizontal pipe exchangers. Heat Mass Tran. 2017;53:2769–84.

Afshari F, Ghasemi Zavaragh H, Di Nicola G. Numerical analysis of ball-type turbulators in tube heat exchangers with computational fluid dynamic simulations. Int J Environ Sci Technol. 2019;16:3771–80.

Arefi-Oskoui S, Khataee A, Safarpour M, Orooji Y, Vatanpour V. A review on the applications of ultrasonic technology in membrane bioreactors. Ultrason Sonochem. 2019;58:104633.

Gholami P, Dinpazhoh L, Khataee A, Orooji Y. Sonocatalytic activity of biochar-supported ZnO nanorods in degradation of gemifloxacin: synergy study, effect of parameters and phytotoxicity evaluation. Ultrason Sonochem. 2019;55:44–56.

Orooji Y, Ghasali E, Moradi M, Derakhshandeh MR, Alizadeh M, Asl MS, Ebadzadeh T. Preparation of mullite-TiB2-CNTs hybrid composite through spark plasma sintering. Ceram Int. 2019;45:16288–96.

Orooji Y, Haddad Irani-Nezhad M, Hassandoost R, Khataee A, Rahim Pouran S, Joo SW. Cerium doped magnetite nanoparticles for highly sensitive detection of metronidazole via chemiluminescence assay. Spectrochim Acta A Mol Biomol Spectrosc. 2020;234:118272.

Abbasian AA, Amani J. Experimental investigation of diameter effect on heat transfer performance and pressure drop of TiO2–water nanofluid. Exp Therm Fluid Sci. 2013;44:520–33.

Barnoon P, Toghraie D, Karimipour A. Application of rotating circular obstacles in improving ferrofluid heat transfer in an enclosure saturated with porous medium subjected to a magnetic field. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09896-1.

Barnoon P, Toghraie D, Salarnia M, Karimipour A. Mixed thermomagnetic convection of ferrofluid in a porous cavity equipped with rotating cylinders: LTE and LTNE models. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09866-7.

Shahsavar A, Entezari S, Toghraie D, Barnoon P. Effects of the porous medium and water-silver biological nanofluid on the performance of a newly designed heat sink by using first and second laws of thermodynamics. Chin J Chem Eng. 2020;28:2928–37.

Shahsavar A, Noori S, Toghraie D, Barnoon P. Free convection of non‐Newtonian nanofluid flow inside an eccentric annulus from the point of view of first‐law and second‐law of thermodynamics. ZAMM-Z ANGEW MATH ME. 2020. https://doi.org/10.1002/zamm.202000266.

Kakac S, Liu H. Heat exchangers—selection, rating and thermal design. CRC Press; 2002.

Zaraki A, Ghalambaz M, Chamkha AJ, et al. Theoretical analysis of natural convection boundary layer heat and mass transfer of nanofluids: effects of size, shape and type of nanoparticles, type of base fluid and working temperature. Adv Powder Technol. 2015;26:935–46.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ahmadi, M.R., Toghraie, D. Numerical analysis of flow and heat transfer in a shell and tube heat exchanger in the gas recirculation cooling system of a diesel engine and the effect of nanofluid on its performance. J Therm Anal Calorim 147, 4853–4871 (2022). https://doi.org/10.1007/s10973-021-10831-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10831-1